Patents

Literature

44results about How to "Peeling achieved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

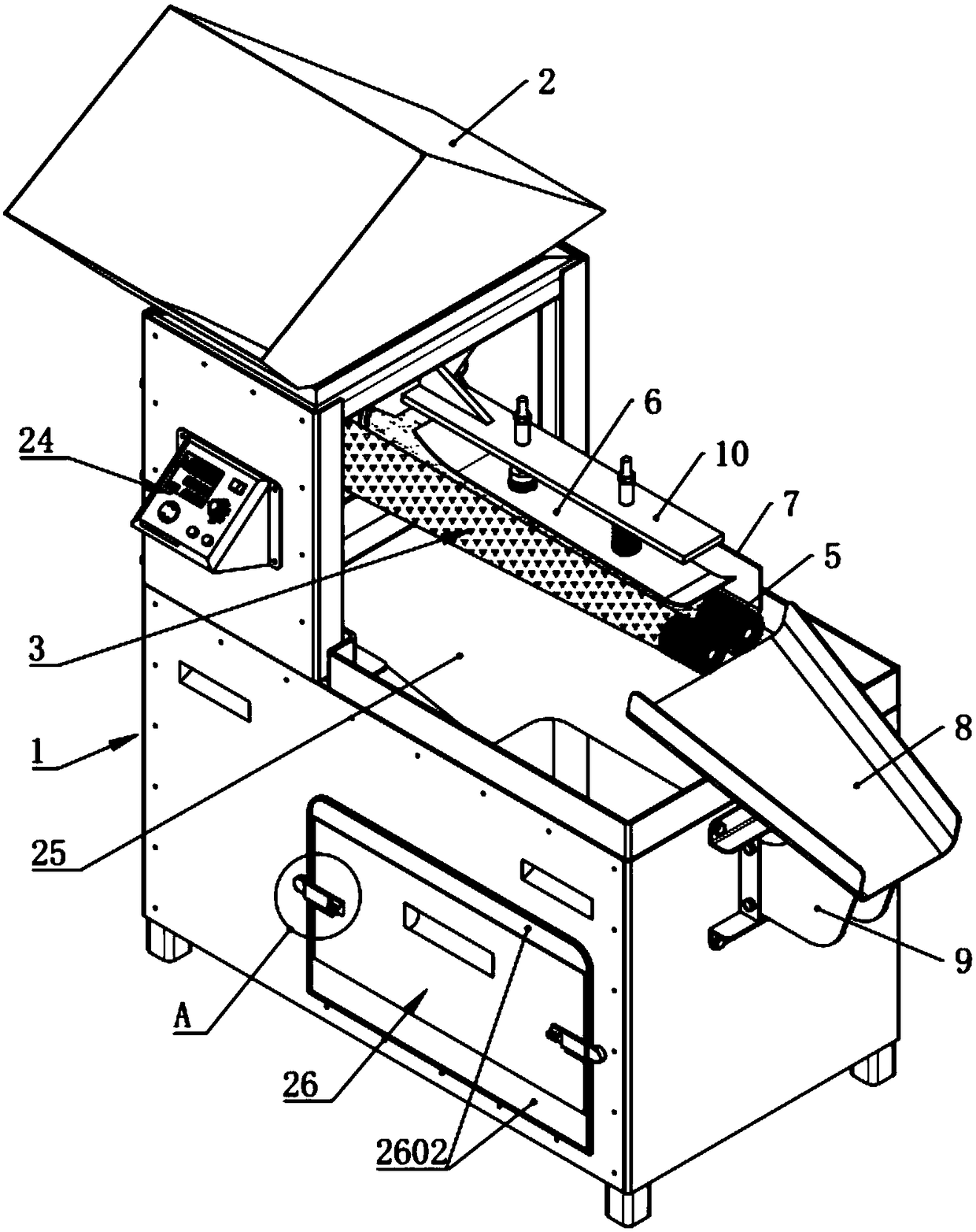

A multifunctional fruit peeling machine

ActiveCN108888084APeeling achievedEasily brokenKitchen fruit stoningMetal working apparatusElectric motor

