A kind of reciprocating twisting type corn threshing device

A technology of corn threshing and threshing board, applied in threshing equipment, agriculture, application, etc., can solve the problems of poor threshing effect, corn damage, and inability to ensure the complete shape of corn, and achieve the effect of improving the threshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

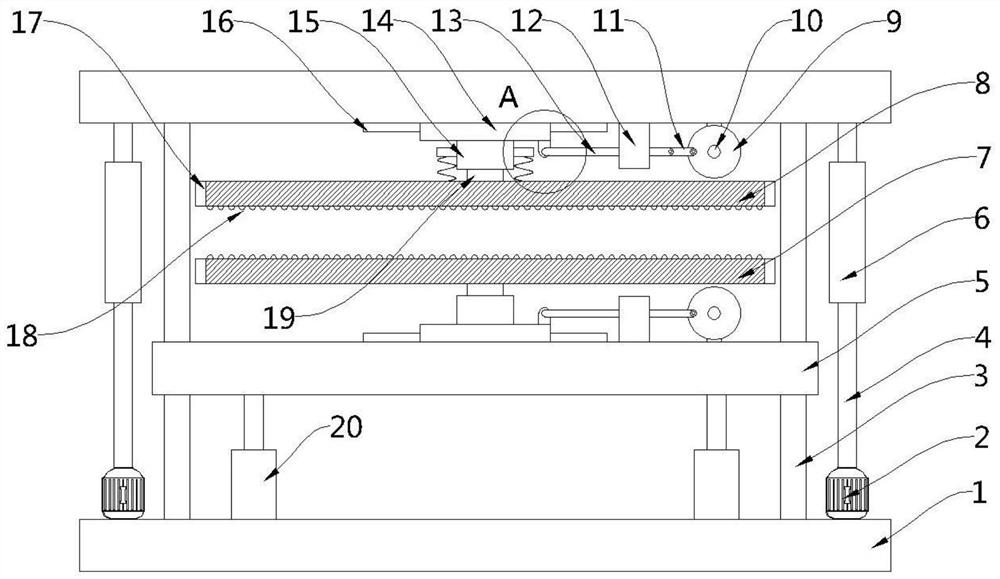

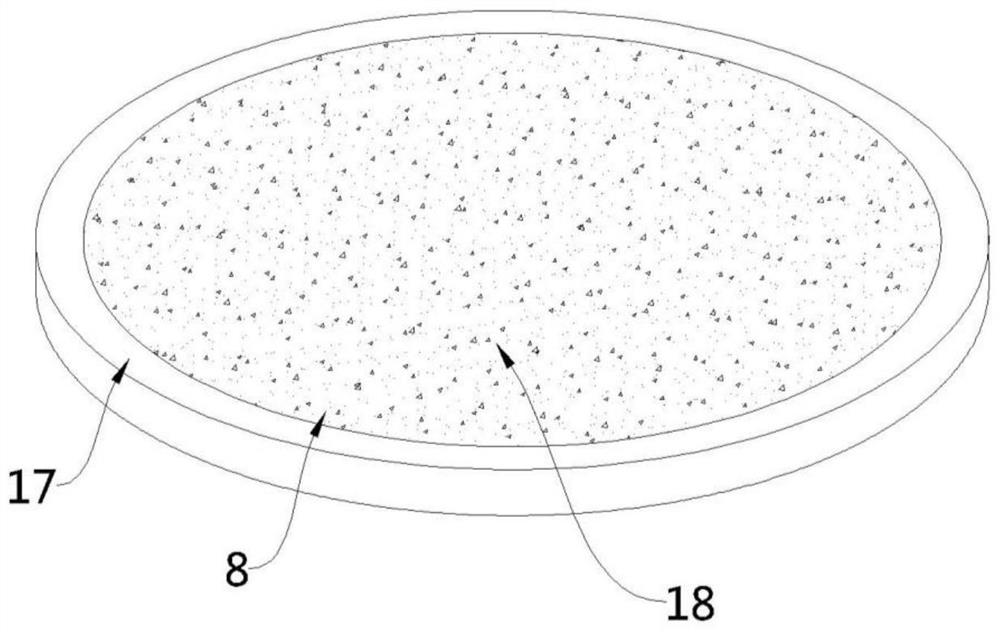

[0026] see Figure 1-3 , the present embodiment provides a reciprocating twisting corn threshing device, comprising a support base plate 1 and a support top plate arranged above the support base plate 1, the upper left and right sides of the support base plate 1 are connected to the support base plate 1 through guide columns 3 The top plate is fixedly connected, the guide column 3 is slidably provided with a lifting plate 5, the bottom of the lifting plate 5 is connected with the support base plate 1 through the lifting assembly 20, and the upper part of the lifting plate 5 is connected with the first threshing plate through the first connecting part 7. The upper part of the lifting plate 5 is also provided with a first driving part for driving the first threshing plate 7 to move horizontally back and forth, and the bottom of the supporting top plate is connected with the second threshing plate 8 through the second connecting part, and the bottom of the supporting top plate A ...

