Harvesting device

A technology for harvesting devices and headers, applied in the direction of harvesters, cutters, threshing equipment, etc., can solve the problems of increasing labor intensity and increasing production costs, so as to reduce labor intensity, reduce production costs, and improve versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

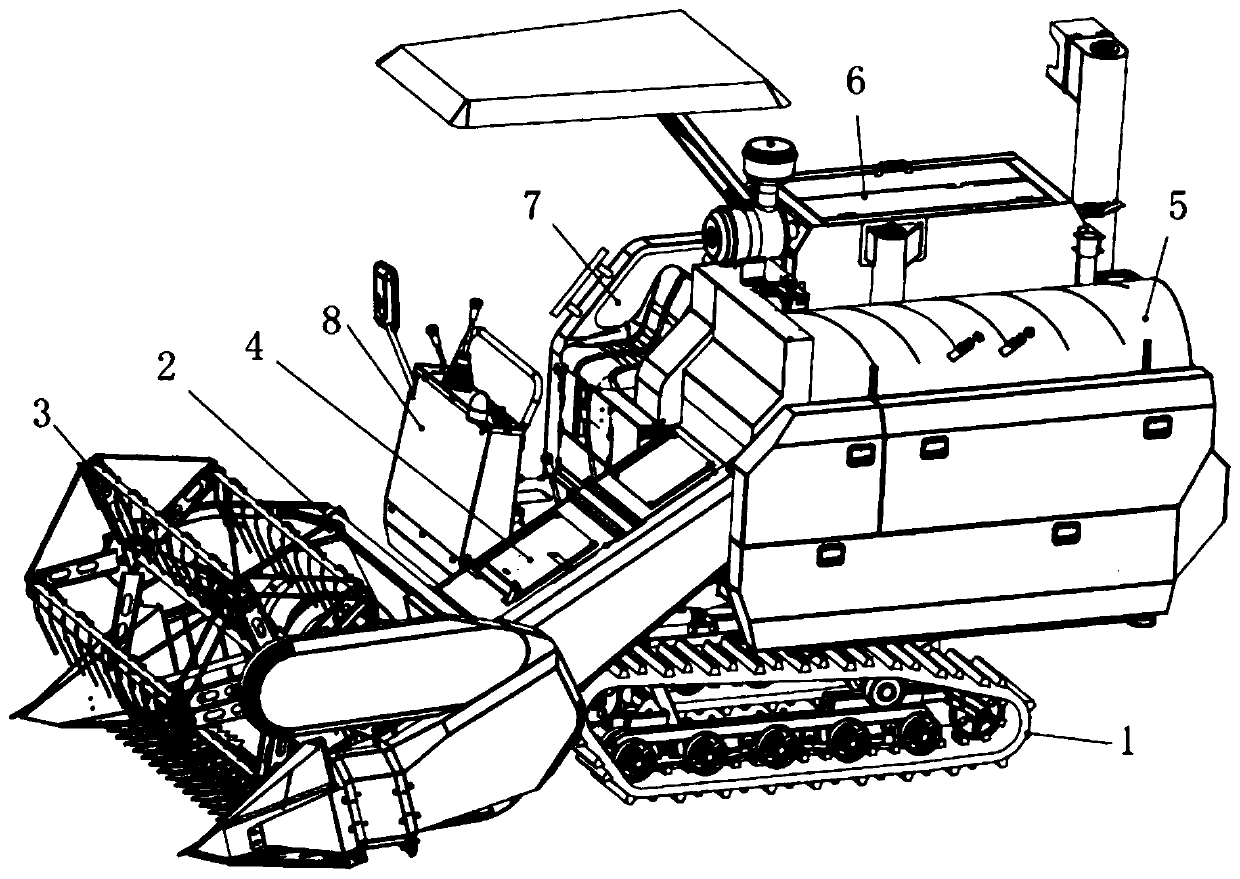

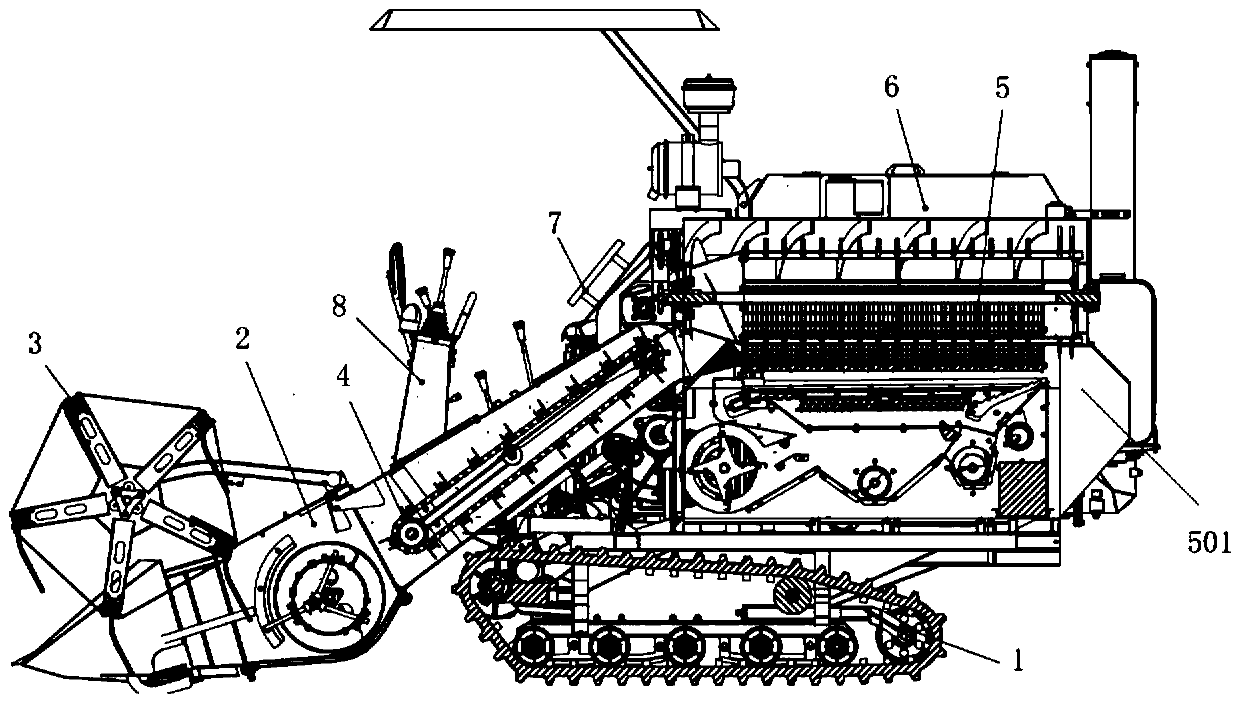

[0026] see figure 1 and figure 2 , Figure 1 to Figure 2 A specific embodiment of a harvesting device of the present invention is provided, wherein, figure 1 It is a schematic diagram of the overall structure of the harvesting device disclosed in Embodiment 1 of the present invention; figure 2 It is a partial sectional view of the harvesting device disclosed in Embodiment 1 of the present invention.

[0027] Such as figure 1 and figure 2 As shown, the harvesting device provided by the present invention can realize corn harvesting and threshing at the same time, can greatly improve the versatility of the equipment, and significantly reduce the labor intensity of farmers. The harvesting device provided by the present invention includes a chassis 1 , a header 2 , a reel 3 , a conveying trough 4 , a threshing and cleaning mechanism 5 , a granary 6 , a power room 7 , and a cab 8 .

[0028] In this solution, the harvesting device includes a chassis 1, which is used to provi...