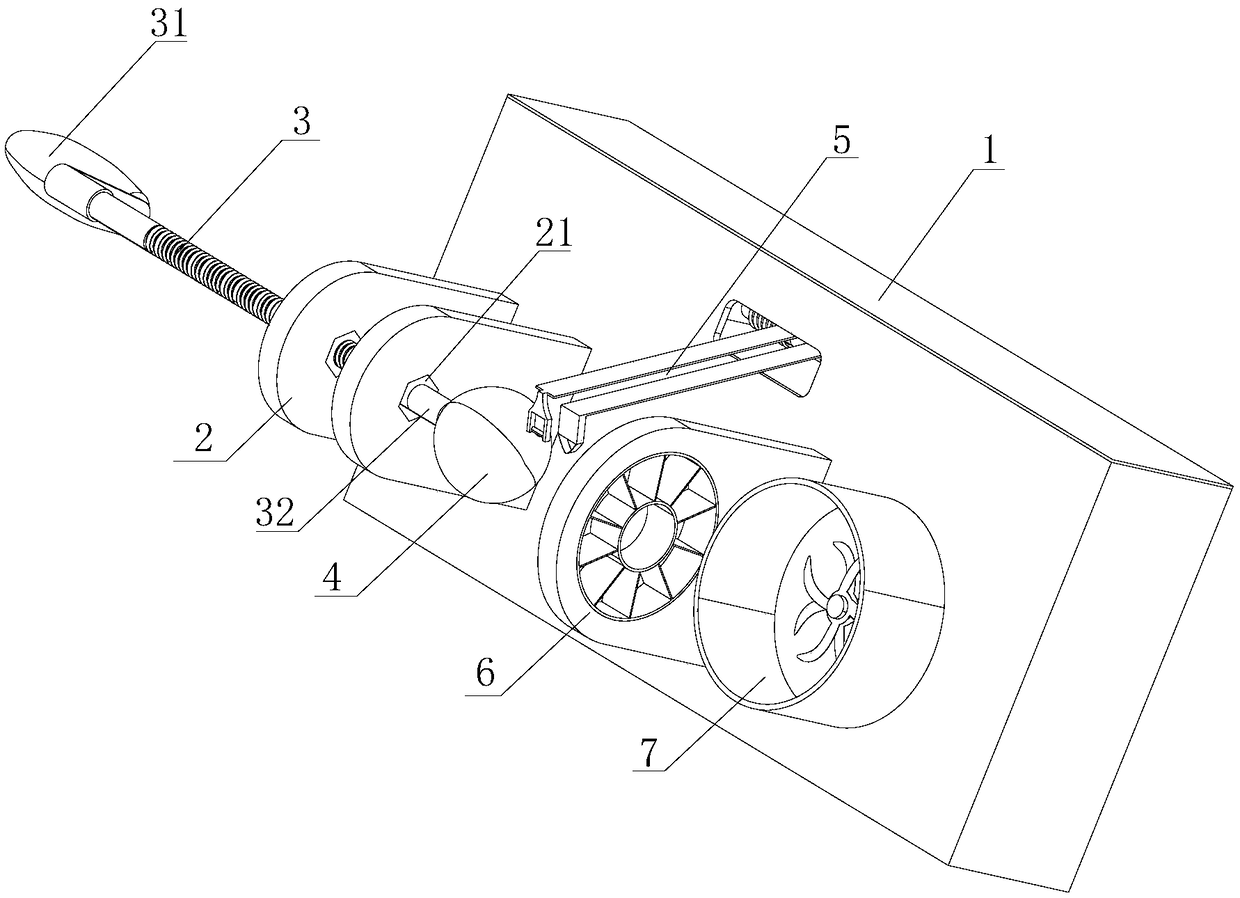

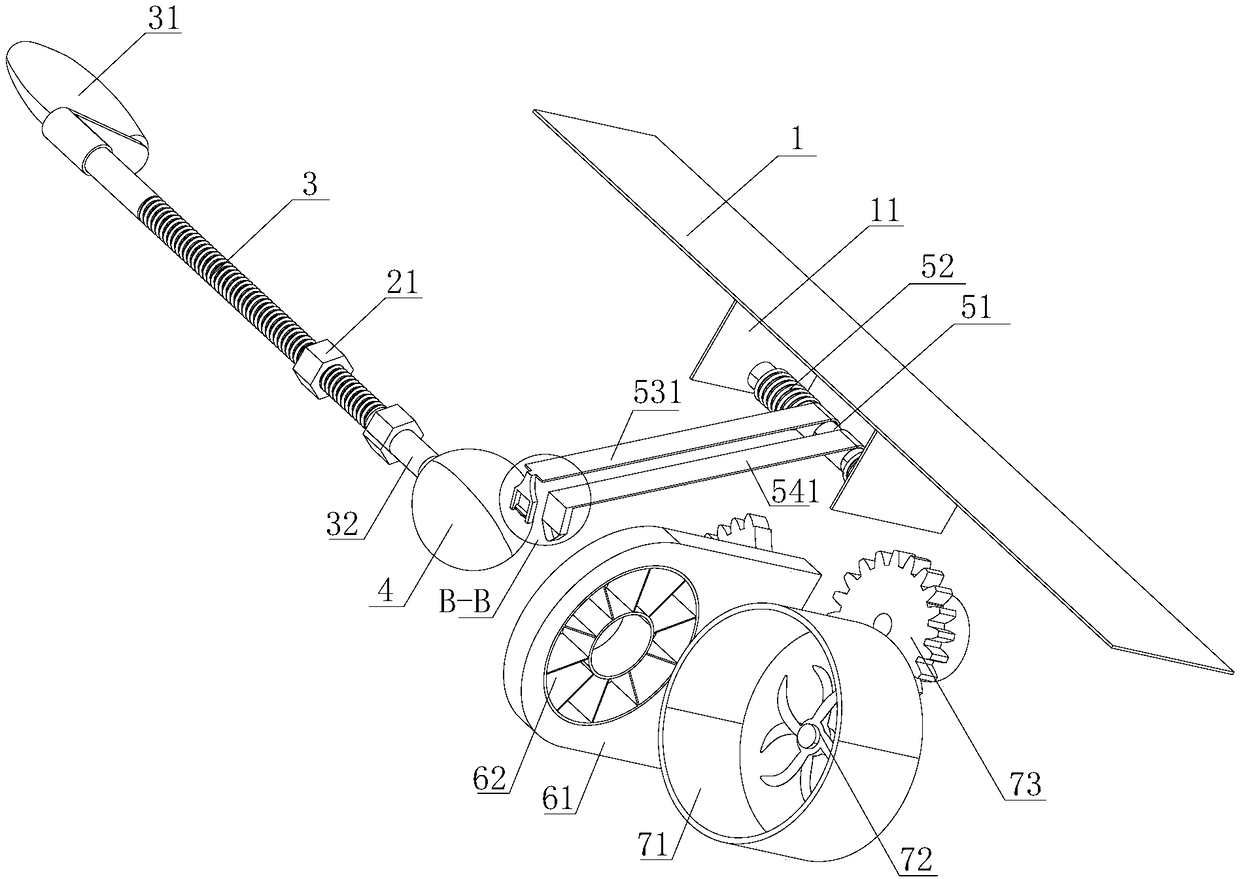

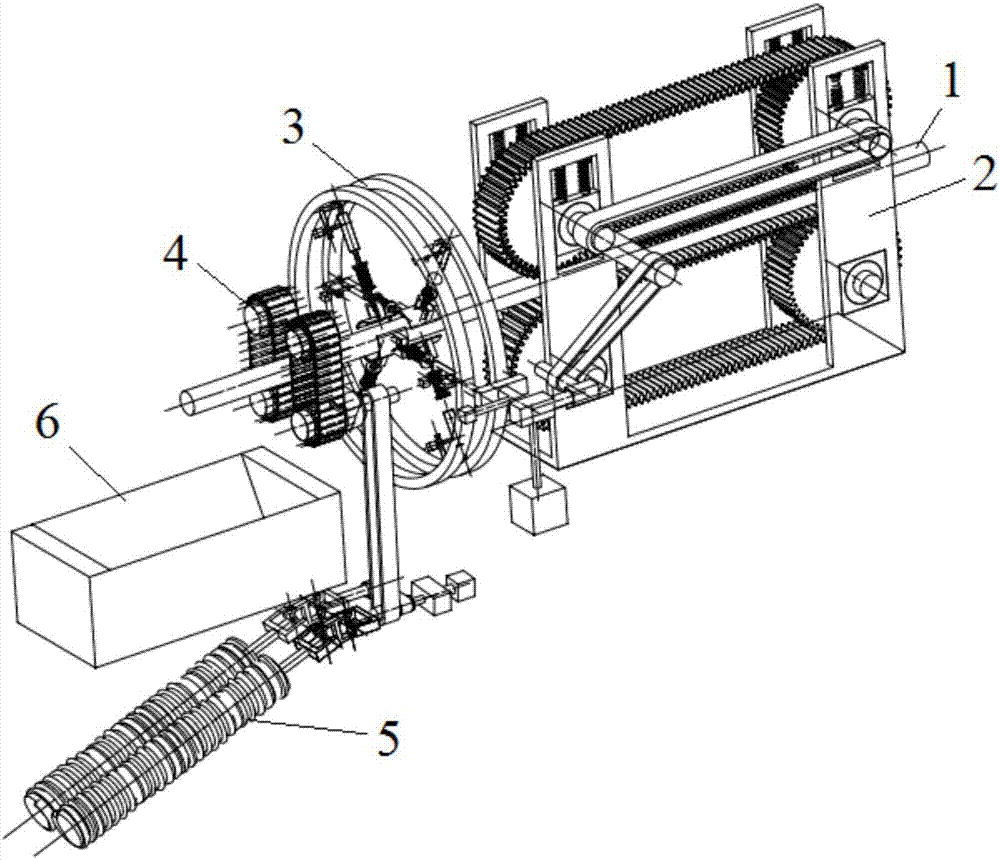

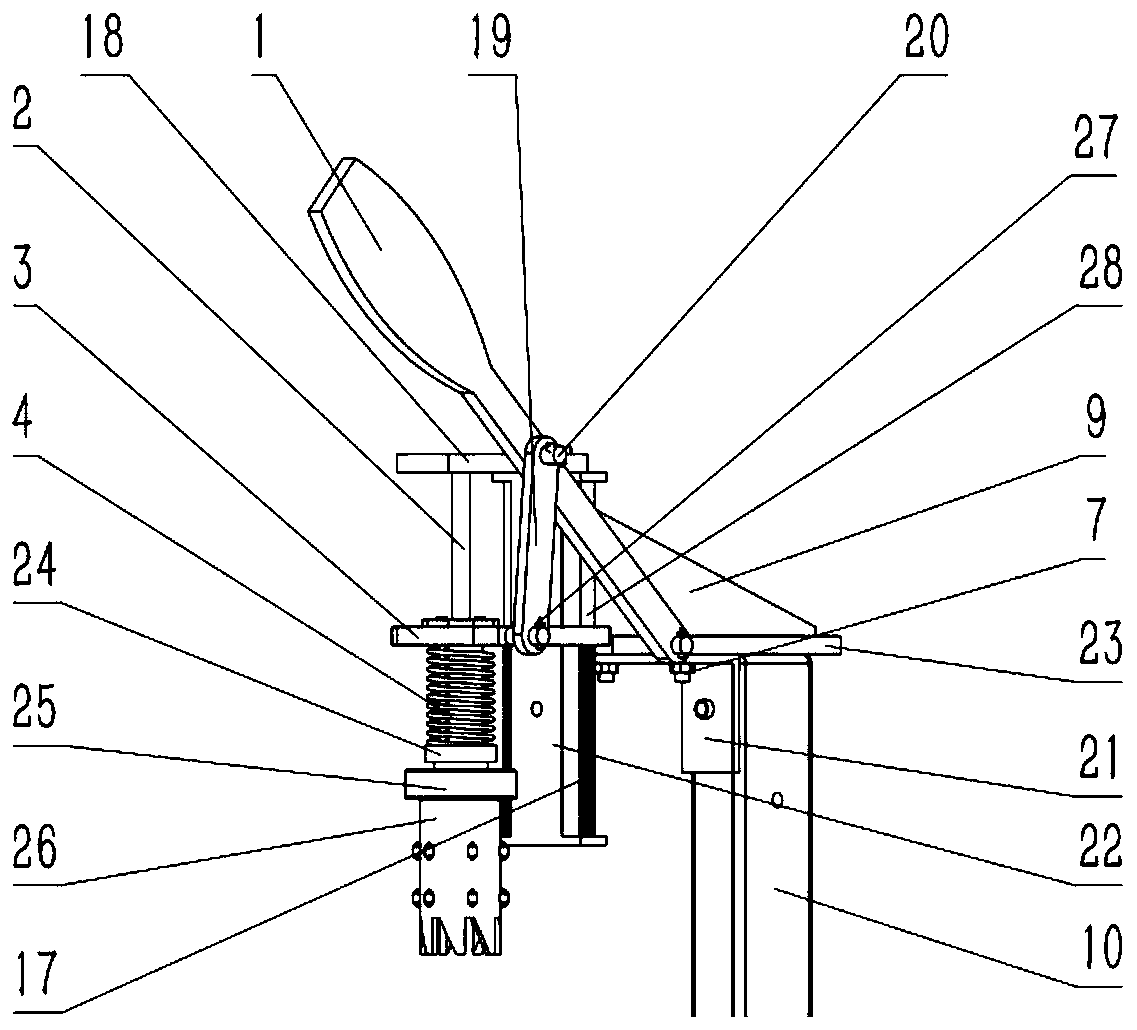

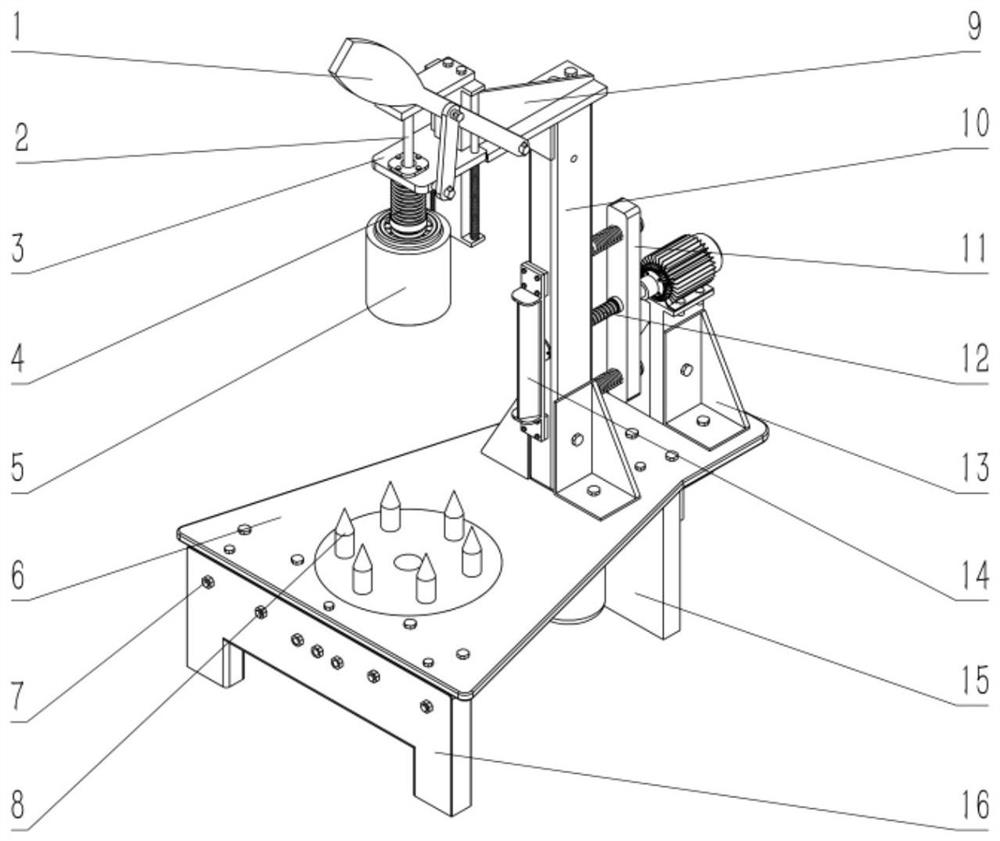

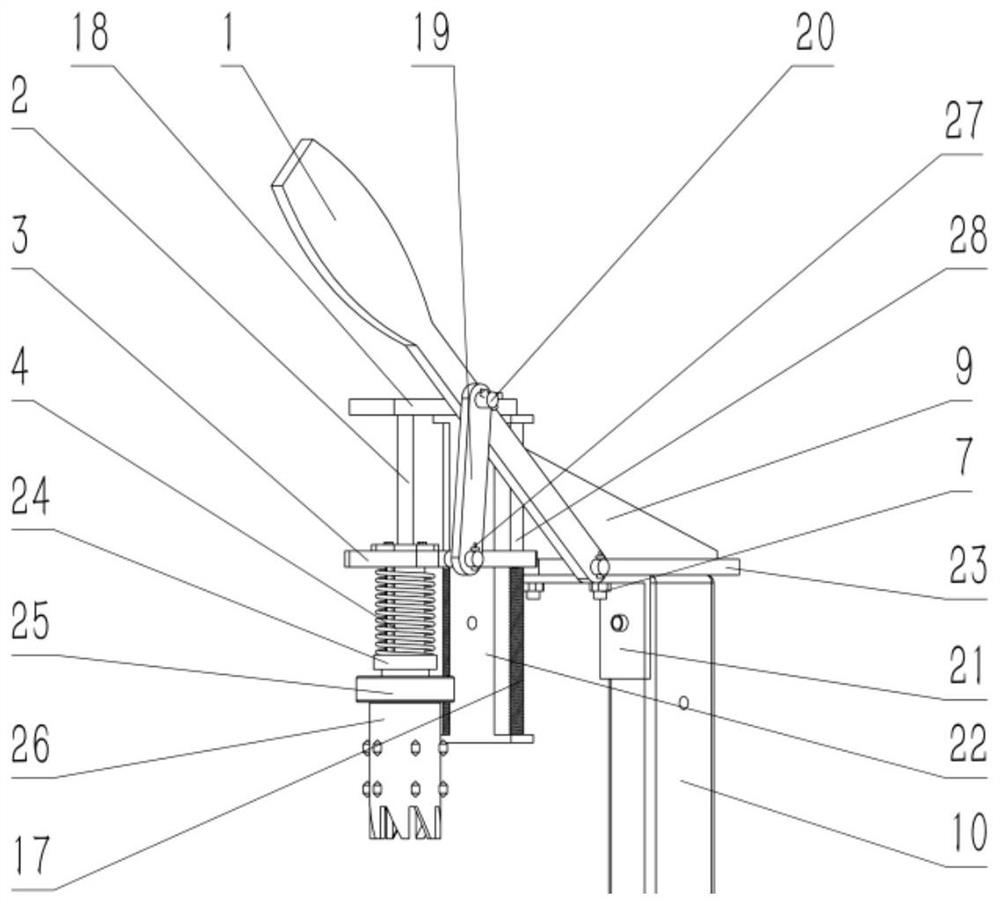

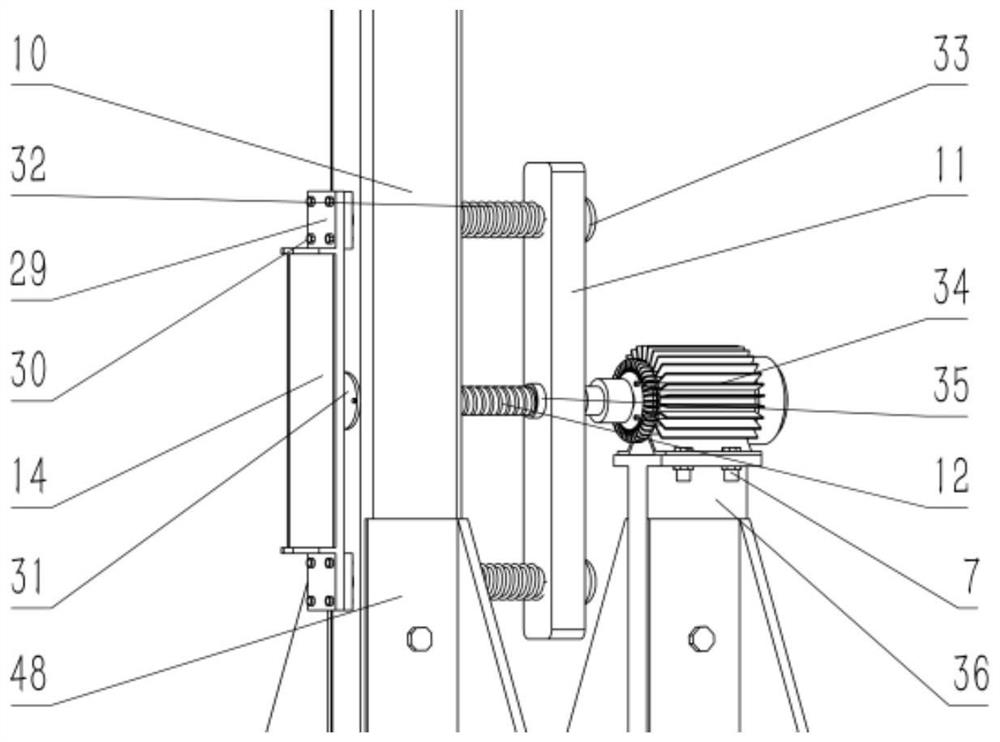

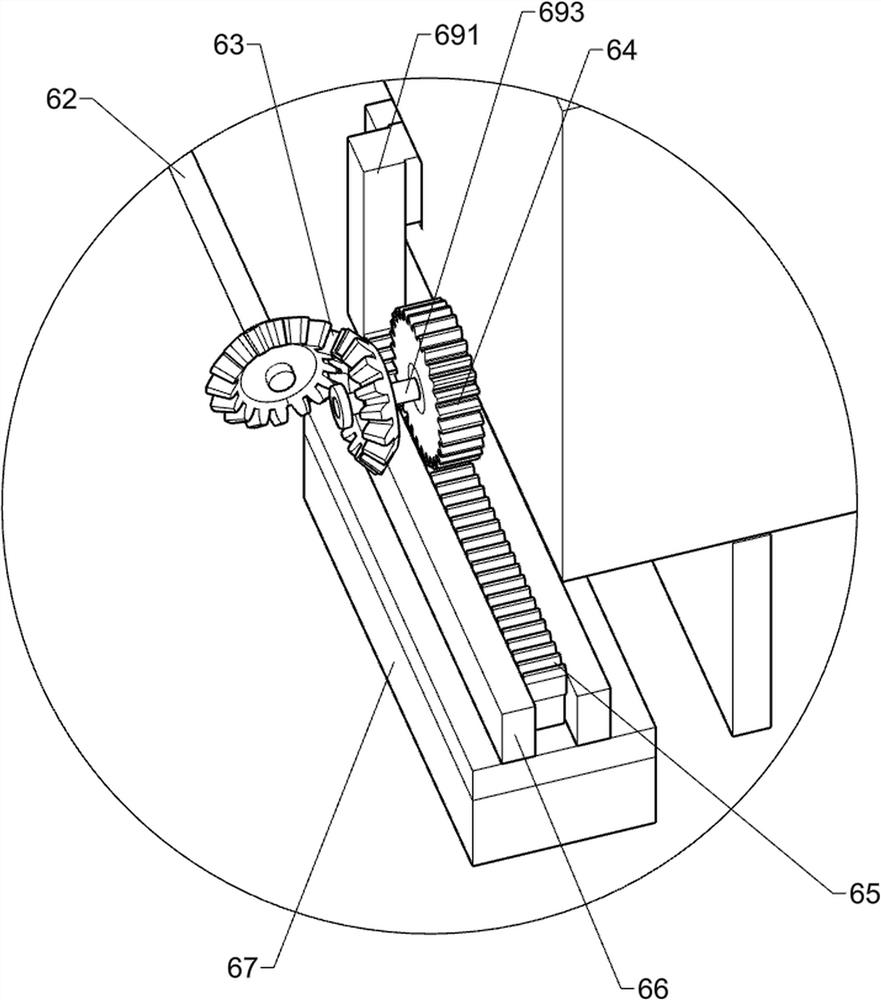

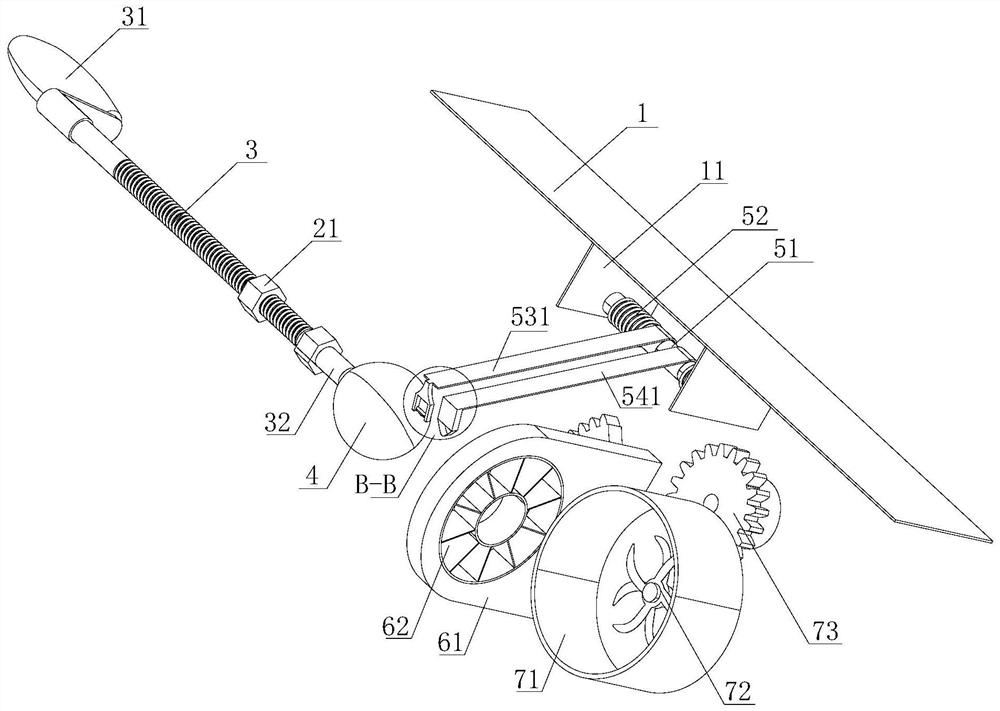

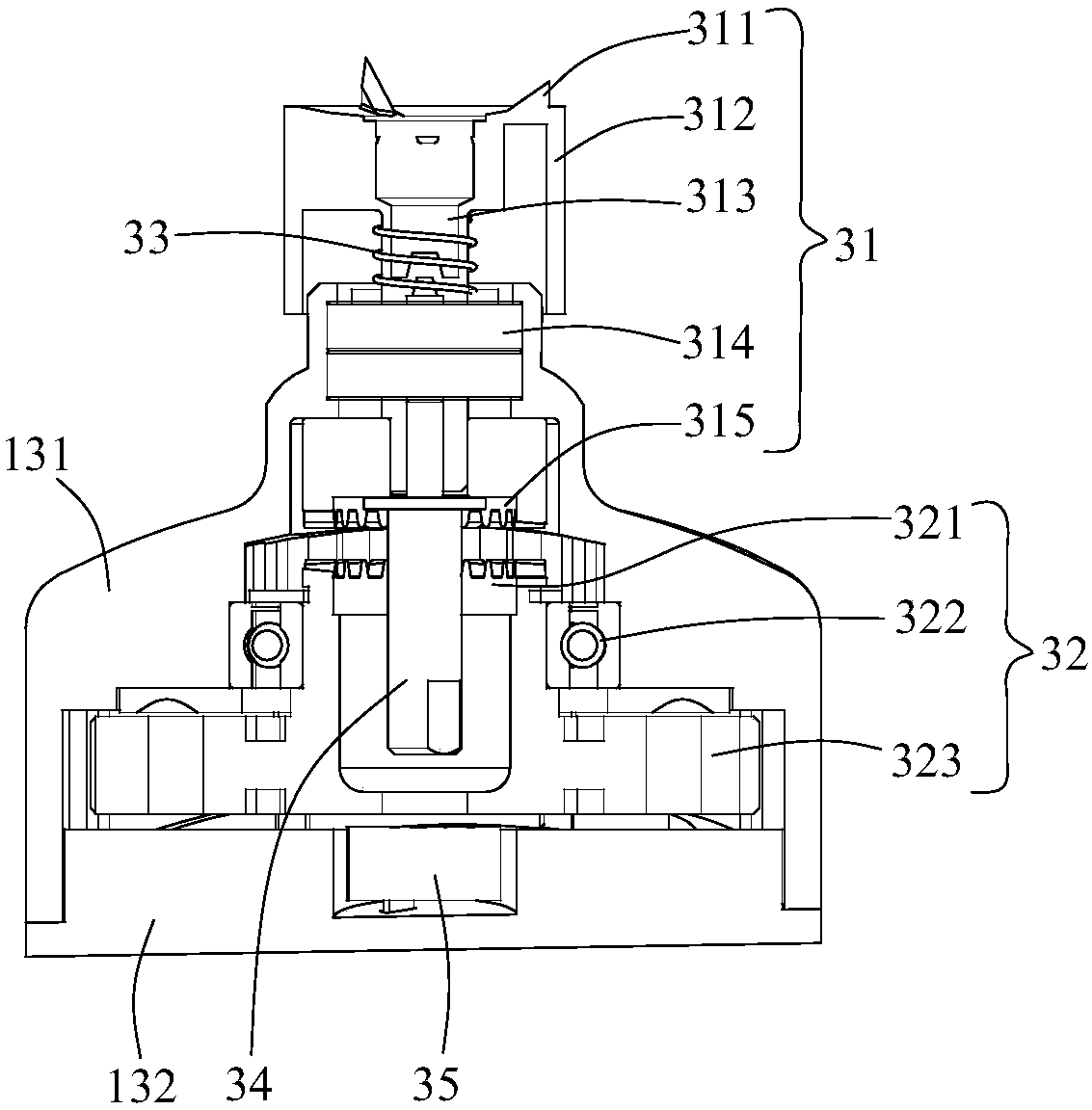

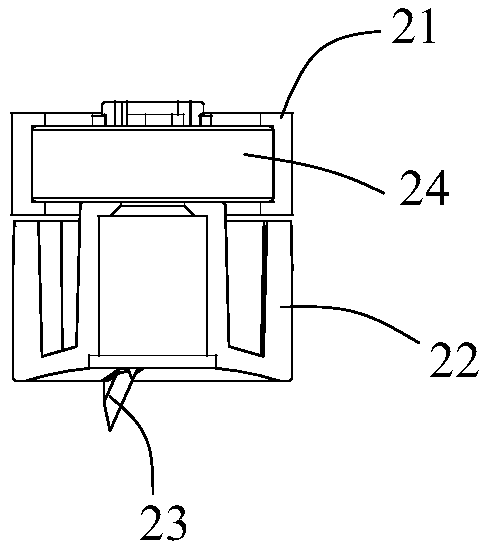

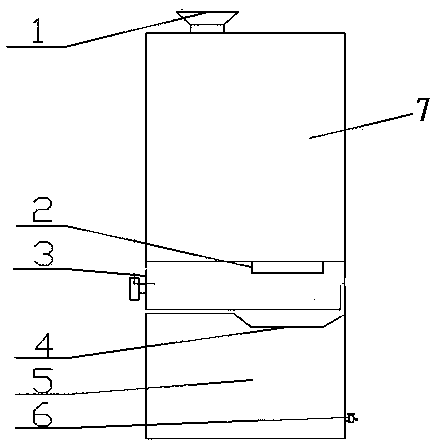

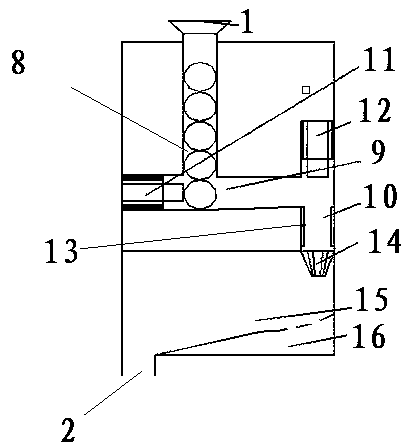

The invention discloses a multifunctional fruit peeling machine, belonging to the technical field of fruit peeling machines, comprises a frame, a support plate, a lead screw, a peeling knife, a cutting block mechanism and a juicer structure, wherein nuts installed in the support plate are connected with the lead screw through threads, the peeling knife is composed of a fixed shaft, a torque spring, a front peeling knife and a rear peeling knife, and the side surfaces of the front peeling knife and the rear peeling knife are provided with a cutting block mechanism fixedly installed on the top of the frame; A lump mechanism comprise a lump holder and a lump knife, a cutting knife is rotatably installed in the upper end groove of the cutting frame, The juicer consists of a container cup, a blade and a driving mechanism. The driving mechanism comprises an electric motor, a first gear, a second gear, a first half tooth, a second half tooth, a third gear and a fourth gear. The first half tooth and the second half tooth are fixedly installed from bottom to top on the rotating shaft where the second gear is located, and two identical blades are positively and reversely installed on the rotating shaft where the fourth gear is located. The invention can integrate the functions of peeling, nucleation and juicing, and realizes the diversification of functions.

