Differential intelligent non-destructive multi-roll thresher for plot corn harvester

A corn harvester, differential-speed technology, applied in the field of differential-speed intelligent non-destructive multi-roller threshing machines for corn harvesters in residential areas, can solve the problems of unreasonable structure, difficult to grasp and low threshing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

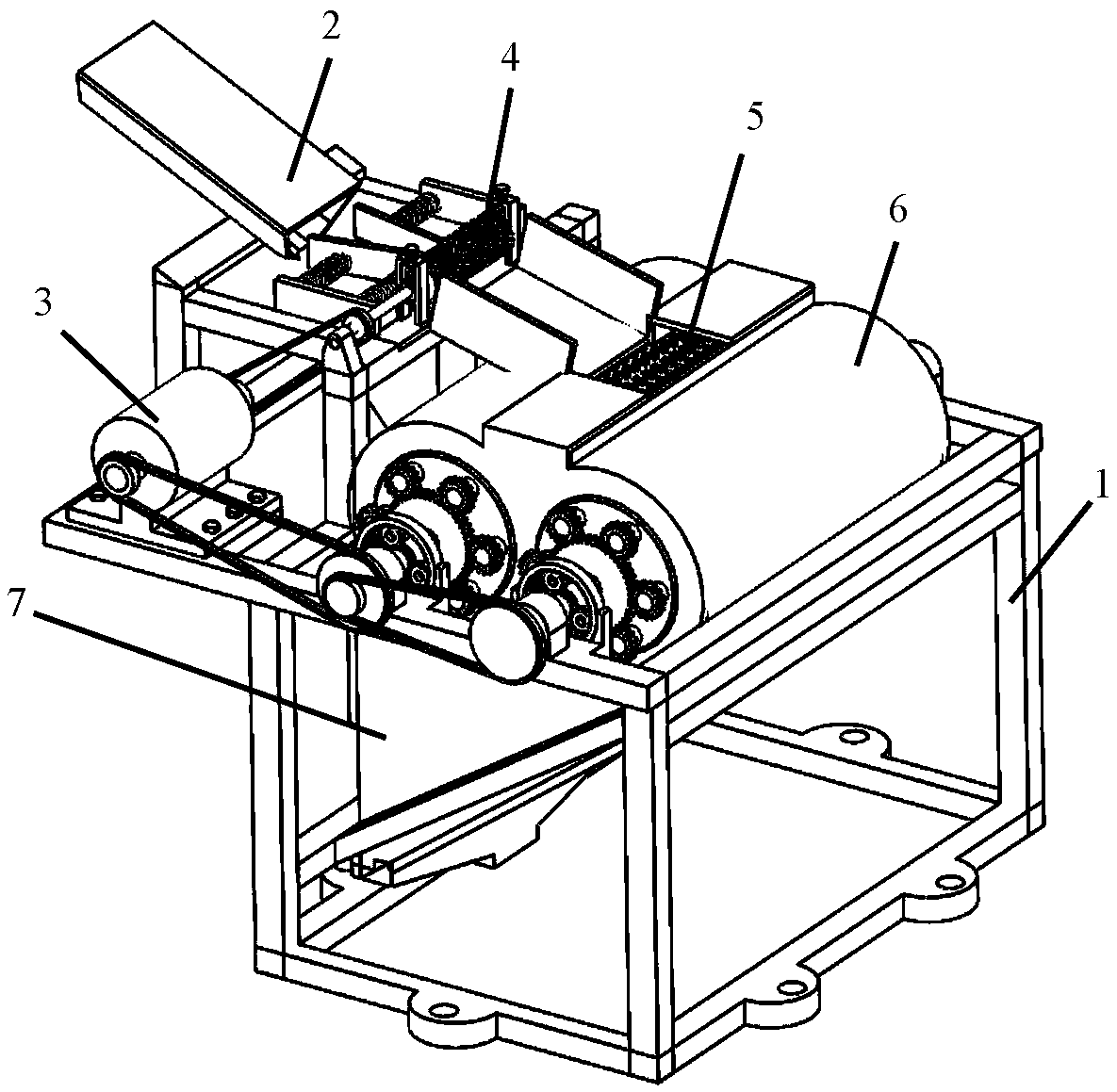

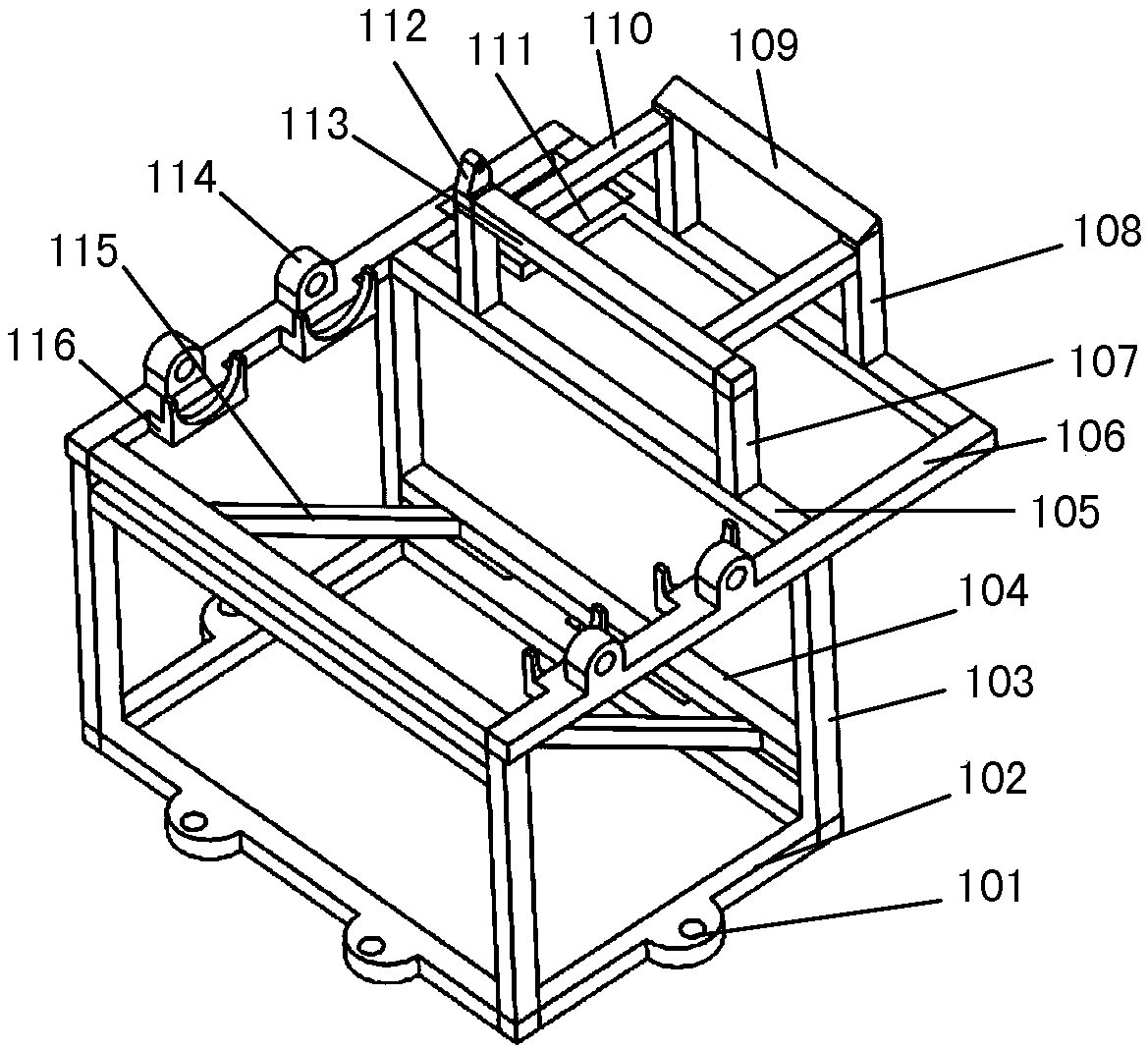

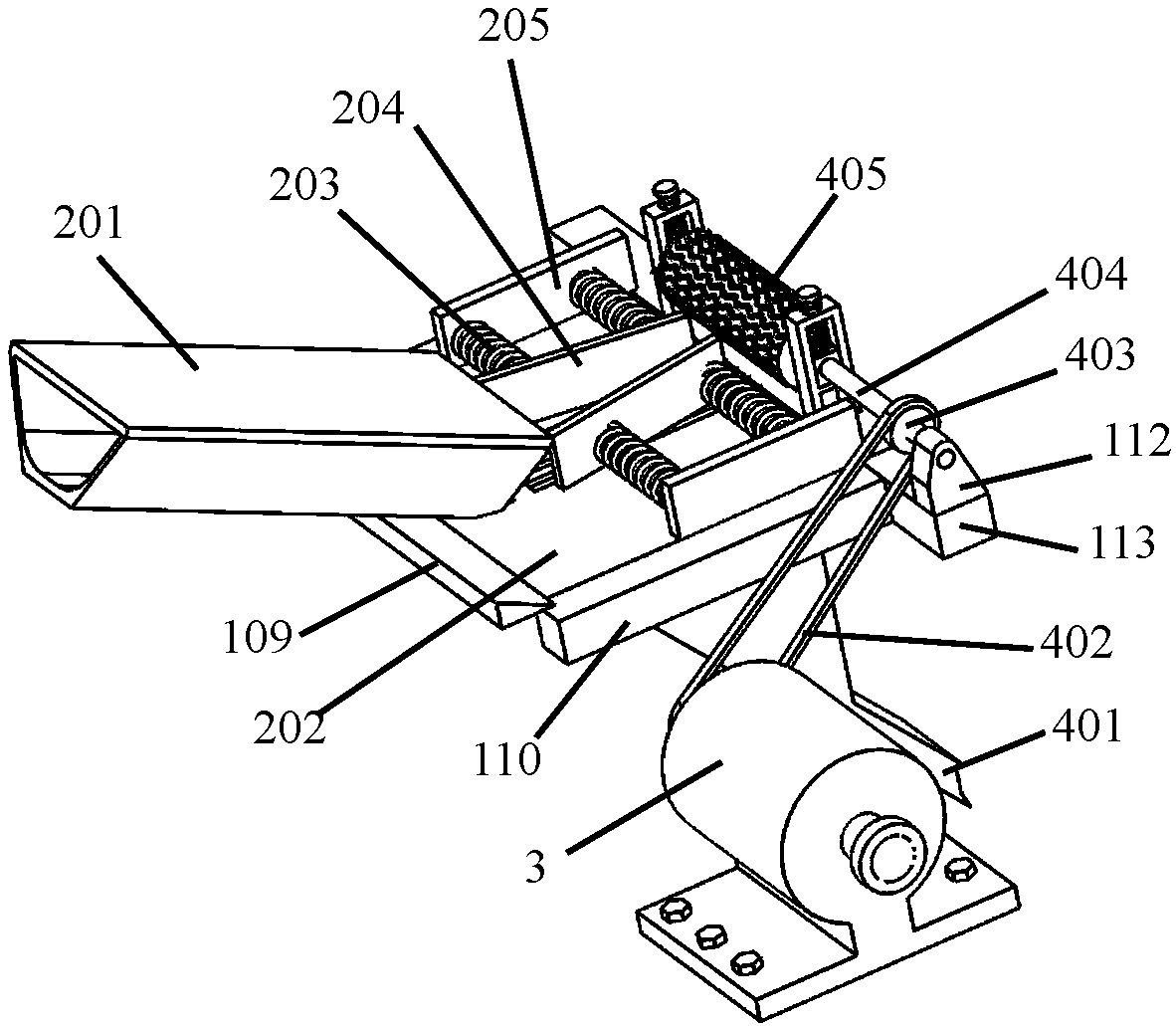

[0044] A differential-speed intelligent non-destructive multi-roller thresher for a plot corn harvester described in this embodiment is shown in Figure 1 to Figure 14 shown.

[0045] Such as figure 1 As shown, the differential-speed intelligent non-destructive multi-roller threshing machine for a small plot corn harvester described in this embodiment is mainly composed of a frame 1, a feeding device 2, a primary threshing device 4, a secondary threshing device, a transmission device, The grain collection device and the intelligent control system are composed of the feeding device 2, the primary threshing device 4, the secondary threshing device and the grain collection device are installed on the frame 1 in order from top to bottom, and the transmission device makes the primary threshing device 4, The secondary threshing device rotates to work, and the intelligent control system detects and records the moisture content of corn ears, and controls the speed of the motor 3 .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com