Patents

Literature

40results about How to "Threshing achieved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

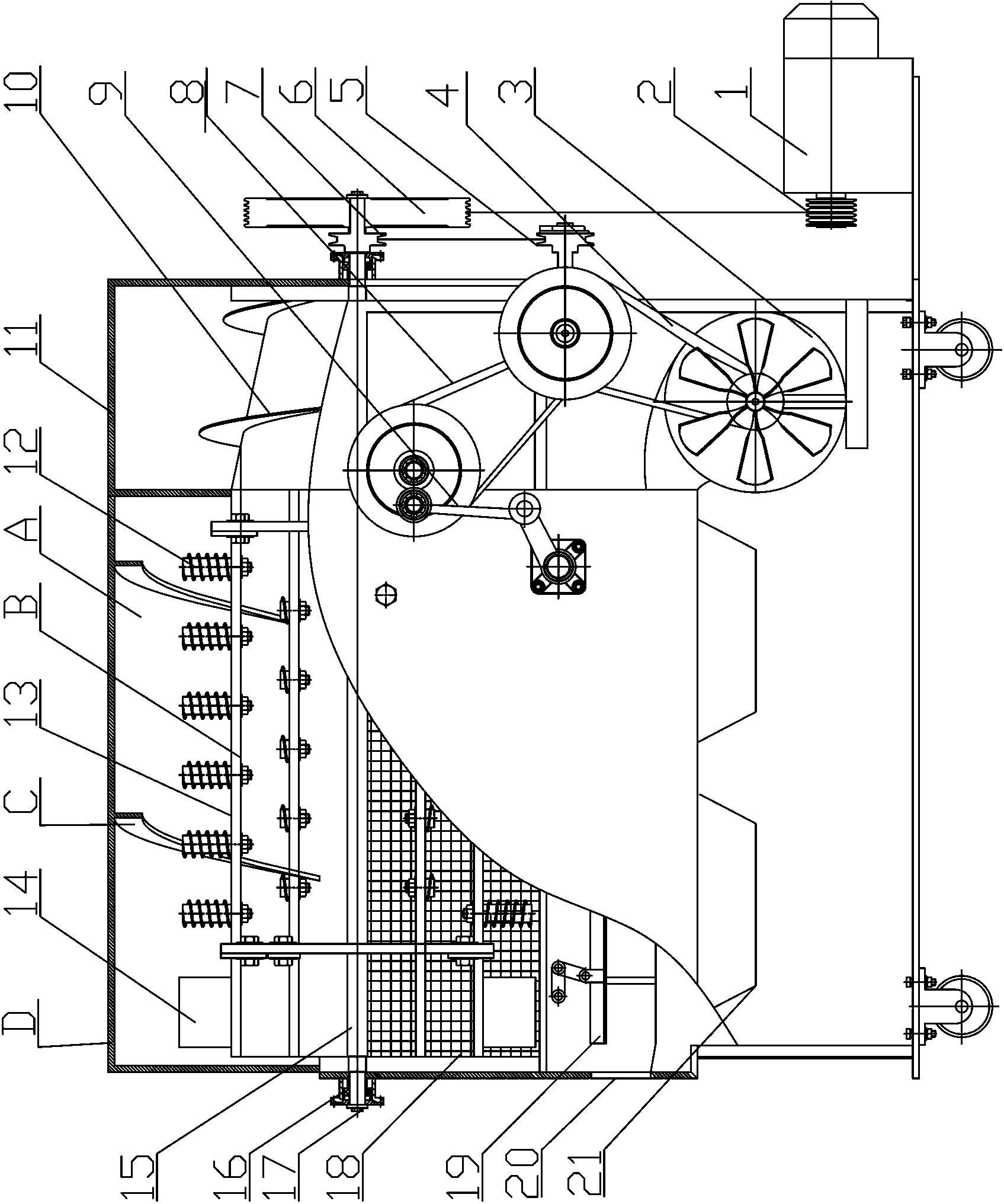

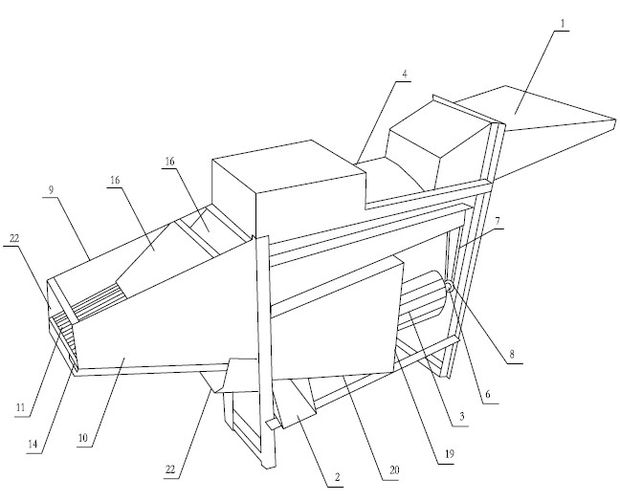

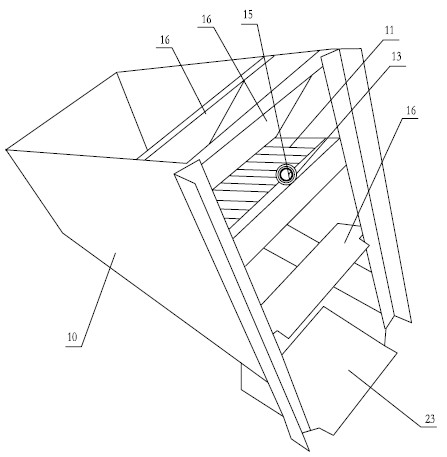

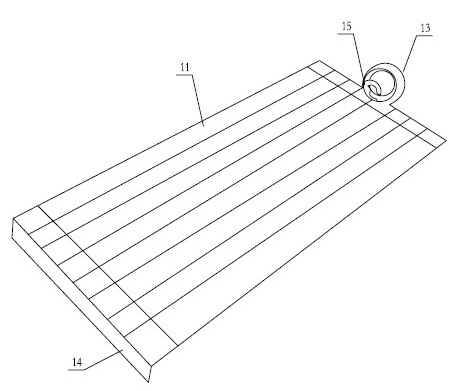

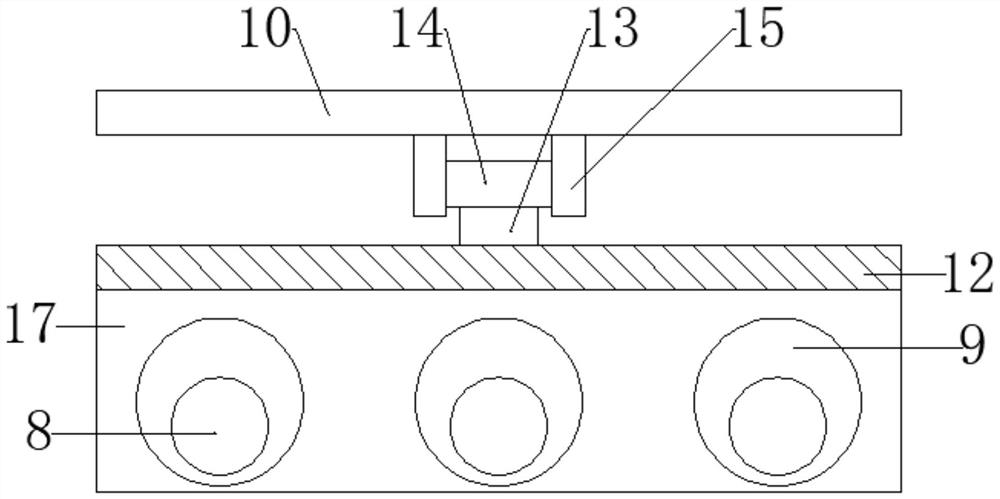

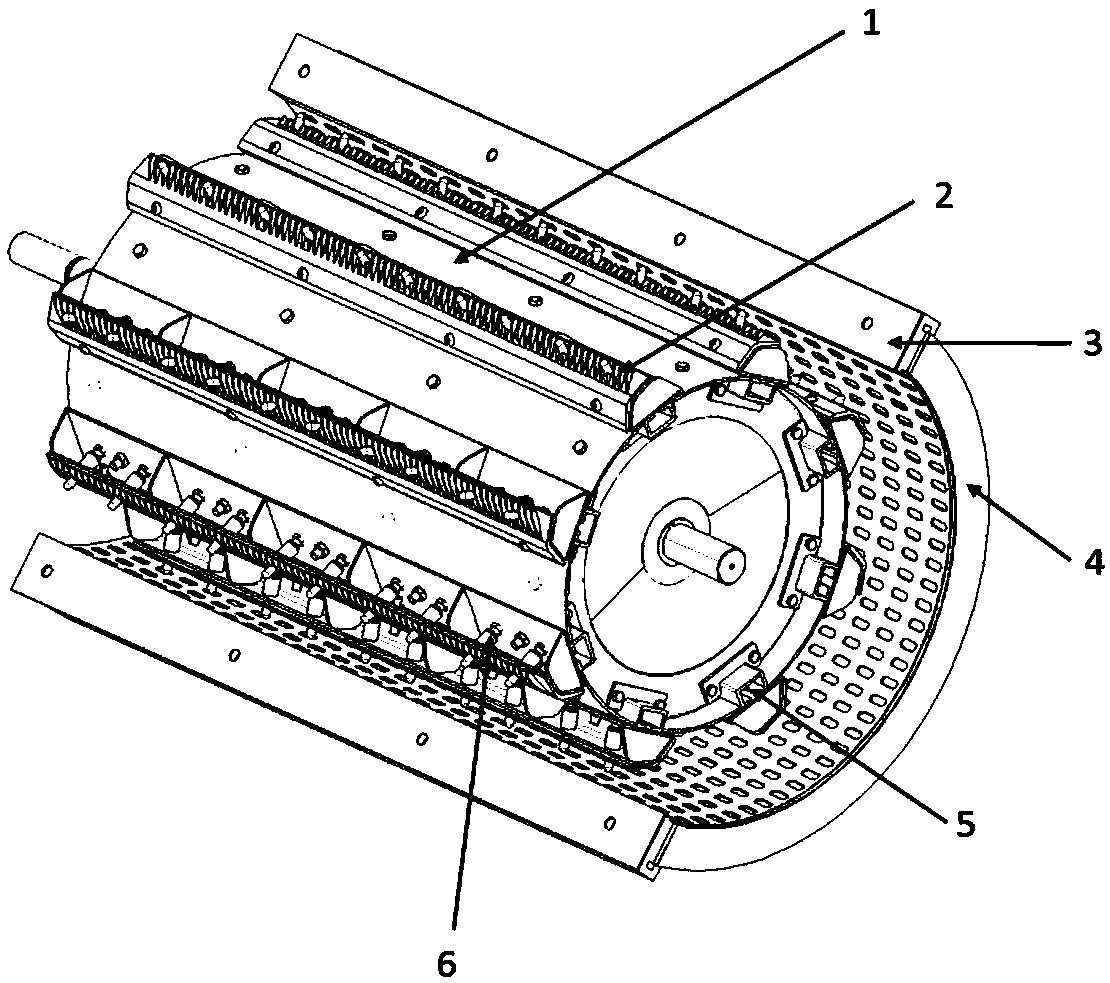

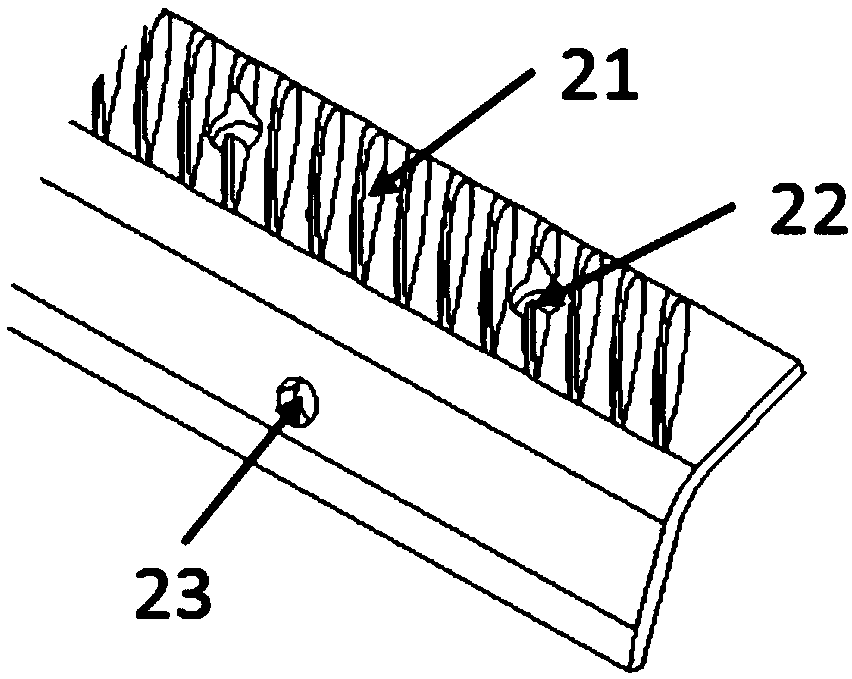

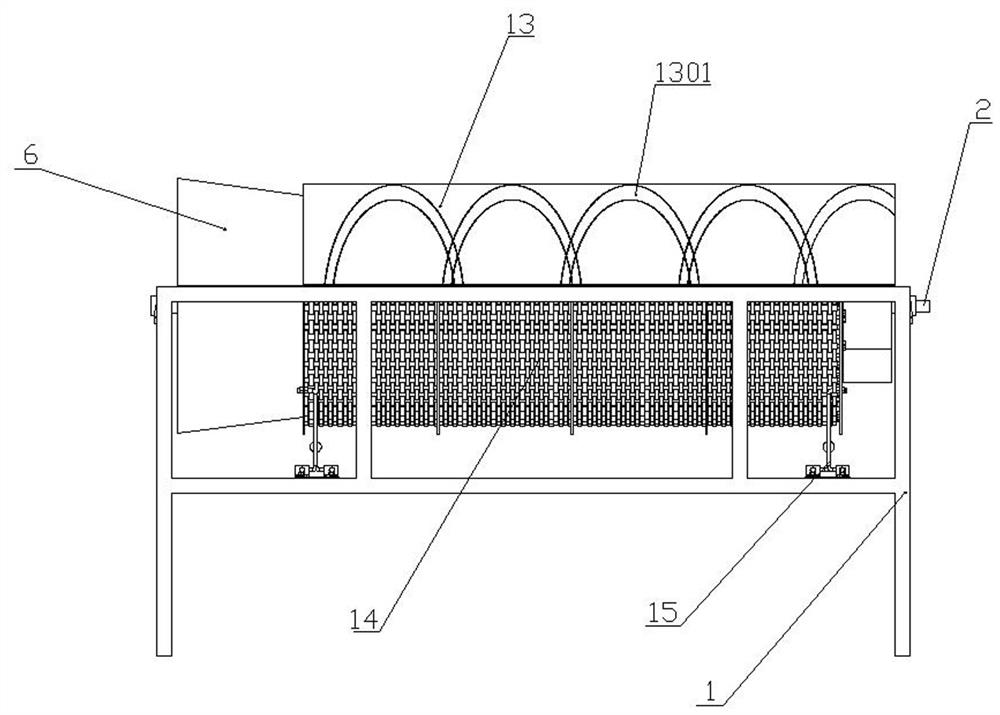

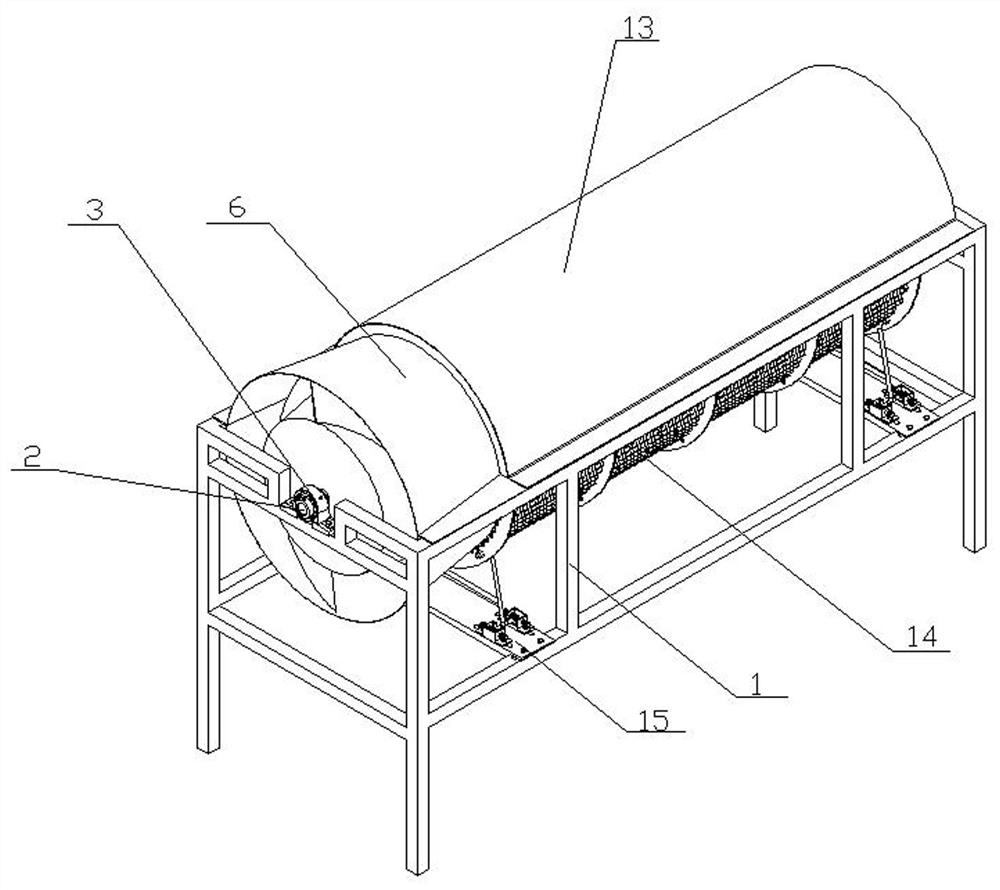

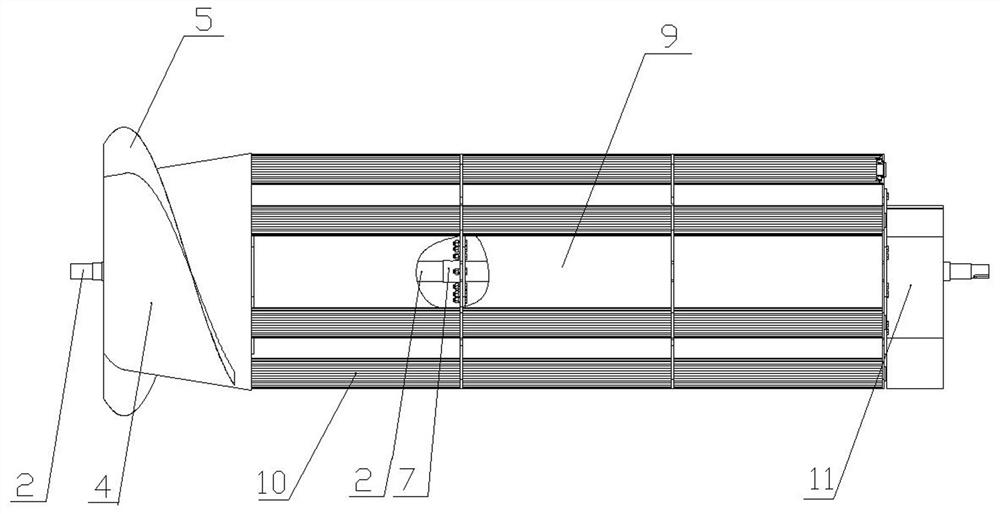

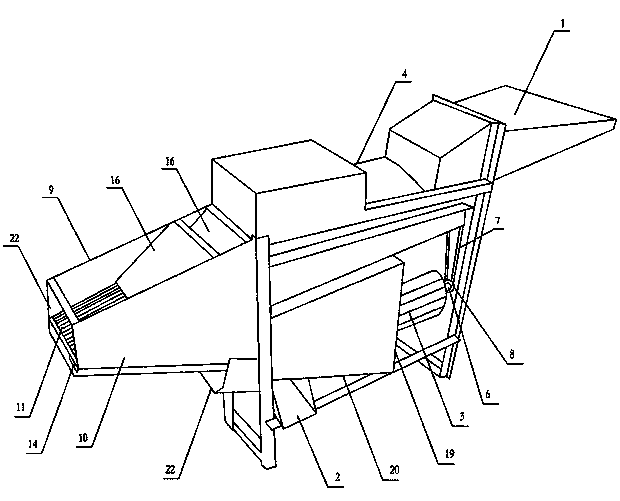

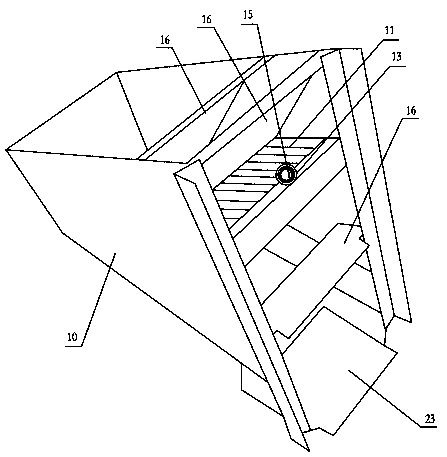

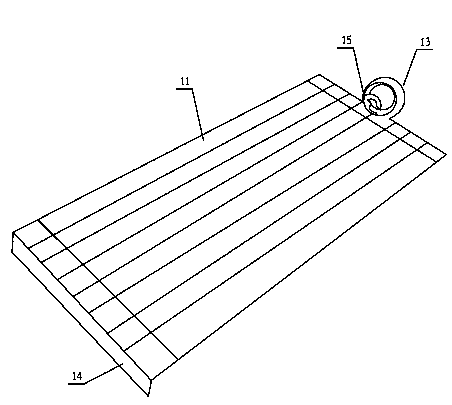

Breeding seed threshing machine used in oilseed rape fields

ActiveCN103975706AFast threshingImprove productivityThreshersAgricultural engineeringTransmission system