Owner:广西宝酱园食品有限公司

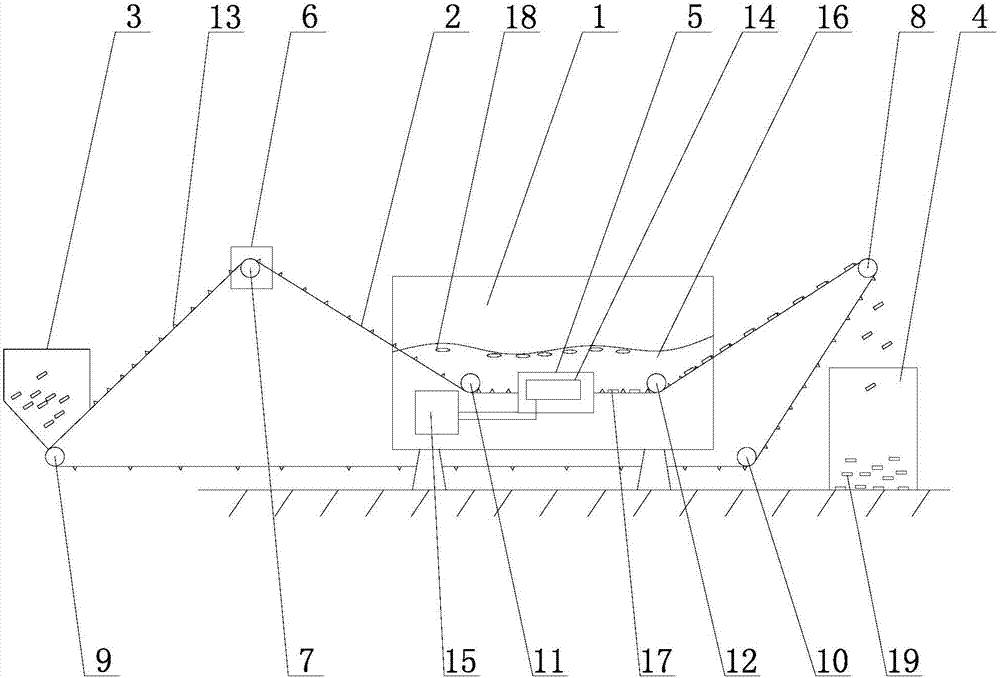

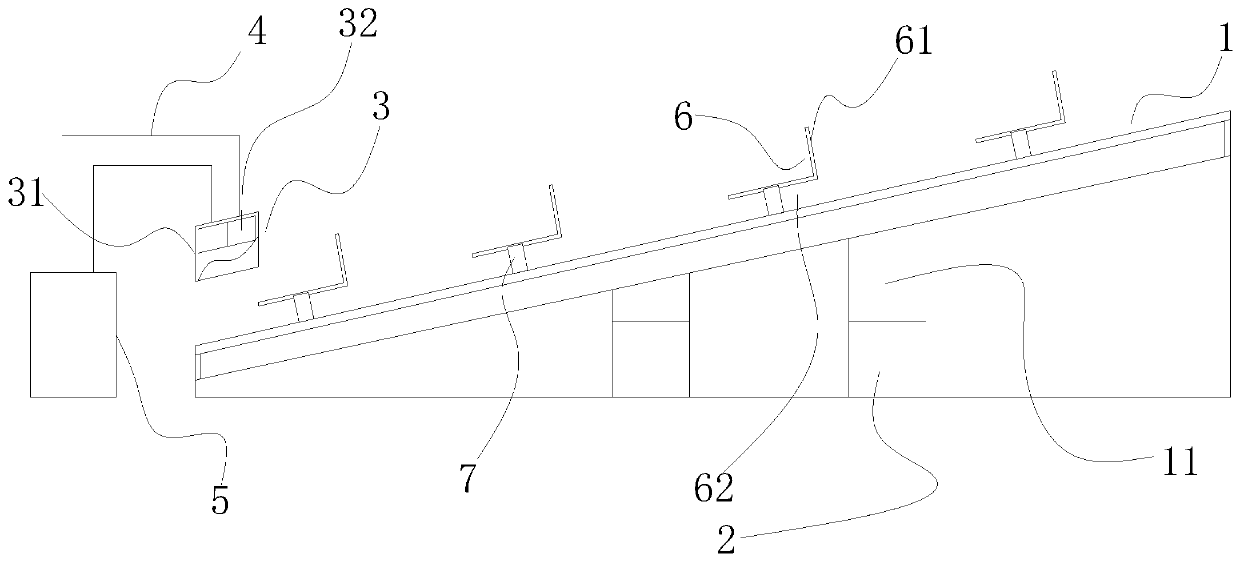

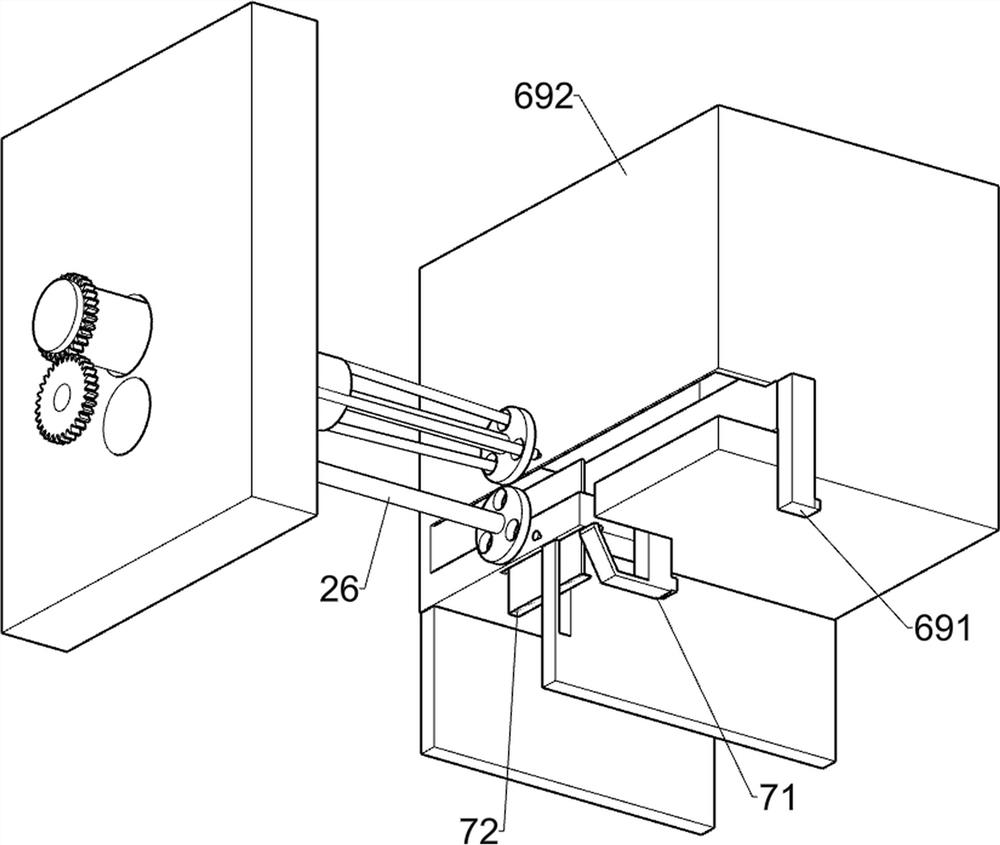

Sugarcane processing method

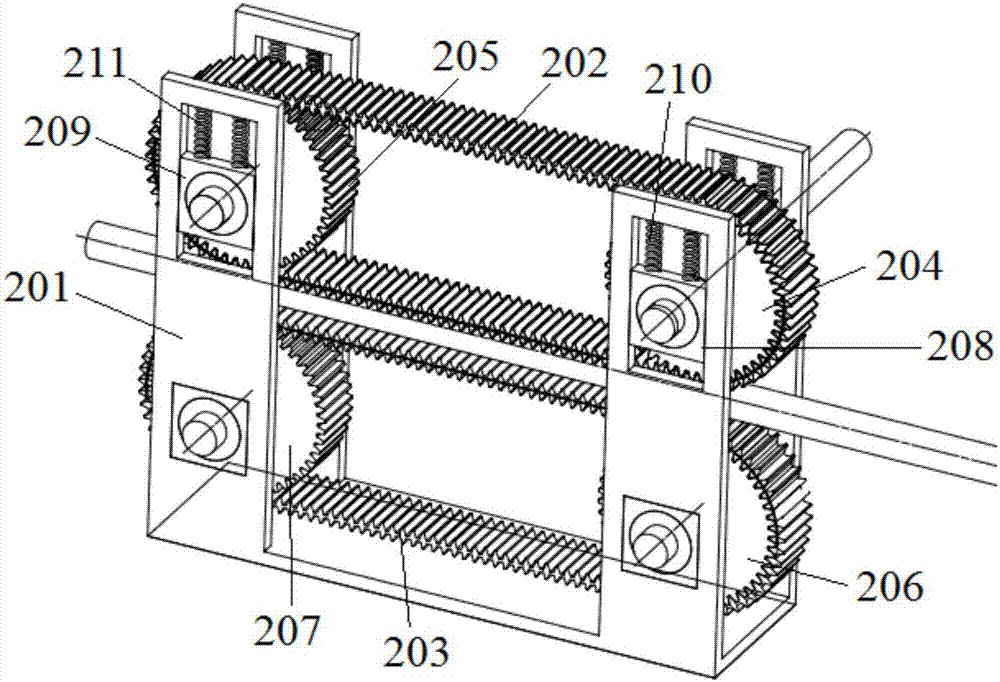

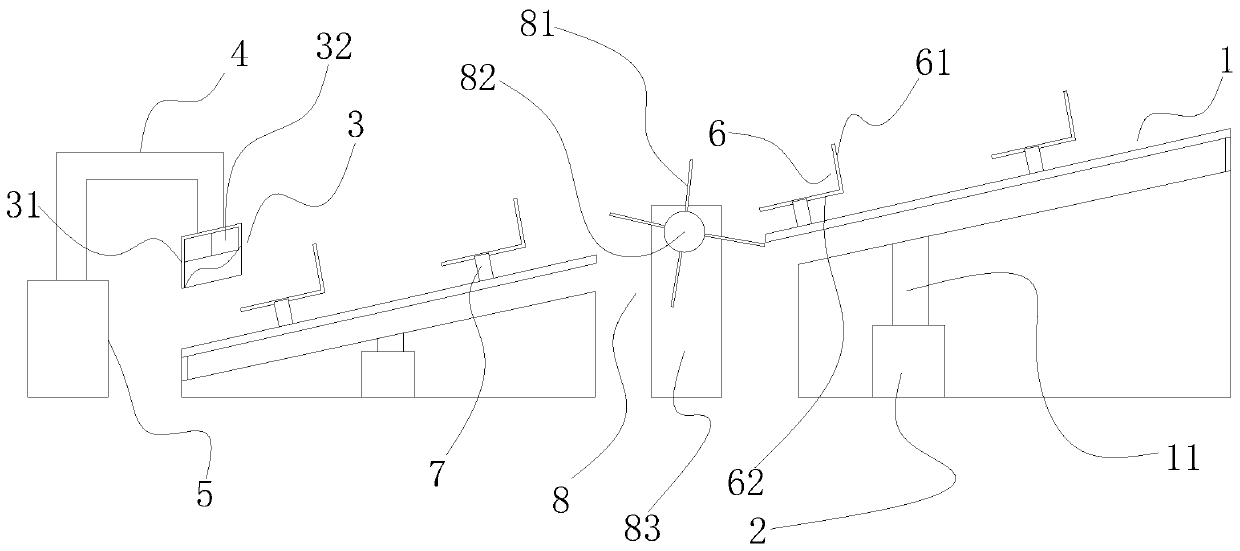

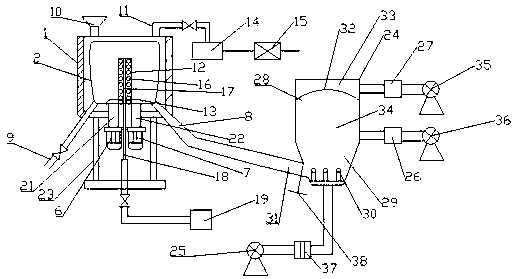

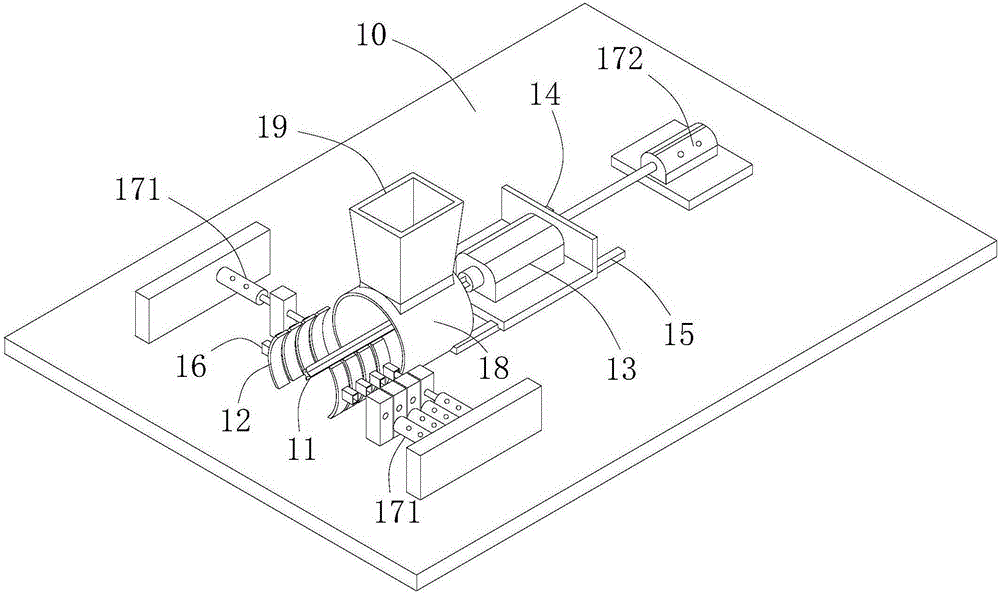

The invention discloses a sugarcane processing method. A sugarcane processing device is adopted and comprises a feeding device, a peeling device, a cutoff device and a separation device. The feeding device, the peeling device and the cutoff device are sequentially arranged in the first direction. The sugarcane processing method comprises the steps that the cutoff device cuts off peeled sugarcane and sugarcane peel, and the cutoff sugarcane and the sugarcane peel are received by the separating device, so that the sugarcane and the sugarcane peel are separated. According to the sugarcane processing method, the special sugarcane processing device is adopted, and the feeding device, the peeling device, the cutoff device and the separation device are matched, the sugarcane is peeled, and the sugarcane peeling operation safety and the peeling efficiency can be improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Potato slicer with peel removal function

