Rapeseed and wheat threshing straw returning machine

A wheat and straw technology, applied in threshing equipment, agricultural machinery and tools, cutting equipment, etc., can solve the problems of inability to thresh crops such as rice and wheat and harmless treatment of straw, large power consumption, and bulky machine body, etc., and achieve compact structure , eliminate motion noise, and achieve the effect of flexible swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

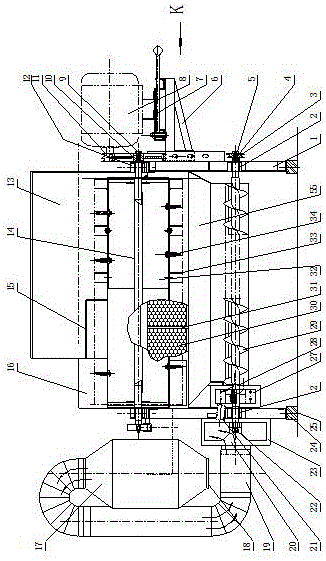

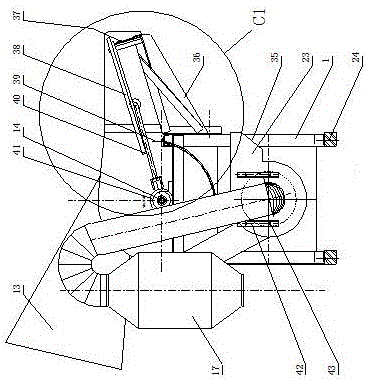

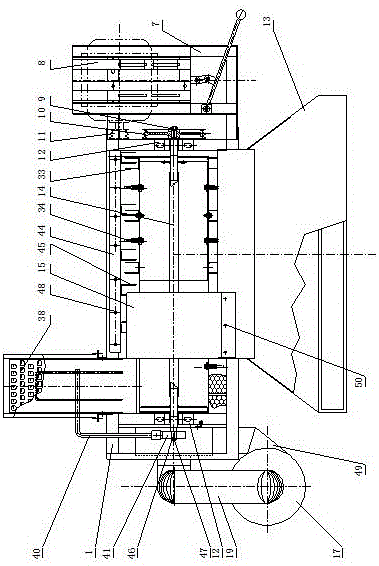

[0041]The present invention will be further described below in conjunction with the accompanying drawings.

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , a rapeseed wheat threshing straw returning machine, comprising:

[0043] Frame 1, the power mechanism located on the right side of frame 1, the drum shaft 14 mounted on the frame 1 horizontally, the right end of the drum shaft 14 is connected to the power mechanism, and the drum shaft 14 is fixed with a threshing drum 32 with threshing teeth 34 ;

[0044] The hood 51 located above the threshing drum 32 and connected to the frame 1, the separating screen 30 located below the threshing drum 32 and mounted on the frame 1, the collecting hopper 55 located below the separating screen 30 and fixed on the frame 1 ;

[0045] An auger 29 is installed at the bottom of the collecting hopper 55, and the auger 29 is fixed on the auger shaft 28, and the right end of the auger shaft 28 is dy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com