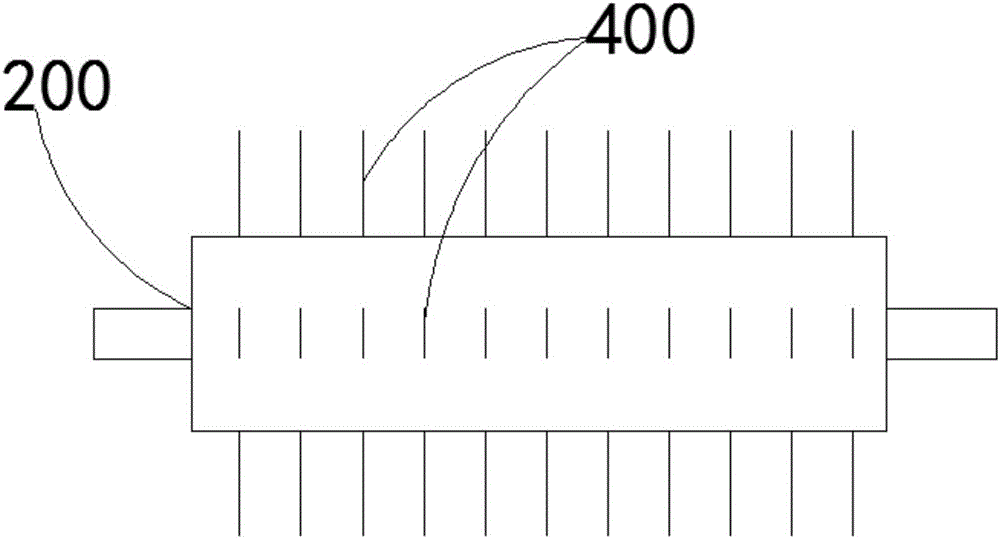

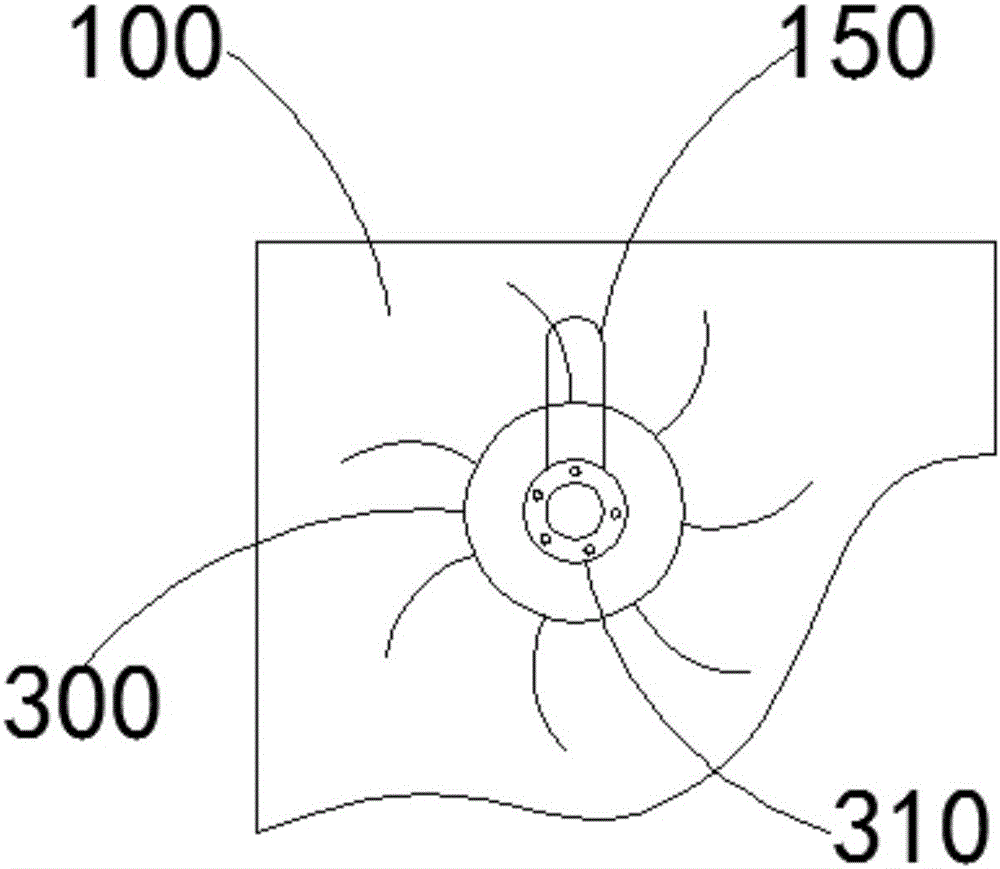

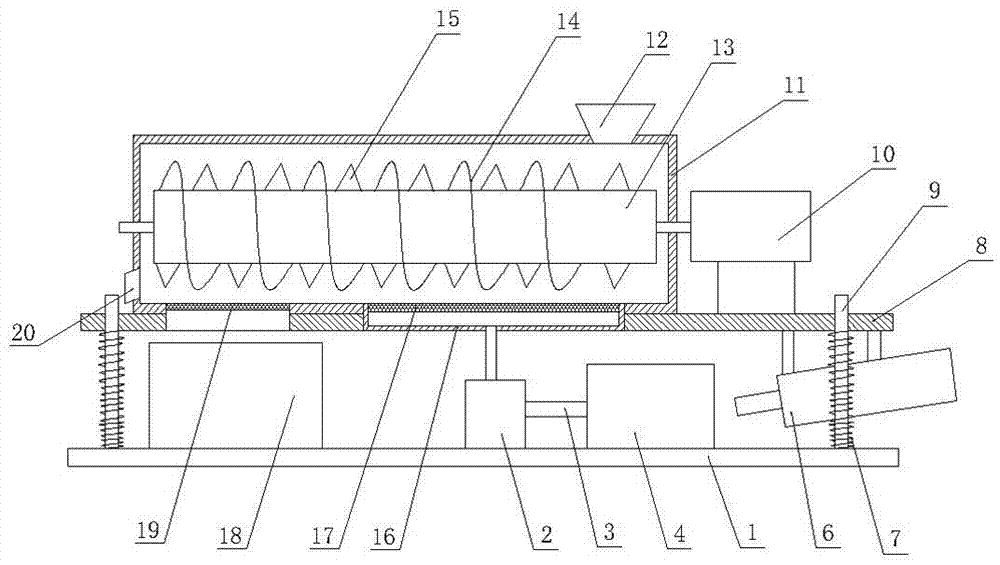

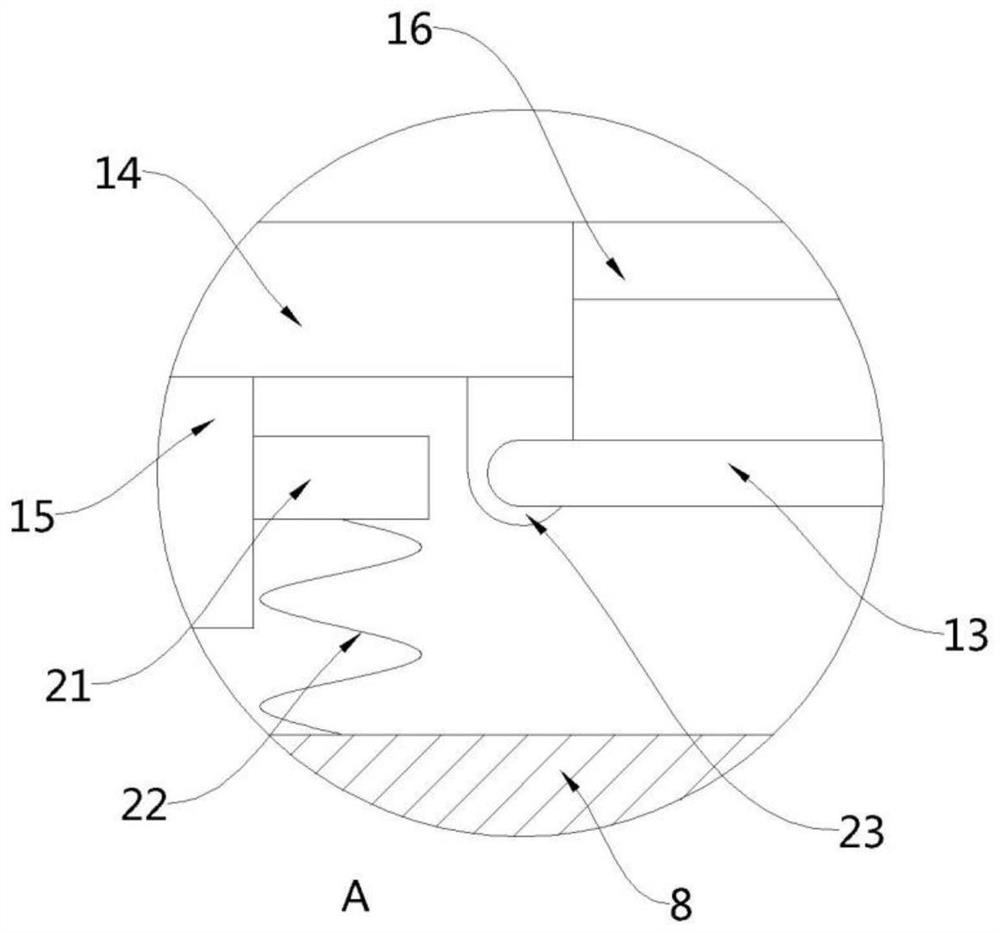

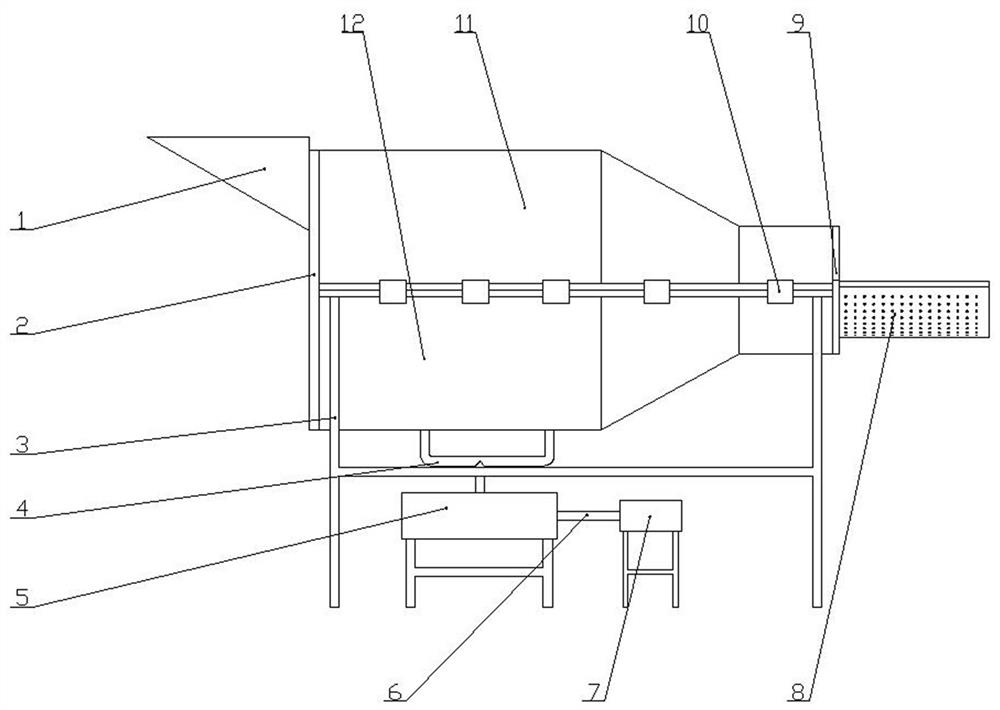

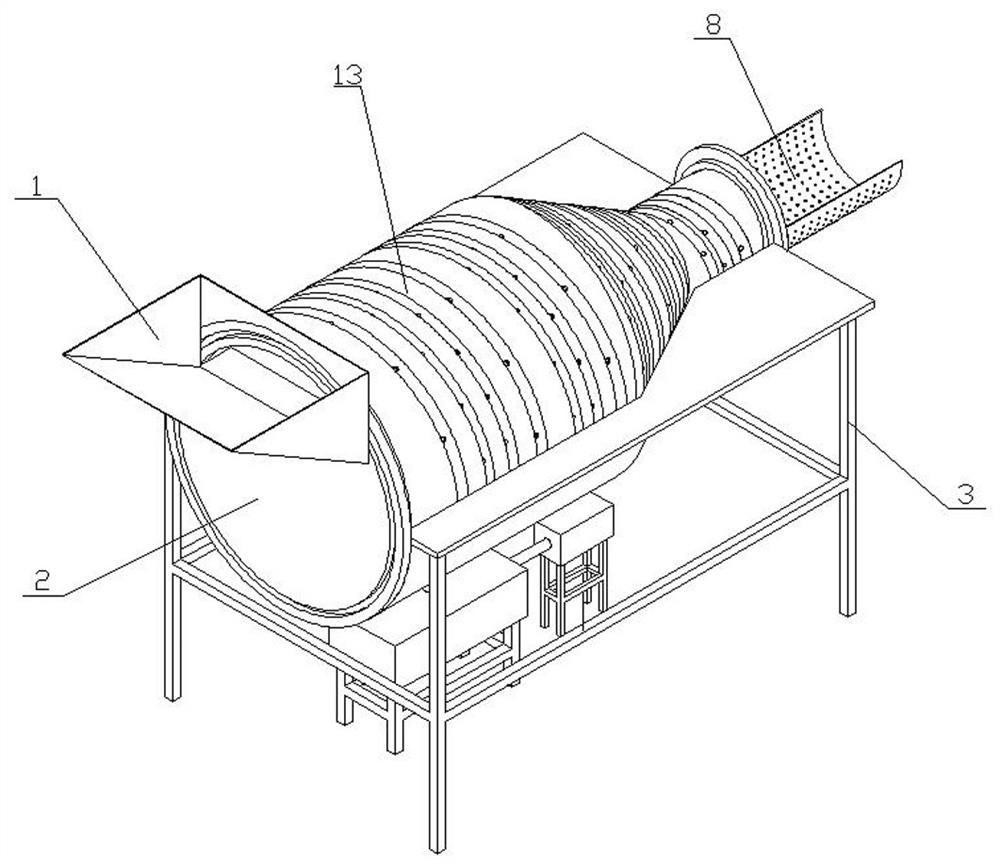

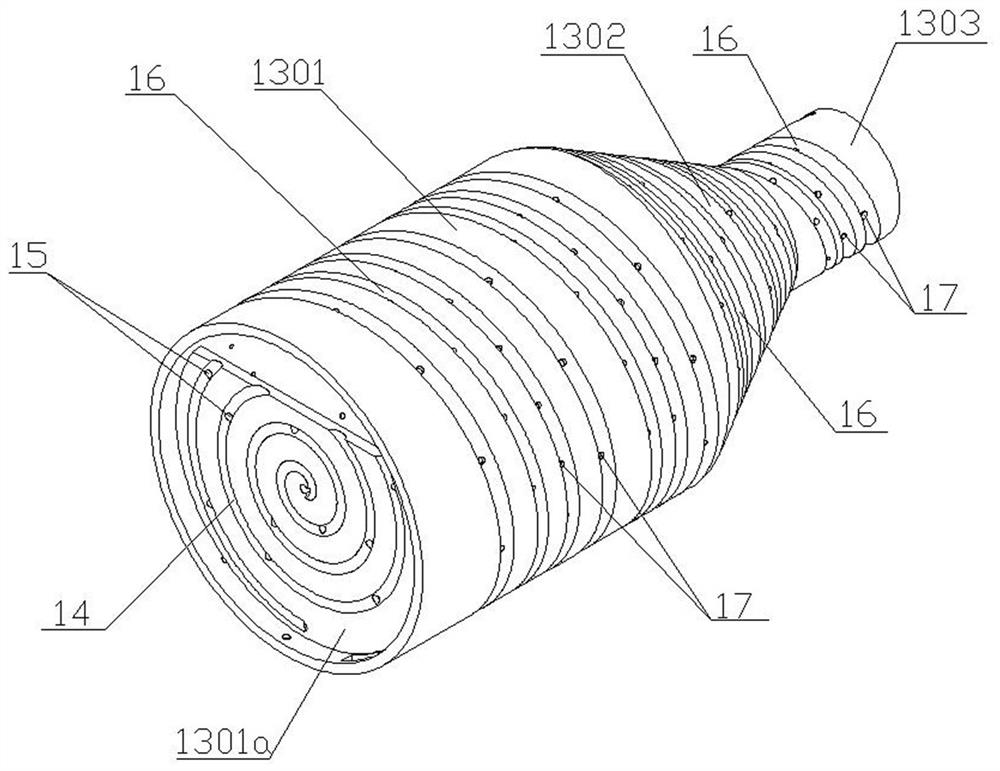

A breeding seed threshing machine used in oilseed rape fields comprises a threshing system, a screening system and a transmission system which are mounted on a frame. The threshing system comprises a threshing chamber, a roller shaft penetrates through the threshing chamber, a feeding auger, a threshing roller and a grass removing plate are sequentially arranged on the roller shaft, a feeding inlet is arranged on the feeding auger, the grass removing plate is provided with a straw outlet, threshing spike teeth which are spirally distributed are arranged on the threshing roller, and a concave screen is arranged below the threshing roller. The screening system comprises a vibrating screen arranged below the concave screen, a seed discharging port is formed below the vibrating screen, a fan air inlet is formed on the frame on one side of the seed discharging port, a screening fan is mounted on the fan air inlet, and a bran outlet is arranged at the position, corresponding to the fan air inlet, of the frame. The transmission system provides power to the roller shaft, the screening fan and the vibrating screen. The breeding seed threshing machine has the advantages that almost no seeds are left in the threshing machine, a good screening effect and short screening time are achieved and an oil seed breakage rate is low.