Owner:LIAONING TECHNICAL UNIVERSITY

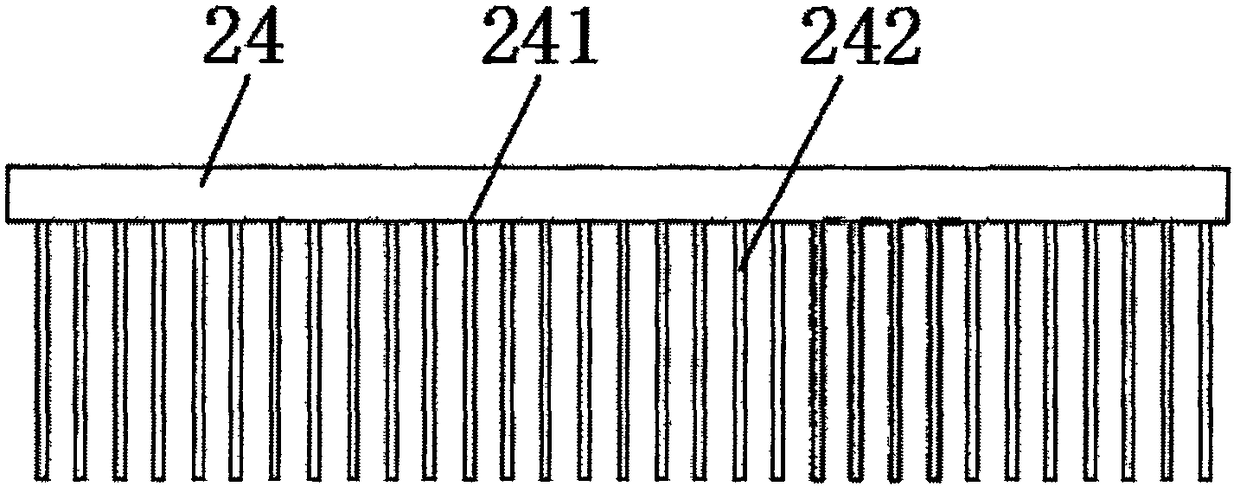

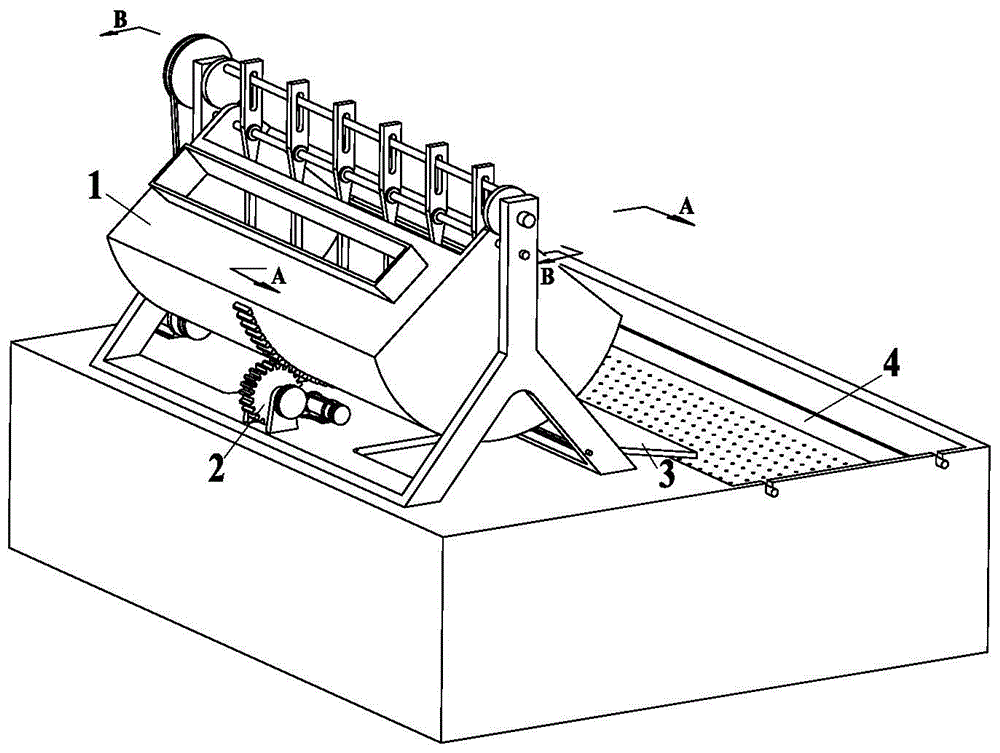

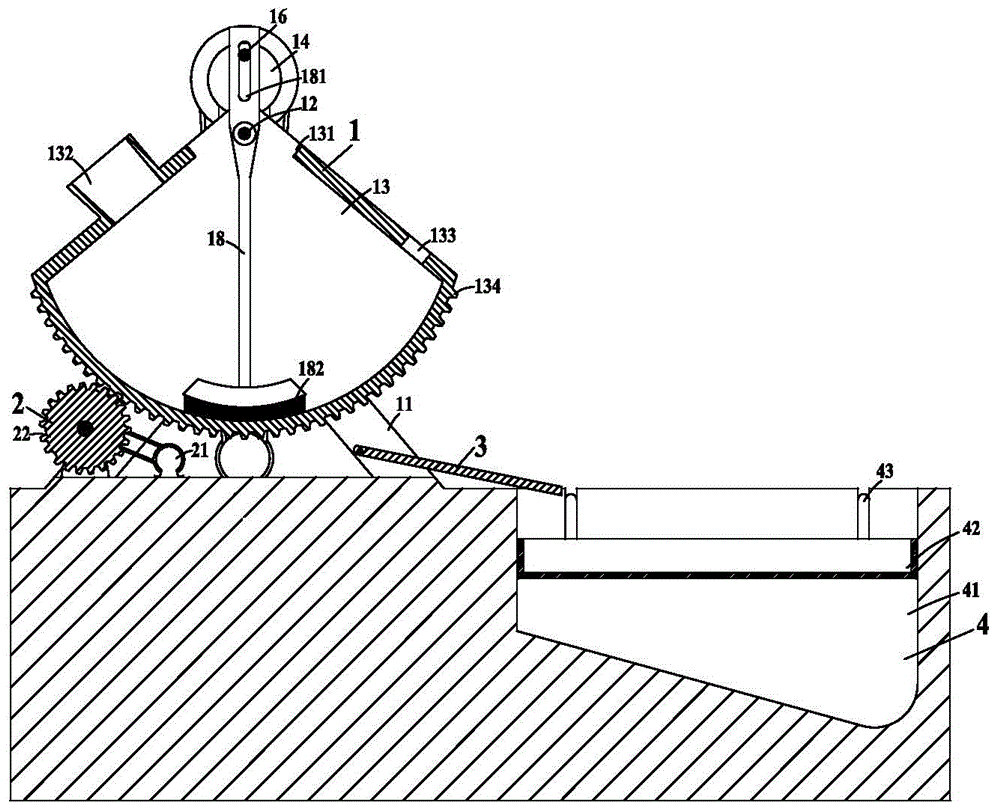

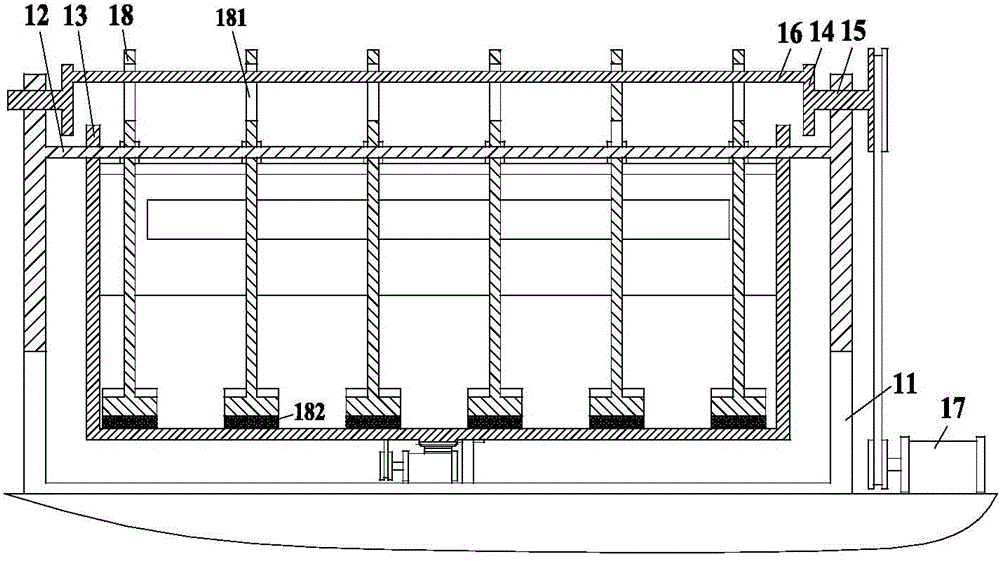

Sesame peeling and cleaning device

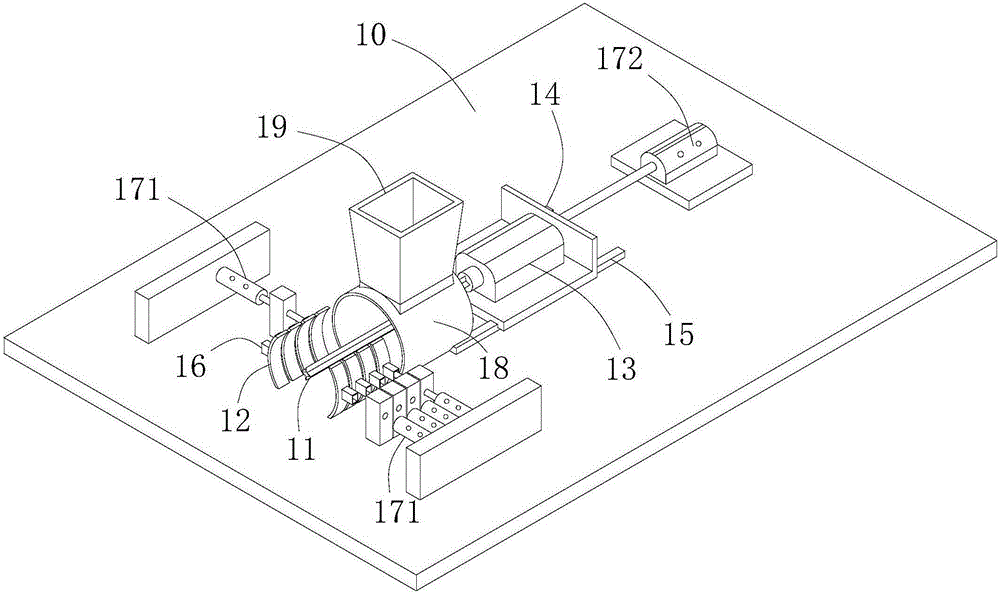

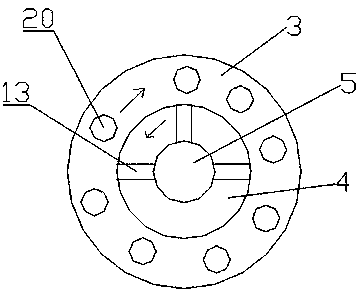

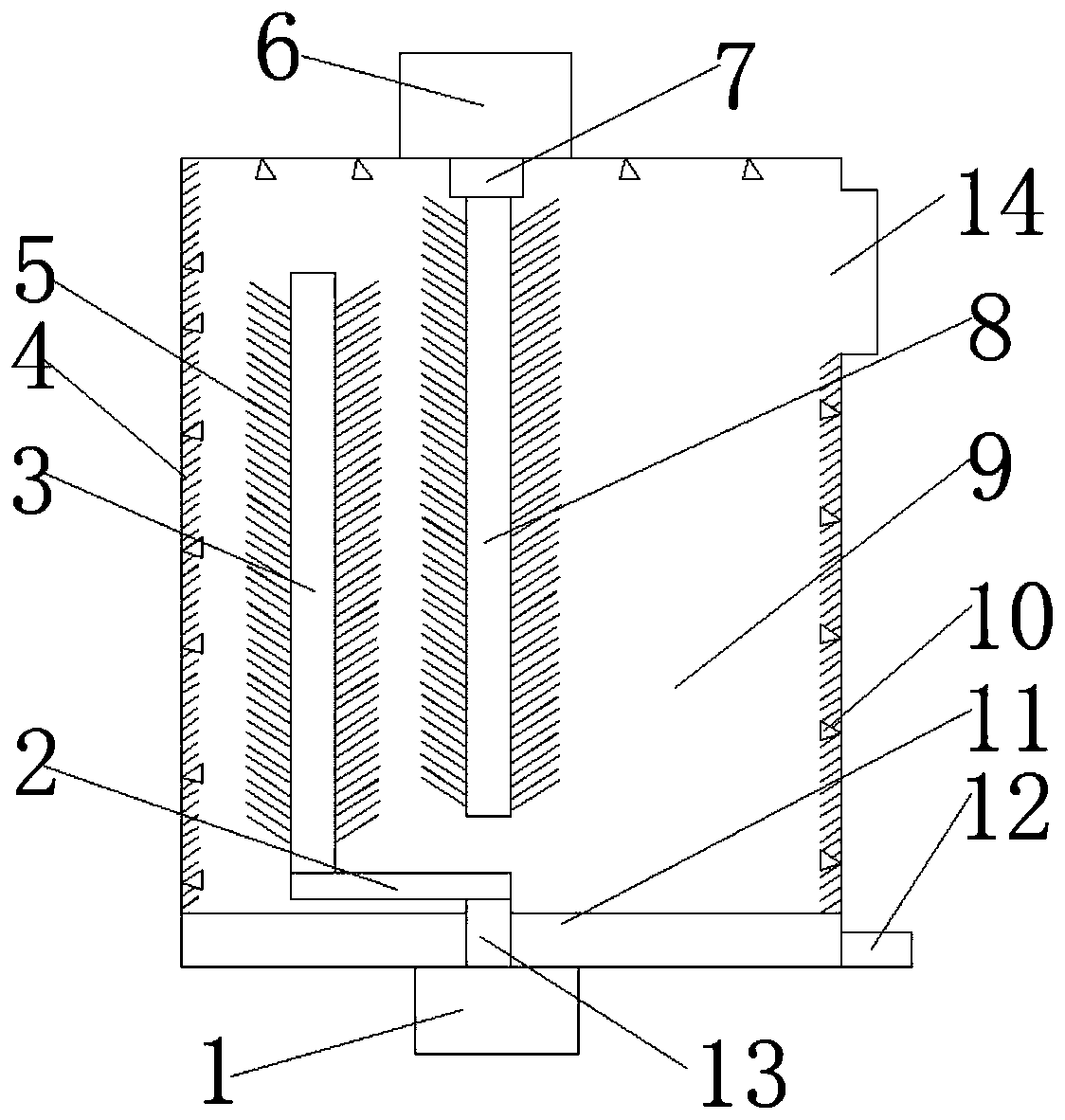

InactiveCN104962385APeeling achievedEffective peelingFatty-oils/fats productionDrive shaftEngineering

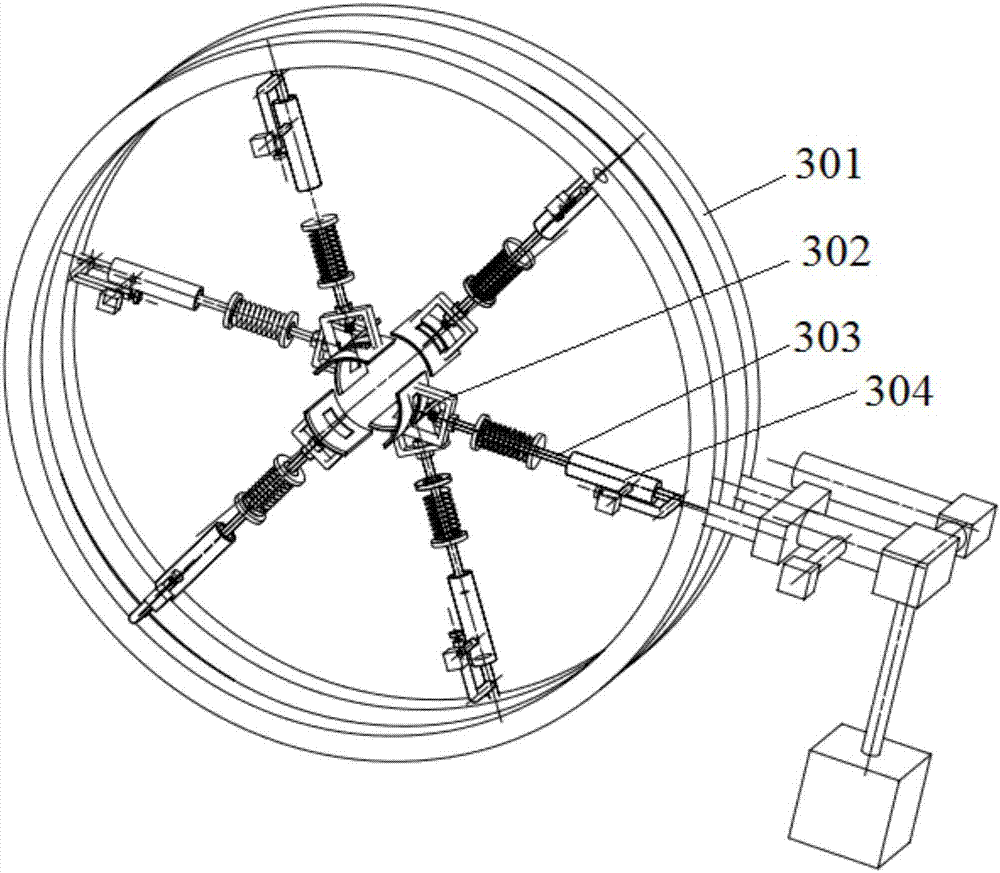

The invention relates to the field of sesame peeling and cleaning, in particular to a sesame peeling and cleaning device. The sesame peeling and cleaning device comprises a peeling device, an overturning device, a conveying plate and a cleaning device, wherein the overturning device is positioned under the peeling device; the conveying plate is positioned at the right side of the peeling device; the cleaning device is positioned at the right lower part of the peeling device; the peeling device comprises a support, a locating and supporting shaft, a shaking kettle, a rotating disc, a rotating shaft, a driving shaft, a peeling motor and rotation poking forks; the cross section of the shaking axe is fan-shaped; the lower ends of the rotation poking forks are provided with rubber hairbrushes; the overturning device comprises an overturning motor and an overturning gear; the cleaning device comprises a cleaning pool, a screening plate and hooks. According to the sesame peeling and cleaning device disclosed by the invention, efficient peeling of the sesame can be realized, and the automatic separating of the sesame and the peel and the cleaning of the sesame can be realized as the sesame can enter the cleaning pool after being peeled.

