Test field millet thresher

A technology of experimental fields and threshing machines, which is applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve problems such as equipment cleaning is not clean, and achieve the effect of preventing millet from falling and threshing effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

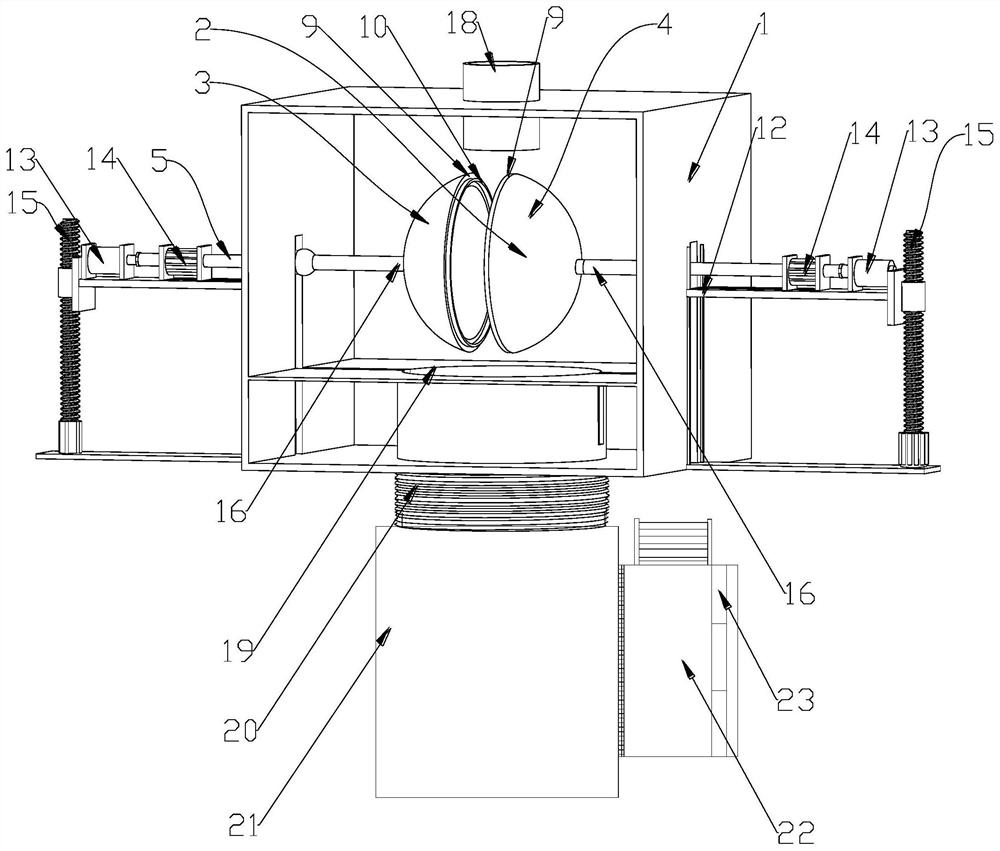

[0044] Such as Figure 1 ~ Figure 4 As shown, this example proposes

[0045] A millet threshing machine for experimental fields, comprising a case 1 and a rubbing mechanism 2 arranged on the case 1, the rubbing mechanism 2 includes