Owner:HUNAN AGRICULTURAL UNIV

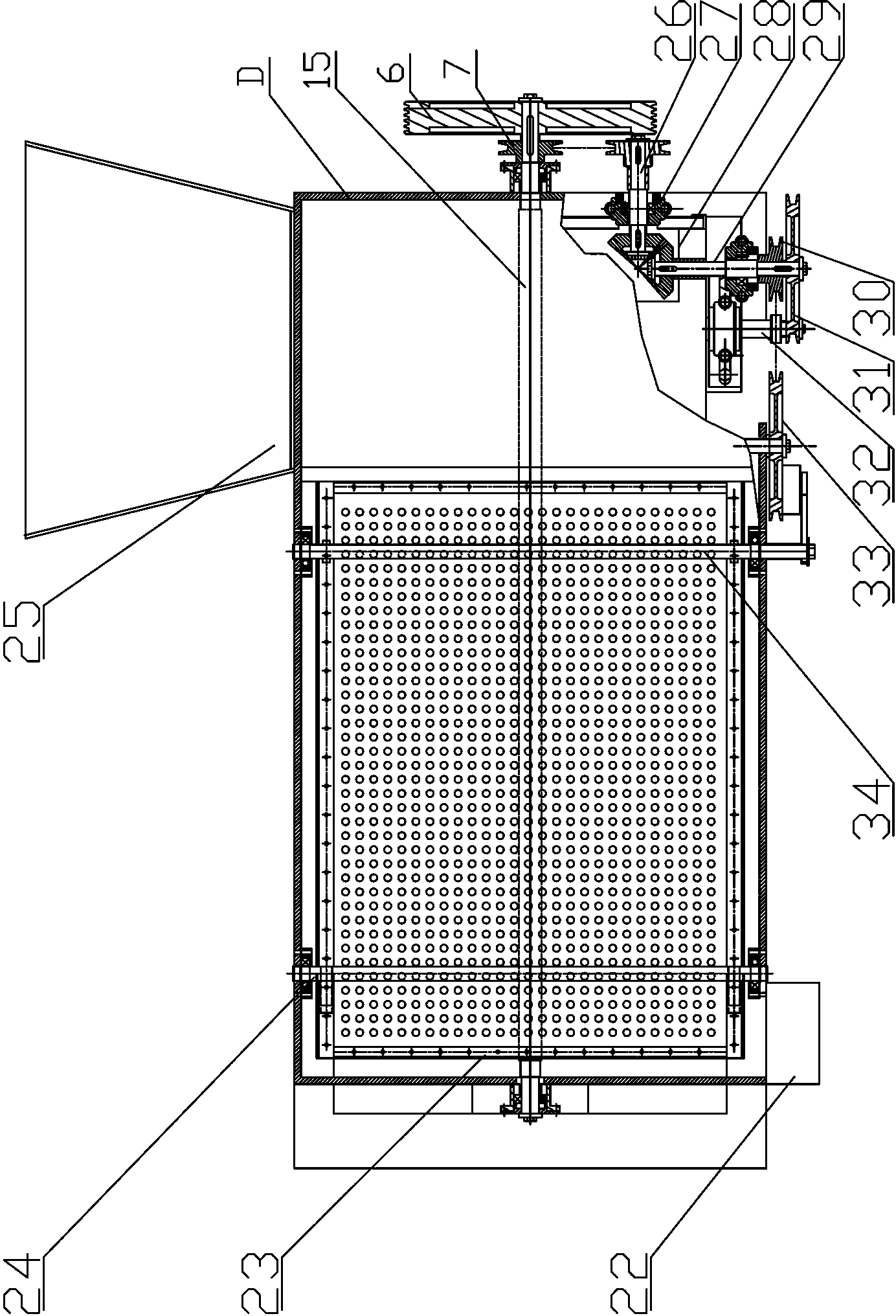

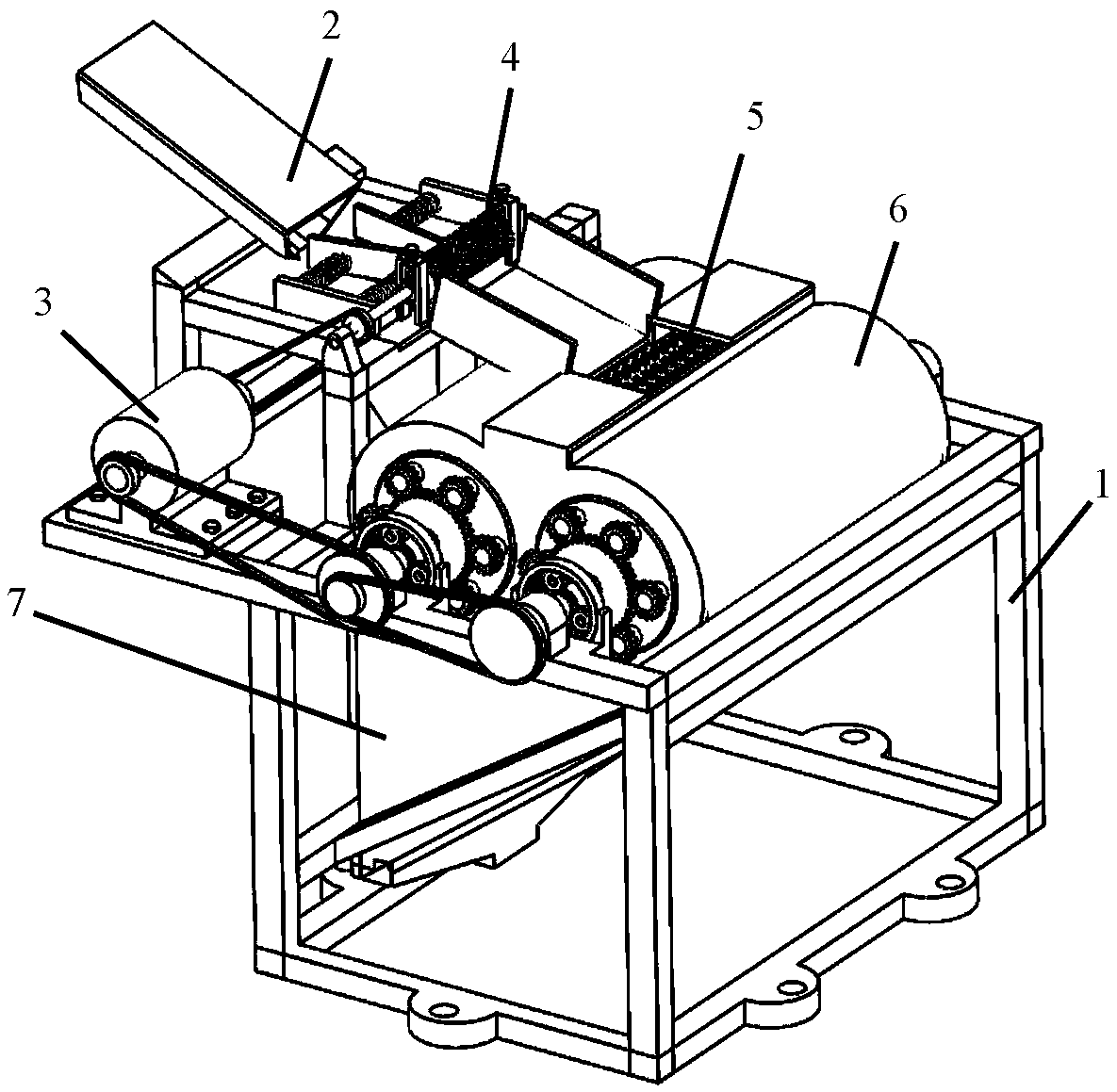

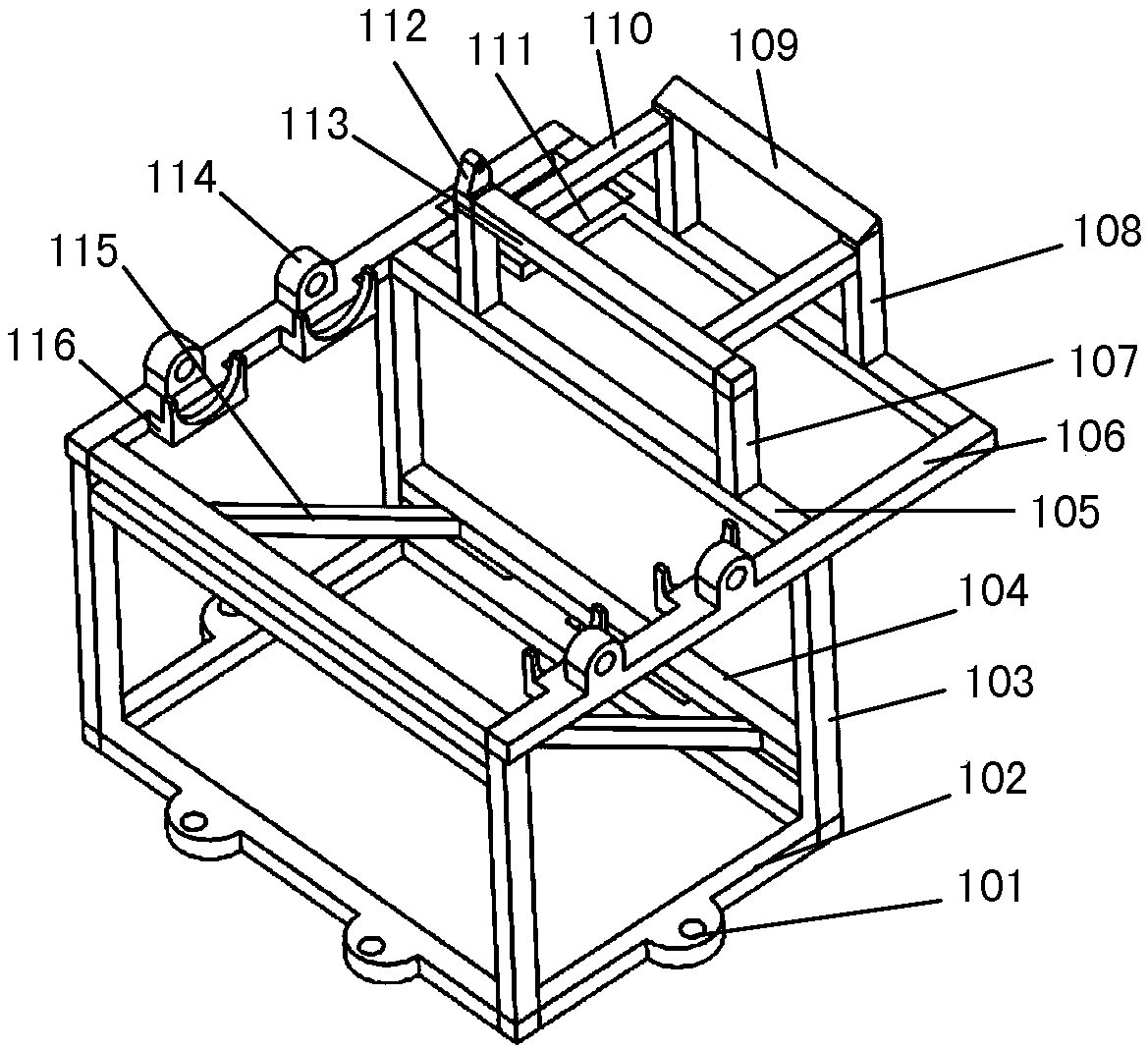

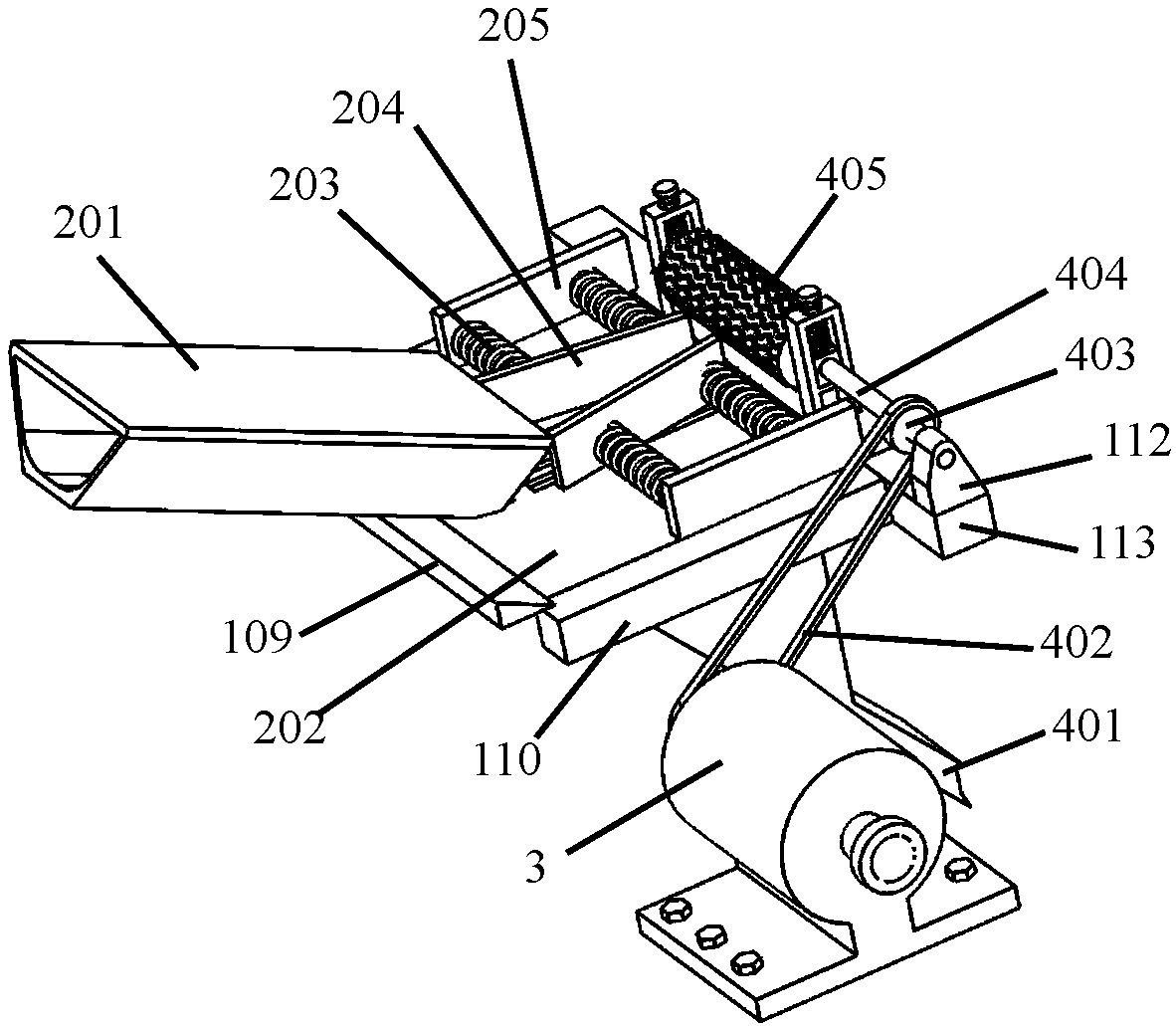

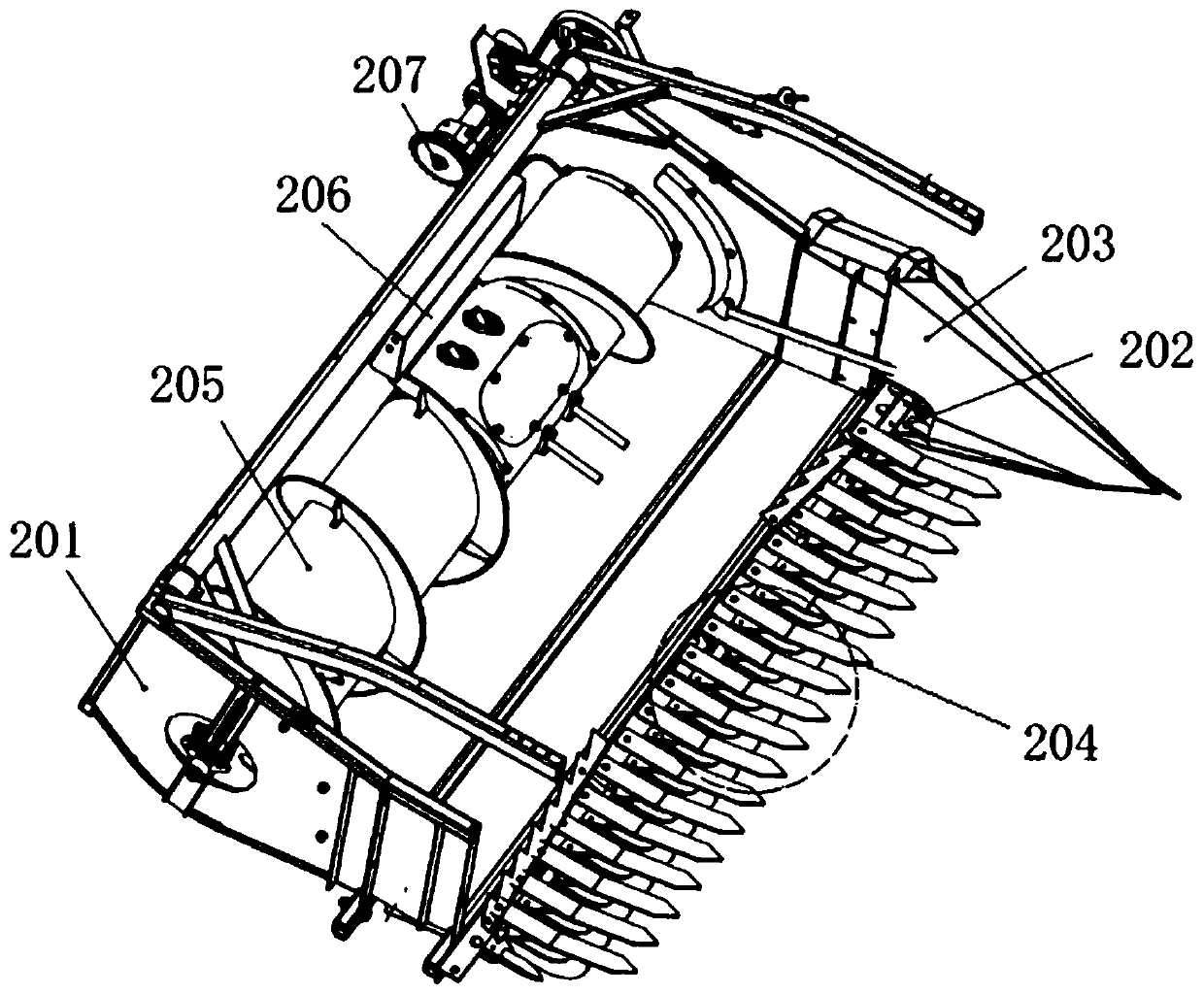

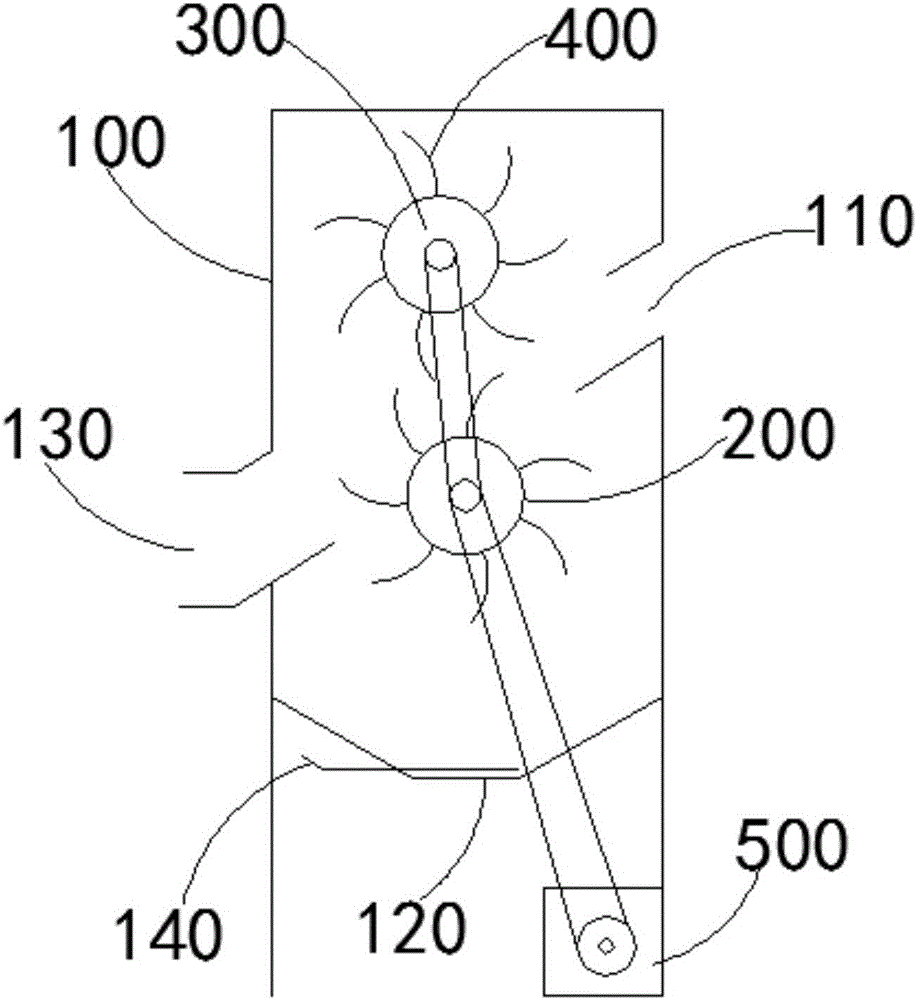

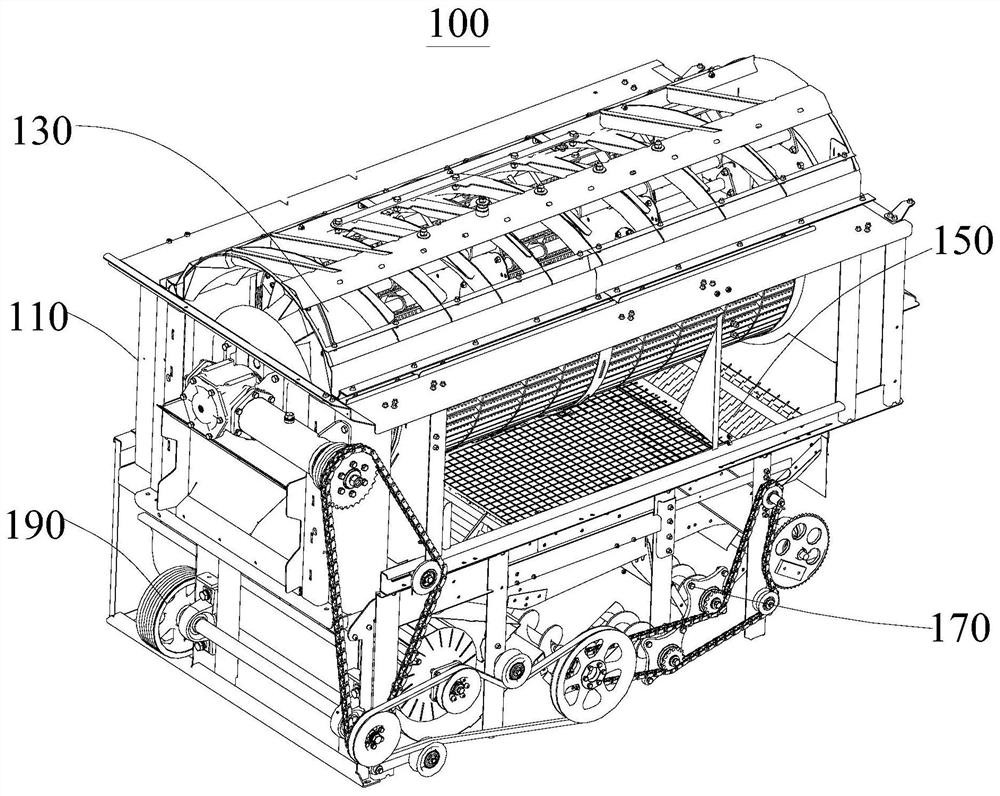

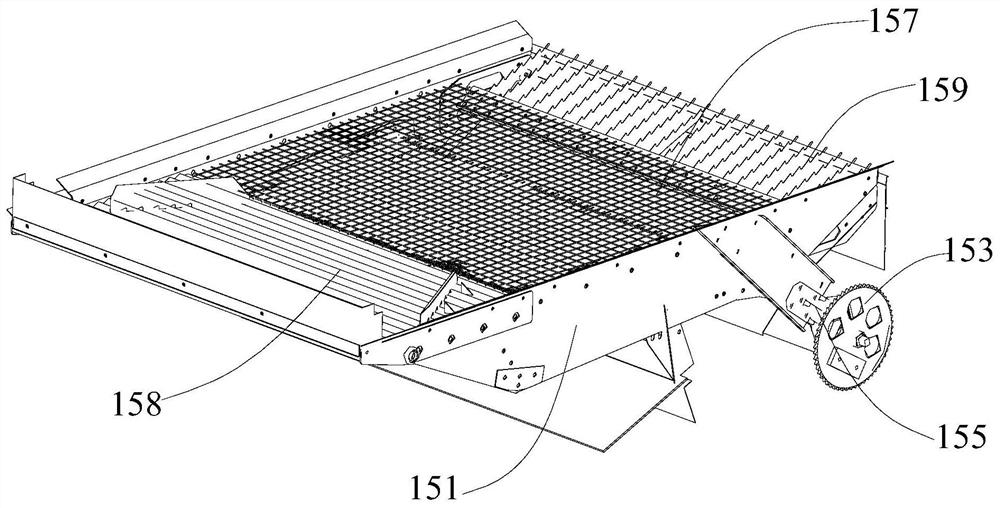

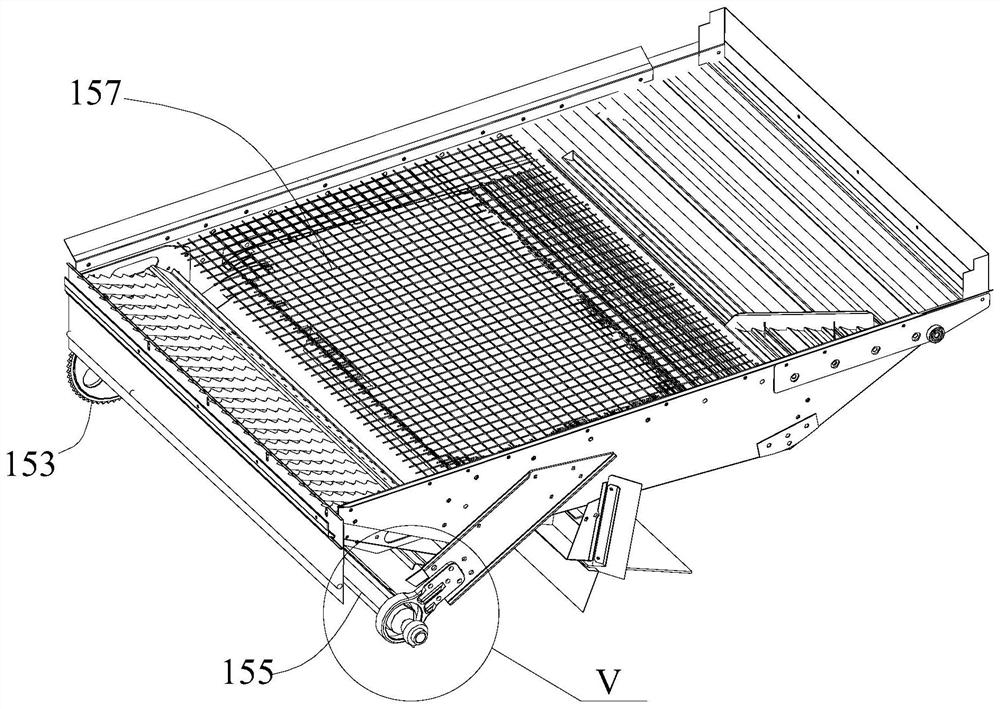

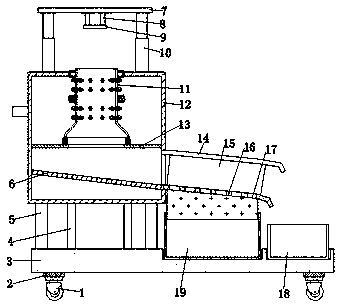

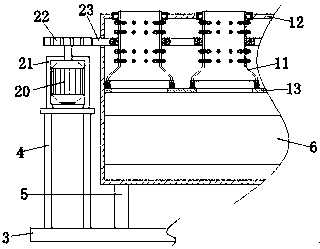

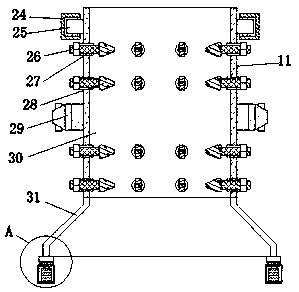

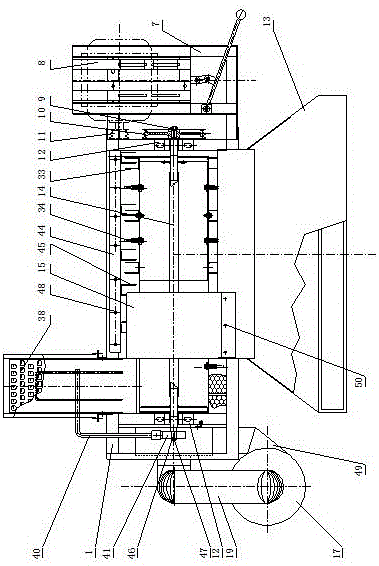

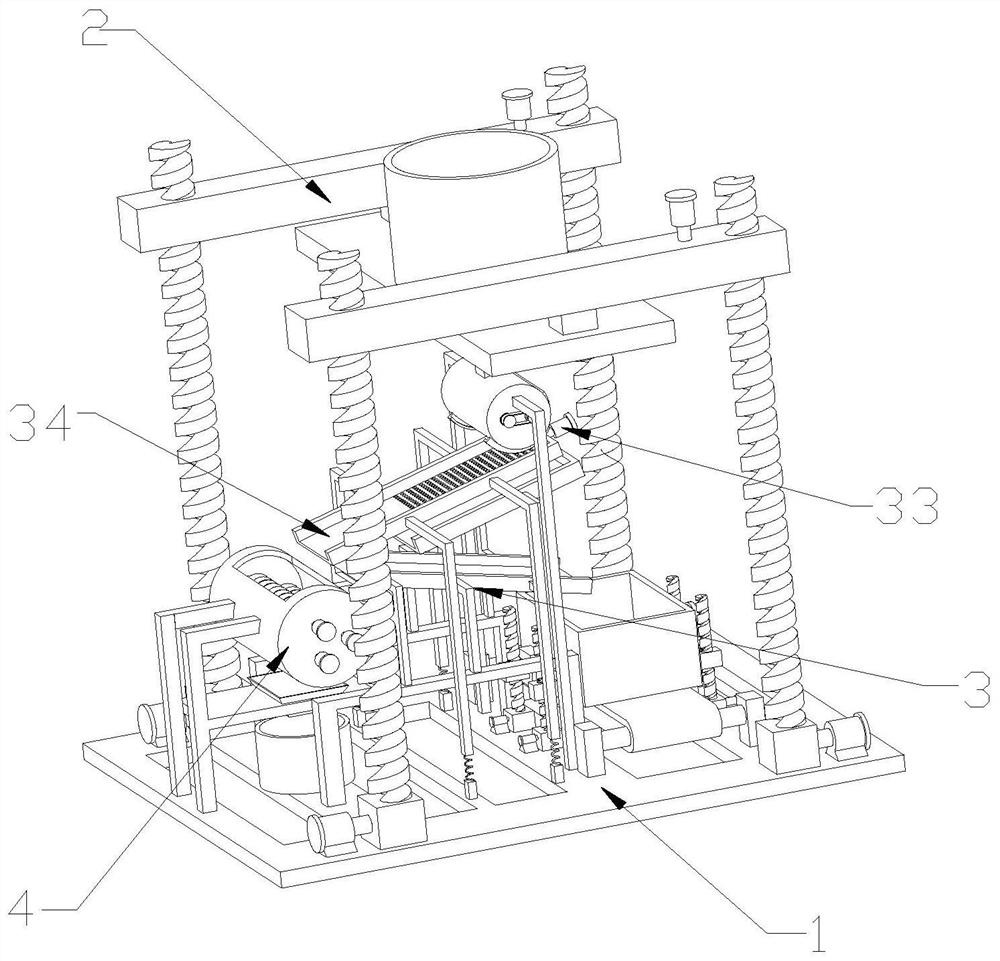

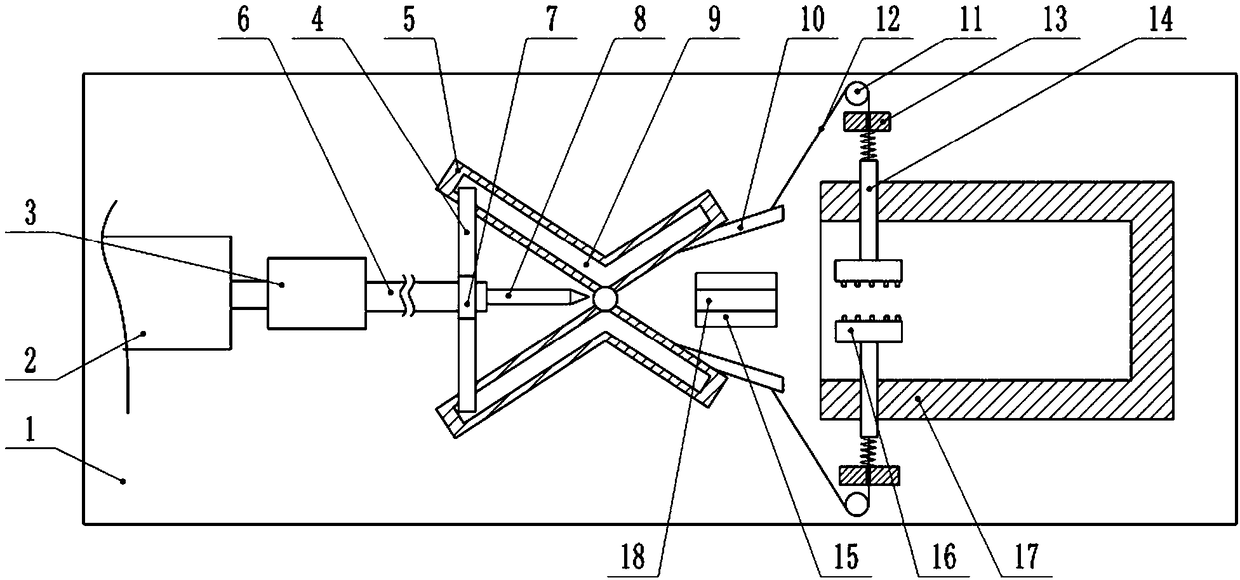

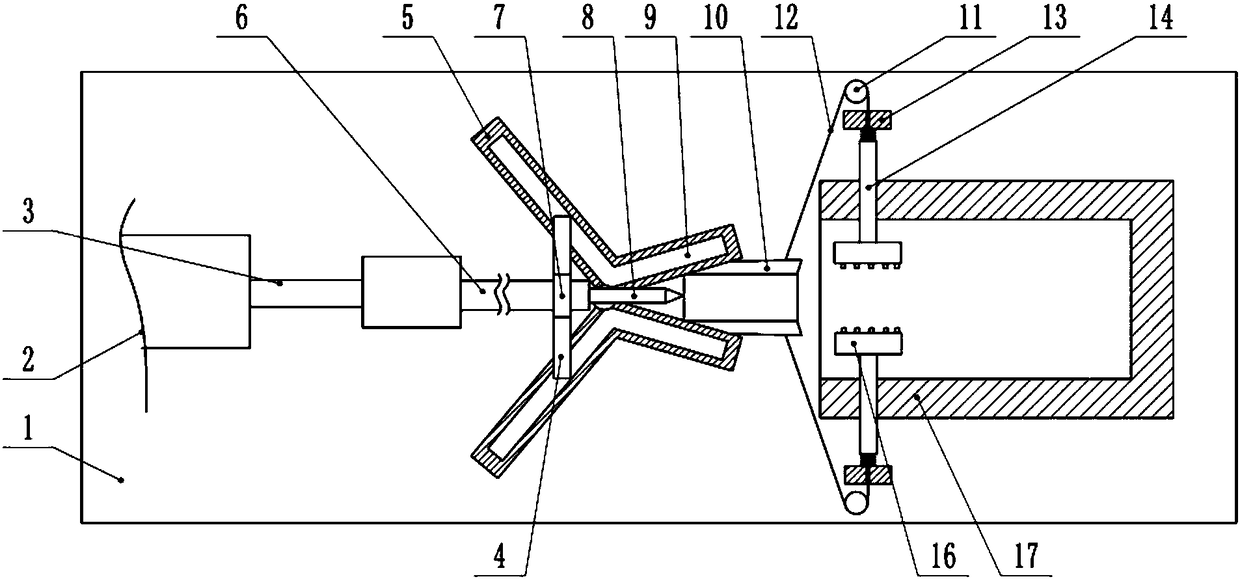

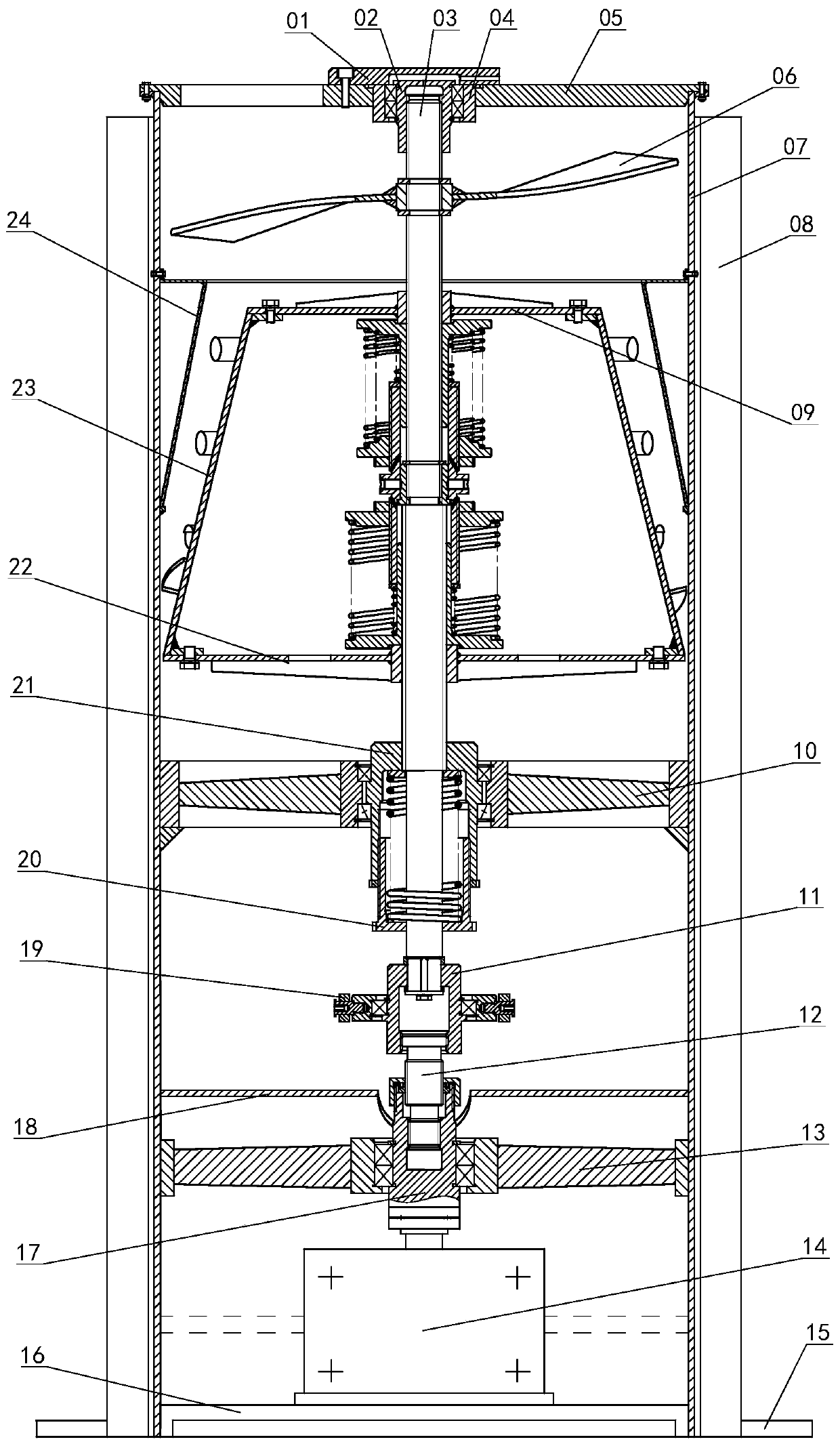

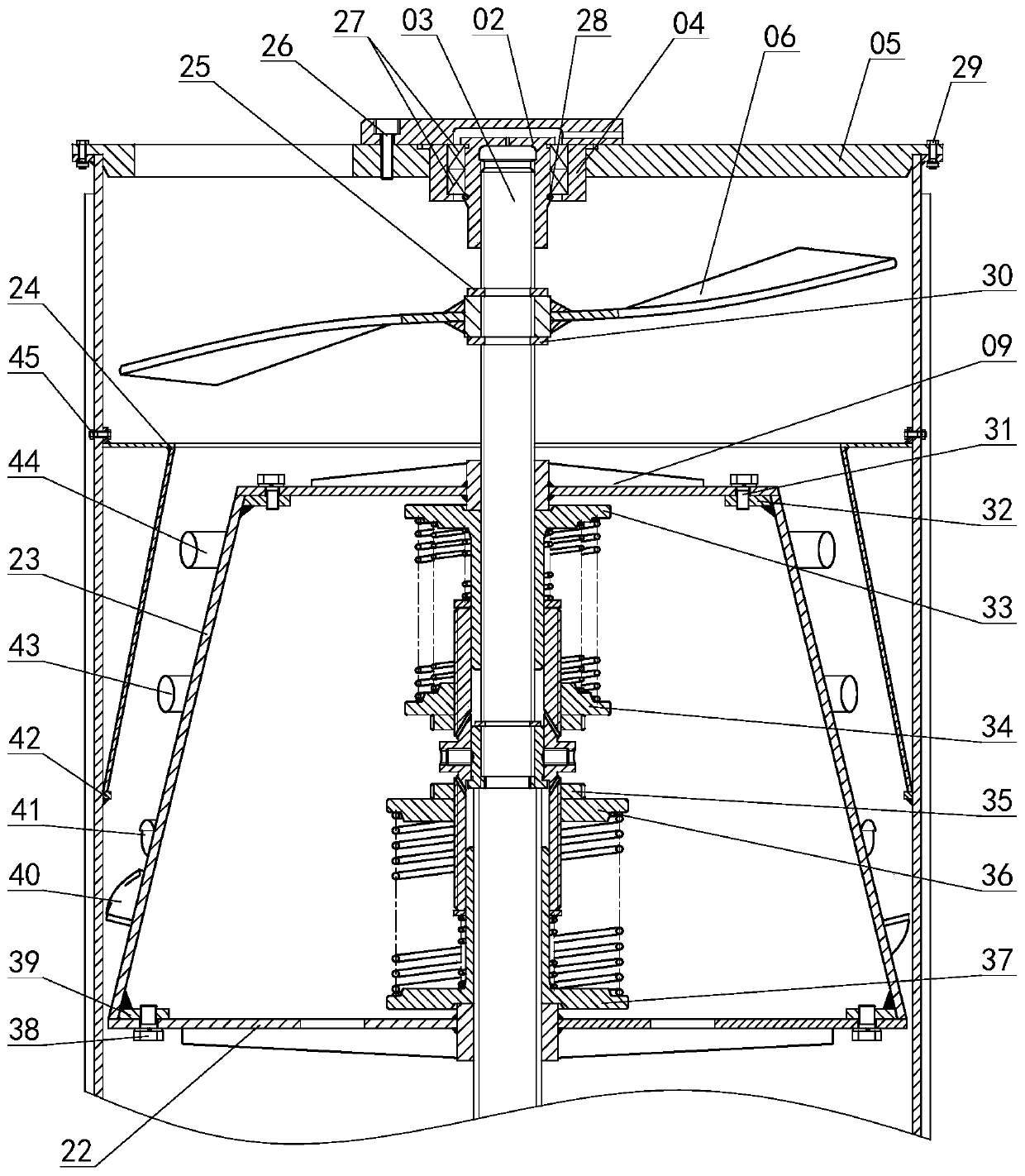

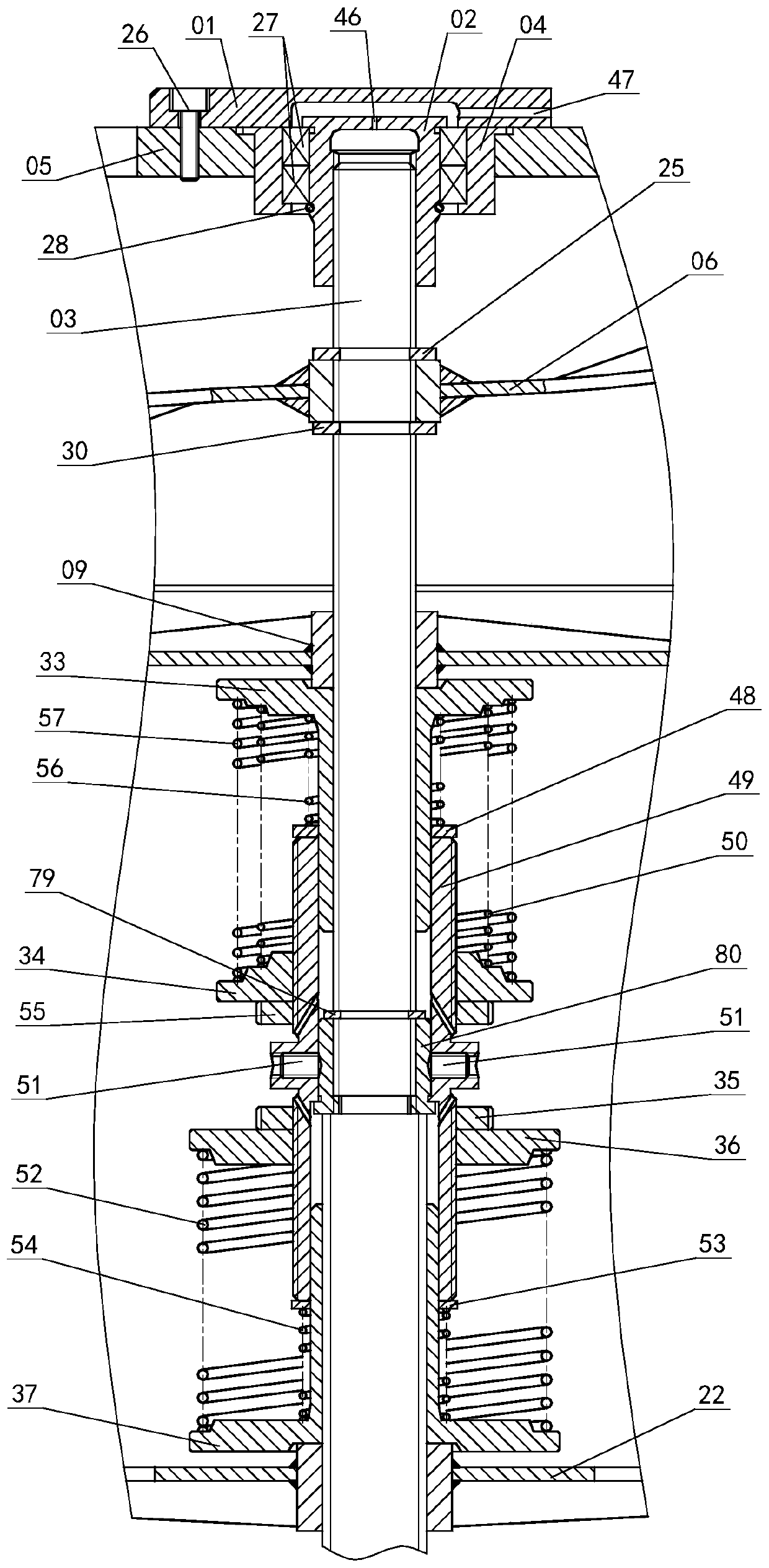

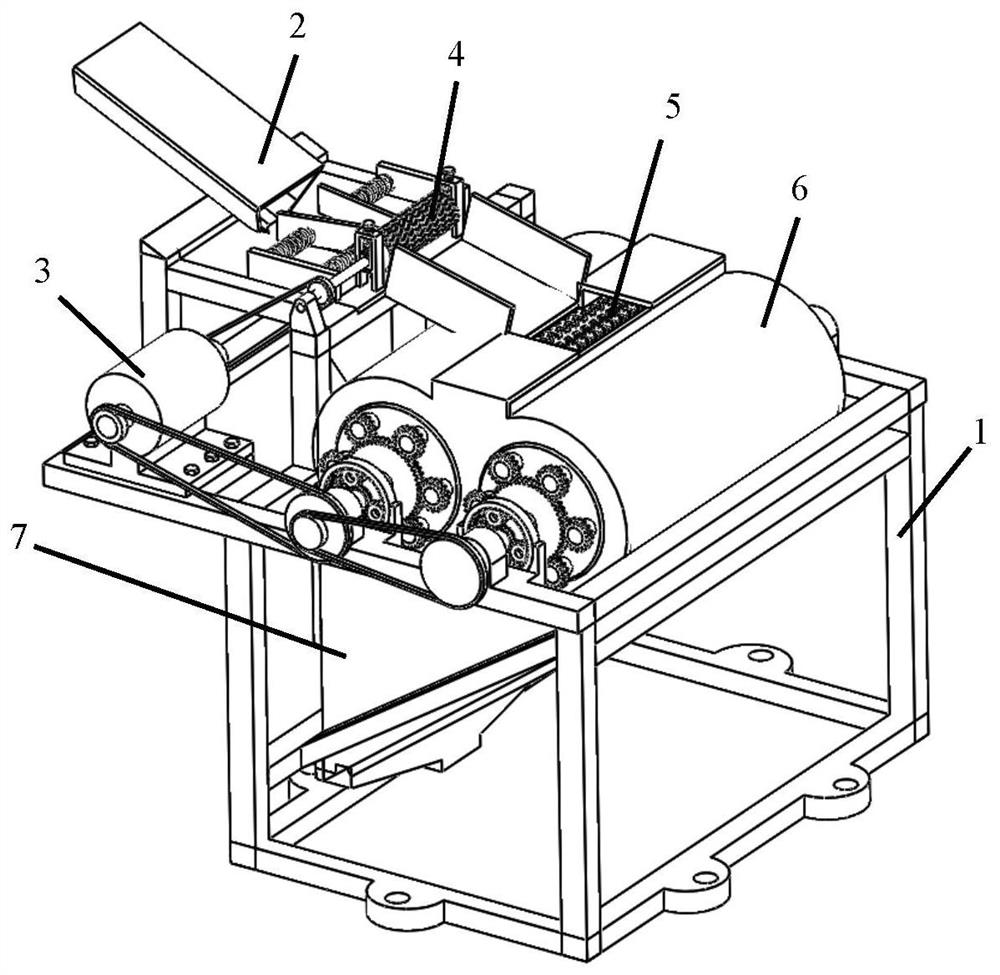

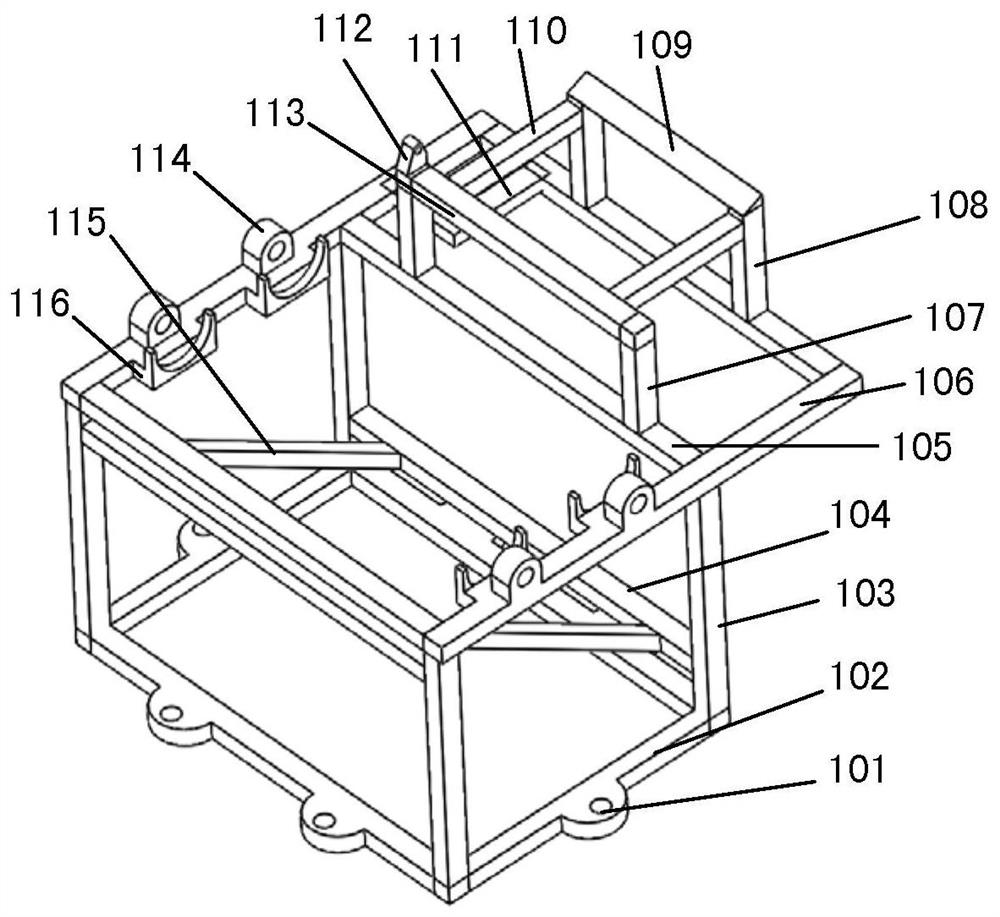

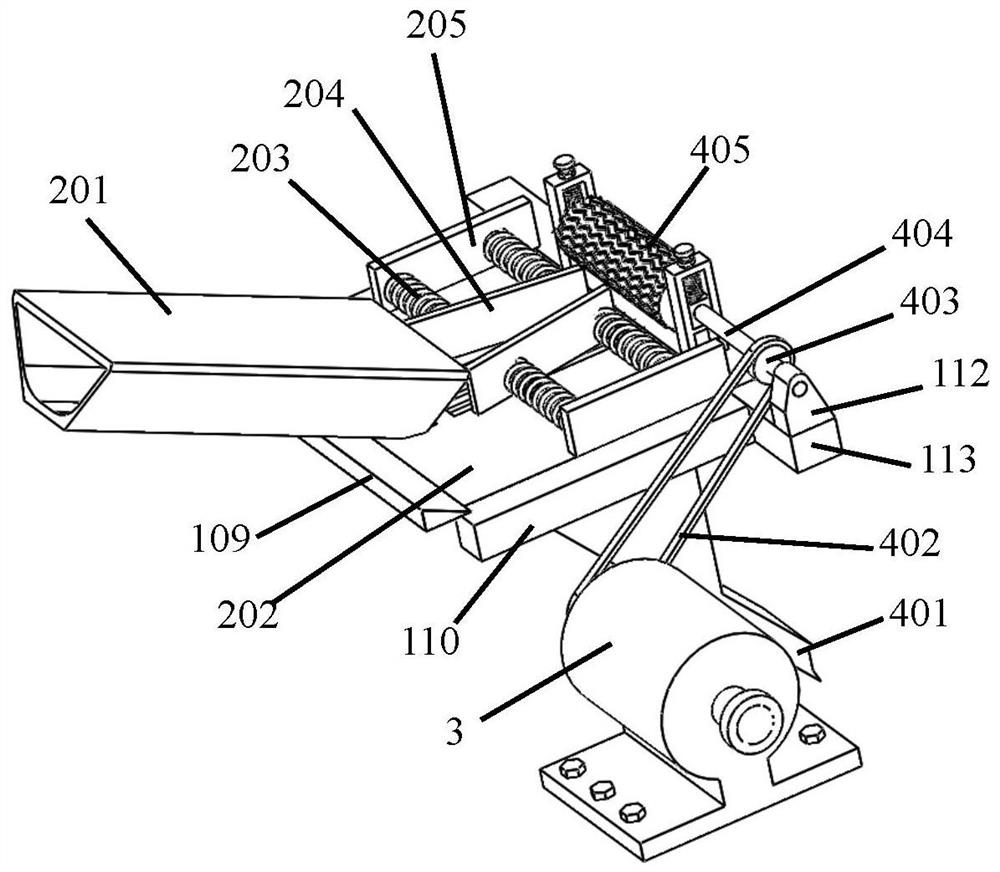

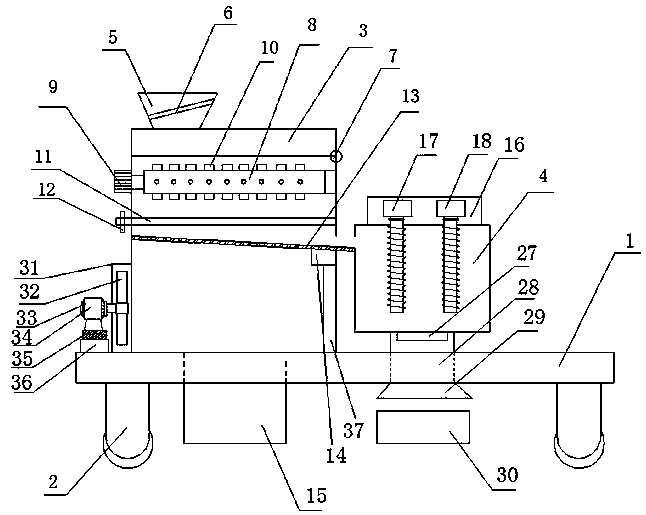

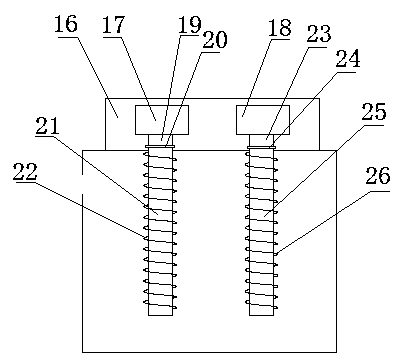

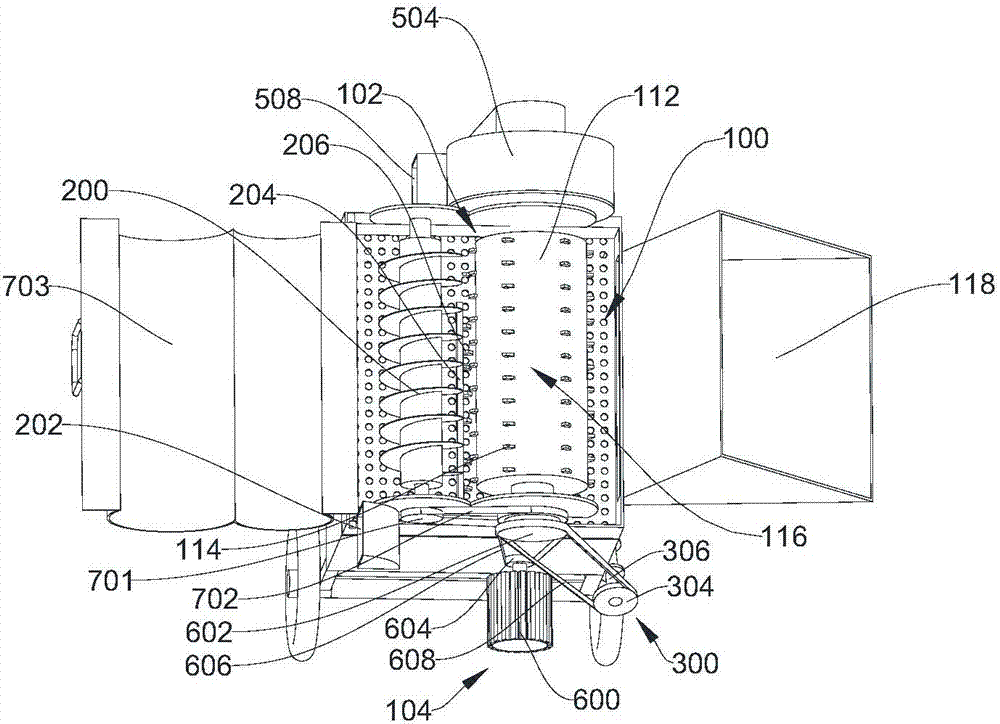

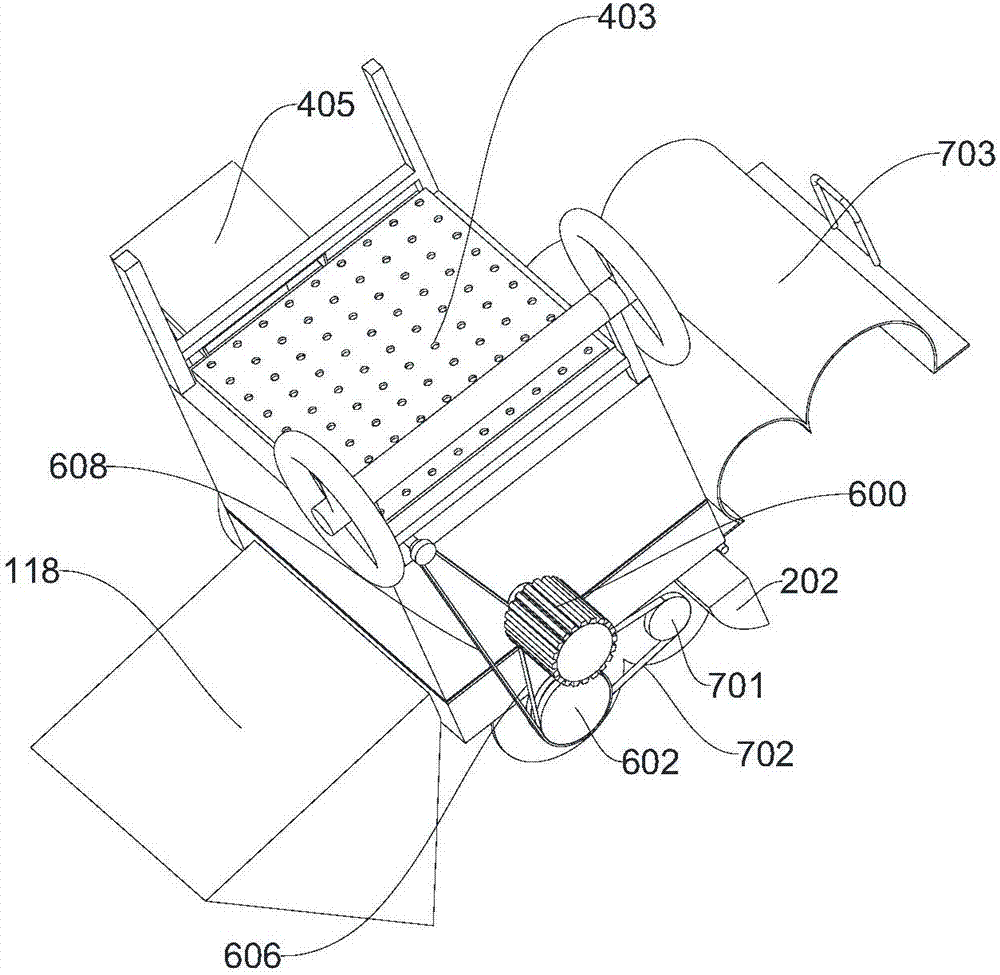

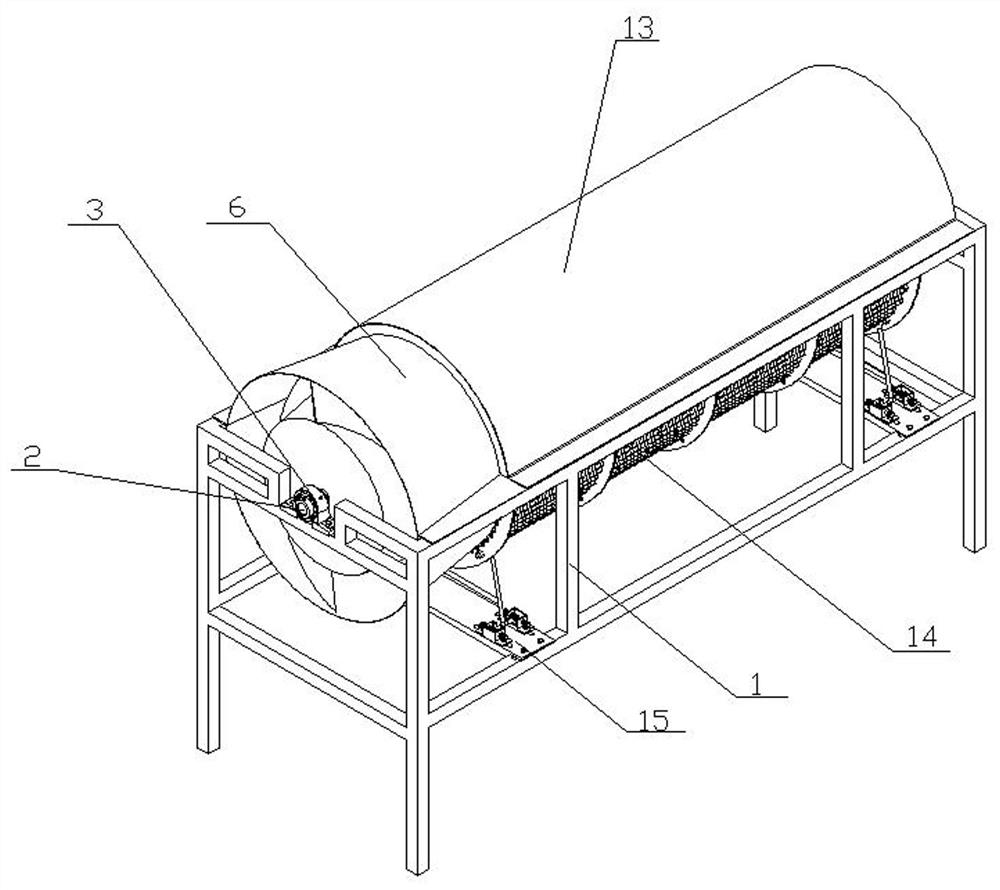

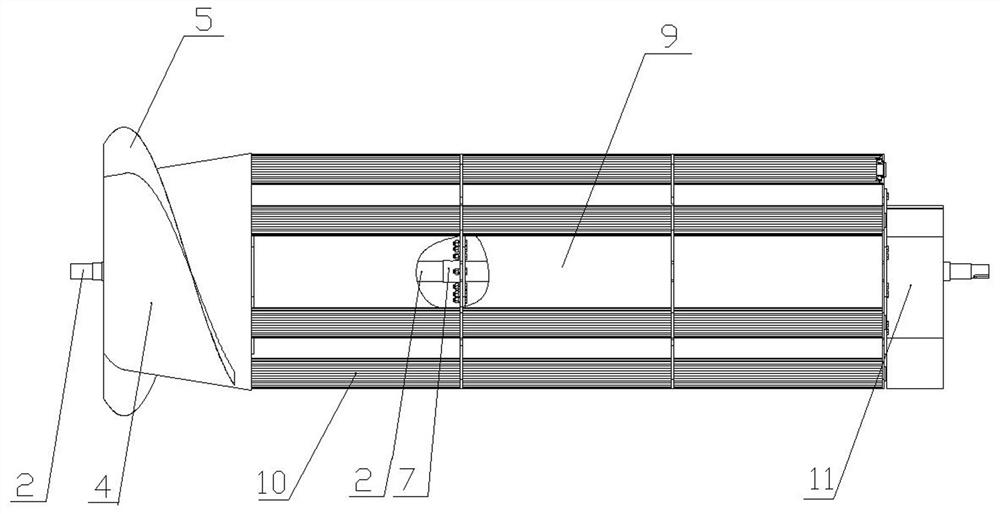

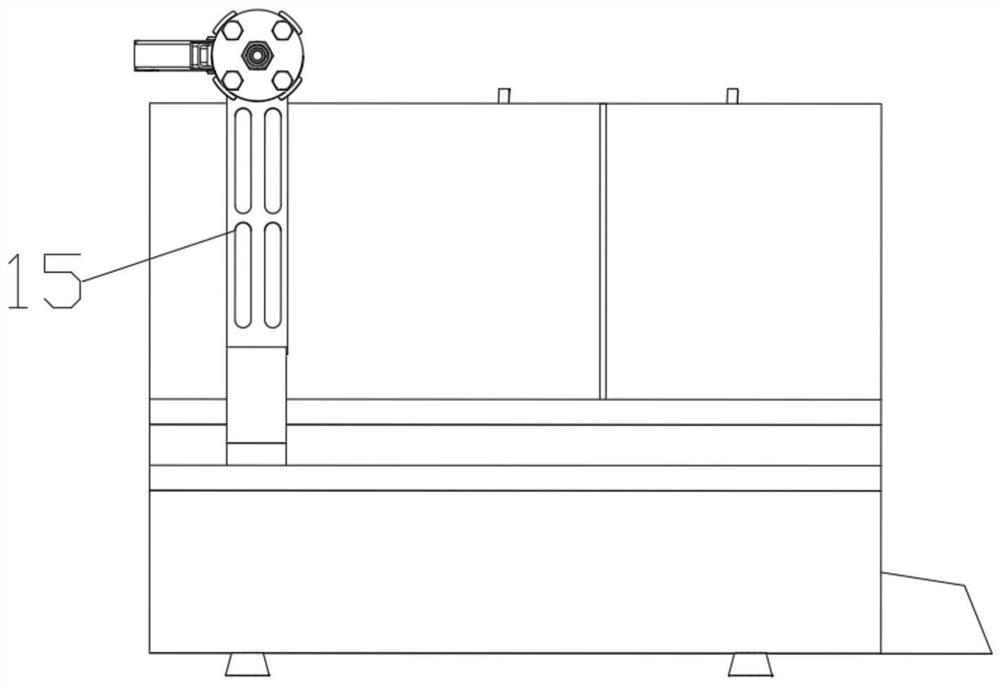

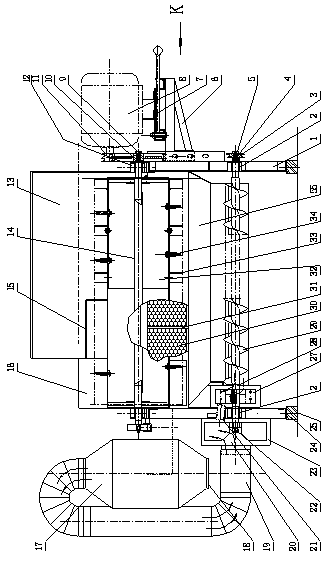

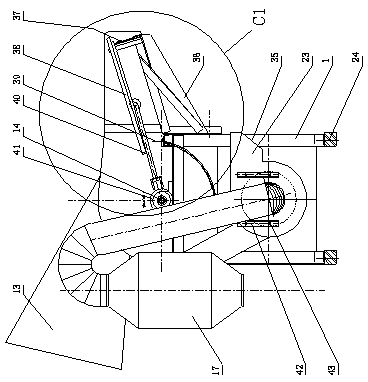

