Novel rice and wheat thresher

A threshing machine, rice and wheat technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of threshing rodents easy to fall off, inconvenient maintenance, etc., to achieve convenient operation, improved connection effect, and firm connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

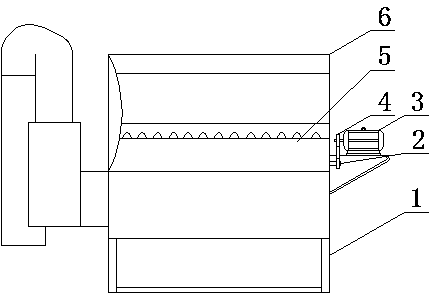

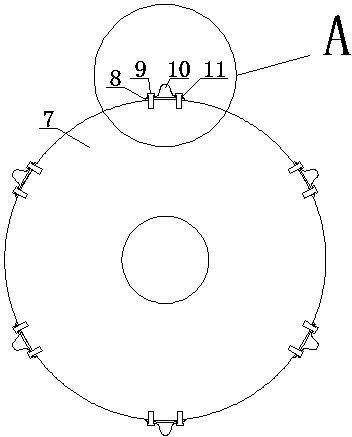

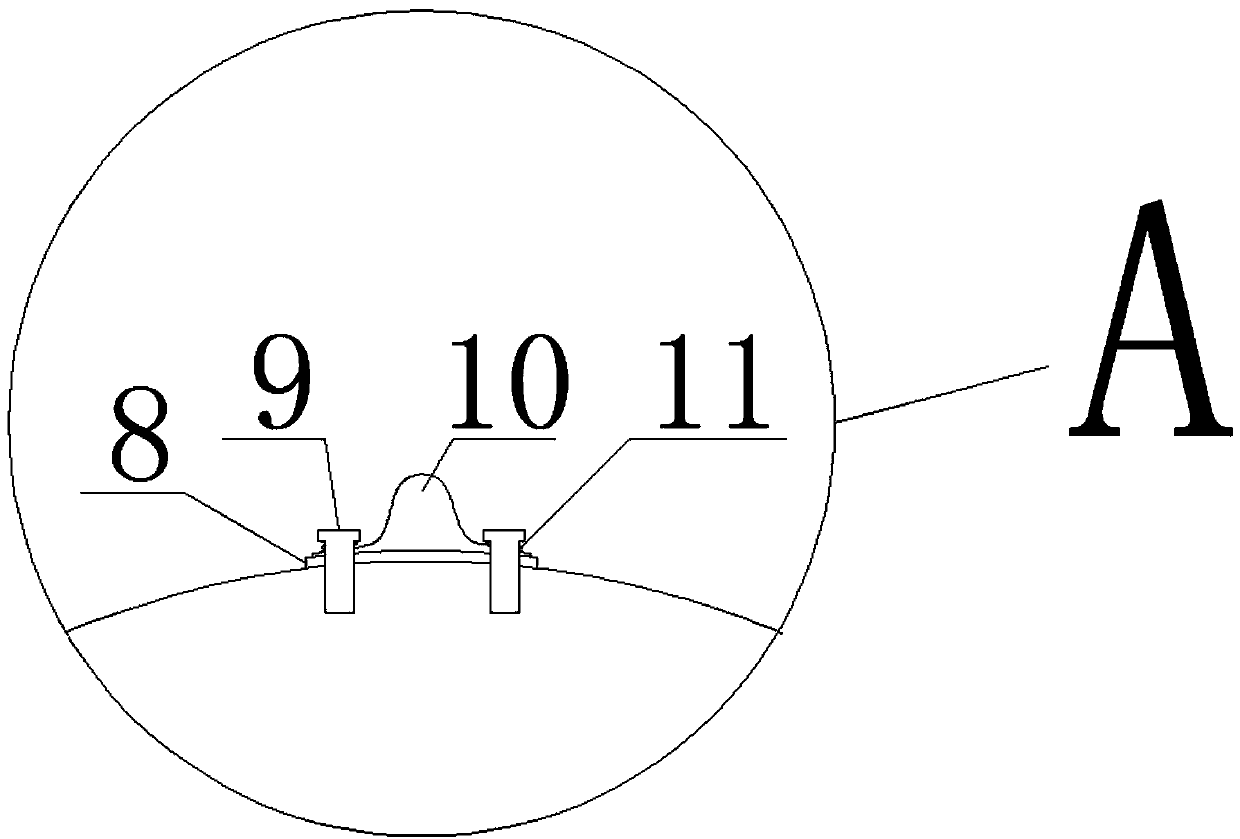

[0022] to combine figure 1 , figure 2 ,and image 3 , the object of the present invention is to provide a novel rice and wheat thresher, comprising a frame 1, a threshing bin 6 is arranged on the frame 1, a threshing cylinder 5 is arranged in the threshing bin 6, and the threshing cylinder 5 is installed on the drum shaft 2, The drum shaft 2 is supported on the frame 1 through bearings, and the drum shaft 2 is driven to rotate by the belt pulley 4 of the driving device 3 . The threshing cylinder 5 includes a threshing cylinder main body 7 and a threshing rod 10, the outer peripheral surface of the threshing cylinder main body 7 is fixedly connected with a fixing bar 8 for fixing the threshing rod 10, and the threshing rod 10 is fixedly installed on the fixing bar 8 through a bolt 9, as a kind of In a preferred manner, the bolts 9 extend into the main body 7 of the threshing cylinder through the fixing strip 8 . The threshing gear 10 of the present invention is connected to...

Embodiment 2

[0028] A new type of rice and wheat thresher, including a frame 1, a threshing bin 6 is arranged on the frame 1, a threshing cylinder 5 is arranged in the threshing bin 6, and the threshing cylinder 5 is installed on a drum shaft 2, and the drum shaft 2 is supported by a bearing On the frame 1, the drum shaft 2 is driven to rotate by the belt pulley 4 of the driving device 3. The threshing cylinder 5 includes a threshing cylinder main body 7 and a threshing gear 10. The outer peripheral surface of the threshing cylinder main body 7 is fixedly connected with a fixing bar 8 for fixing the threshing gear 10, and the threshing gear 10 is fixedly installed on the fixing bar 8 by a bolt 9. The threshing gear 10 of the present invention is welded on the drum main body 7 and has the characteristics of being fastened and not falling off.

[0029] The bolt 9 is equipped with an elastic washer 11 for fastening the threshing rod 10.

[0030] Ten fixing strips 8 are evenly distributed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com