Chopping, threshing and dust removal device for corns

A dust removal device and corn technology, applied in the field of agricultural machinery, can solve the problems of corn kernel husking, low threshing efficiency, corn kernel damage, etc., and achieve the effects of simple device structure, improved threshing efficiency, and reduced damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

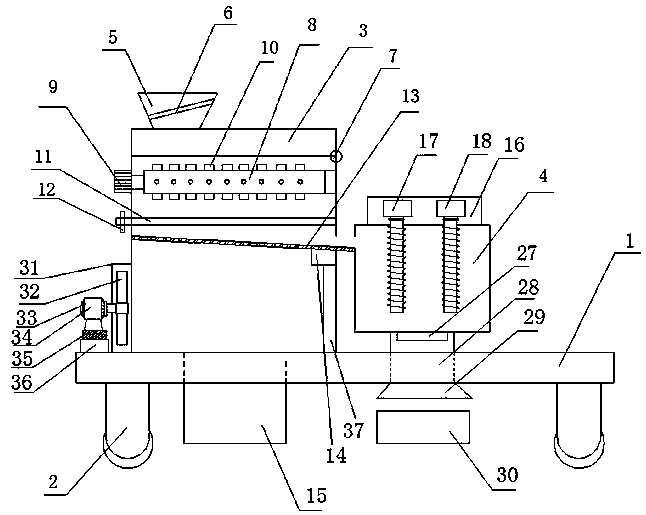

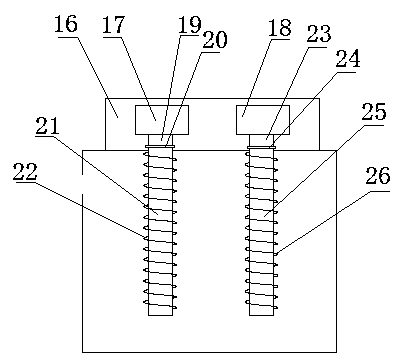

[0016] Such as Figure 1-2 As shown, a corn chopping, threshing and dust removal device includes a base 1, a universal wheel 2 is arranged below the base 1, a threshing chamber 3 and a crushing chamber 4 are fixedly arranged above the base 1; the left end of the top of the threshing chamber 3 A feed inlet 5 is provided, and a baffle 6 is inlaid inside the feed inlet 5; a threshing chamber button switch 7 is installed on the outer wall of the threshing chamber 1, and a rotating shaft 8 is arranged inside the threshing chamber 3, and a There is a bidirectional motor 9, and the rotating shaft 8 is connected with the bidirectional motor 9; a screen 11 is arranged below the rotating shaft 8, and the screen 11 is connected with the screen handrail 12, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com