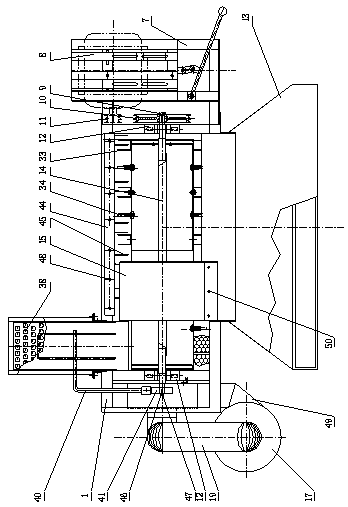

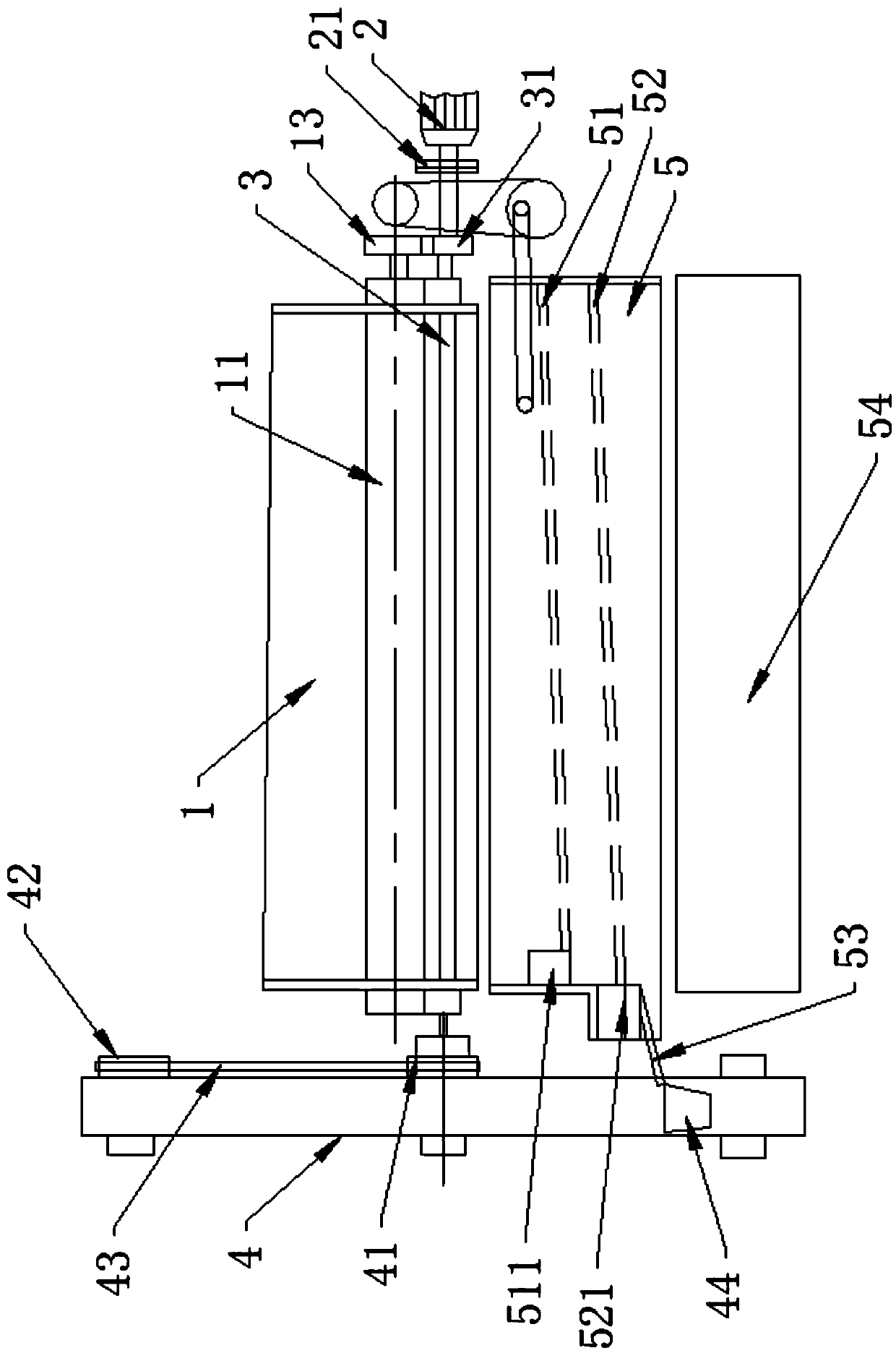

Differential intelligent non-destructive multi-roll thresher for plot corn harvester

ActiveCN108966852ANon-destructive threshingThreshing achievedThreshersIntelligent control systemWater content

The invention discloses a differential intelligent non-destructive multi-roll thresher for a plot corn harvester. The thresher mainly comprises a frame (1), a feeding device (2), a primary threshing device (4), a secondary threshing device, a transmission device, a grain collection device and an intelligent control system, wherein the feeding device (2), the primary threshing device (4), the secondary threshing device and the grain collection device are sequentially mounted on the frame (1) from top to bottom, the transmission device enables the primary threshing device (4) and the secondary threshing device to rotatably work, and the intelligent control system detects and records the water content of corn ears and controls the rotation speed of a motor (3). The thresher adopts a two-stepthreshing process, non-destructive threshing of corns is realized as the intelligent control system detects the water content of the corn ears and adjusts the rotation speed of the motor (3), and thethresher is reasonable in structure and convenient to use.

