Rice single ear threshing machine

A technology of thresher and threshing mechanism, applied in threshing equipment, agricultural machinery and implements, application and other directions, can solve the problems of time-consuming and laborious, the threshing effect of a single rice ear is not very good, and the work efficiency is low, and achieve the effect of good threshing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

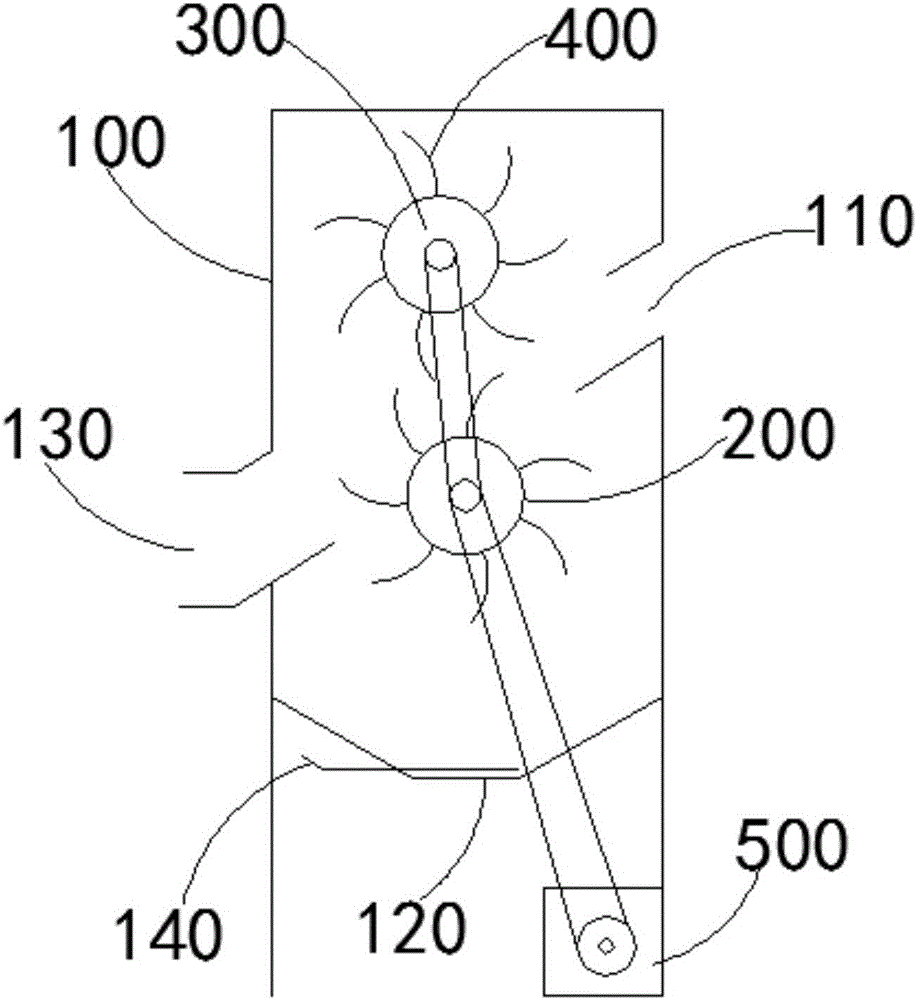

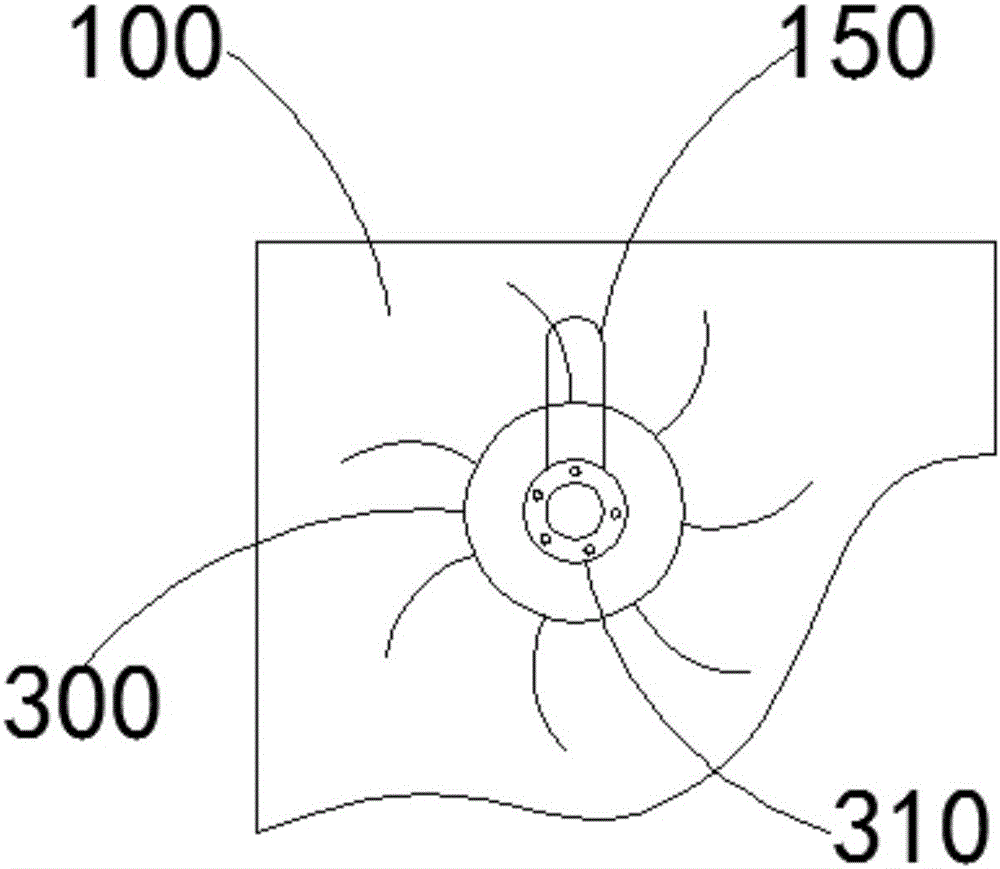

[0040] Please refer to figure 1 -3. This embodiment provides a rice single ear thresher, which includes a casing 100 and a first threshing mechanism.

[0041] Wherein, the casing 100 includes a casing and a bracket, and the casing is welded to the top of the bracket. Both the shell and the bracket are made of carbon steel to ensure that it has sufficient mechanical strength, and at the same time, the outer surface is painted with a paint layer to delay rust and corrosion and prolong the service life.

[0042] The casing 100 is provided with a rice inlet 110 , a grain outlet 120 and a waste outlet 130 for discharging branches, cobs and stalks, wherein the rice inlet 110 and the waste outlet 130 are located on the grain outlet 120 . Both the rice inlet 110 and the grain outlet 120 are provided with a guide plate, which is used to guide the rice into the casing 100 from the rice inlet 110 and guide the threshed stalks out of the casing 100 from the waste outlet 130 .

[0043] I...

no. 2 example

[0057] Please refer to Figure 4 , this embodiment provides a rice single-ear thresher, its composition structure, working principle and technical effect obtained are basically the same as those of the first embodiment, the difference is that the rice single-ear thresher provided by this embodiment is in the first On the basis of the embodiment, a cutting device is added.

