Agriophyllum squarrosum threshing mechanism, threshing machine and threshing method

A technology of threshing mechanism and thresher, which is applied in threshing equipment, agricultural machinery and implements, agriculture, etc., can solve the problems of low harvesting and threshing efficiency, large manual workload, etc., so as to improve artificial threshing efficiency, low operating resistance, and broken grains. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

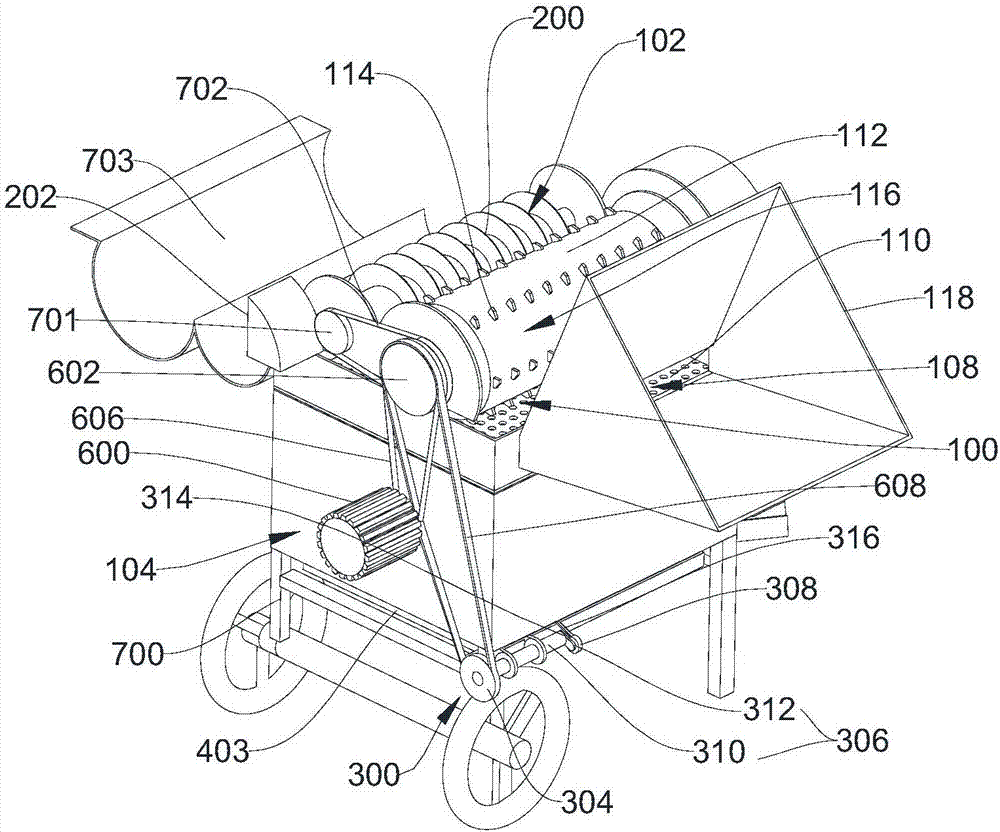

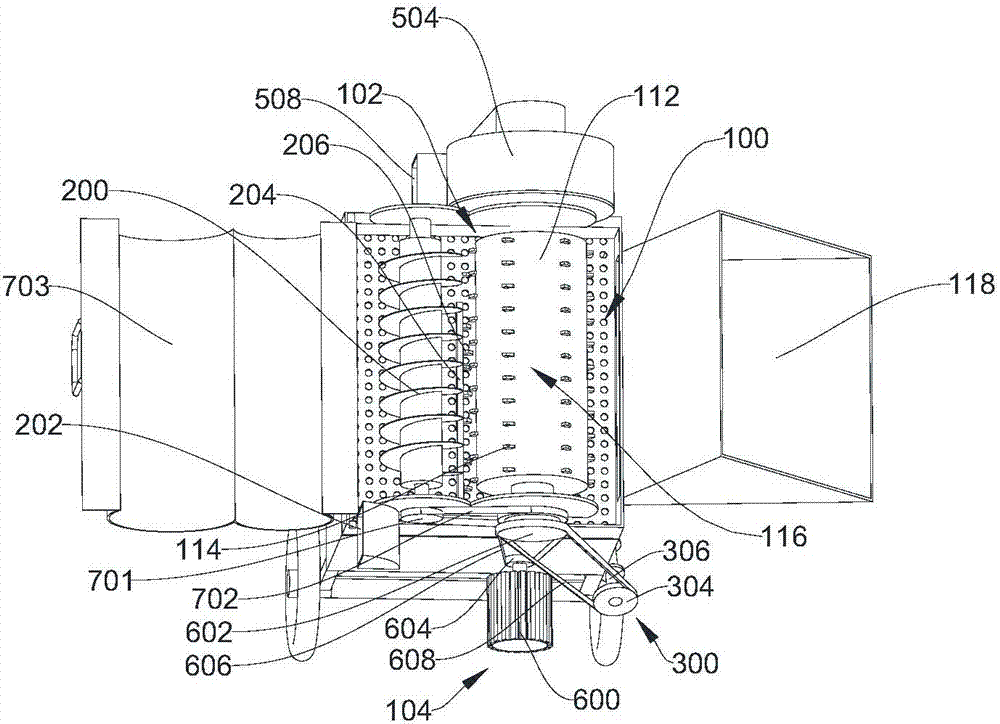

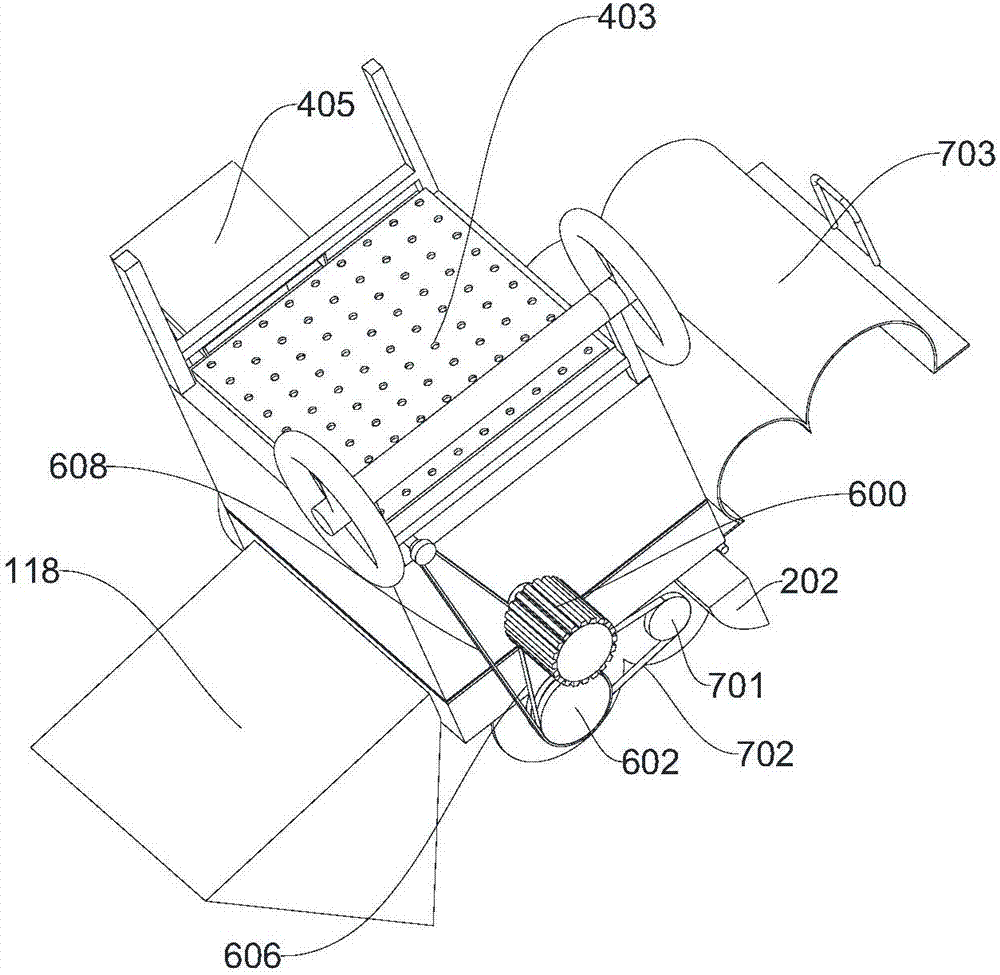

[0038] Embodiment 1, with reference to Figure 1 to Figure 6 .

[0039] The sand rice thresher provided by the present embodiment, such as figure 1 As shown, it includes a frame 700 , a cleaning and separating assembly and a sand rice threshing mechanism, and the sand rice threshing mechanism and the cleaning and separation assembly are arranged on the frame 700 . The sand rice threshing mechanism provided by the invention, such as figure 1 Shown, comprise threshing chamber 100, threshing assembly 102 and power unit 104; A plurality of first cutters 114 are arranged at intervals on the circumferential surface, and the threshing cylinder 112 is rotatably installed in the threshing chamber 100 , and the power device 104 drives the threshing cylinder 112 to rotate.

[0040] Sand rice does not have ears similar to crops, therefore, general threshers cannot achieve the threshing of sand rice. In this application, the whole plant of sand rice is sent into the threshing chamber 100...

Embodiment 2

[0060] The present embodiment provides a method for threshing sand rice, including the following steps: rolling and chopping step: crushing and chopping the whole plant sand rice; screening step: screening out the fallen sand rice seeds; bract cleaning step: using upward The bracts and sand rice particles are separated by sucking away the bracts.

[0061] It should be noted that the sequence of the above steps does not represent the sequence of threshing. The three steps can be carried out at the same time, or can be carried out in a manner such as the crushing step, the screening step, and the bract cleaning step.

[0062] The method of crushing and chopping the whole plant of sand rice overcomes the problem that sand rice has no ears similar to rice and other crops, the seeds are wrapped in each leaf axil of the plant, and the whole plant has thorns, which cannot be harvested by conventional threshers. The bract cleaning step of sucking up the bracts is because the bracts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com