Owner:HAINAN UNIVERSITY

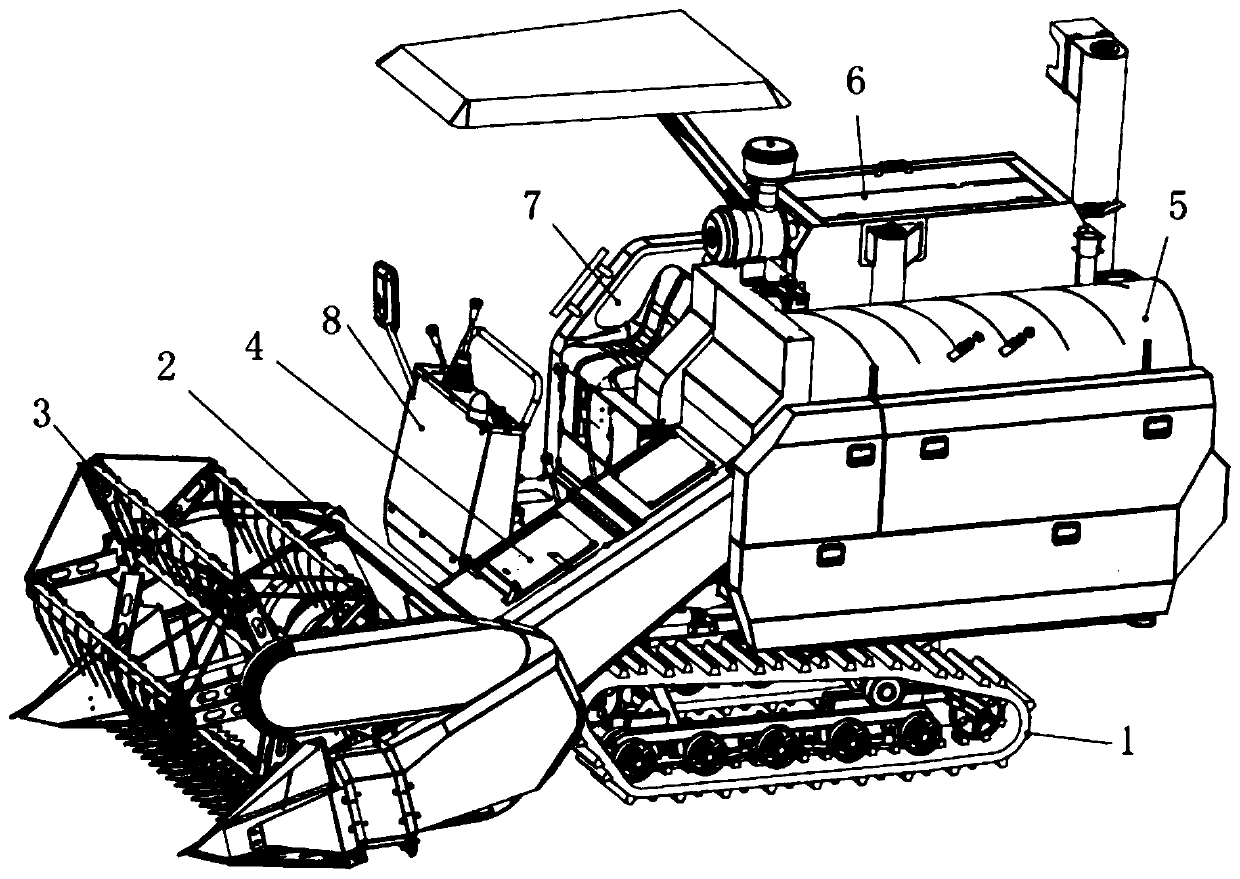

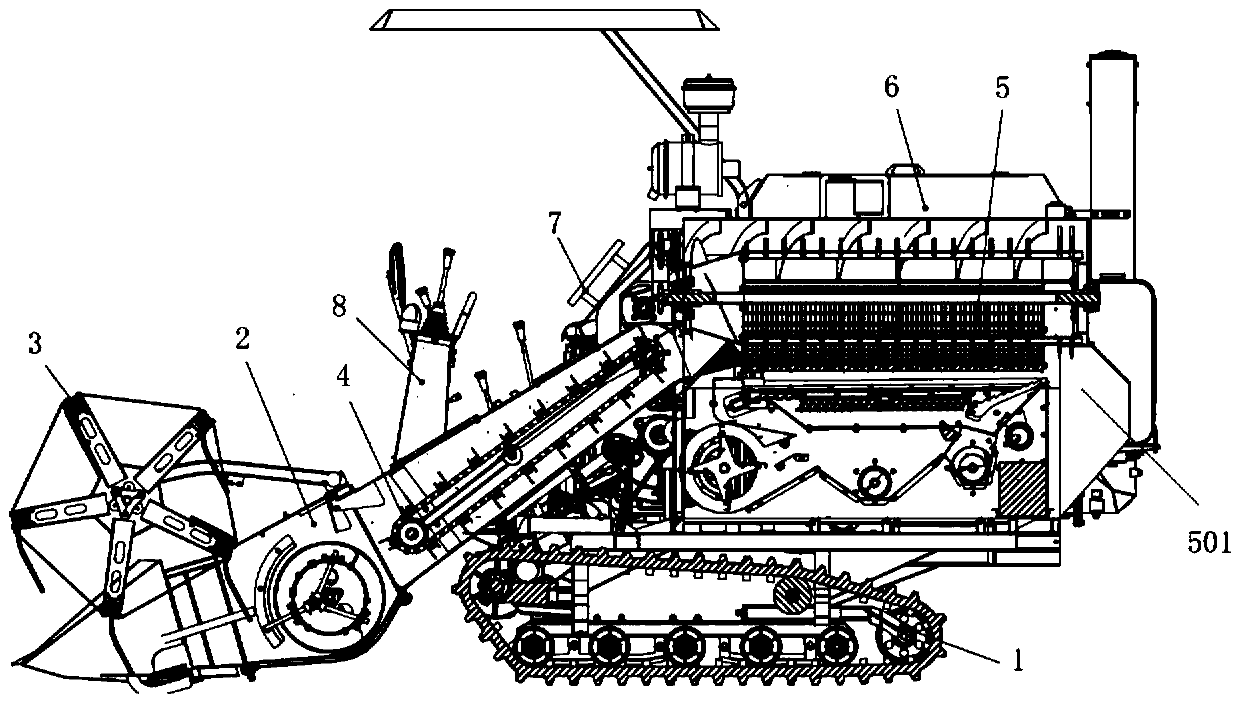

Harvesting device

PendingCN110754207AThreshing achievedReduce labor intensityMowersThreshersAgricultural scienceAgricultural engineering

The invention discloses a harvesting device which comprises a chassis. A header is arranged at the front end of the chassis, a reel is arranged on the upper portion of the header and used for poking outer crops to be harvested to the header, a conveying groove is connected on the header, a threshing separation mechanism is arranged on the conveying groove in a conveying direction and used for threshing and separating of the crops, a granary is connected on the threshing separation mechanism, and a power chamber is arranged on the chassis and connected with the chassis, the header, the reel, the conveying groove and the threshing separation mechanism. According to the structure design of the harvesting device, corn cobs can be picked off from field stalks, threshing of the corn cobs can beachieved, so that universality of the harvesting device is greatly improved, production cost is reduced, and the labor intensity of farmers is reduced.

Owner:HUNAN NONGGUANG AGRI EQUIP CO LTD

Corn thresher with screening and winnowing device

InactiveCN102630436AThreshing achievedAvoid adding transmission structuresThreshersAgricultural scienceAgricultural engineering

The invention relates to the field of farm machineries, and in particular relates to a corn thresher with a screening and winnowing device. The corn thresher comprises a feed hopper, a threshing device, a discharge opening and a motor, wherein a threshing rotary shaft is arranged in the threshing device, one end of the threshing rotary shaft is connected with the motor, a winnowing device is arranged at the lower part of the threshing device, the winnowing device comprises a winnowing box, a feeding opening and a blade, the blade is directly connected with one end of a motor shaft, and the other end of the motor shaft is connected with the threshing rotary shaft of the threshing device through a belt and a belt pulley; and a screening device is arranged at the other end of the threshing device and comprises a screening box, a screen and a vibration rotary shaft connected with the screen, and the other end of the threshing rotary shaft is directly and eccentrically connected with the other end of the vibration rotary shaft. The corn thresher disclosed by the invention has the advantages that one motor simultaneously and synchronously drives the threshing rotary shaft to rotate, the screen to vibrate and the blade of the winnowing device to rotate, and the threshing device also threshes corns; and the screen vibrates to screen niblets and corncobs.

Owner:李禄海

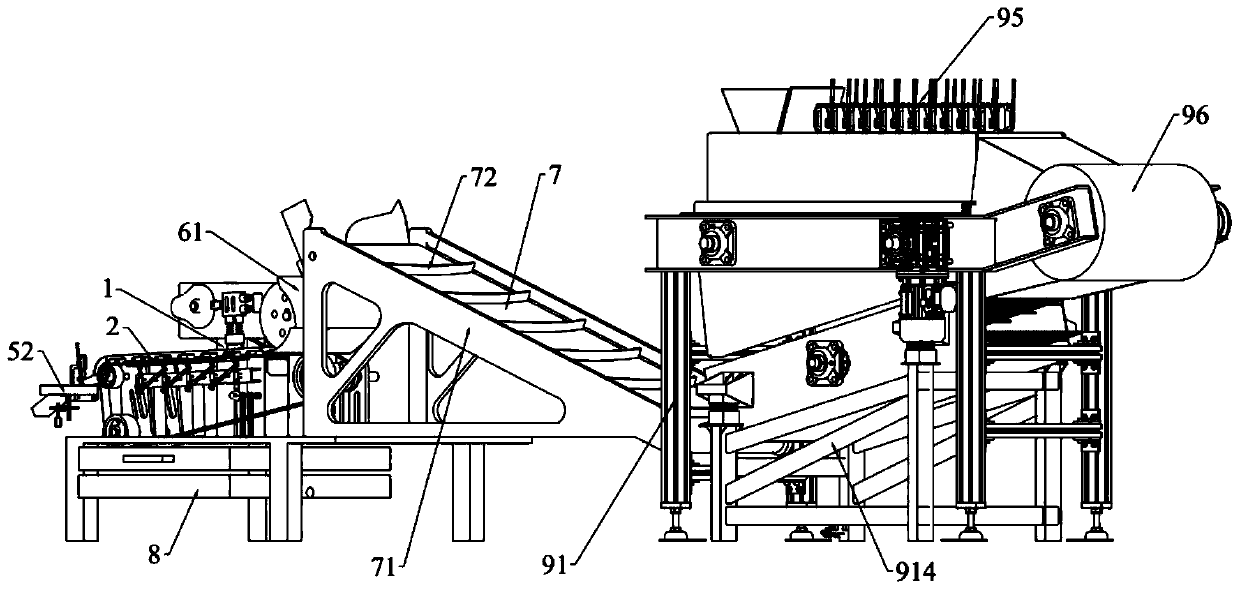

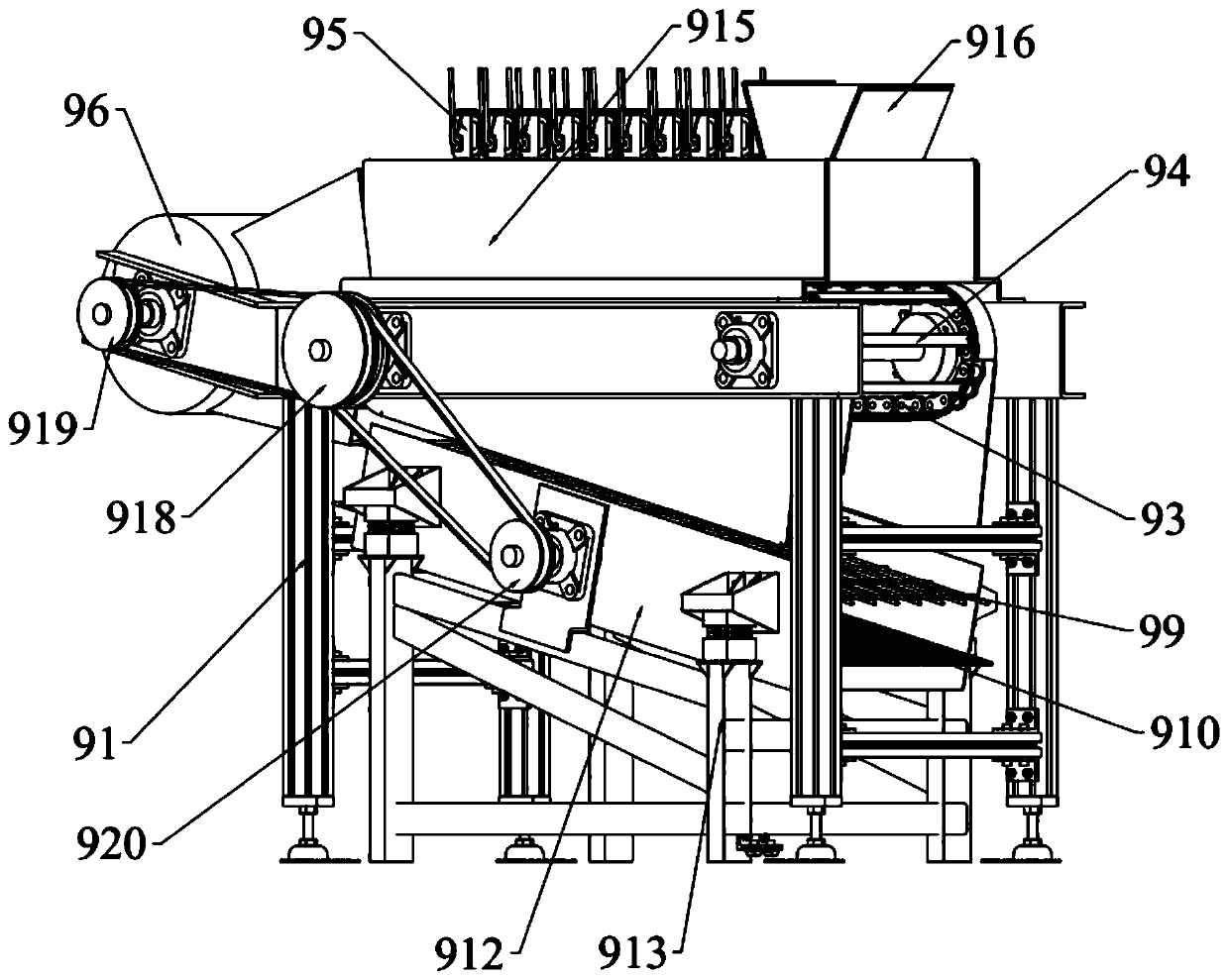

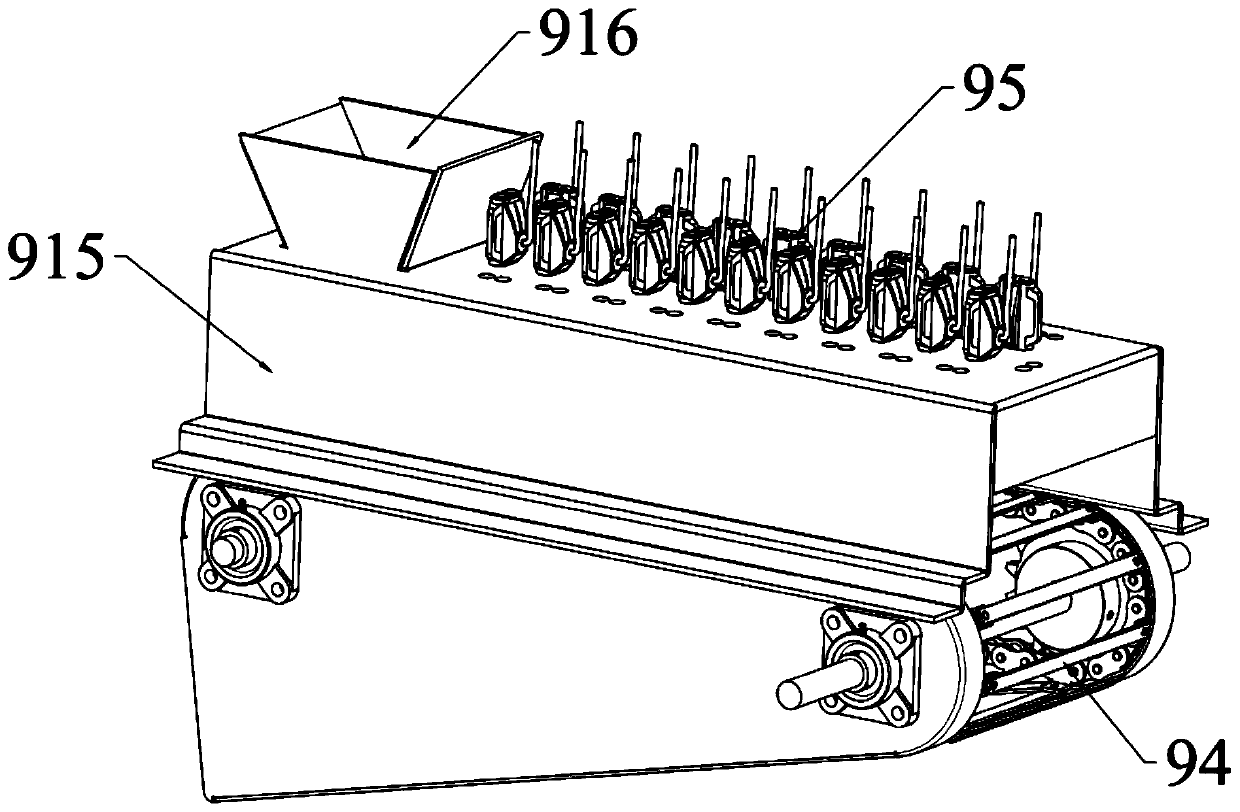

Threshing and husking integrated machine for fresh lotus seeds

The invention discloses a threshing and husking integrated machine for fresh lotus seeds, and relates to the technical field of agricultural machinery, solving the problems that it is difficult to thresh and husk the fresh lotus seeds and to integrate these two steps. The threshing and husking integrated machine is provided with a fresh-lotus-seed threshing device. The fresh-lotus-seed threshing device mainly comprises a fresh-lotus-seedpod fiber breaking mechanism, a lotus seed and lotus seedpod separating mechanism and a lotus seed and debris separating mechanism, and is used to thresh the fresh lotus seeds. The threshing and husking integrated machine is provided with a lotus seed husking device. The lotus seed husking device mainly comprises a lotus seed husking conveyor belt, a lotusseed husk cutting mechanism and a lotus seed husk squeezing mechanism, and is used to husk the lotus seeds. The threshing and husking integrated machine for the fresh lotus seeds has the advantages that the lotus seeds are threshed and husked through the fresh-lotus-seed threshing device and the lotus seed husking device; the whole process can well protect the lotus seeds without damage to the lotus seeds; the machine can adapt to the lotus seeds different in size during husking, the efficiency is high, and the effect is good.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Rice single ear threshing machine

ActiveCN105917863AGood threshing effectMake up for the defect of poor threshing effectThreshersEngineeringThreshing machine

The invention relates to a rice single ear threshing machine, and belongs to the field of agricultural machines. The rice single ear threshing machine comprises a machine casing and a first threshing mechanism, wherein the machine casing is provided with a rice inlet, a grain outlet and a waste outlet; the first threshing mechanism comprises a first drum, a second drum and a first engine, and the first engine is used for driving the first drum and the second drum to rotate; first brush strips are respectively arranged on the first drum and the second drum, and are used for removing grains from stems; a threshing gap is formed between the first drum and the second drum, the rice can pass through the threshing gap, and the threshing gap corresponds to the rice inlet; the grain outlet is positioned at the bottom part of the machine casing, and the waste outlet is positioned at one side, away from the rice outlet, of the first threshing mechanism. The rice single ear threshing machine has the advantages that the two drums with the brush strips are arranged at interval to form the threshing gap structure, and the rice can be threshed through the threshing gap; the threshing effect is good, and the grains, stems, ear stalks and stem stalks of the rice can be effectively separated; the purpose of single ear threshing is realized, and the mutual mixing is avoided.

Owner:NINGXIA UNIVERSITY

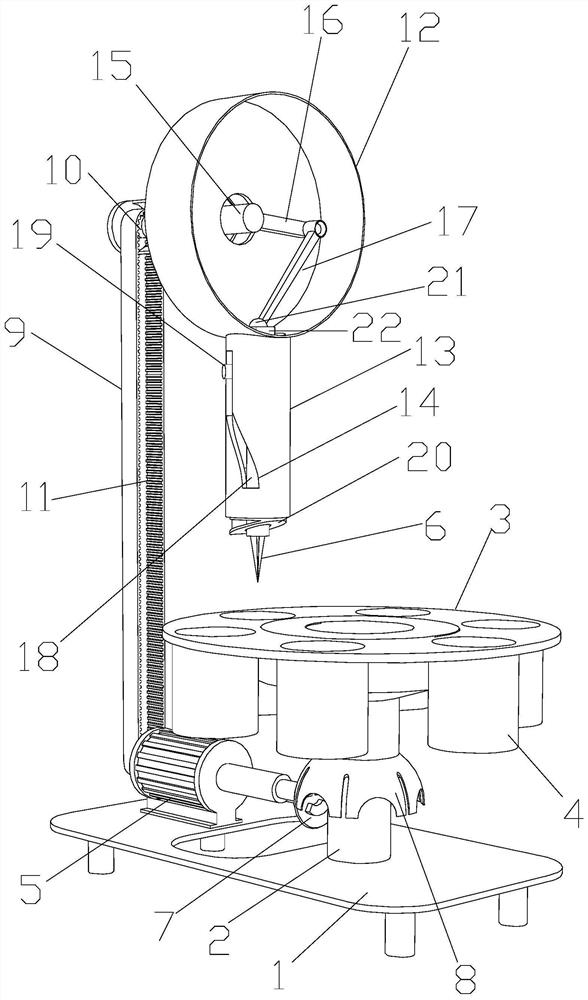

Corn threshing machine

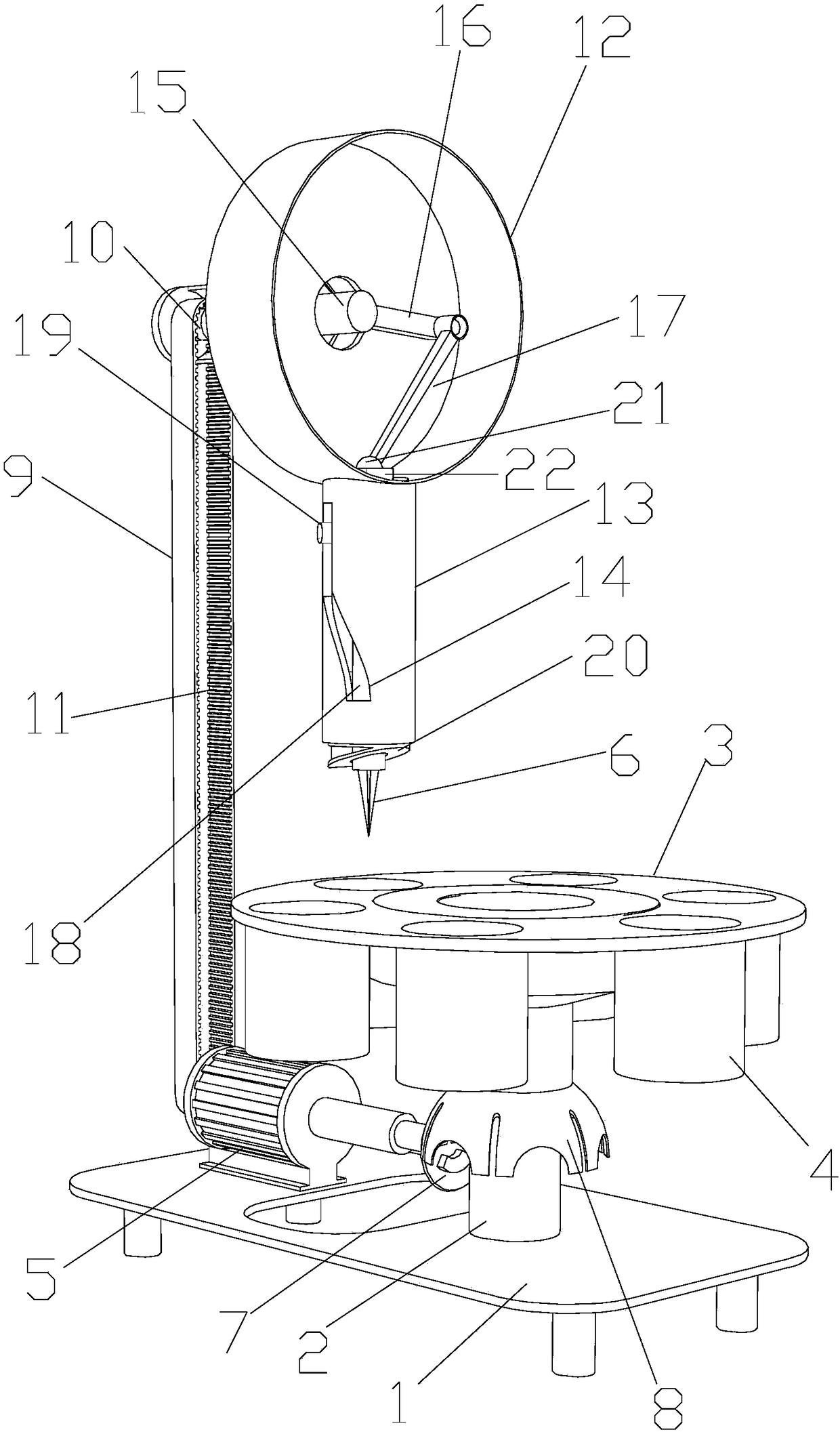

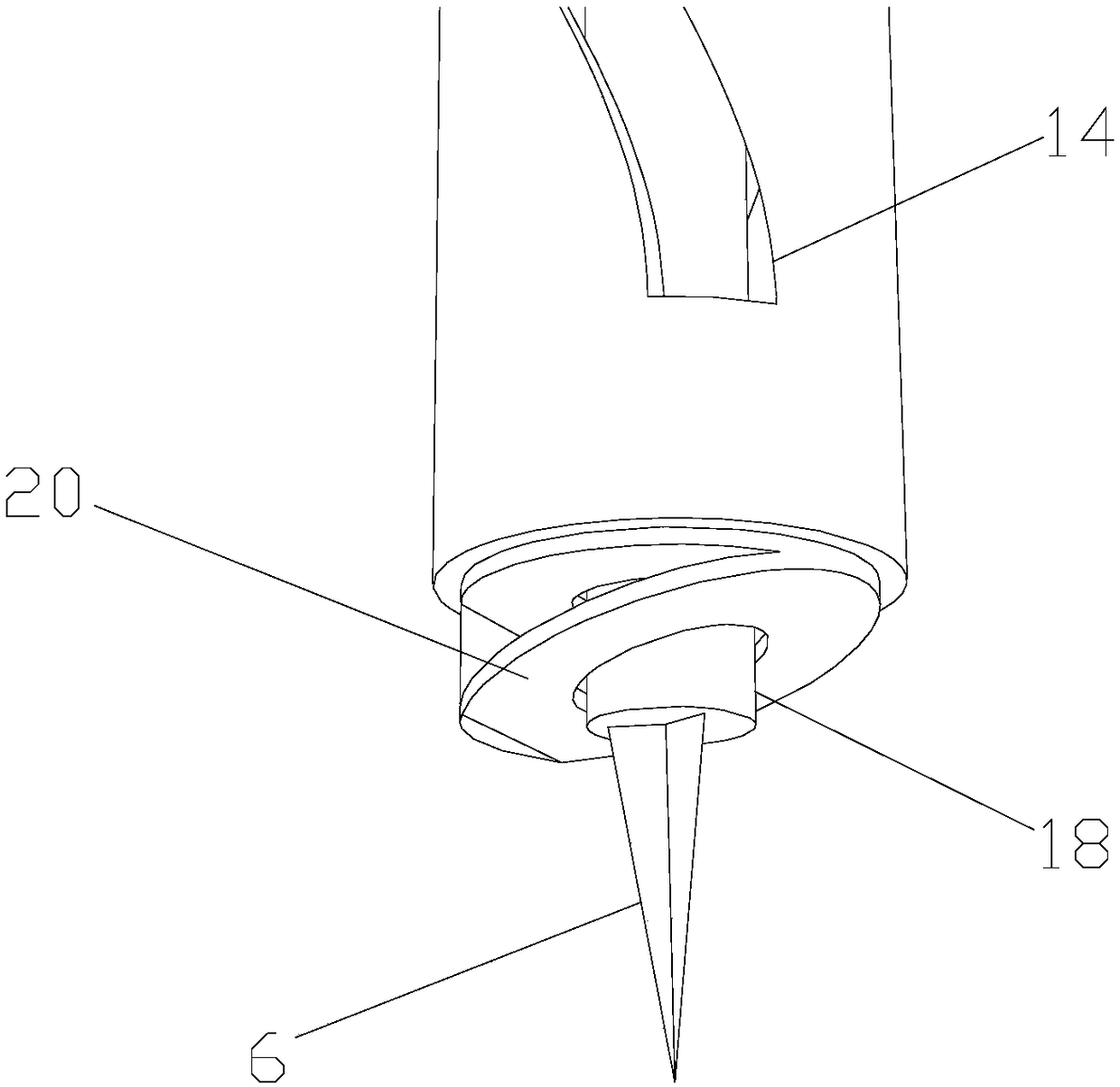

The invention relates to a corn threshing machine. The corn threshing machine comprises a base, wherein a rotating disk shaft is rotatably arranged on the base; the upper part of the rotating disk shaft is coaxially and fixedly connected with a horizontal rotating disk; a plurality of threshing cylinders are uniform arranged on the rotating disk at intervals along a circumferential direction; thebase is also fixedly provided with a horizontal double-shaft extension motor; one output shaft of the double-shaft extension motor drives the rotating disk shaft to rotate through a space grooved wheel mechanism; the other output shaft of the double-shaft extension motor is connected with a crank connecting rod mechanism located above the threshing cylinders through a synchronous toothed belt mechanism; and the bottom part of the crank connecting rod mechanism is fixedly connected with a threshing cone corresponding to the threshing cylinders. The corn threshing machine provided by the invention has the advantages of low price, small size, high efficiency, conservation of labor, and applicability to daily use for peasant household.