Owner:安徽中盛粮油进出口有限公司

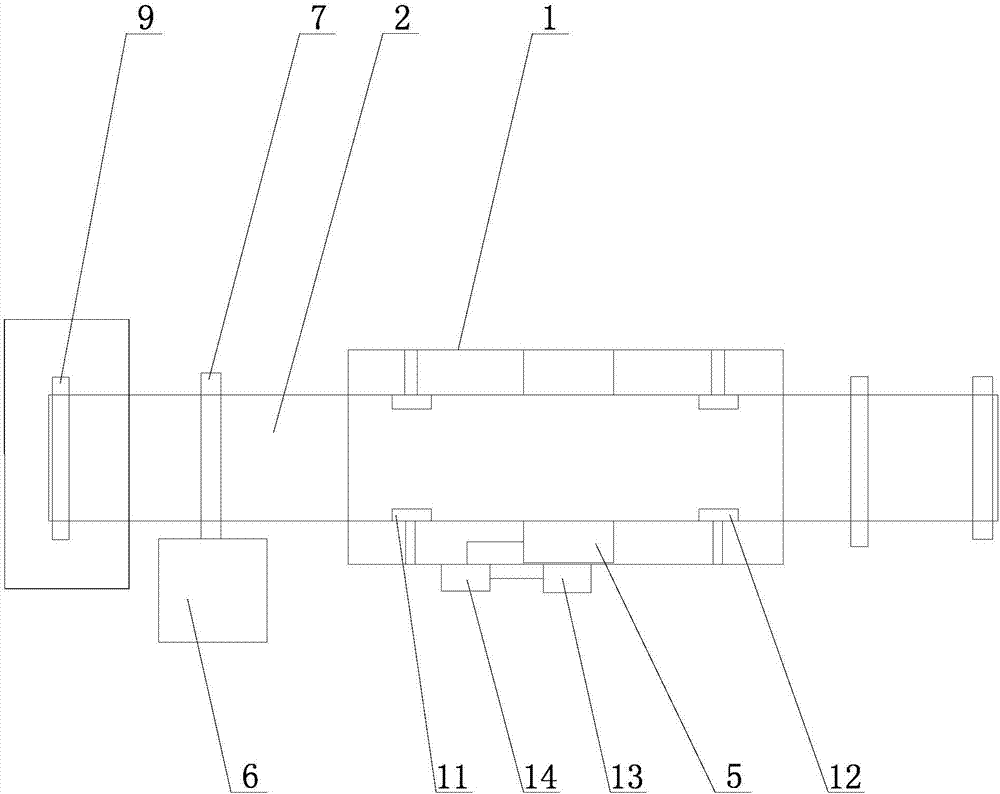

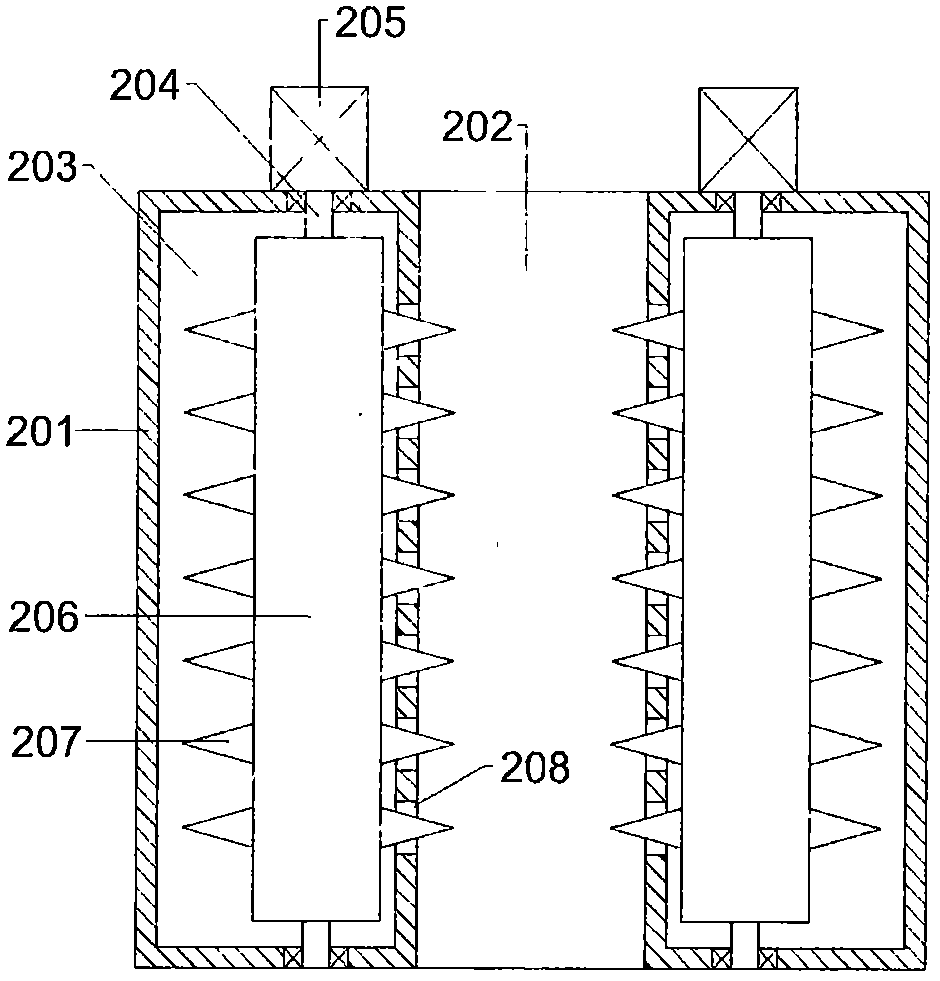

Ultrasonic garlic clove peeling device and method

InactiveCN107006878APeeling achievedImprove peeling efficiencyFood treatmentMechanical engineeringUltrasonic generator

The invention provides an ultrasonic garlic clove peeling device and method. The device comprises a container, a conveying belt penetrates into the container and installed on a driving device, a feed inlet is connected with one end of the conveying belt, a discharge opening is connected with the other end of the conveying belt, and an ultrasonic generator is arranged on the inner wall of the container. The device has the advantages of being simple in structure, capable of achieving peeling through ultrasound, high in peeling efficiency, high in peeling rate, low in bruise rate and the like.

