Corn thresher

A technology for thresher and corn kernels, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of high crushing rate, slow threshing speed, unsatisfactory threshing effect, etc., and achieve high threshing rate and good threshing effect. , The effect of fast threshing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

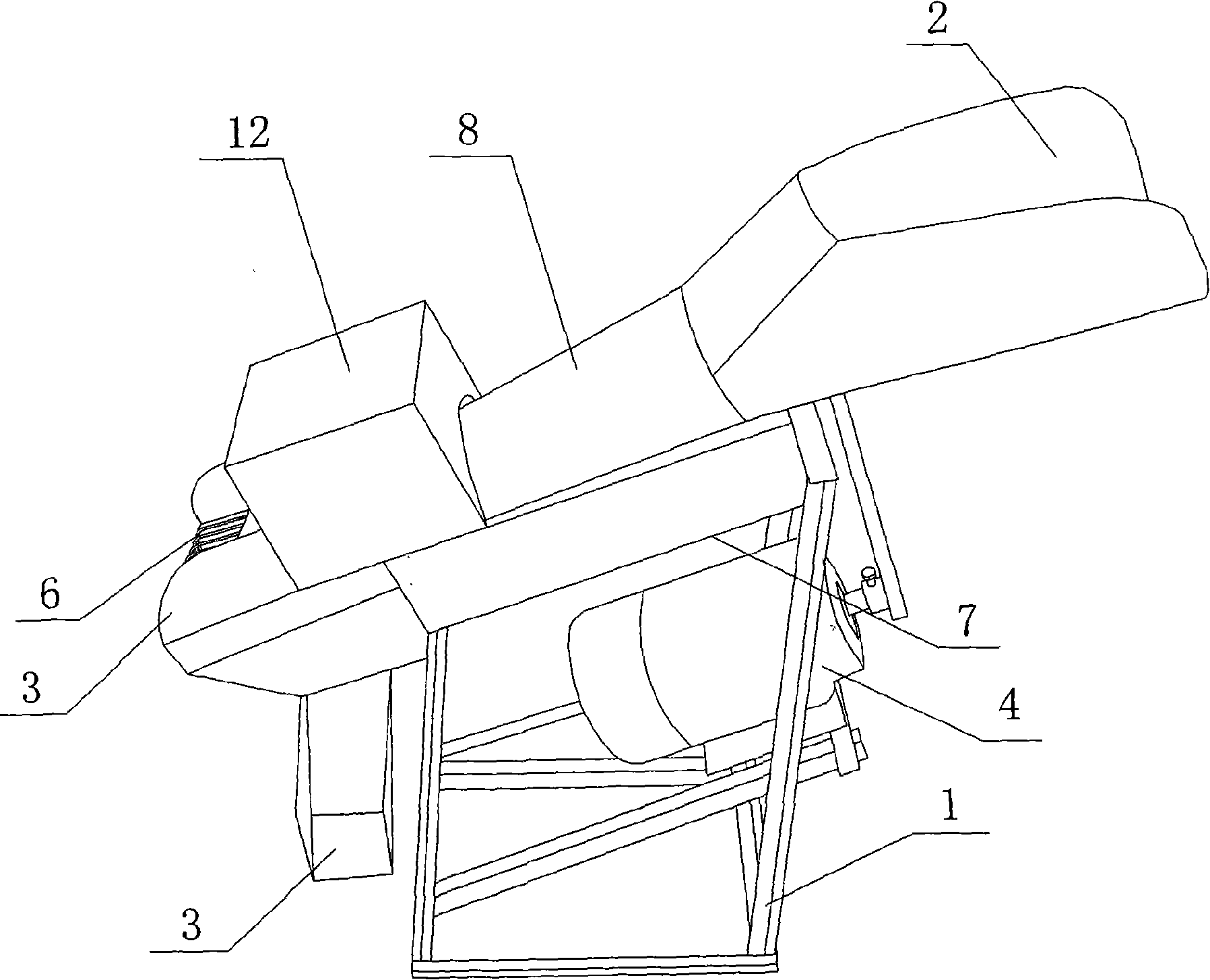

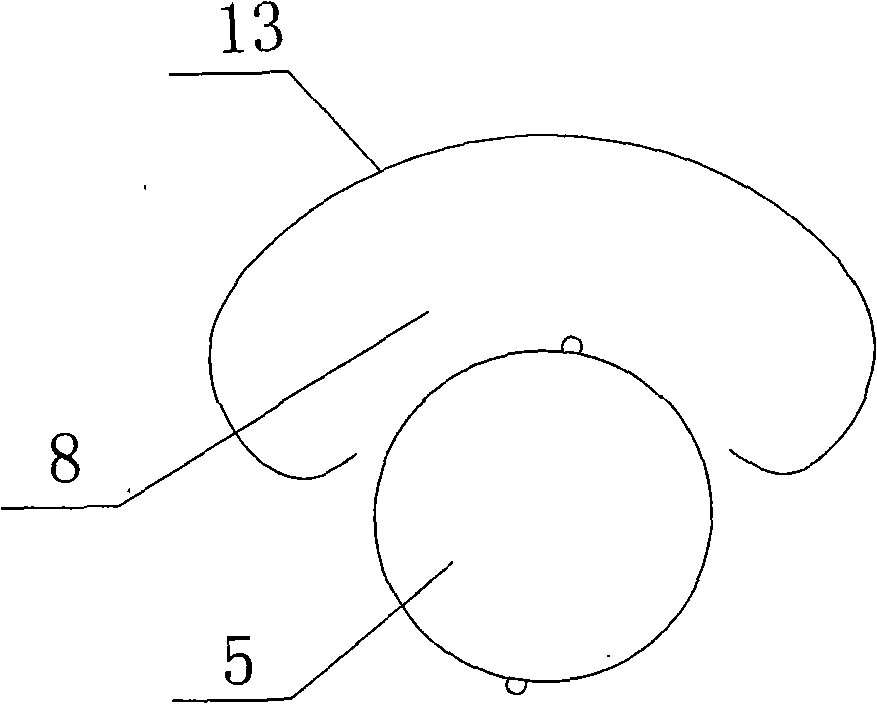

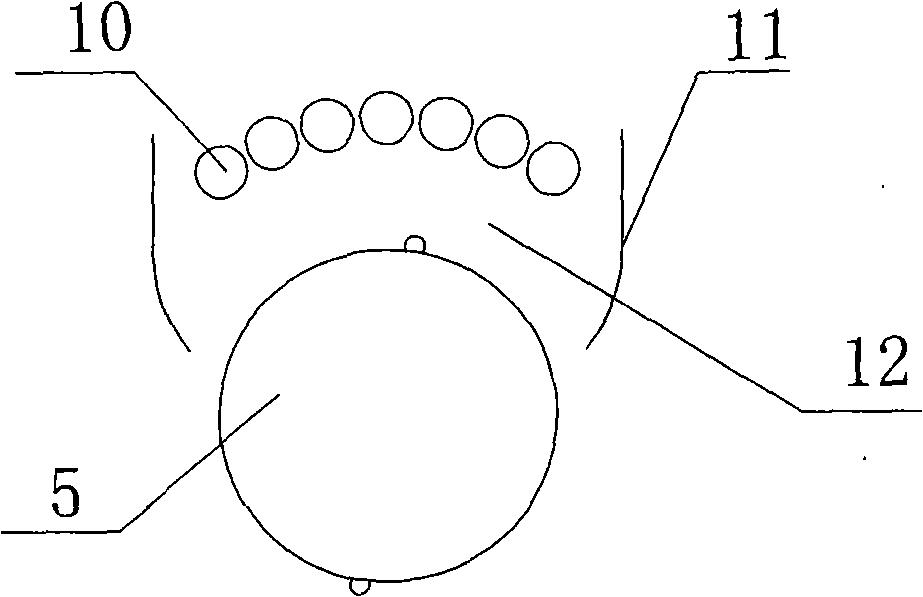

[0026] Such as Figure 1-9 A corn thresher shown includes a support 1, a feed hopper 2, a threshing device, a discharge port 3 and a power unit 4, the feed hopper 2 is connected with the threshing device, and a threshing cylinder 5 is arranged in the threshing device, The threshing cylinder 5 is driven by the power device 4, the power device 4 generally adopts a motor, the discharge port 3 is located at the bottom of the threshing device, and a screen structure 6 for separating corncobs and corn kernels is arranged between the discharge port 3 and the threshing device. The threshing device includes a threshing bin which is sequentially segmented above the threshing barrel 5 and a material-receiving bottom plate 7 located below the threshing barrel 5. The whole threshing bin is large and small; the first stage threshing bin 8 is connected with the feeding hopper 2, The opening diameter of the upper end of the first threshing bin 8 is larger than the opening diameter of the lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com