Pedaled rotary-drum rice threshing machine

A pedal-operated, thresher technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems that ordinary farmers cannot afford the cost, the degree of automation is not high, and the thresher is labor-intensive, etc., saving manpower and saving The effect of energy, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

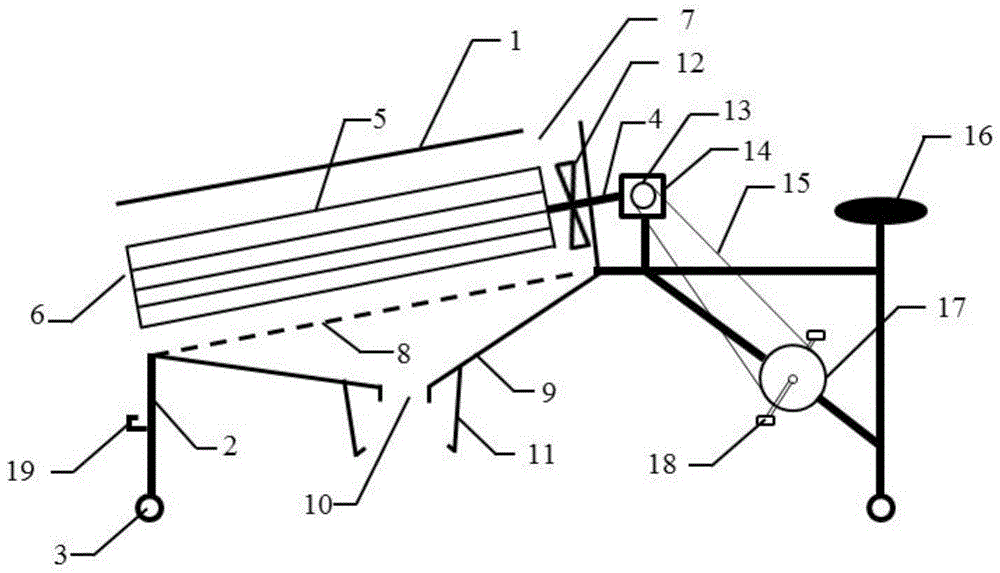

[0031] Such as figure 1 Shown, a kind of foot-operated rotary drum rice thresher comprises threshing cylinder 1, support 2 and action wheel 3, is characterized in that, also comprises pedal 18, driving wheel 17, driven wheel 13 and cushion 16, described threshing The drum 1 includes a feeding port 7 and a straw outlet 6, and the threshing drum 1 is provided with a threshing shaft 4, and the threshing shaft 4 is provided with a fan 12 and a threshing drum 5; the bottom of the threshing drum 1 is provided with a sieve hole 8; A hinge 15 is connected to the driven wheel 13, and the driven wheel 13 is connected to the threshing shaft 4 through a gearbox 14.

[0032] Wherein, the level of the feed inlet 7 is higher than that of the straw outlet 6; the threshing rotating shaft 4 is parallel to the threshing cylinder 1; the threshing cylinder is a hollow cylinder composed of metal rods; the length of the threshing cylinder is It is 1.5 meters; the diameter of the threshing drum is 2...

Embodiment 2

[0034] Such as figure 1 Shown, a kind of foot-operated rotary drum rice thresher comprises threshing cylinder 1, support 2 and action wheel 3, is characterized in that, also comprises pedal 18, driving wheel 17, driven wheel 13 and cushion 16, described threshing The drum 1 includes a feeding port 7 and a straw outlet 6, and the threshing drum 1 is provided with a threshing shaft 4, and the threshing shaft 4 is provided with a fan 12 and a threshing drum 5; the bottom of the threshing drum 1 is provided with a sieve hole 8; A hinge 15 is connected to the driven wheel 13, and the driven wheel 13 is connected to the threshing shaft 4 through a gearbox 14.

[0035] Wherein, the level of the feed inlet 7 is higher than that of the straw outlet 6; the threshing rotating shaft 4 is parallel to the threshing cylinder 1; the threshing cylinder is a hollow cylinder composed of metal rods; the length of the threshing cylinder is It is 1 meter; the diameter of the threshing drum is 30cm...

Embodiment 3

[0037] Such as figure 1 Shown, a kind of foot-operated rotary drum rice thresher comprises threshing cylinder 1, support 2 and action wheel 3, is characterized in that, also comprises pedal 18, driving wheel 17, driven wheel 13 and cushion 16, described threshing The drum 1 includes a feeding port 7 and a straw outlet 6, and the threshing drum 1 is provided with a threshing shaft 4, and the threshing shaft 4 is provided with a fan 12 and a threshing drum 5; the bottom of the threshing drum 1 is provided with a sieve hole 8; A hinge 15 is connected to the driven wheel 13, and the driven wheel 13 is connected to the threshing shaft 4 through a gearbox 14.

[0038] Wherein, the level of the feed inlet 7 is higher than that of the straw outlet 6; the threshing rotating shaft 4 is parallel to the threshing cylinder 1; the threshing cylinder is a hollow cylinder composed of metal rods; the length of the threshing cylinder is It is 1.2 meters; the diameter of the threshing drum is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com