Embodiment 2

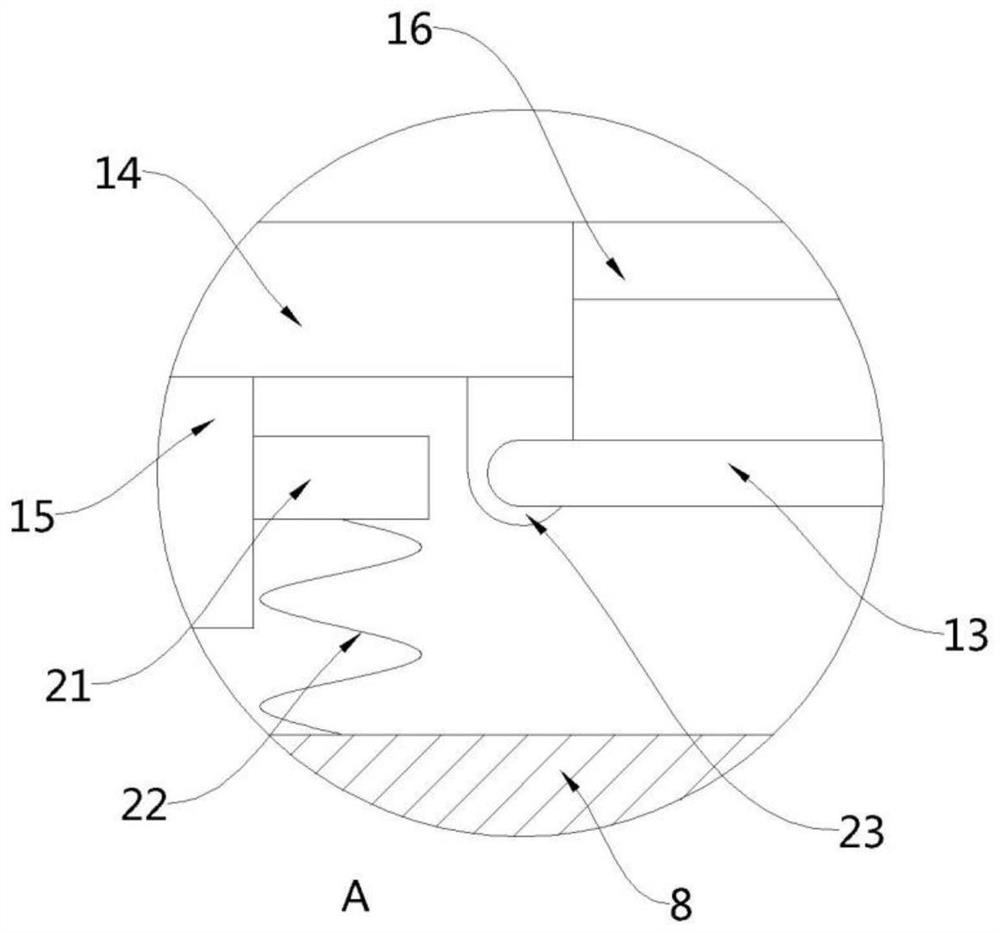

[0043] see figure 1 and image 3 , a reciprocating twisting type corn threshing device. Compared with Embodiment 1, the side wall of the supporting cylinder 15 corresponding to the second driving part of this embodiment is provided with a fixed plate 21, and the fixed plate 21 is connected to the second The threshing plates 8 are connected by elastic members 22 .

[0044] When the first threshing plate 7 and the second threshing plate 8 twisted and threshed the corn, the elastic support was provided for the second threshing plate 8 by the elastic member 22, thereby improving the distance between the second threshing plate 8 and the first threshing plate 7 The support effect of corn, so as to further improve the detachment effect of corn.

[0045] Specifically, the elastic member 22 is a spring.

[0046] The embodiment of the present invention has the advantage of good corn threshing effect. The first driving part drives the first threshing plate 7 to move horizontally on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com