Owner:XIAN UNIV OF TECH

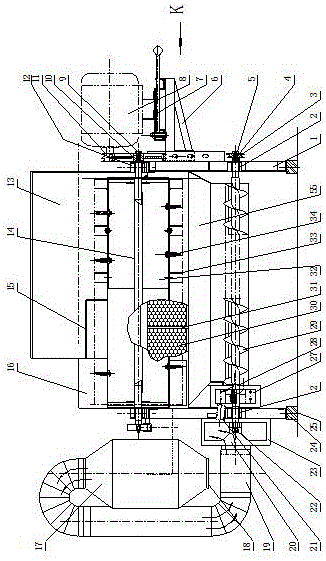

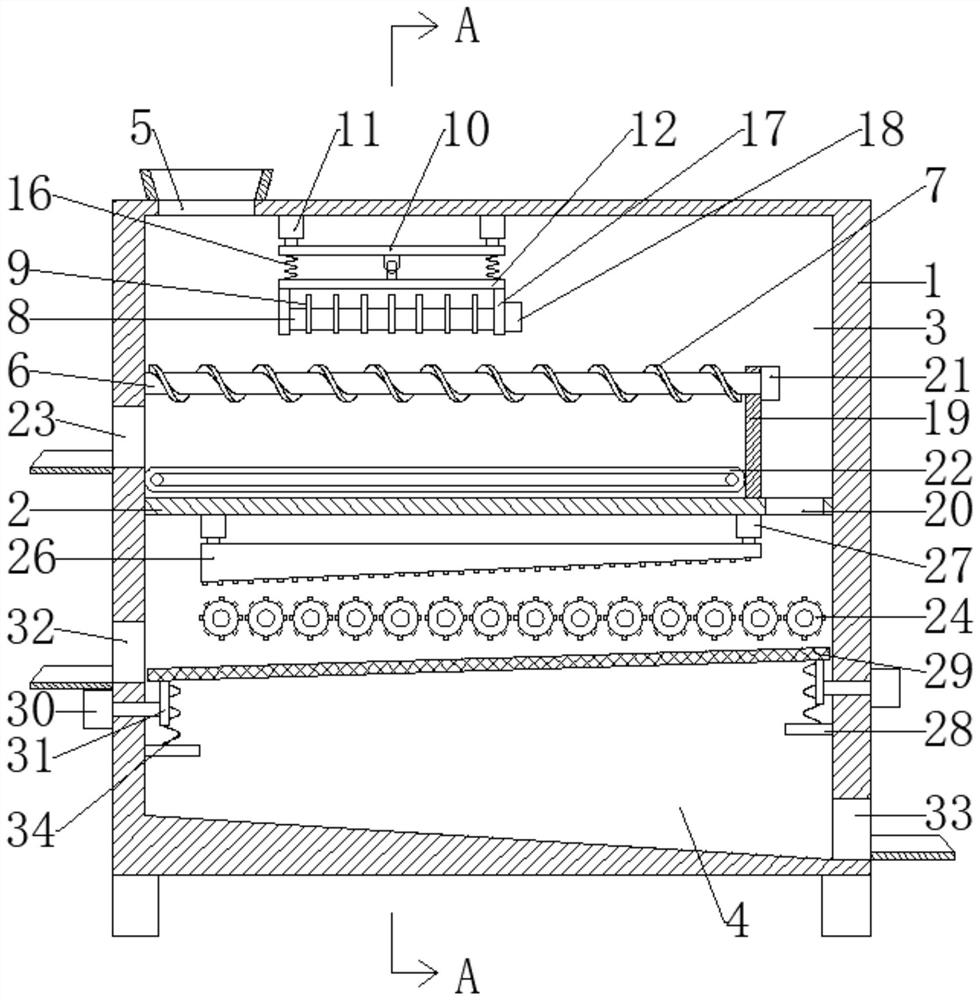

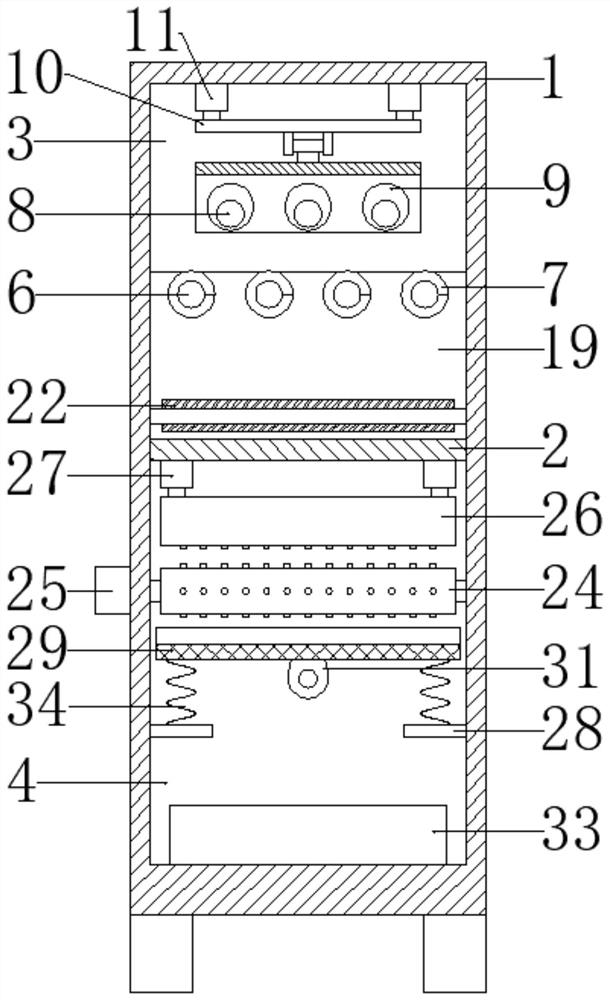

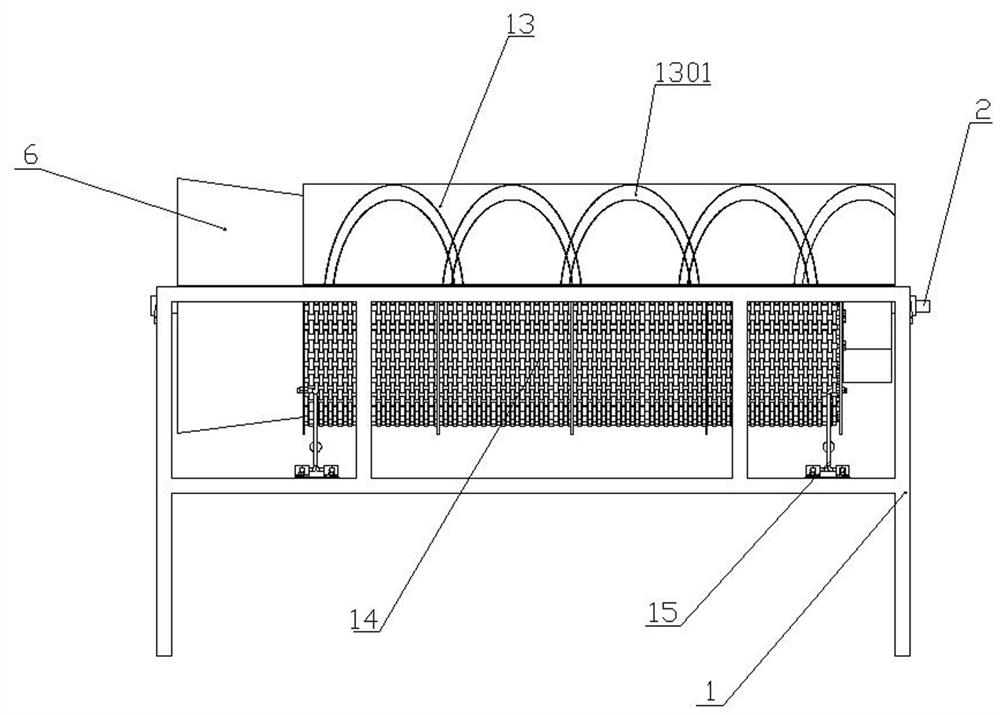

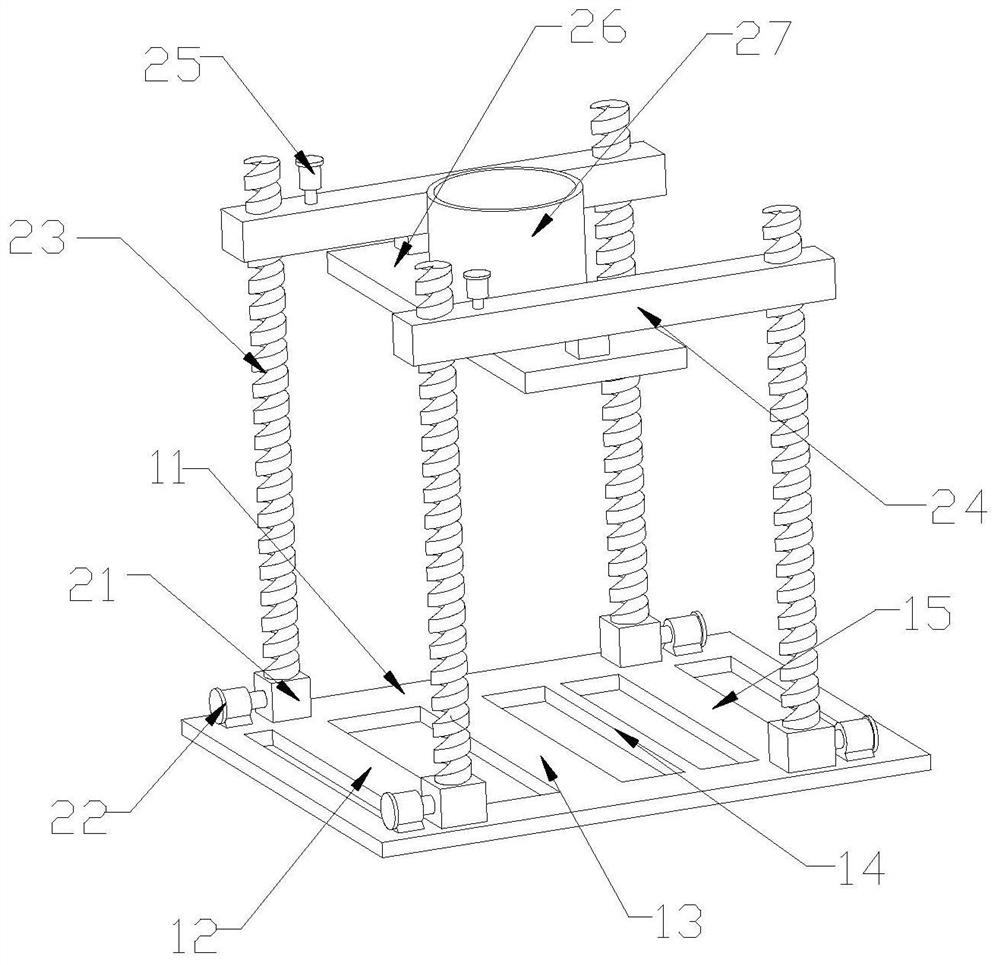

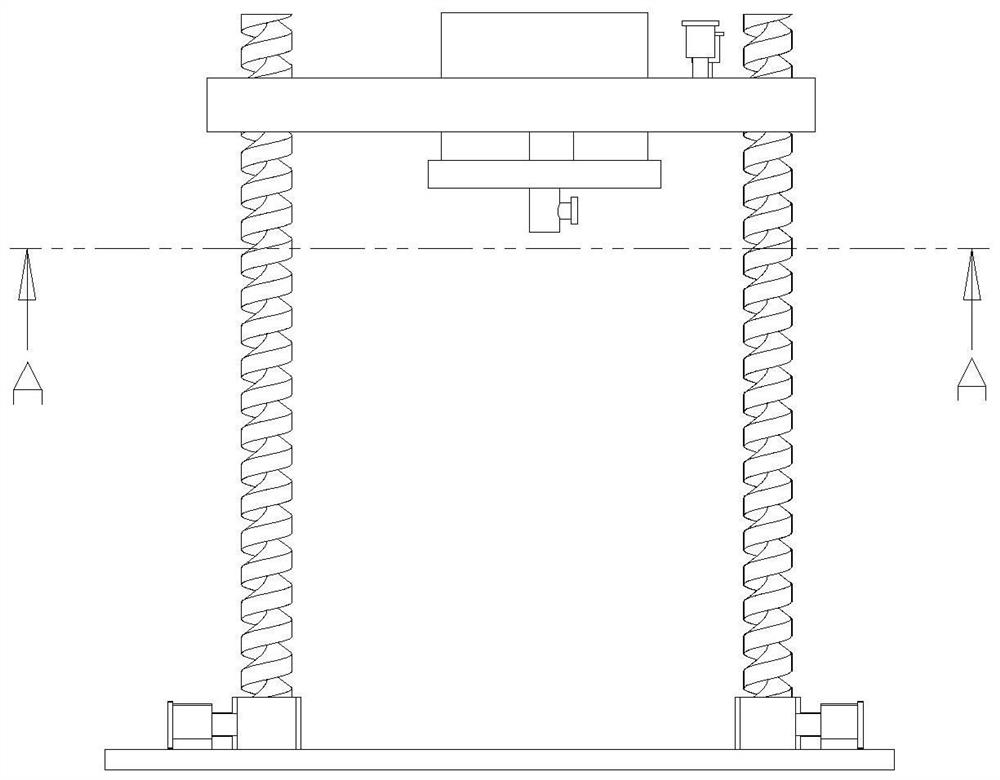

Seed threshing and cleaning device

PendingCN111742717AReduce impurityThreshing achievedThreshersAgricultural scienceAgricultural engineering

The embodiment of the invention provides a seed threshing and cleaning device, and relates to the field of agricultural machinery. The seed threshing and cleaning device comprises a rack, a roller threshing mechanism, a vibration screening mechanism, a material conveying mechanism and a driving mechanism, wherein the roller threshing mechanism is arranged at the top of the rack, the vibration screening mechanism is arranged in the middle of the rack and located below the roller threshing mechanism, the material conveying mechanism is arranged at the bottom of the rack and located below the vibration screening mechanism, and the driving mechanism is arranged on one side of the rack and is in transmission connection with the roller threshing mechanism, the vibration screening mechanism and the material conveying mechanism. Compared with the prior art, the seed threshing and cleaning device can achieve the function of threshing, cleaning and conveying forage grass seed; and meanwhile, thecleaning effect can be improved by adopting a multi-layer vibration woven screening mode, and the rate of impurities in the seeds is low.

Owner:GRASSLAND RES INST OF CHINESE ACAD OF AGRI SCI

Corn threshing device with screening function for agricultural production

The invention belongs to the technical field of corn threshing devices, and particularly relates to a corn threshing device with a screening function for agricultural production. In order to solve theproblems that an existing corn threshing device has no screening function, and workers cannot separate corn kernels and corncobs conveniently, the corn threshing device comprises a base plate, four supporting columns are welded to the outer wall of the top of the base plate, one threshing box is welded to the top ends of the four supporting columns, a push handle is welded to the position, closeto the top, of the outer wall of one side of the threshing box, one inclined dripping plate is welded to the portions, close to the bottoms, of the inner walls of the two sides of the threshing box, arectangular discharging hole is formed in the portion, close to the bottom, of the outer wall of one side of the threshing box, and the outer wall of the bottom of the dripping plate is welded to theinner wall of the bottom of the discharging hole. The corn threshing device is compact in structure, is used for performing corn threshing in agricultural production and has the screening function, aworker can separate corn kernels and corncobs conveniently, and the using convenience of the device is improved.

Owner:六安科创教育信息咨询有限公司

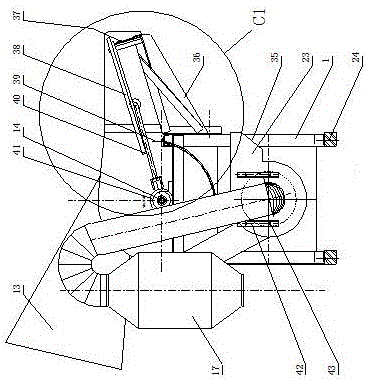

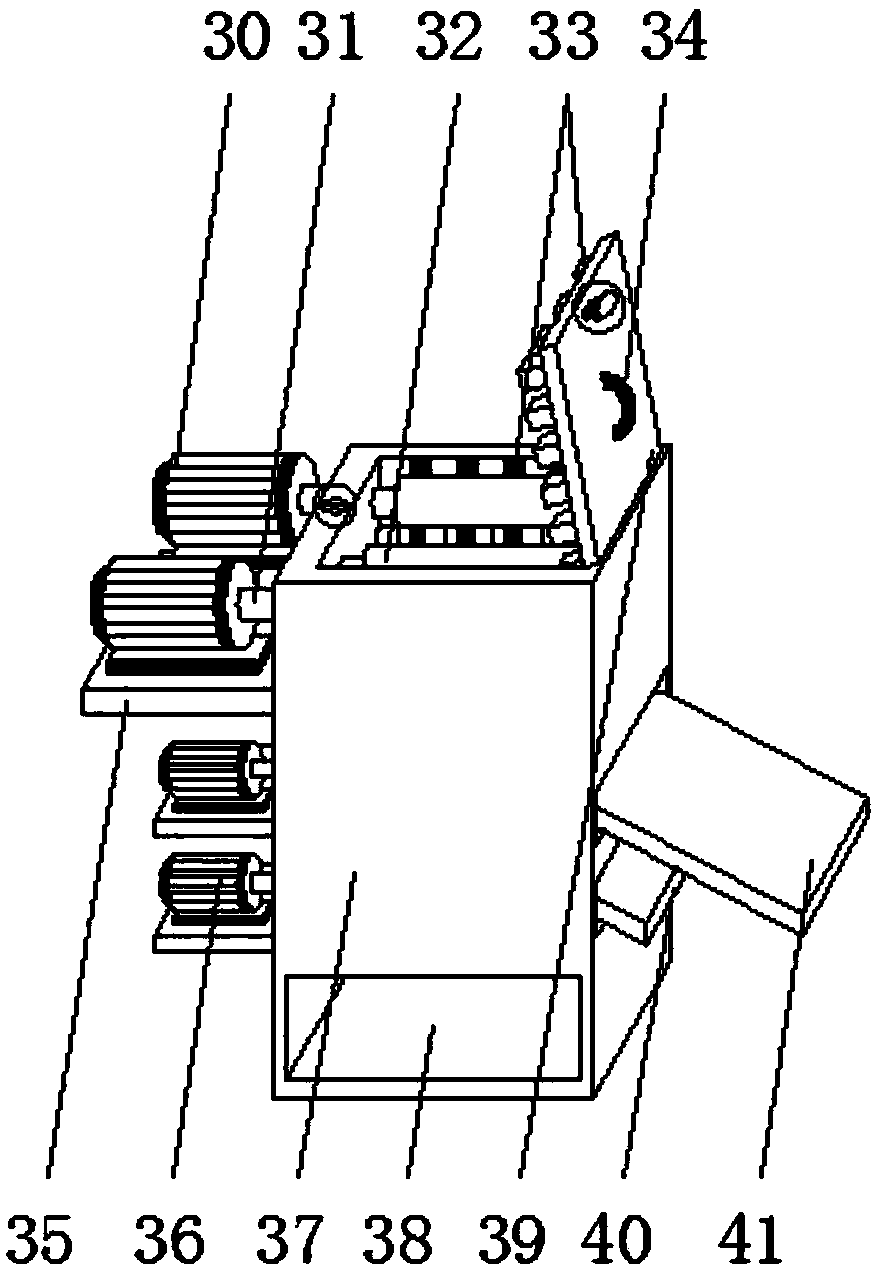

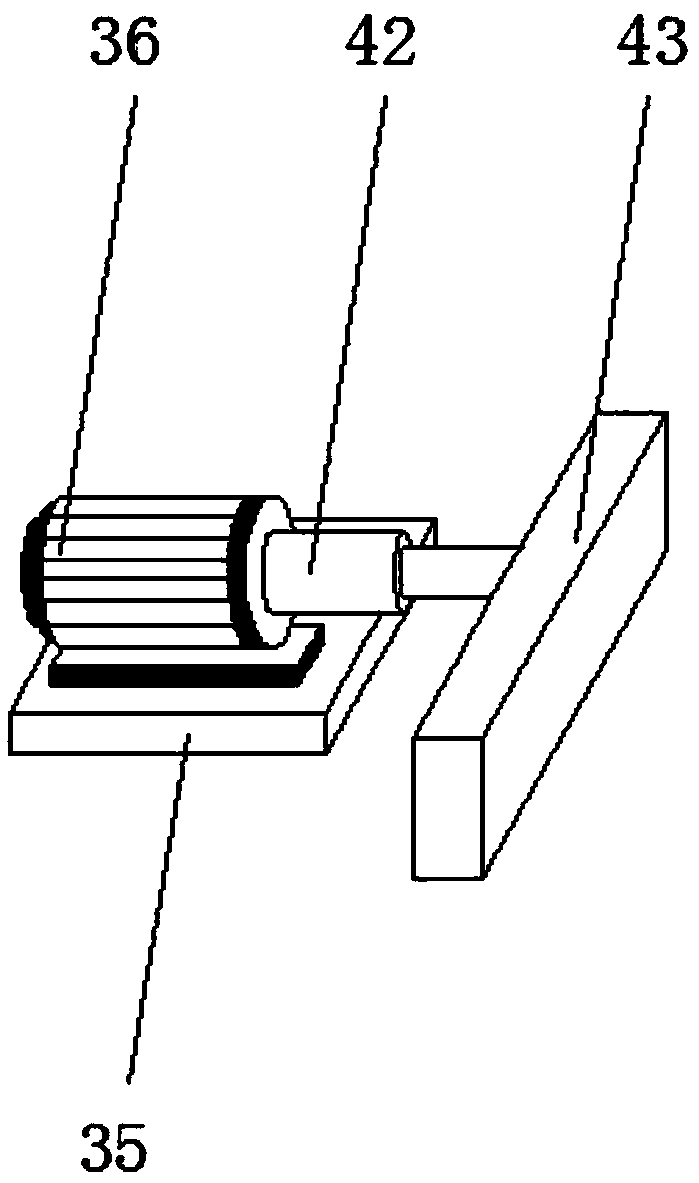

Rapeseed and wheat threshing straw returning machine

The invention discloses a rapeseed and wheat threshing straw returning machine which comprises a rack (1), a power mechanism, a threshing cylinder (32), a hood (51) on the upper surface of the threshing cylinder (32), a material feeding hopper (13), a straw discharging opening, a separation screen (30) below the threshing cylinder (32), a material collection hopper (55) below the separation screen (30), a packing auger (29) and a cyclone separation machine (17), and is characterized in that a straw discharging cover (16) is arranged outside the straw discharging opening; a vibration screen plate (38) is arranged in the straw discharging cover (16), and is fixed at one end of a connection rod (40); the other end of the connection rod (40) is connected with an eccentric wheel (41); a material return hopper (36) is arranged below the vibration screen plate (38); the outer end of the vibration screen plate (38) is fixed at one end of a cloth clamping rubber block (37); the other end of the cloth clamping rubber block (37) is fixed on the rack (1); a fixed blade (45) extending into a threshing cavity is fixed on the rack (1); a movable blade (33) is fixed on the threshing cylinder (32).

Owner:JIANGSU RAINPAT DATA SERVICE

A kind of integrated corn harvesting device

The invention relates to the technical field of agricultural machinery, in particular to an integrated harvesting device for corn, which includes a box body, and a partition board is fixedly installed in the box body, and the partition board divides the inner cavity of the box body into a A peeling chamber and a threshing chamber located below, the peeling chamber is provided with a peeling mechanism, and the threshing chamber is provided with a threshing mechanism; the top of the box body is provided with a feed port communicated with the peeling chamber, The right side of the box body is provided with a discharge port that communicates with the threshing chamber, and the partition plate is provided with a port that communicates with the peeling chamber and the threshing chamber; the present invention drives the corn through the conveying roller. When the ear moves, it drives the ear of corn to rotate. When the conveying roller drives the ear of corn to move below the cutting shaft, the corn husk is chopped by the cutting knife, so as to realize the peeling of the ear of corn, and the peeling efficiency is high.

Owner:HENAN VOCATIONAL COLLEGE OF AGRI

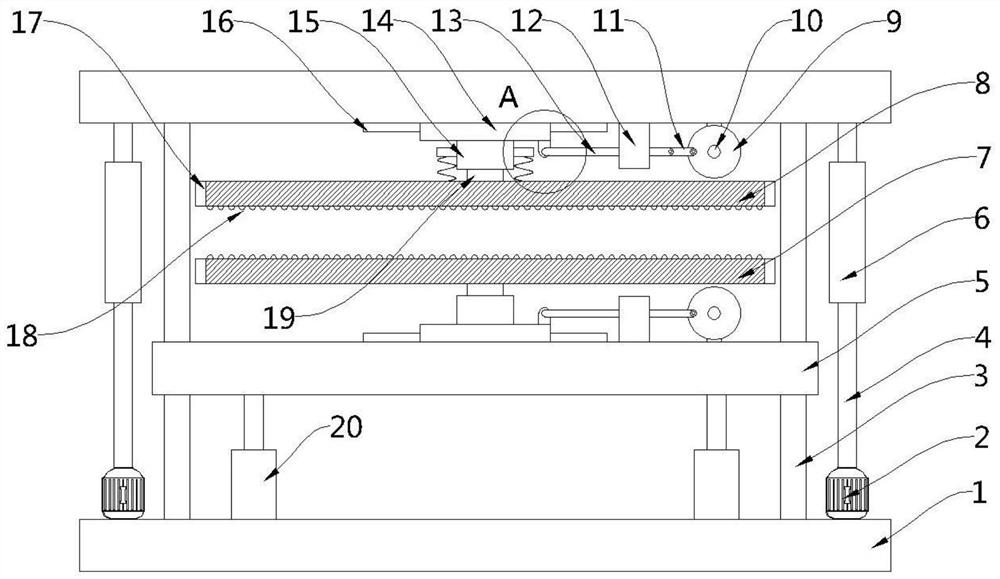

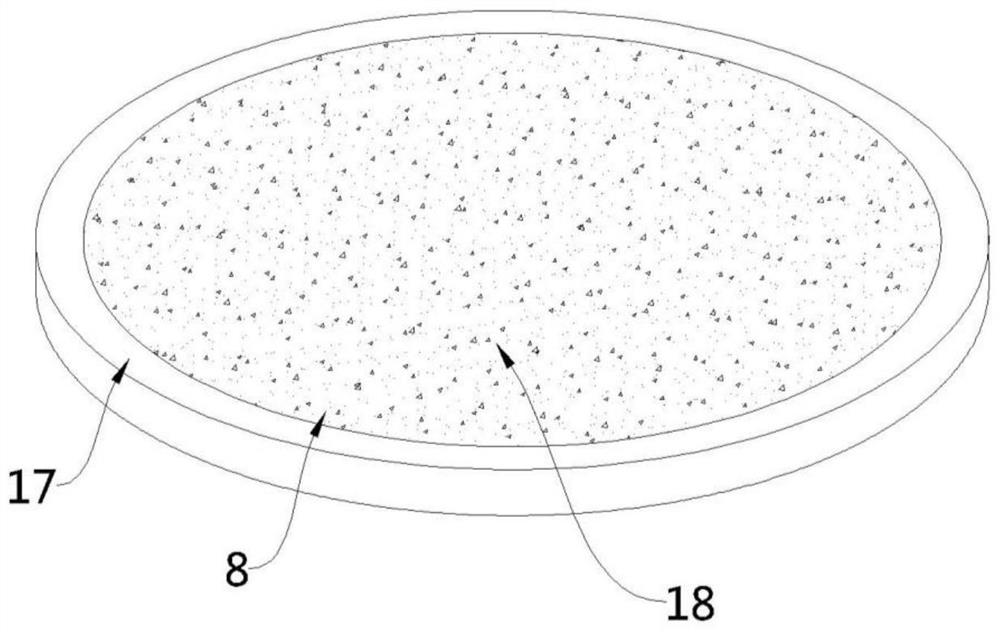

Rice threshing and straw smashing mechanism

ActiveCN111631023ARealize automatic feeding processEasy to reuseMowersThreshersAgricultural scienceAgricultural engineering

The invention discloses a rice threshing and straw smashing mechanism. The rice threshing and straw smashing mechanism comprises a bottom plate, an automatic feeding module, an automatic threshing module and a straw smashing module. The automatic feeding module comprises a first lead screw, a first motor, a transverse rod, a second motor, a second lead screw and a rice storage tank. The automaticthreshing module comprises a threshing machine, a screening plate, a vibration motor, a third lead screw, a third motor and a lifting base. And the straw crushing module comprises a crusher, a fifth motor and a crushed straw collecting tank. The automatic feeding module is arranged, and automatic feeding of rice can be achieved under the condition that manpower is not needed. And the straw crushing module is arranged, so that threshed rice straw can be crushed and collected, and secondary utilization is facilitated. The automatic threshing module is arranged, threshed rice can be screened while automatic threshing of the rice is achieved, and the problem that manual screening is still needed after traditional rice threshing is solved. The problems that in the prior art, rice is threshed manually, and threshed straw is difficult to collect are solved.

