Roller structure of corn thresher

A threshing machine and drum technology, applied in threshing equipment, agricultural machinery and tools, applications, etc., can solve the problems that corn kernels are easy to be caught in the skin and discharged from the tuyere, affect the threshing effect, and the corn damage rate is high. Low, better effect, clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

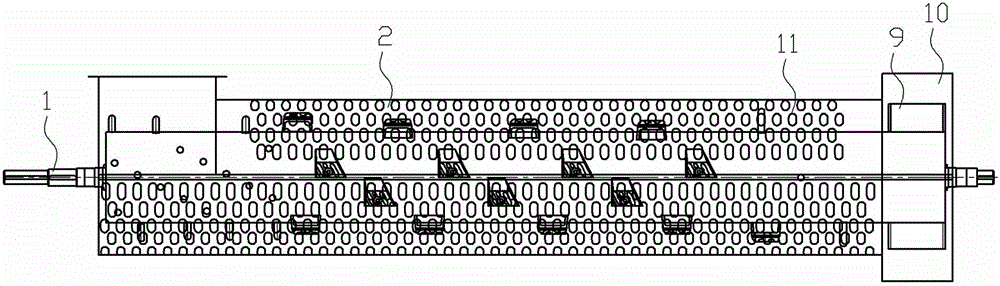

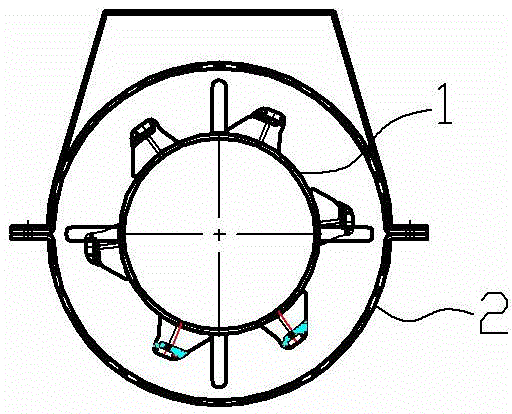

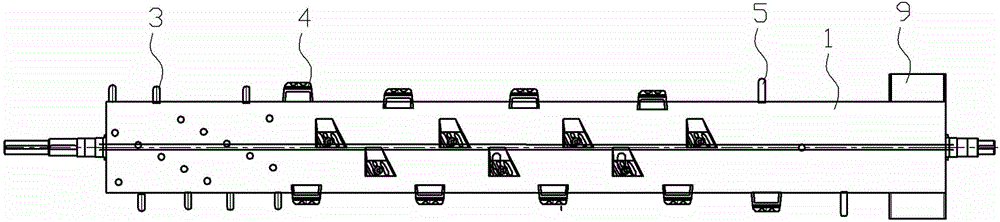

[0012] like figure 1 , 2 As shown in and 3, it includes a rotor 1 and a sieve cylinder 2, the outer wall of the rotor 1 is spirally arranged with peeling nails 3, rubbing blocks 4 and cleaning nails 5 from the input end to the output end, and the rubbing block The front end surface and one side end surface of 4 are slopes that play a guiding role, and its top surface is provided with a rib 6 that is consistent with the direction of the side slope. Peeling spikes 3 can peel off the corn husks from the cob in advance, and then squeeze and knead the rubbing block 4 to make the threshing more clean and thorough. Cleaning spikes 5 can shake out the grains caught in the corn husks to prevent loss of grains waste. The ribs on the top of the kneading block 4 can improve the threshing efficiency. Peeling nail teeth 3 quantity is far more than cleaning nail teeth 5, but its height is smaller than cleaning nail teeth. The side slopes of the kneading block 4 are consistent with the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com