Embodiment 2

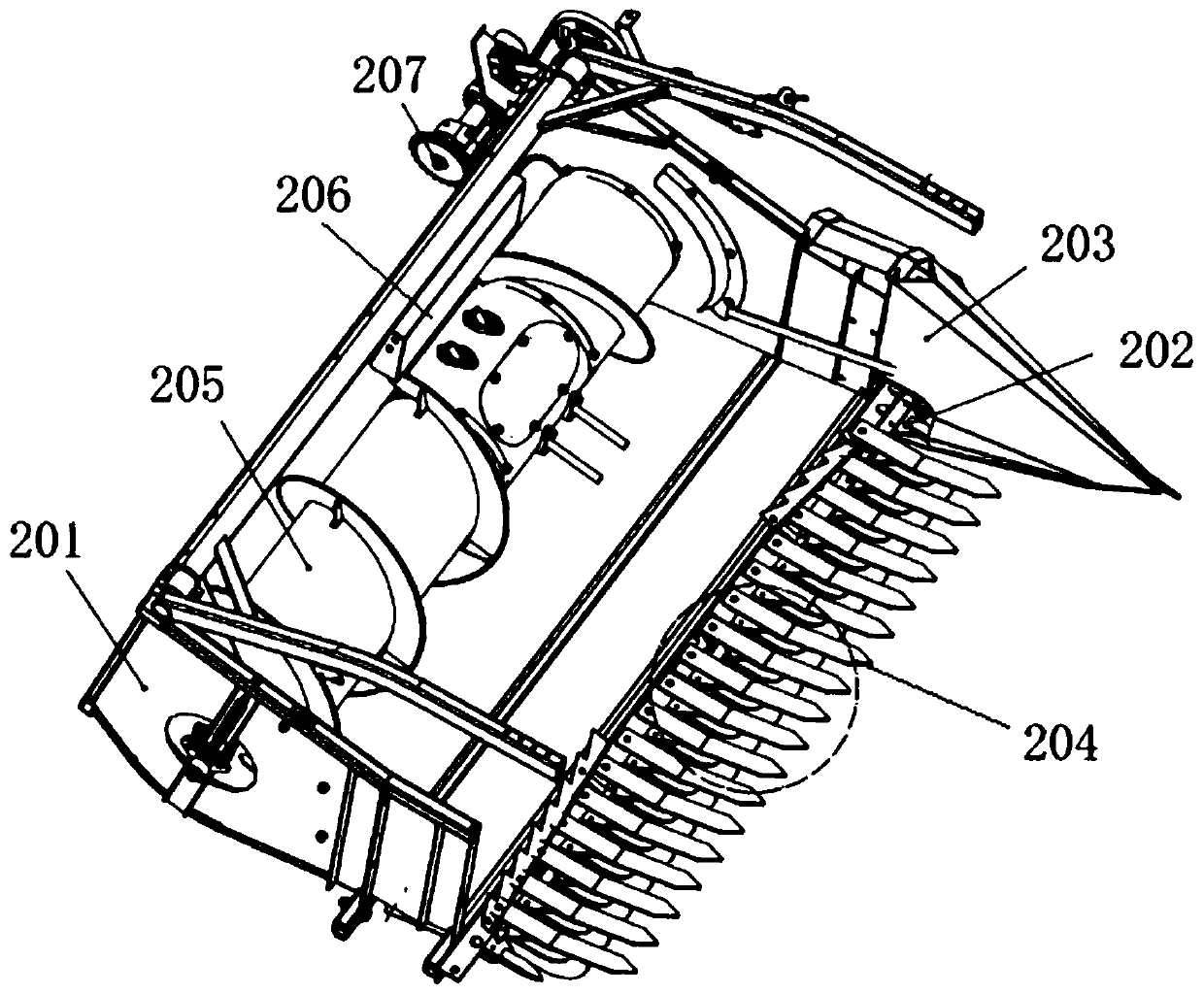

[0036] see image 3 and Figure 4 , image 3 and Figure 4 A specific embodiment of the header of the present invention is provided, wherein, image 3 It is a schematic diagram of the overall structure of the header disclosed in Embodiment 2 of the present invention; Figure 4 It is an enlarged schematic diagram of the receiving rack disclosed in Embodiment 2 of the present invention.

[0037]In this embodiment, in order to further facilitate the shearing of crop stems, preferably, the header 2 includes a platform 201, a cutting knife 202 is arranged in front of the platform 201, and dividers are arranged on both sides of the cutting knife 202. Grain plate 203, above the cutter 202 is provided with a material receiving frame 204, the inner cavity of the platform 201 is provided with a conveying auger 205, the side plate of the platform 201 is provided with a material guide port 206 and the material guide The port 206 is located in the conveying direction of the conveying ...

Embodiment 3

[0041] see Figure 5 and Figure 6 , Figure 5 and Figure 6 A specific embodiment of a threshing and cleaning mechanism of the present invention is provided, wherein, Figure 5 It is a schematic structural view of the threshing and cleaning mechanism disclosed in Embodiment 3 of the present invention; Figure 6 It is a structural schematic diagram of the vibrating screen disclosed in Embodiment 3 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com