Corn harvesting device

A harvesting device and corn technology, applied in threshing equipment, applications, agricultural machinery and tools, etc., can solve problems such as poor threshing effect and achieve good threshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

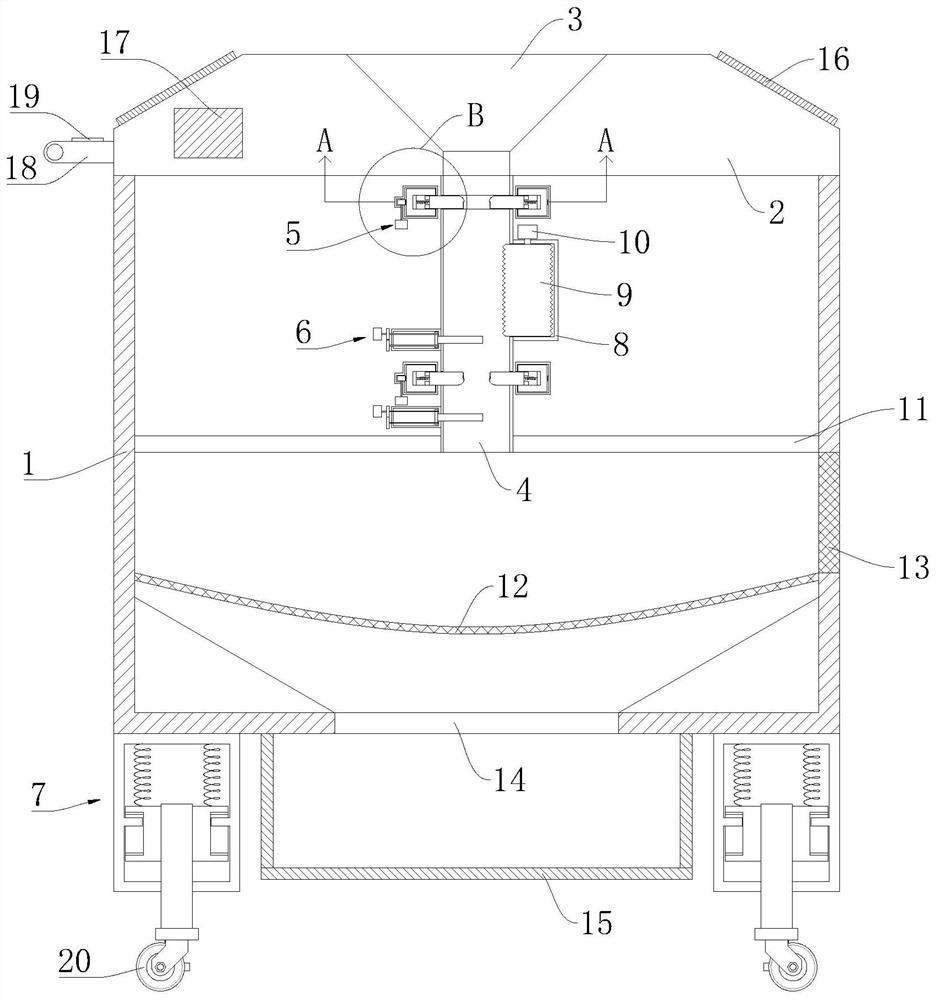

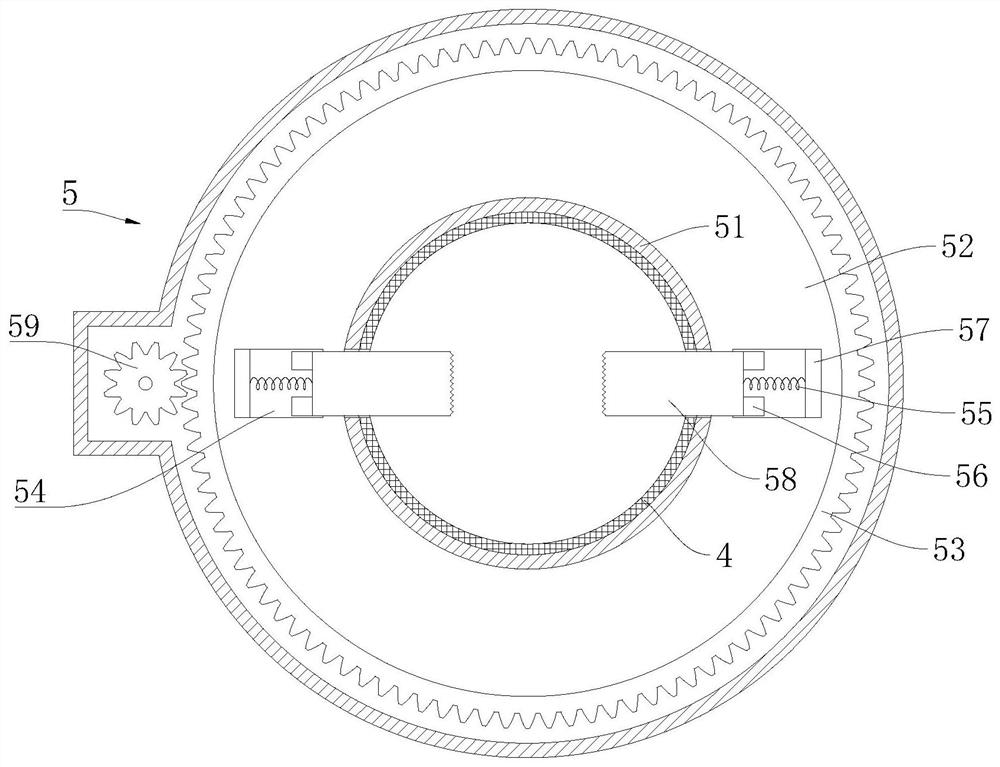

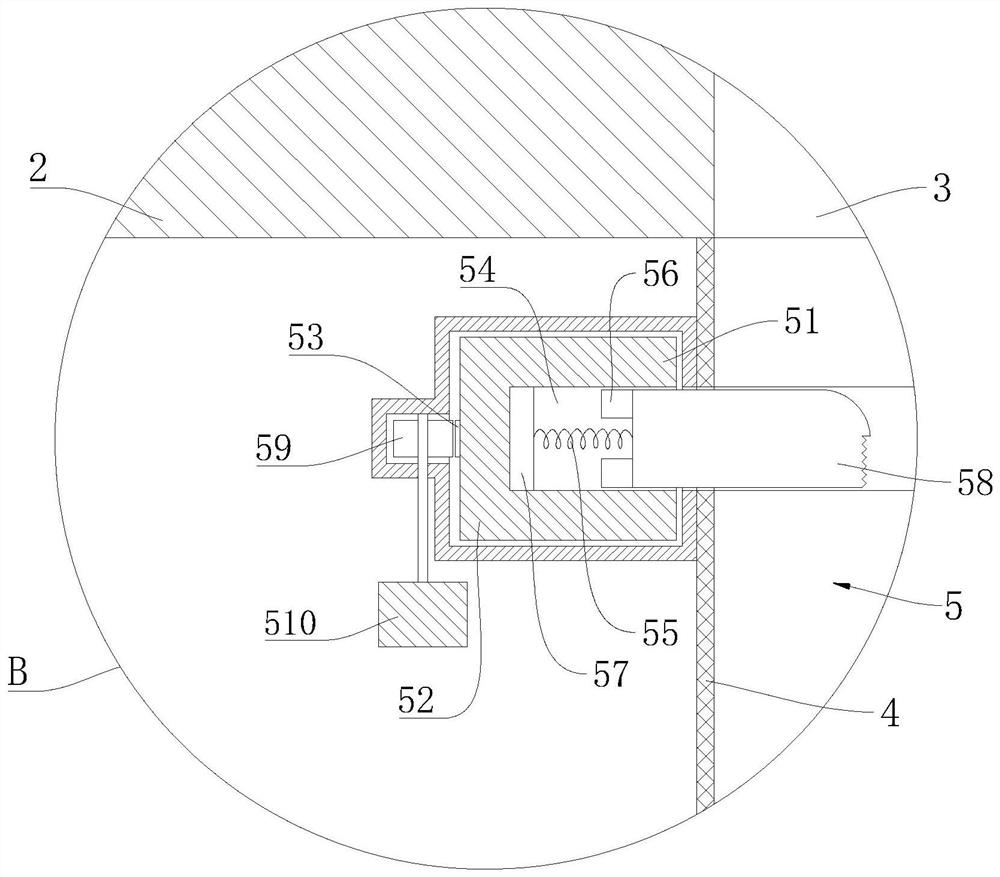

[0023] refer to Figure 1-5 , a corn harvesting device, comprising an outer box body 1, a fixed cover on the upper end of the outer box body 1 is provided with a box cover 2, a handle 18 is fixedly installed on one side of the box cover 2, a feeding port 3 is opened in the middle part of the box cover 2, and the box cover 2. A connecting pipe 4 is fixedly installed in the middle of the lower surface. When the corn is put into the feeding port 3, the corn will enter the connecting pipe 4. A clamping piece 5 is fixedly installed above the outer surface of the connecting pipe 4. The middle part of the outer surface of the connecting pipe 4 is A fixed shell 8 is fixedly installed on the side, and a first micromotor 10 is fixedly installed above the fixed shell 8. A threshing roller 9 is fixedly installed at the lower end of the control output of the first micromotor 10. The threshing roller 9 is arranged inside the fixed shell 8. The first micromotor 10 start-up will drive the thr...

Embodiment 2

[0031] refer to figure 1 , as another preferred embodiment of the present invention, on the basis of Embodiment 1, a solar cell panel 16 is fixedly installed on the outer side of the upper end surface of the case cover 2, and a storage battery 17 is fixedly installed on the inner side of the case cover 2, and the solar cell panel 16 passes through The wire is electrically connected to an inverter, and the inverter is electrically connected to the battery 17. A control panel 19 is fixedly installed on the upper end of the handle 18. The control panel 19 is electrically connected to the battery 17 through a wire, and the control panel 19 is also connected to the second battery through a wire. A micromotor 10, the second micromotor 510, the third micromotor 68 and the electromagnet 57 are electrically connected, and there is an angle between the length direction of the solar panel 16 and the horizontal plane, so that the solar panel 16 is more convenient to receive Under sunlight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com