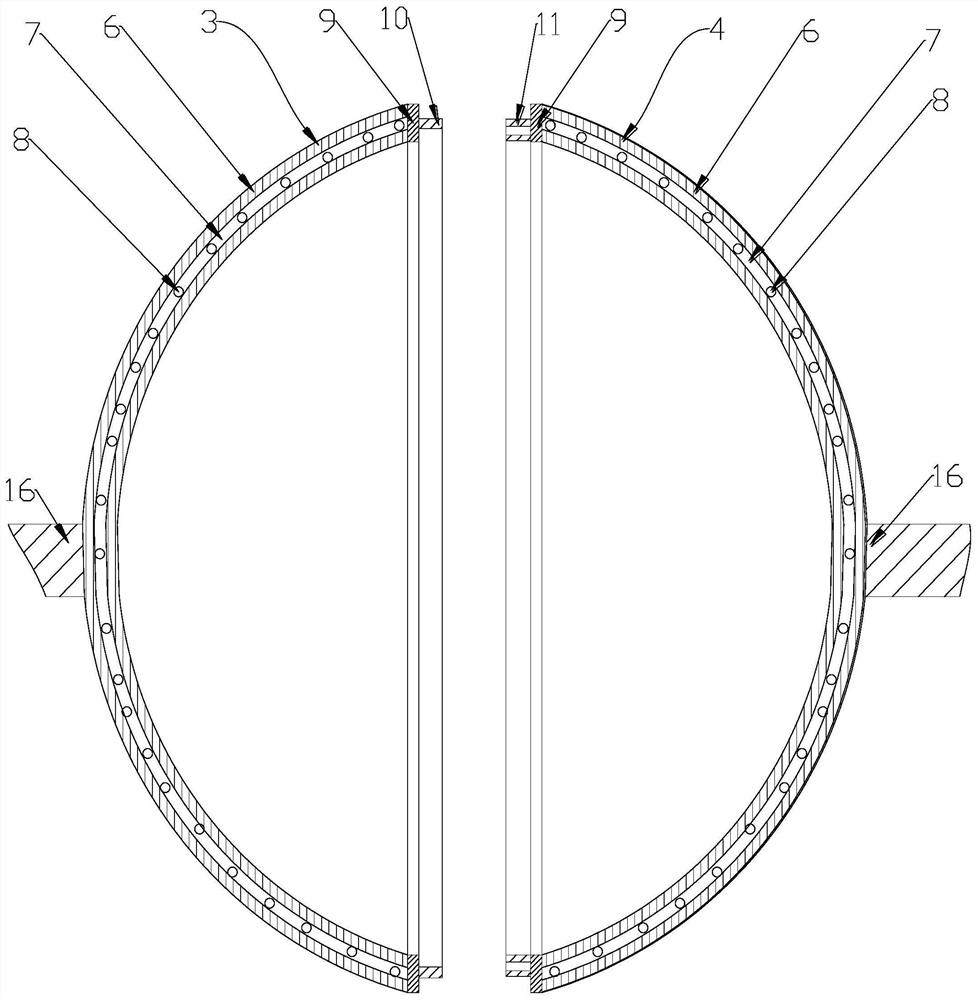

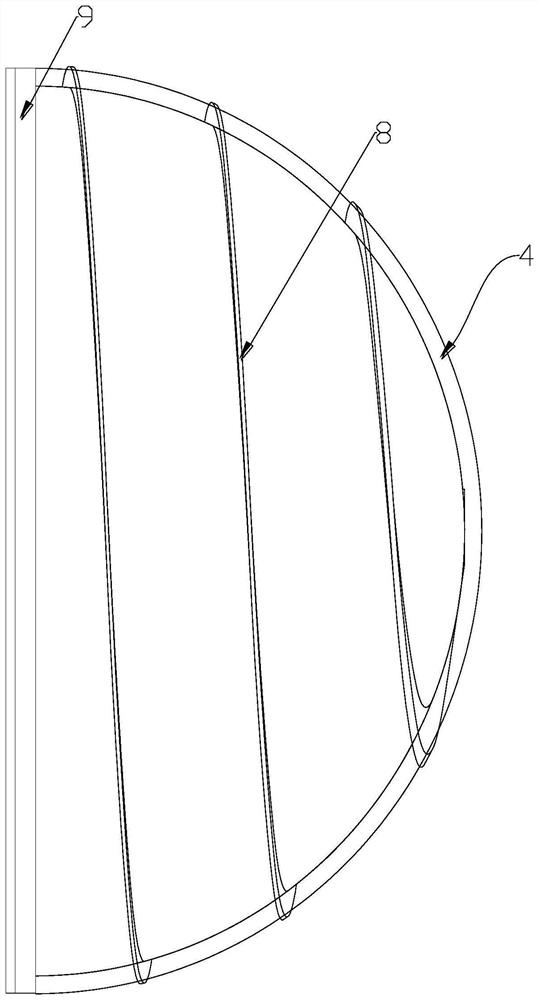

[0046] The first elastic shell 3 is arranged in the case 1,

[0047] The second elastic shell 4 is arranged in the chassis 1, the first elastic shell 3 and the second elastic shell 4 are synchronously lifted, cooperate with each other and rotate in opposite directions,

[0048] The driving mechanism 5 is arranged on the chassis 1 , and the driving mechanism 5 drives the first elastic shell 3 and the second elastic shell 4 .

[0049] In this example, since the thresher required in the experimental field does not need to deal with large-scale threshing work, its main purpose is how to thresh different batches of millet without confusing each other. This millet thresher in the experimental field is improved The kneading mechanism 2 realizes that a...

Embodiment 2

[0082] Such as Figure 5 As shown, on the basis of Example 1, the position of feeding is further improved to prevent the kneading mechanism from being able to accurately act on the millet.

[0083] On the basis of embodiment 1, further, also include

[0084] Feeding auxiliary components are arranged in the cabinet 1, and the feeding auxiliary components include

[0085] The feed conical pipe 24 is arranged on the chassis 1 and communicates with the feed port 18, and the outlet of the feed conical pipe 24 faces the center of the first elastic shell 3 and the second elastic shell 4 after opening. Location,

[0086] There are two feeding auxiliary half-shells 25, which are respectively arranged on the first elastic shell 3 and the second elastic shell 4. The two feeding auxiliary half-shells 25 can form a cylindrical passage, and the inner diameter of this cylindrical passage is larger than that of the feeding cone. the outlet diameter of the tube,

[0087] In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com