Owner:安徽省阜阳市海泉粮油工业股份有限公司

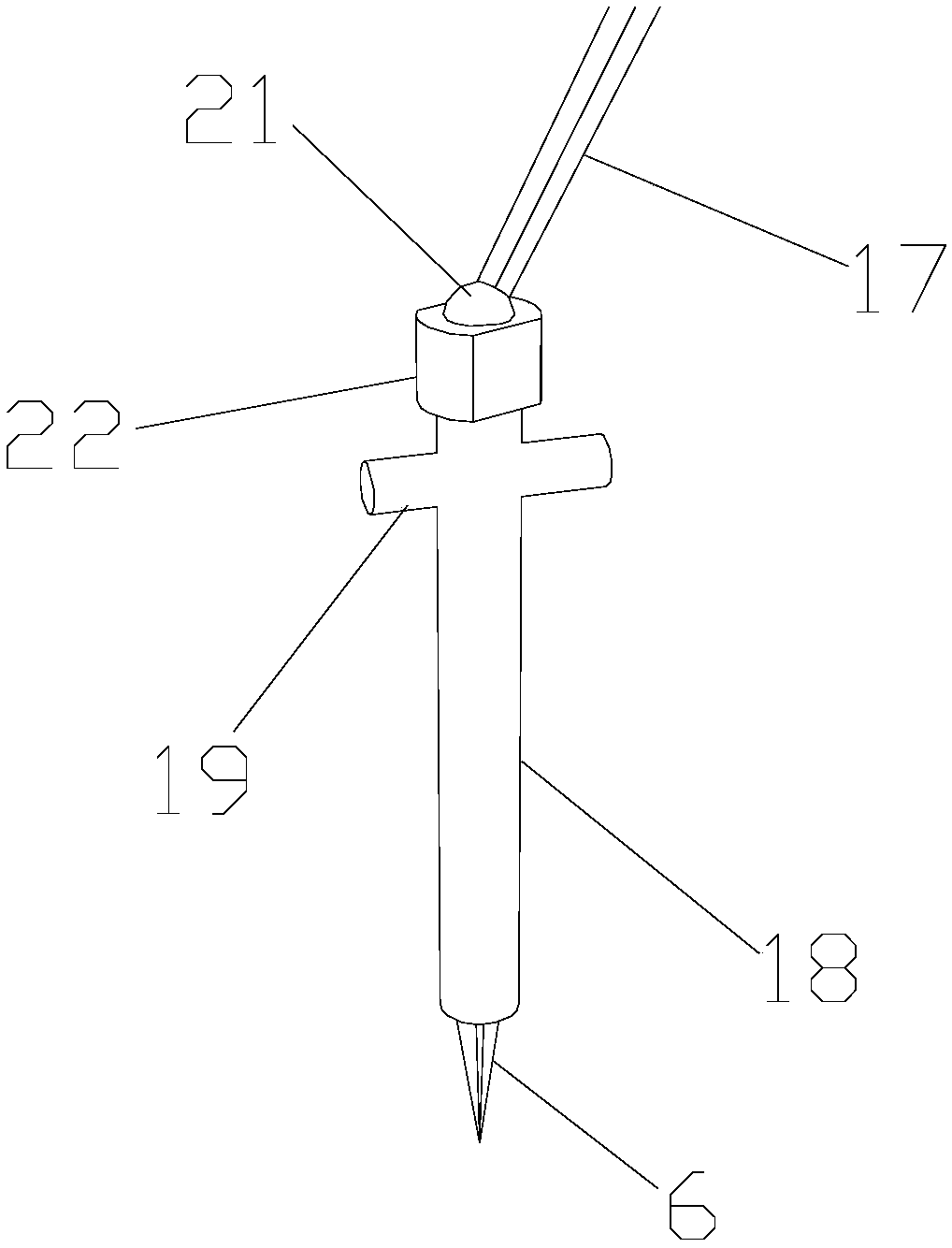

Corn threshing device

The invention belongs to the technical field of agricultural machines, and particularly discloses a corn threshing device. The corn threshing device comprises a workbench, a feeding shaft and a powermechanism capable of driving the feeding shaft to move and rotate, and a puncturing rod for puncturing corn is arranged at the end, away from the power mechanism, of the feeding shaft; two mutually-symmetrical V-shaped rods are hinged onto the workbench, clamping plates are fixedly connected to the ends, away from the puncturing rod, of the two V-shaped rods, sliding grooves are formed in the twoV-shaped rods, a pushing rod is slidingly connected between the two sliding grooves, is rotationally connected on the feeding shaft, is mutually perpendicular to the feeding shaft, and is an elastic stretchable rod; a material hopper is arranged on the workbench, sliding blocks are slidingly connected on the two sides of the material hopper, threshing structures for corn threshing are arranged onthe sides, close to each other, of the two sliding blocks, elastic pieces are arranged between the ends, away from the threshing structures, of the sliding blocks and the workbench, and a pulling lineis connected between the ends, away from the threshing structures, of the sliding blocks and the clamping plates. According to the corn threshing device in the technical scheme, automatic clamping and fixing of corn are achieved, and threshing efficiency is high.

Owner:重庆众点农业有限公司

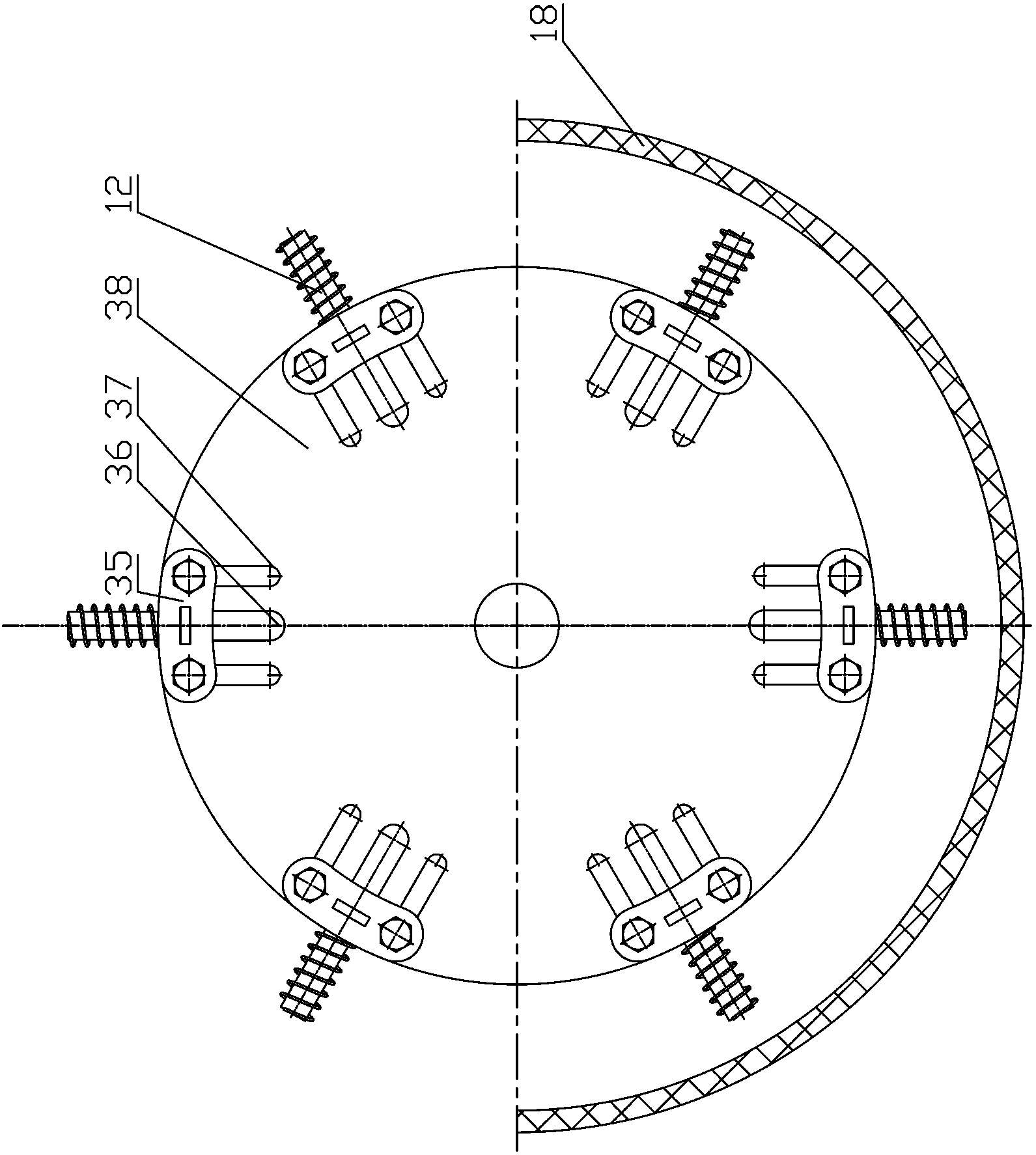

Corn kernel threshing and separating device

The invention provides a corn kernel threshing and separating device. The corn kernel threshing and separating device comprises a threshing roller provided with combined threshing components, and eachcombined threshing component comprises thread rod teeth and retractable ball spike teeth; matched threshing concave plates are arranged below the threshing roller and installed on a rack, and the threshing concave plates comprise the upper fixed punched concave plate and the lower movable punched concave plate matched with the upper fixed punched concave plate. Through the threshing components with the retractable ball spike teeth, the threshing effect is enhanced, and the kernel damage is reduced; besides, through the threshing concave plates with the mesh size adjustable, continuous stepless regulation of the concave plate mesh size is realized, the adaptability of a corn kernel direct harvesting machine is enhanced, the kernel damage rate is further reduced, the threshing performance and the screening performance are improved, and thus direct harvesting of corn kernels at different moisture contents is met; meanwhile, the effect of harvesting rice and wheat crops at the same time can be achieved, and the use performances of a combine harvester is improved.

Owner:JIANGSU UNIV

Horizontal corn threshing machine

InactiveCN107231896AThreshing achievedAvoid separabilityThreshersAgricultural engineeringThreshing machine

The invention discloses a horizontal corn threshing machine, which comprises a threshing shell; one end of the threshing shell is provided with a feed port, and the other end is provided with a core discharge port; The rotating shaft at the end protrudes from the threshing shell; the drum is equipped with a threshing motor to drive it to rotate; the drum is provided with conical teeth and spiral plate teeth; The air outlet is connected to the inside of the ash collection box through pipes, and the air inlet of the suction fan is connected to the inside of the ash collection cover through pipes; the threshing shell is provided with a grain outlet between the core discharge port and the ash outlet, and the support plate A through groove is opened at the grain opening, and the grain outlet and the through groove form a grain outlet channel; the threshing shell is provided with a corn grain filter at the grain outlet. The invention is favorable for popularization and application.

Owner:四川东工电机有限公司

Corn thresher as food machinery

Owner:NANTONG TAIYING NEW MATERIAL SCI & TECH CO LTD

Float Control Axial Flow Threshing Method for Chia Threshing

The invention discloses a floating control axial-flow type threshing method for threshing salvia hispanica. The floating control axial-flow type threshing method for threshing the salvia hispanica disclosed by the invention has the beneficial effects that a floating control axial-flow type threshing machine is adopted for implementing threshing operation, and the gravity is utilized to play a rolein natural guiding, so that the cost for power and labor is effectively reduced; simultaneously, a motor drives a transmission shaft to rotate, further a roller shell rotates, and threshing operationis realized by rotation of three crushing rods arranged on the roller shell, and the threshing force in the process of threshing operation is adjustable, so that the loss of the damage of threshed salvia hispanica seeds due to nonuniform threshing force is effectively reduced; when abnormal conditions or accidents occur in the threshing process, a power-control operating rod is operated, and thena power-control operating disc drives a transmission-control spline sleeve to descend rapidly to cut off power instantaneously so as to avoid further enlargement of the abnormal conditions or accidents.