[0058] The above-mentioned cutting device is disposed at a position corresponding to the waste outlet 130 on the casing 100 . Specifically, the cutting device includes a fixed knife 600 , a moving knife 610 and a cutting motor for driving the moving knife 610 to rotate. Wherein, both the fixed knife 600 and the movable knife 610 are elongated, the fixed knife 600 is fixedly installed on the top of the waste outlet 130 , and its cutting edge is positioned downward, and the stem flows out from the bottom of the fixed knife 600 . The moving knife 610 is rotatably connected to a rotating rod 620 and is perpen...

no. 3 example

[0062] Please refer to Figure 5 -7. This embodiment provides a rice single-ear thresher. Its composition, working principle and technical effects are basically the same as those of the first embodiment or the second embodiment. The difference is that the rice The single ear thresher has added a second threshing mechanism on the basis of the first embodiment or the second embodiment.

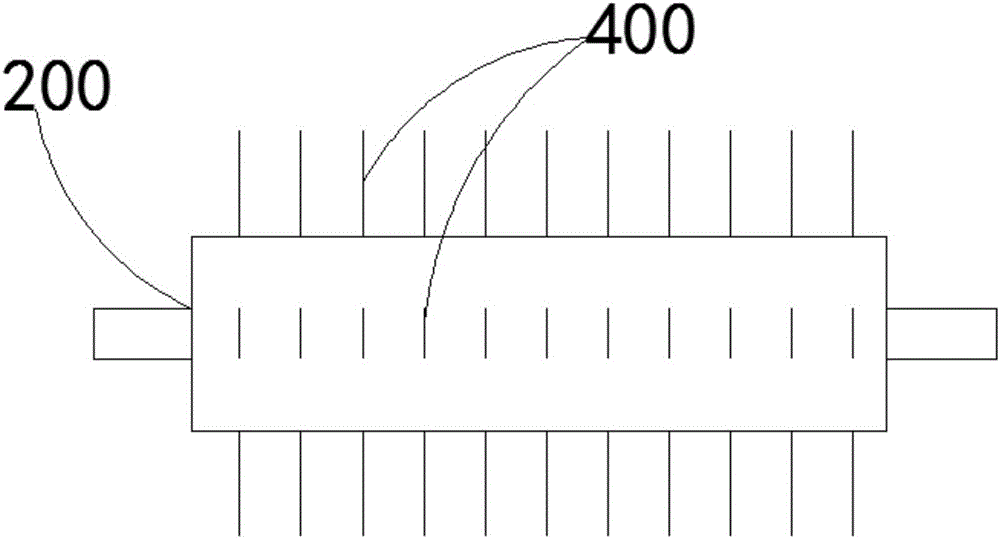

[0063] The above-mentioned second threshing mechanism is used for secondary threshing of the rice passing through the threshing gap. Specifically, the second threshing mechanism includes a third drum 700 rotatably connected in the housing 100 and a second motor for driving the third drum 700 to rotate.

[0064] Wherein, the third roller 700 is in the shape of a round tube and is inclined. The specific angle of inclination is determined according to actual needs, generally 15°-30°. The side wall of the third cylinder 700 is provided with a plurality of grain filter holes 710, a plurality of gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com