Method for preparing adenosine

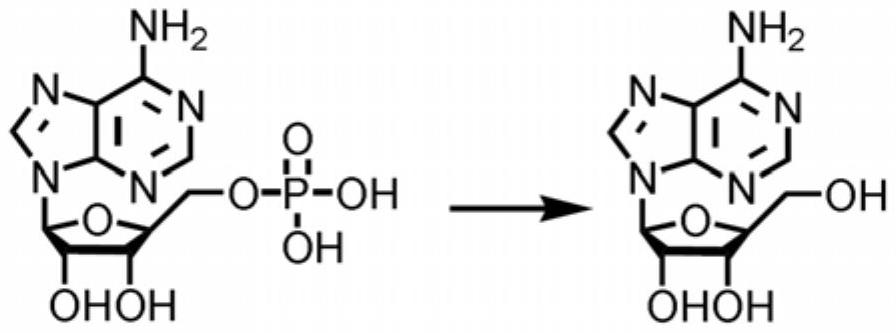

An adenosine and hydrolysis reaction technology, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of unfriendly environment, long process route and high cost, and achieves less types of impurities, efficient hydrolysis, Yield-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of embodiment 1 adenosine

[0026] Weigh 10.0 g of adenylic acid and add it to the reaction flask, add 75 mL of purified water, start stirring, and then slowly add NaOH aqueous solution to it until the adenylic acid is completely dissolved. First add 10.0 g of sodium citrate to the reaction solution, and then slowly add citric acid to adjust the pH to 4.7. Heat up, reflux for 40h, stop heating and allow the reaction solution to cool to room temperature naturally. The reaction solution was concentrated and desalted to obtain 4.2 g of adenosine with a yield of 54.5% and a purity of 99.5%.

Embodiment 2

[0027] The preparation of embodiment 2 adenosine

[0028] Weigh 10.0 g of adenylic acid and add it into the reaction flask, add 100 mL of purified water, start stirring, and then slowly add KOH aqueous solution to it until the adenylic acid is completely dissolved. Firstly, 10.0 g of ammonium citrate was added to the reaction solution, and then acetic acid was slowly added to adjust the pH value to 6.0. Raise the temperature to 90°C, keep it warm for 60h, stop heating and let the reaction solution cool down to room temperature naturally. The reaction solution was concentrated and desalted to obtain 5.8 g of adenosine with a yield of 75.3% and a purity of 99.3%.

Embodiment 3

[0029] The preparation of embodiment 3 adenosine

[0030] Weigh 10.0 g of adenylic acid and add it into the reaction flask, add 60 mL of methanol, start stirring, and then slowly add ammonia water thereinto until the adenylic acid is completely dissolved. First add 10.0 g of sodium oxalate to the reaction solution, and then slowly add formic acid to adjust the pH value to 3.0. Heat up, reflux for 20h, stop heating and allow the reaction solution to cool to room temperature naturally. The reaction solution was concentrated and desalted to obtain 6.0 g of adenosine with a yield of 77.9% and a purity of 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com