Owner:HUNAN AGRICULTURAL UNIV

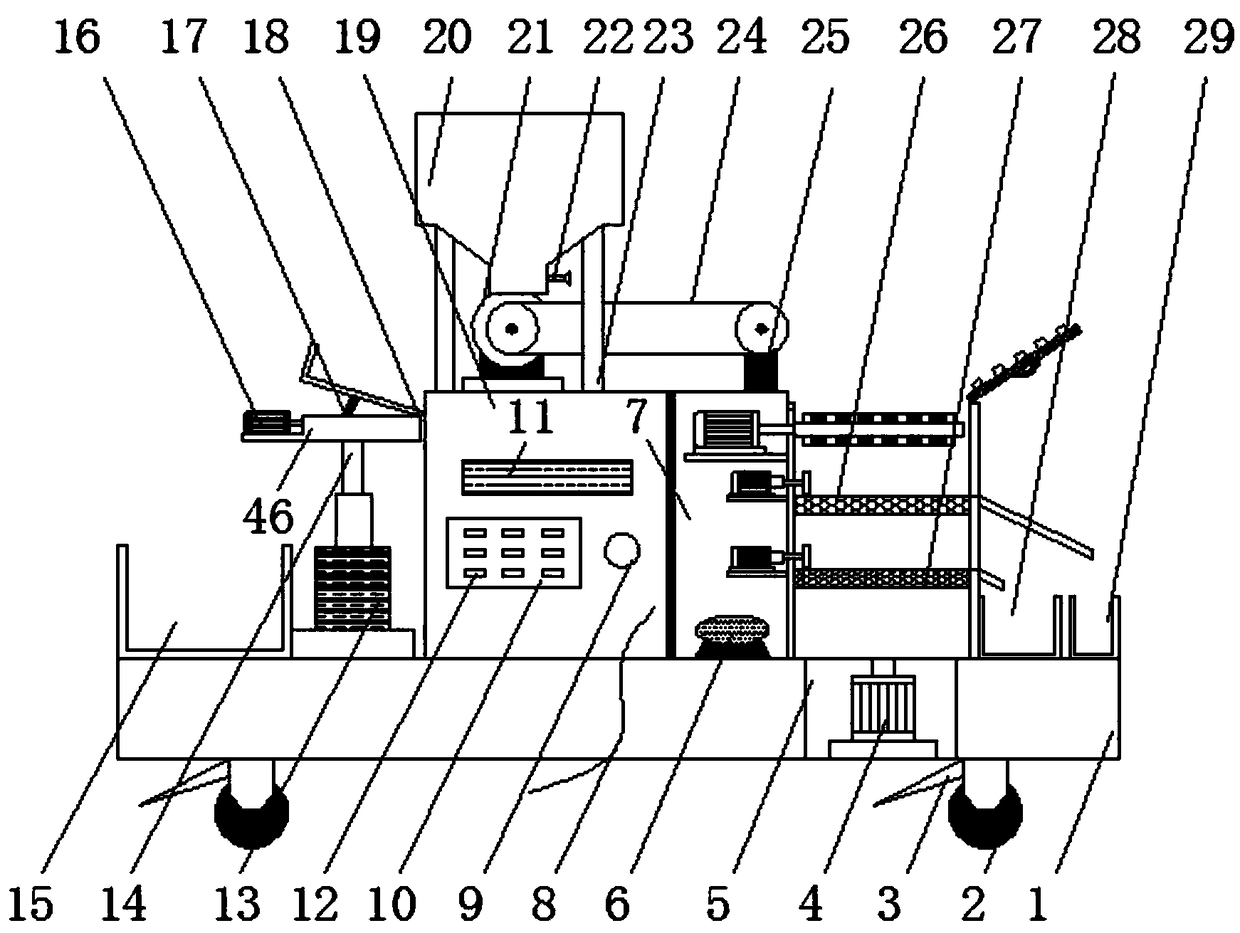

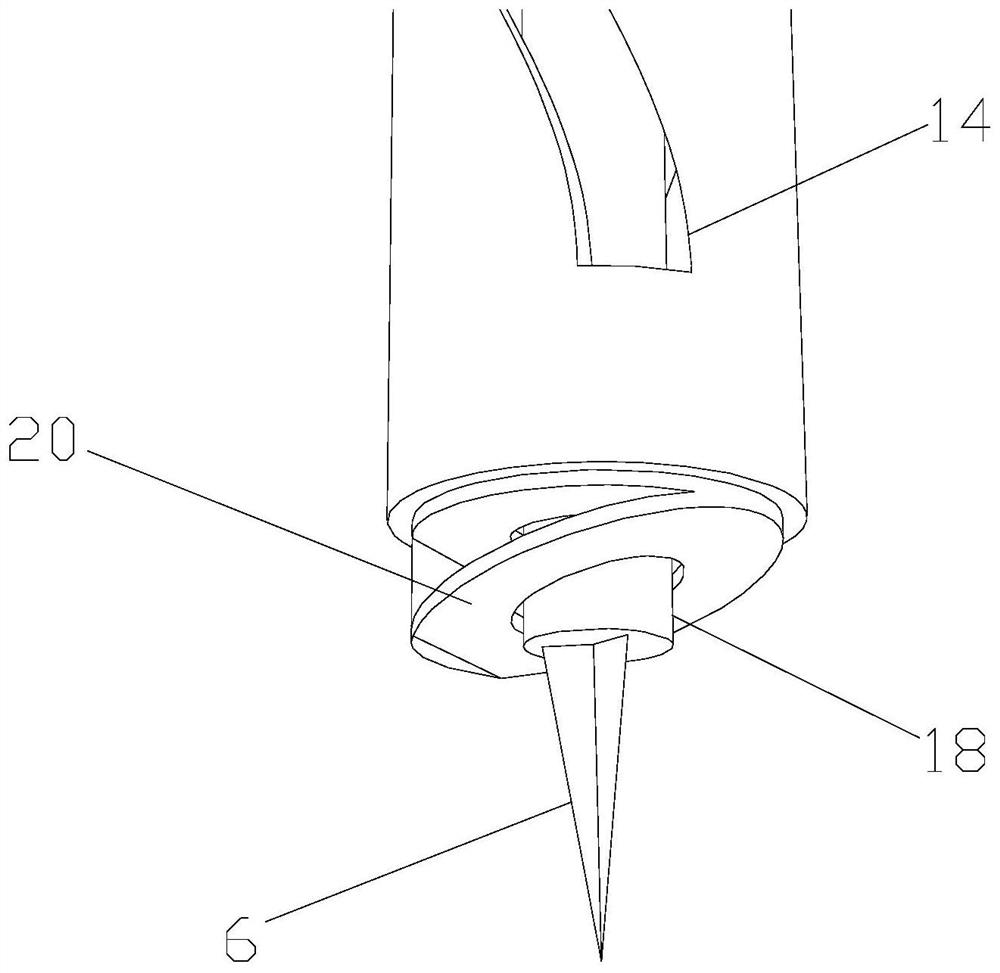

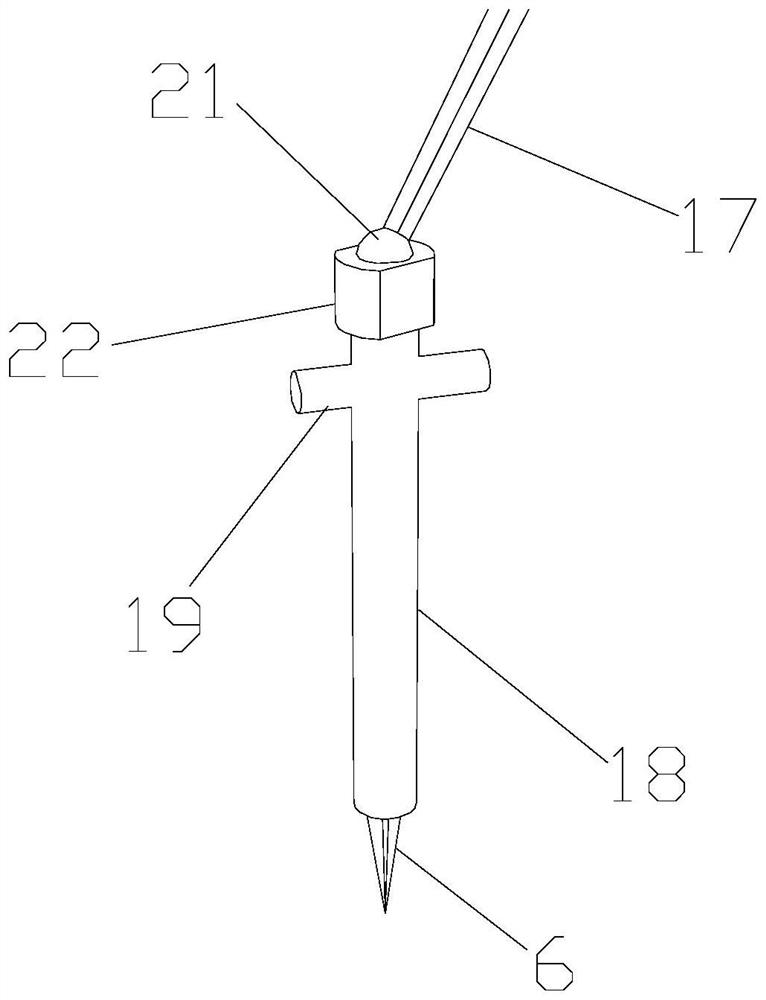

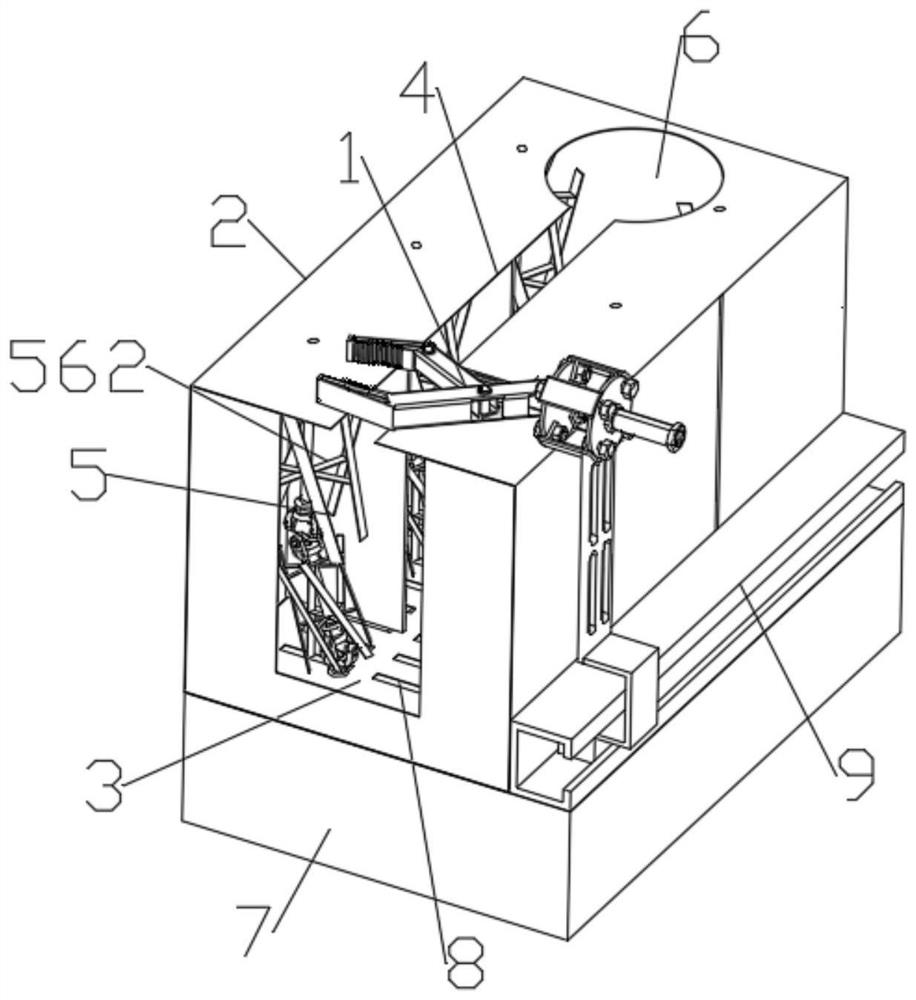

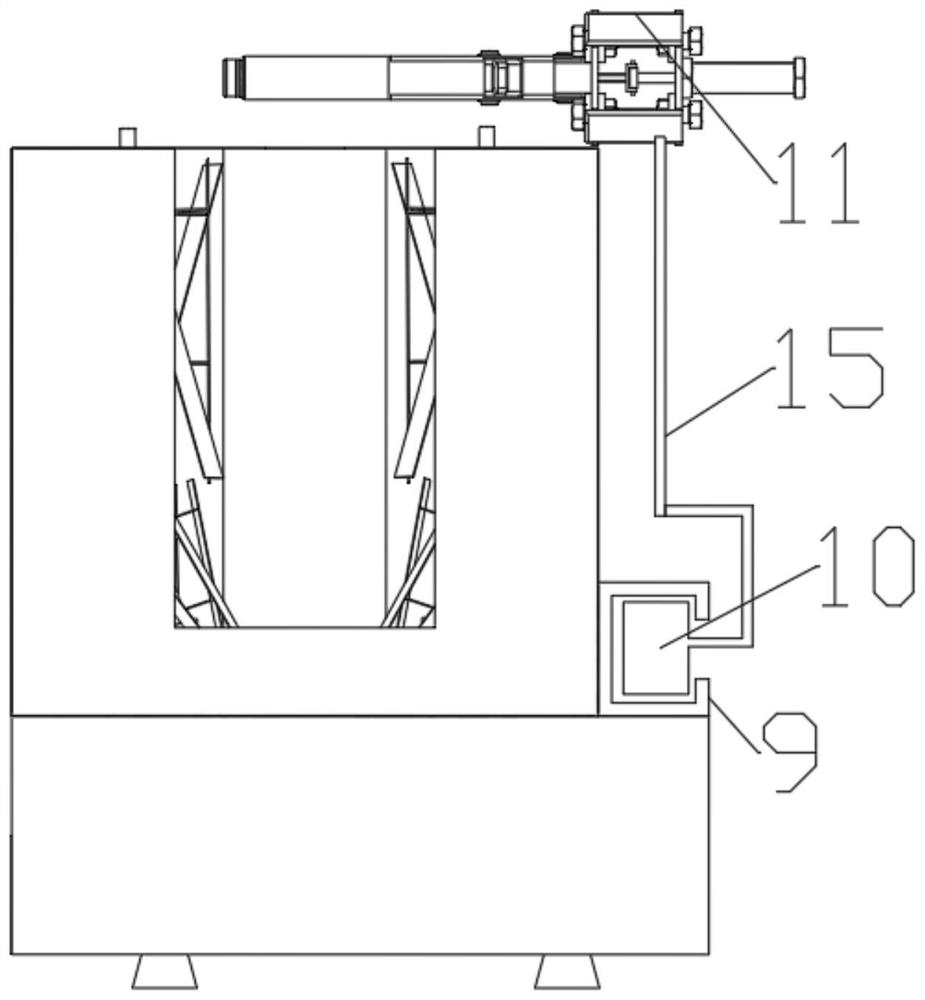

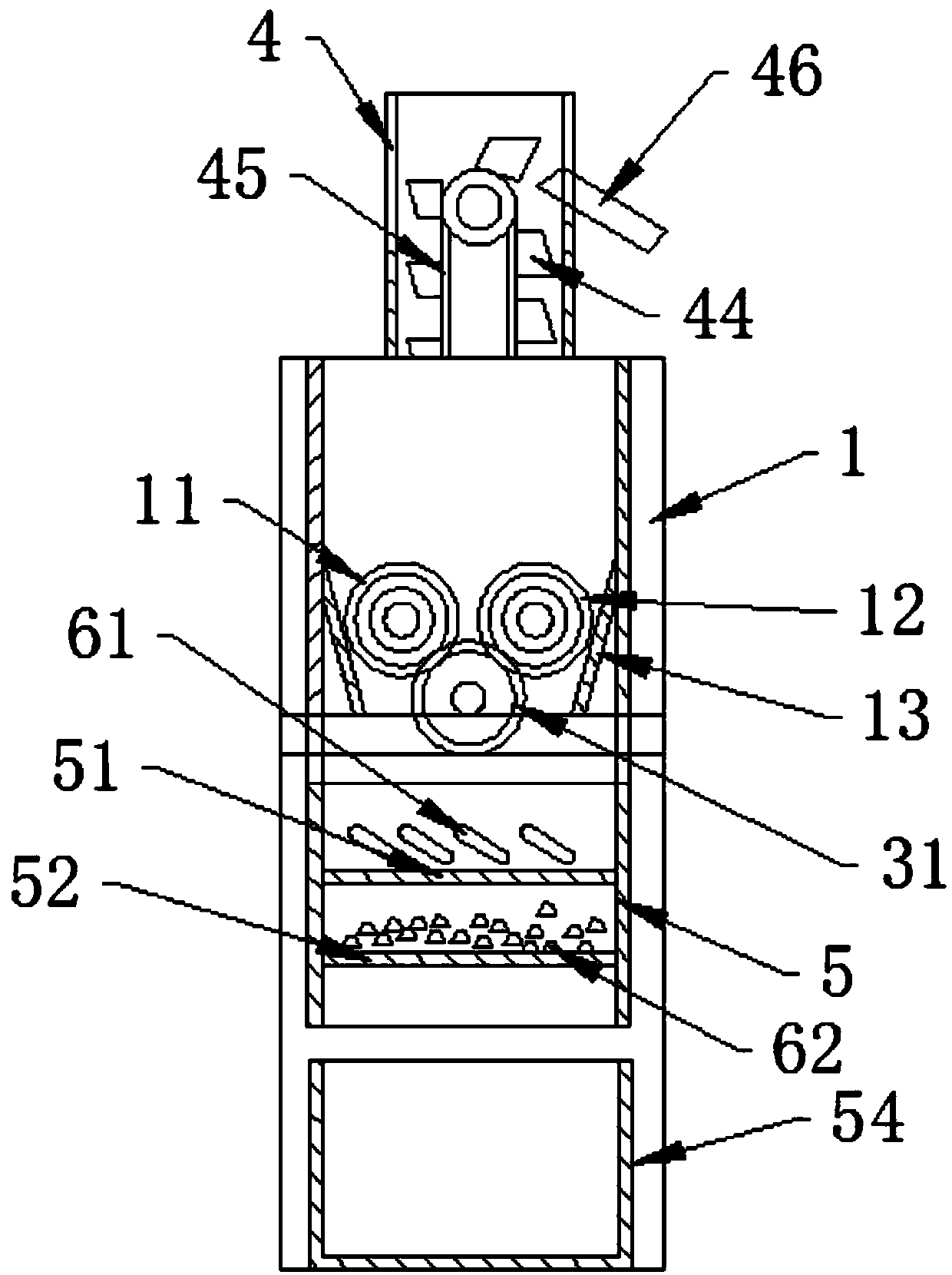

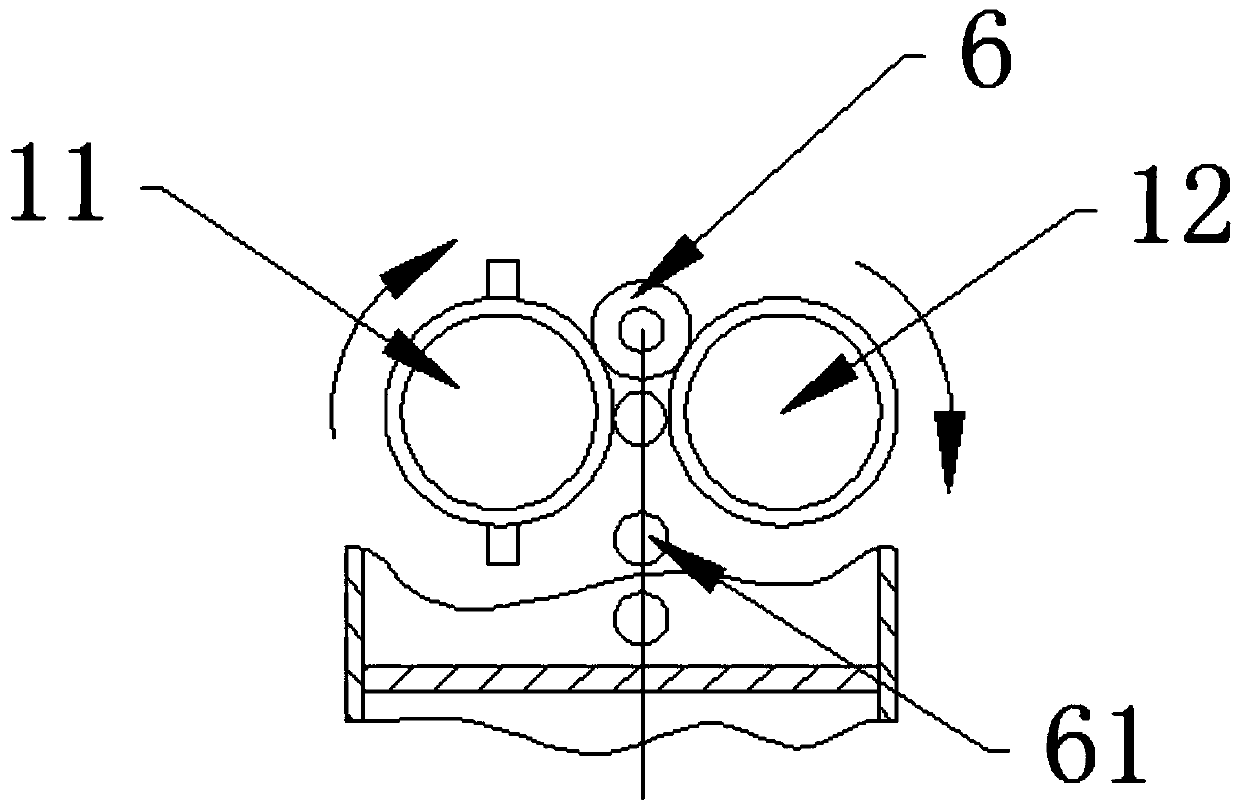

A differential speed intelligent non-destructive multi-roller thresher for a corn harvester in a plot

ActiveCN108966852BNon-destructive threshingThreshing achievedThreshersAgricultural engineeringIntelligent control

The invention discloses a differential-speed intelligent non-destructive multi-roller thresher for a corn harvester in a plot. The thresher is mainly composed of a frame (1), a feeding device (2), a primary threshing device (4), a secondary threshing device, a transmission device, a grain collection device and an intelligent control system. The feeding device (2), the primary The threshing device (4), the secondary threshing device and the grain collecting device are installed on the frame (1) sequentially from top to bottom, and the transmission device makes the primary threshing device (4) and the secondary threshing device rotate and work, intelligently controlled The system detects and records the moisture content of corn ears, and controls the rotating speed of the motor (3). The thresher of the present invention adopts two threshing processes, the intelligent control system detects the moisture content of corn ears, adjusts the rotation speed of the motor (3), and realizes non-destructive threshing of corn. The thresher has a reasonable structure and is easy to use.

Owner:HAINAN UNIV

A kind of corn thresher

Owner:XIAN UNIV OF TECH

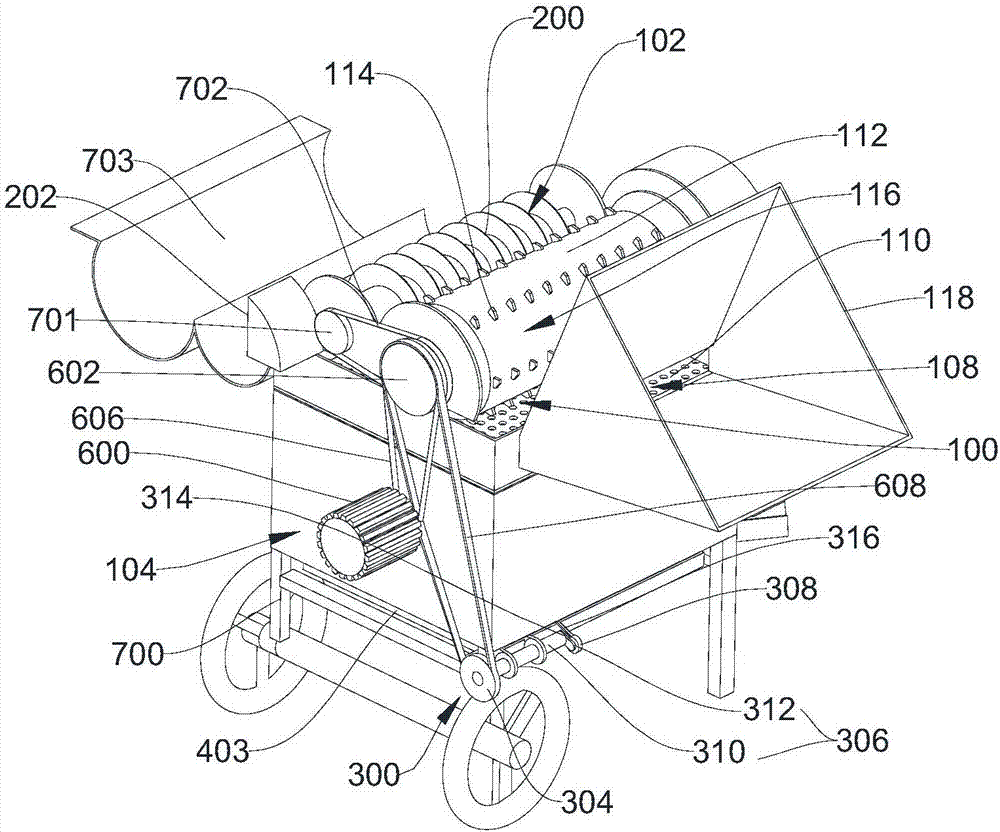

Double-flexible grinding and rubbing type millet threshing device

A double-flexible grinding and rubbing type millet threshing device comprises a machine frame, a rotary threshing assembly, a micro-motion threshing assembly and a driving assembly, the rotary threshing assembly, the micro-motion threshing assembly and the driving assembly are arranged on the machine frame, the rotary threshing assembly comprises a center shaft, a feeding section, a threshing section and a straw discharging section, and the feeding section, the threshing section and the straw discharging section are sequentially arranged in a butt joint manner in the length direction of the center shaft in a left-and-right manner; a threshing element of the threshing section is a rotatable flexible rubber roller, and the rotatable flexible rubber roller can also rotate around a rigid shaftof the rotatable flexible rubber roller; and the micro-motion threshing assembly is composed of a concave plate screen erected on the machine frame and a swing supporting device arranged below the concave plate screen, and the rotatable flexible rubber roller is matched with the concave plate screen in the micro-motion threshing assembly to form a double-flexible-coupling threshing gap. Accordingto the grinding and rubbing type millet threshing device under the double-flexible coupling effect, the crushing rate of millet in the threshing process can be greatly reduced, and the threshing rateand the threshing quality of the millet are improved.

Owner:HENAN UNIV OF SCI & TECH

Chopping, threshing and dust removal device for corns

The invention relates to a chopping, threshing and dust removal device for corns. The chopping, threshing and dust removal device comprises a base, wherein a threshing chamber and a smashing chamber are fixedly arranged above the base; the left end of the top of the threshing chamber is provided with a feeding hole; a rotation shaft is arranged in the threshing chamber; the outer side wall is provided with a bidirectional motor; the rotation shaft and the directional motor are connected; a screen cloth is arranged below the rotation shaft; an inclined vibration sieve plate is fixedly arrangedbelow the screen cloth; the bottom of the threshing chamber is provided with a particle collection box; the lower end of the vibration sieve plate is connected with the smashing chamber; the top of the smashing chamber is provided with a motor chamber; a first motor and a second motor are arranged in the motor chamber and are respectively connected with a first spiral chopping knife and a second spiral chopping knife; the bottom of the smashing chamber is fixedly provided with the sieve plate and a discharging pipeline; the bottom of the discharging pipeline is fixedly provided with a discharging hole; a waste slag collection box is arranged below the discharging hole. The chopping, threshing and dust removal device for corns has the advantages of simple structure and convenience in use, the damage rate of corn kernels is lowered, and threshing efficiency is improved.

Owner:成都金宏丰科技有限公司

Agriophyllum squarrosum threshing mechanism, threshing machine and threshing method

ActiveCN107211657AThreshing achievedAchieve separationSaving energy measuresThreshersThreshing machineAgriophyllum squarrosum

The invention discloses an agriophyllum squarrosum threshing mechanism, a threshing machine and a threshing method, and belongs to the field of threshing devices. The agriophyllum squarrosum threshing mechanism comprises a threshing chamber, a threshing component and a power device, a material receiving screen is arranged at the bottom of the threshing chamber, the threshing component comprises a threshing roller, a plurality of first cutting knives are arranged on the circumference surface of the threshing roller at intervals, and the threshing roller is rotatably arranged in the threshing chamber. The threshing machine comprises a frame, a selection and separation component and the agriophyllum squarrosum threshing mechanism, the selection and separation component comprises a vibration box with a vibrating screen, and the vibration box is obliquely arranged. Agriophyllum squarrosum does not have tassels similar to corps such as rice, seeds are wrapped by tassels with splinters in leaf axillae on plants, overall plate has splinters, the agriophyllum squarrosum cannot be harvested by the aid of a conventional threshing machine. According to the agriophyllum squarrosum threshing mechanism, the threshing machine and the threshing method, the agriophyllum squarrosum is threshed by cutting off the overall plants, shortcomings of an existing mode are overcome, and the threshing efficiency of the agriophyllum squarrosum is greatly improved.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

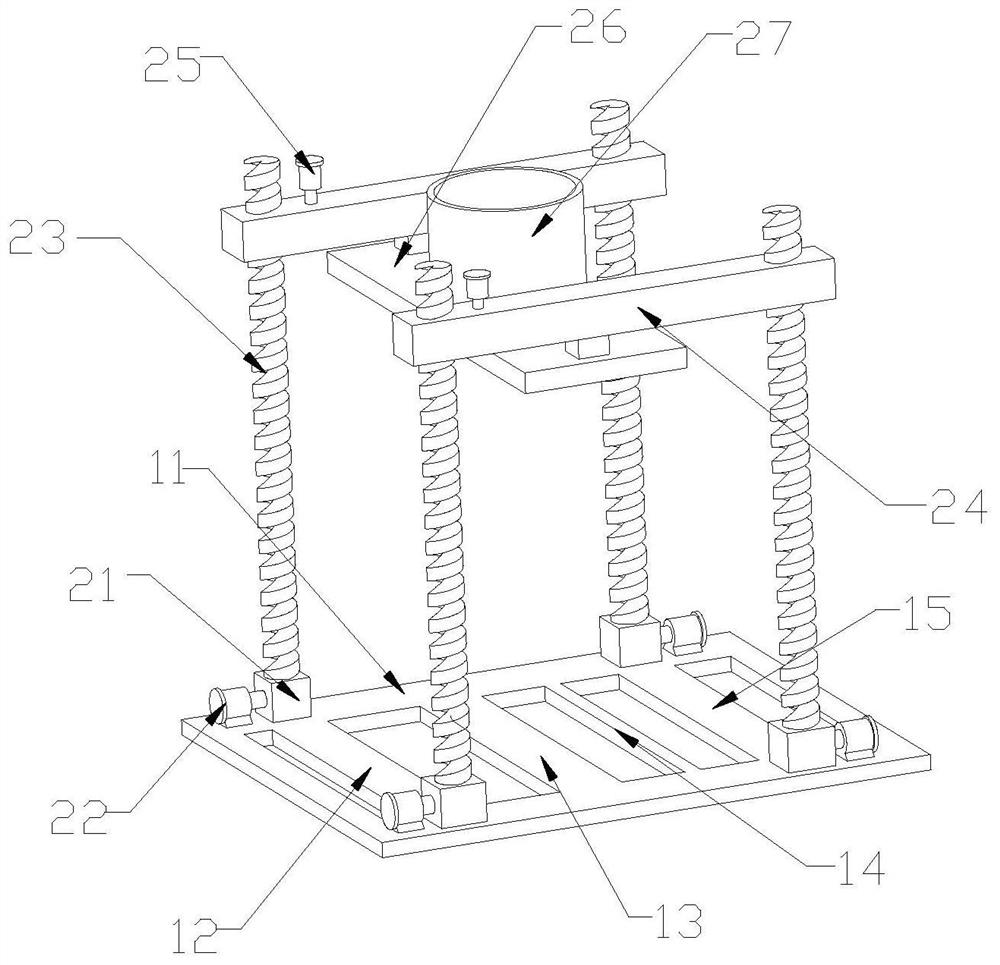

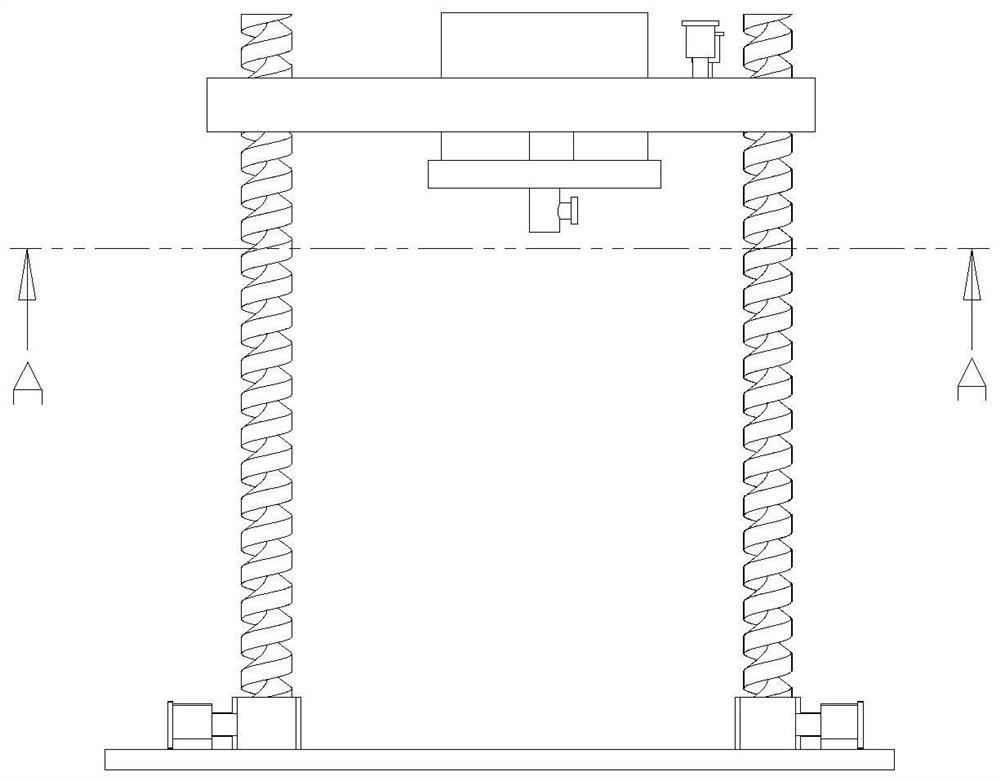

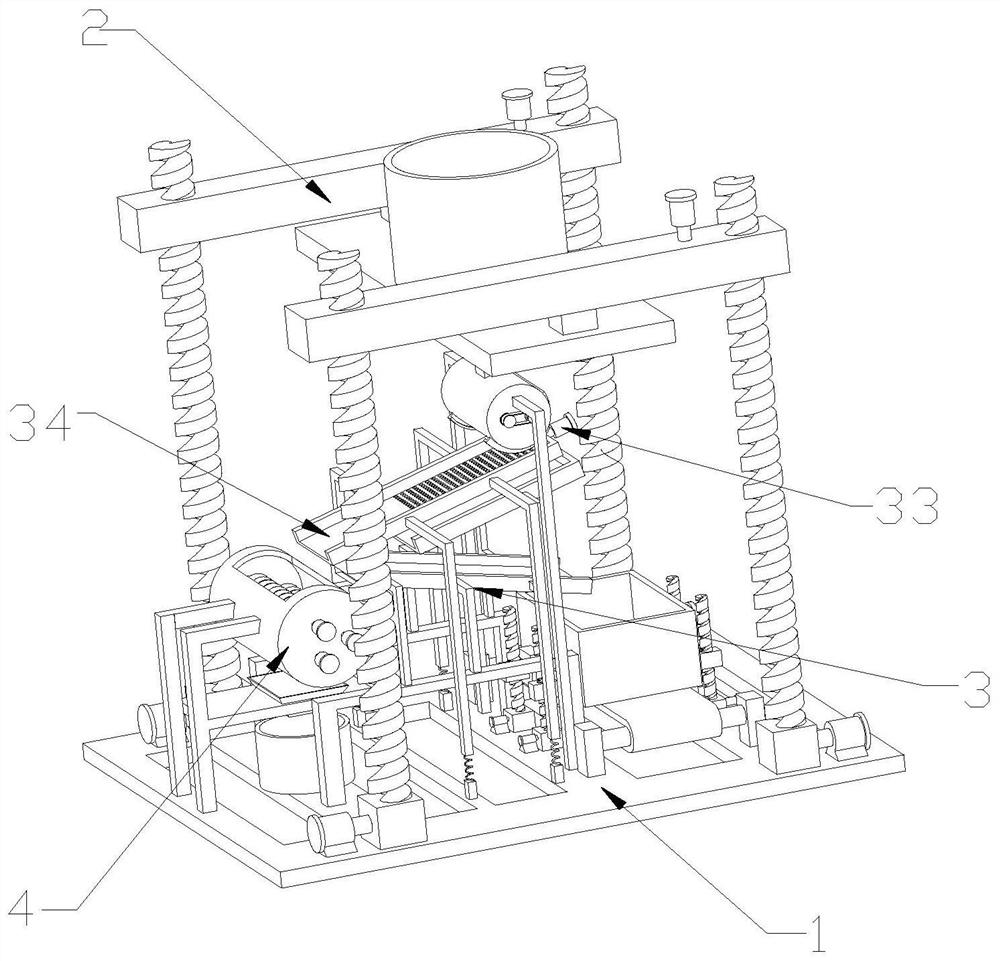

A kind of reciprocating twisting type corn threshing device

ActiveCN111615936BImprove threshing effectThreshing achievedThreshersAgricultural engineeringThreshing

The invention provides a reciprocating twisting type corn threshing device, belonging to the technical field of food processing, comprising a support base plate and a support top plate arranged above the support base plate, and the upper left and right sides of the support base plate are connected with the support plate through guide columns. The top plate is fixedly connected, and a lifting plate is slidably arranged on the guide column. The embodiment of the present invention has the advantages of good corn threshing effect and complete corn threshing shape. The first driving part drives the first threshing plate to move horizontally on the upper part of the lifting plate, and the second driving part drives the second threshing plate to move horizontally at the bottom of the supporting top plate. Reciprocating movement, using the relative movement between the first threshing plate and the second threshing plate to realize the threshing of corn; when the first threshing plate and the second threshing plate move horizontally to the maximum displacement, the third driving part drives the first threshing plate The plate and the second threshing plate rotate in reverse, so that the corn produces a twisting effect in the direction of rotation, thereby further improving the corn threshing effect.

Owner:新疆先锋伟业种子有限公司

A millet threshing device based on pneumatic vortex agitation

ActiveCN112106529BAvoid rigid breakageIntegrity guaranteedThreshersBulrush milletStructural engineering

A millet threshing device based on pneumatic vortex agitation, including a frame, a shell assembly, a threshing assembly and an air flow assembly, the shell assembly is horizontally erected on the frame, and the shell assembly includes an upper shell and a lower shell that are arranged up and down Body, the upper and lower shells are symmetrically surrounded to form a cavity-like structure for accommodating the threshing assembly, the threshing assembly is clamped inside the shell assembly, and its outer surface is in line with the shell assembly A certain gap is reserved between the upper shell, the lower shell and the large end cover. The threshing assembly is composed of a threshing section, a layering section, and a discharge section that are sequentially arranged on the left and right. The airflow assembly is arranged below the shell assembly. To deliver airflow to the gap between the housing assembly and the threshing assembly. The invention utilizes the airflow impact friction mode to carry out threshing, which can greatly reduce the breakage rate of the millet in the threshing process and improve the threshing quality of the millet.

Owner:HENAN UNIV OF SCI & TECH

A double-flexible millet threshing device

Owner:HENAN UNIV OF SCI & TECH

Rice threshing and straw crushing mechanism

ActiveCN111631023BRealize automatic feeding processEasy to reuseMowersThreshersElectric machineryProcess engineering

The invention discloses a rice threshing and straw crushing mechanism, which comprises a bottom plate, an automatic feeding module, an automatic threshing module and a straw crushing module. The automatic feeding module includes a first lead screw, a first motor, a cross bar, a second motor, a second lead screw and a rice storage tank; the automatic threshing module includes a thresher, a screening plate, a vibrating motor, a third lead screw, a third A motor and a lifting base; the straw crushing module includes a grinder, a fifth motor and a straw crushing collection tank. The invention is provided with an automatic feeding module, which can realize automatic feeding of rice without manpower. It is equipped with a straw crushing module, which can crush and collect the threshed rice straw for secondary use. Equipped with an automatic threshing module, it can screen the threshed rice while realizing the automatic threshing of rice, which solves the problem that traditional rice still needs manual screening after threshing. The invention solves the problems of manpower threshing rice and difficult collection of threshed straw in the prior art.

Owner:安徽省阜阳市海泉粮油工业股份有限公司

Agricultural threshing machine

ActiveCN111788940AThreshing achievedEasy to operateThreshersHand equipmentsAgricultural scienceAgricultural engineering

The invention discloses an agricultural threshing machine, and belongs to the technical field of agricultural threshing. The agricultural threshing machine comprises a clamping assembly, a shell and aplurality of scraper assemblies, wherein the clamping assembly is in contact with a corncob at an end of corn and is used for clamping the corn in a vertical state; a first opening for the corn to pass through is formed in the front side of the shell, a second opening for the corn to be guided is formed in the top of the shell in the length direction of the shell in an extending mode, and the first opening communicates with the second opening; and the scraper assemblies are located on two sides of the interior of the shell. According to the agricultural threshing machine, a first scraper is in transmission connection with a vertical rotating shaft and is used for threshing the cylindrical outer side of the corn, and a second scraper is in transmission connection with an inclined rotatingshaft and is used for threshing the conical outer side of the corn, so that the corn can be completely threshed, the threshing efficiency of the corn is improved, and resource waste is prevented.

Owner:WENZHOU UNIV OUJIANG COLLEGE

Rape rice wheat multi-purpose thresher

A multi-purpose threshing machine for oilseed rapes and grains comprises a frame (1), a power mechanism, a threshing cylinder (32), a hood (51) on the threshing cylinder (32), a feed hopper (13), a stalk discharge outlet, a separation sieve (30) below the threshing cylinder (32), a collection hopper (55) below the separation sieve (30), an auger (29) and a cyclone separator (17). The multi-purpose threshing machine is characterized in that one side of the hood (51) is hinged to the frame (1), and the other side of the hood (51) is buckled with the frame (1); a box iron (26) with a downward opening is welded to the frame (1) on the side of the hinged surface axially; another box iron (26) with a downward opening is welded to the frame (1) on the side of the buckling surface axially, one corner of an angle iron (44) is fixed onto the box iron (26), and a gap is reserved between the other corner of the angle iron (44) and the outer side of the box iron (26); one end of the separation sieve (30) is embedded in the opening of the box iron (26), and the other end of the separation sieve (30) is pressed in the gap.

Owner:JIANGSU RAINPAT DATA SERVICE

Corn thresher with screening and winnowing device

InactiveCN102630436BThreshing achievedAvoid adding transmission structuresThreshersAgricultural scienceAgricultural engineering

The invention relates to the field of farm machineries, and in particular relates to a corn thresher with a screening and winnowing device. The corn thresher comprises a feed hopper, a threshing device, a discharge opening and a motor, wherein a threshing rotary shaft is arranged in the threshing device, one end of the threshing rotary shaft is connected with the motor, a winnowing device is arranged at the lower part of the threshing device, the winnowing device comprises a winnowing box, a feeding opening and a blade, the blade is directly connected with one end of a motor shaft, and the other end of the motor shaft is connected with the threshing rotary shaft of the threshing device through a belt and a belt pulley; and a screening device is arranged at the other end of the threshing device and comprises a screening box, a screen and a vibration rotary shaft connected with the screen, and the other end of the threshing rotary shaft is directly and eccentrically connected with the other end of the vibration rotary shaft. The corn thresher disclosed by the invention has the advantages that one motor simultaneously and synchronously drives the threshing rotary shaft to rotate, the screen to vibrate and the blade of the winnowing device to rotate, and the threshing device also threshes corns; and the screen vibrates to screen niblets and corncobs.

Owner:李禄海

Full-automatic corn thresher

The invention provides a full-automatic corn thresher, and belongs to the field of corn threshing devices. The full-automatic corn thresher comprises a machine case, a first rotary drum and a second rotary drum which are arranged in a matching manner, wherein the first rotary drum and the second rotary drum are arranged in the machine case and are connected with each other in opposite in a rotarymanner; the axes of the first rotary drum and the second rotary drum are arranged in parallel with the longitudinal center line of the machine case; the outer ring of the first rotary drum is arrangedadjacent to the inner wall of the machine case; the outer ring of the second rotary drum is arranged adjacent to the inner wall of the machine case; a certain gap is arranged between the first rotarydrum and the second rotary drum; and a plurality of first threshing teeth protruding outwards are uniformly distributed on the outer ring of the first rotary drum. The full-automatic corn thresher can realize automatic threshing of corn and automatic screening of corncobs and corn kernels, is high in automation degree, low in strength and high in efficiency.

Owner:WUWEI JINWEI ENVIRONMENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com