Owner:SHANDONG MARIA MACHINERY

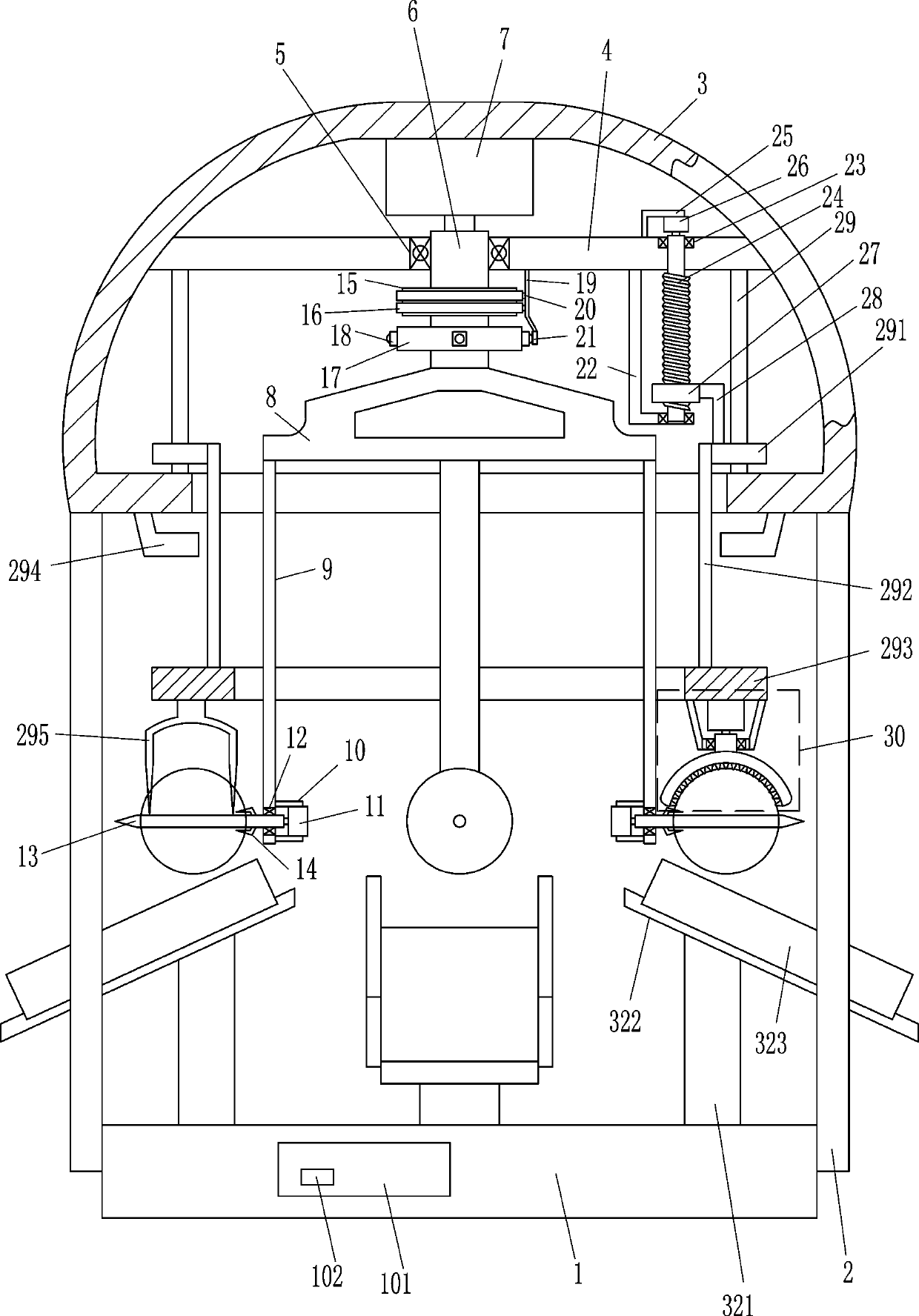

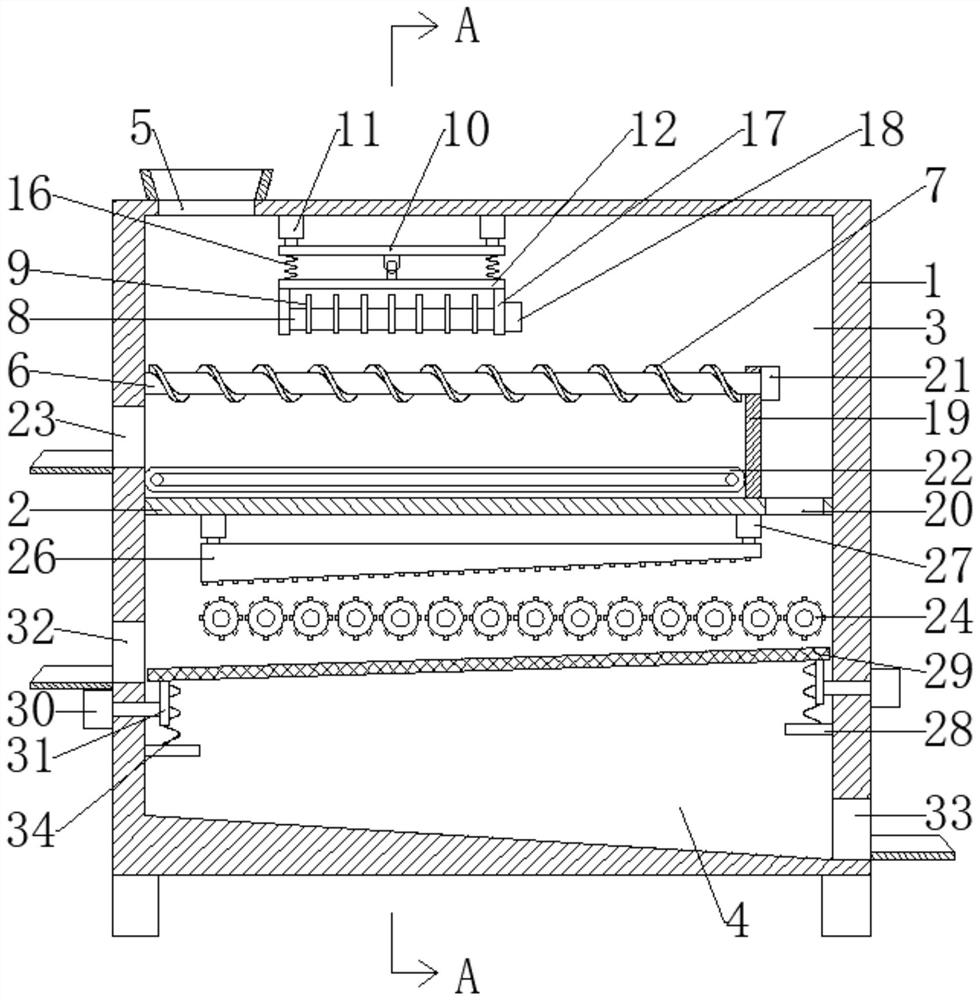

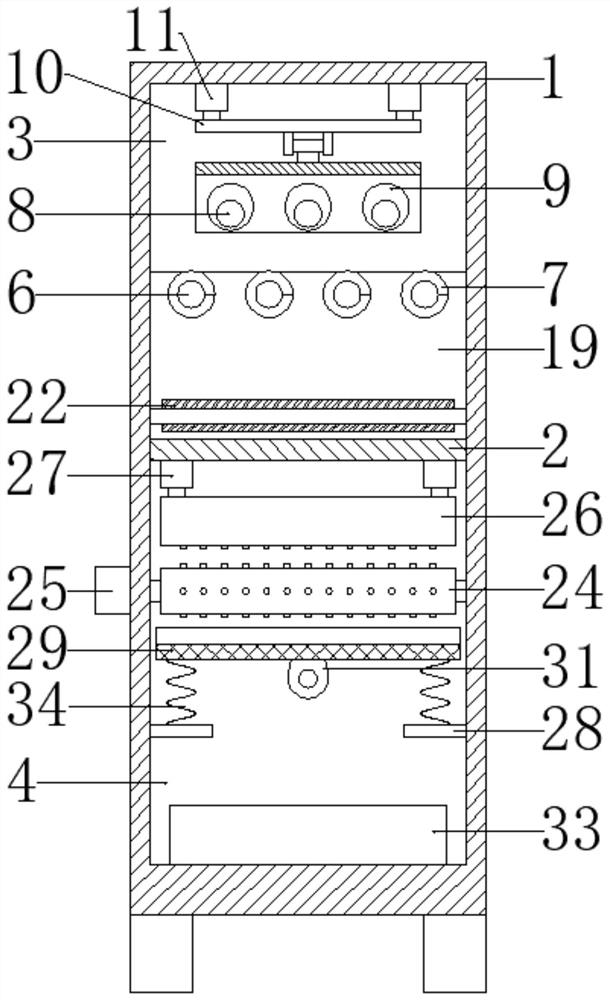

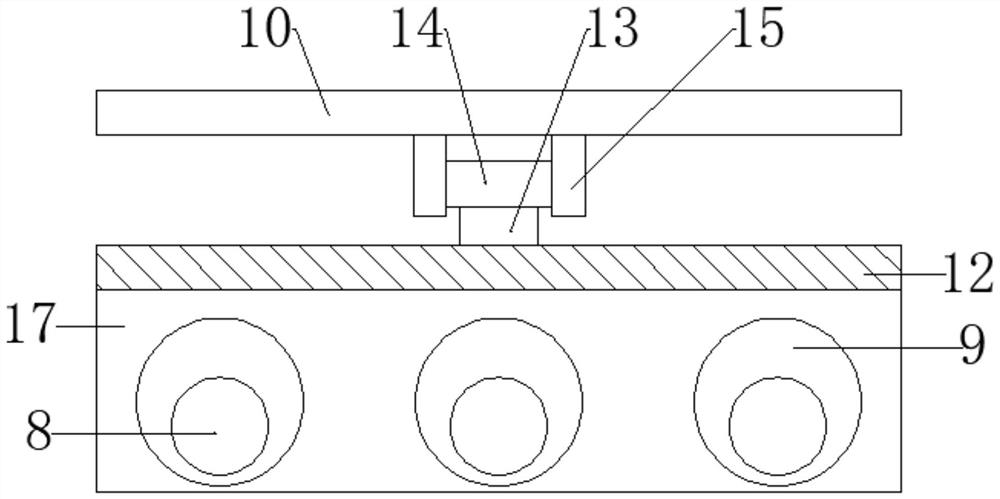

Intelligent processing equipment for mass production apples in apple orchard

InactiveCN110326798AImprove processing efficiencyThe processing process is clean and hygienicVegetable peelingMotor driveEngineering

The invention relates to processing equipment, in particular to intelligent processing equipment for mass production apples in an apple orchard and provides intelligent processing equipment for mass production apples in the apple orchard, which is relatively sanitary and integrates cleaning, peeling and collection functions to solve the technical problem. The technical scheme is as follows: the intelligent processing equipment for mass production apples in the apple orchard comprises a bottom plate, a control box, a battery main switch, a support plate, an arc box, a connecting plate, a firstbearing seat, a first rotating rod and the like, wherein the control box is mounted on the left side of the front side of the bottom plate and comprises a power module and a control module, the powermodule is connected with a switching power supply through a wire, and the control module is connected with the power module through a wire. A first gear motor drives a mounting rack to rotate continuously to drive a puncture rod to move continuously, so that cleaning, peeling, end cutting and apple pushing can be sequentially performed, the apple processing efficiency is improved, meanwhile, touchof apples by human hands is not required, and the processing process is relatively clean and sanitary.

Owner:申丽丽

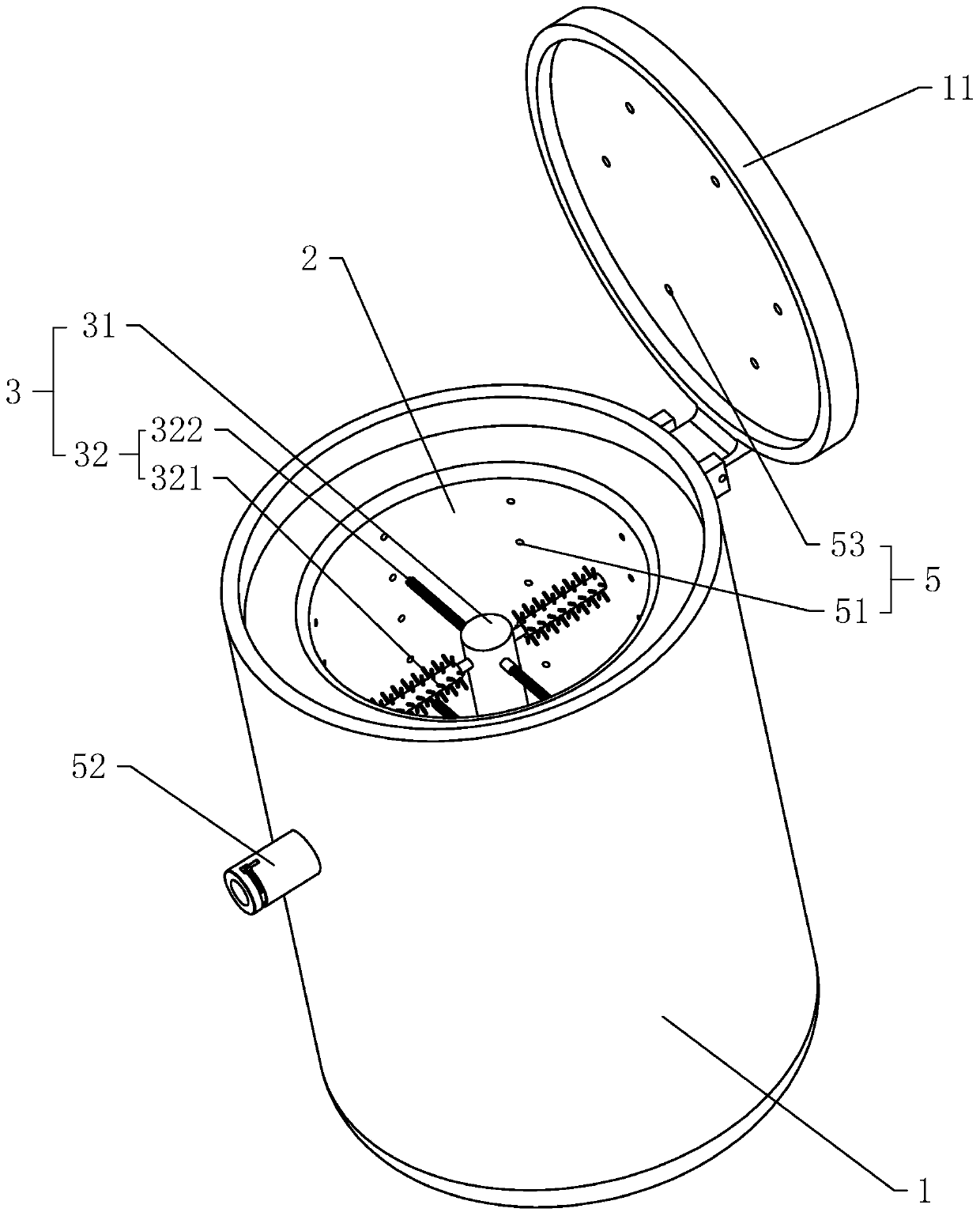

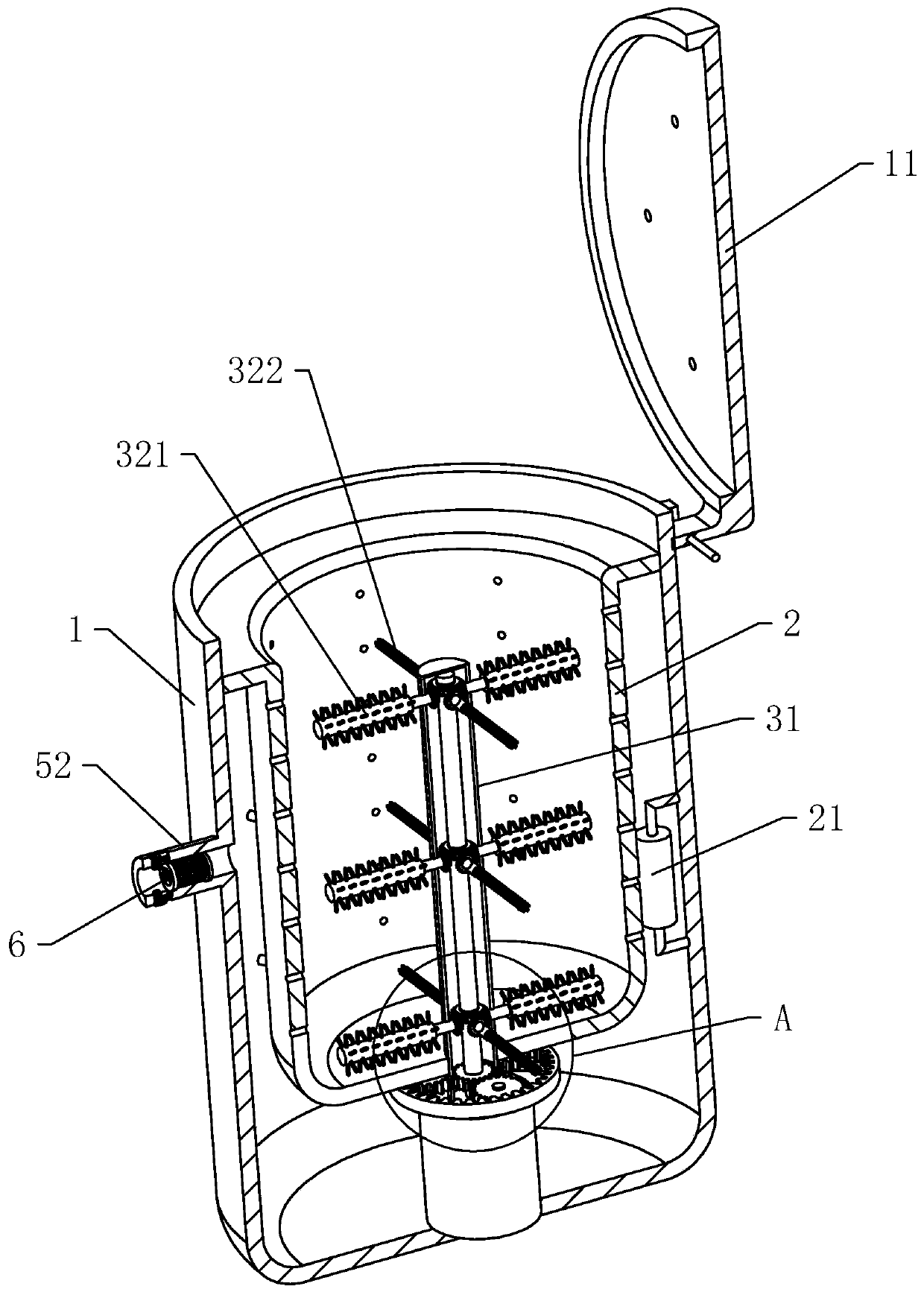

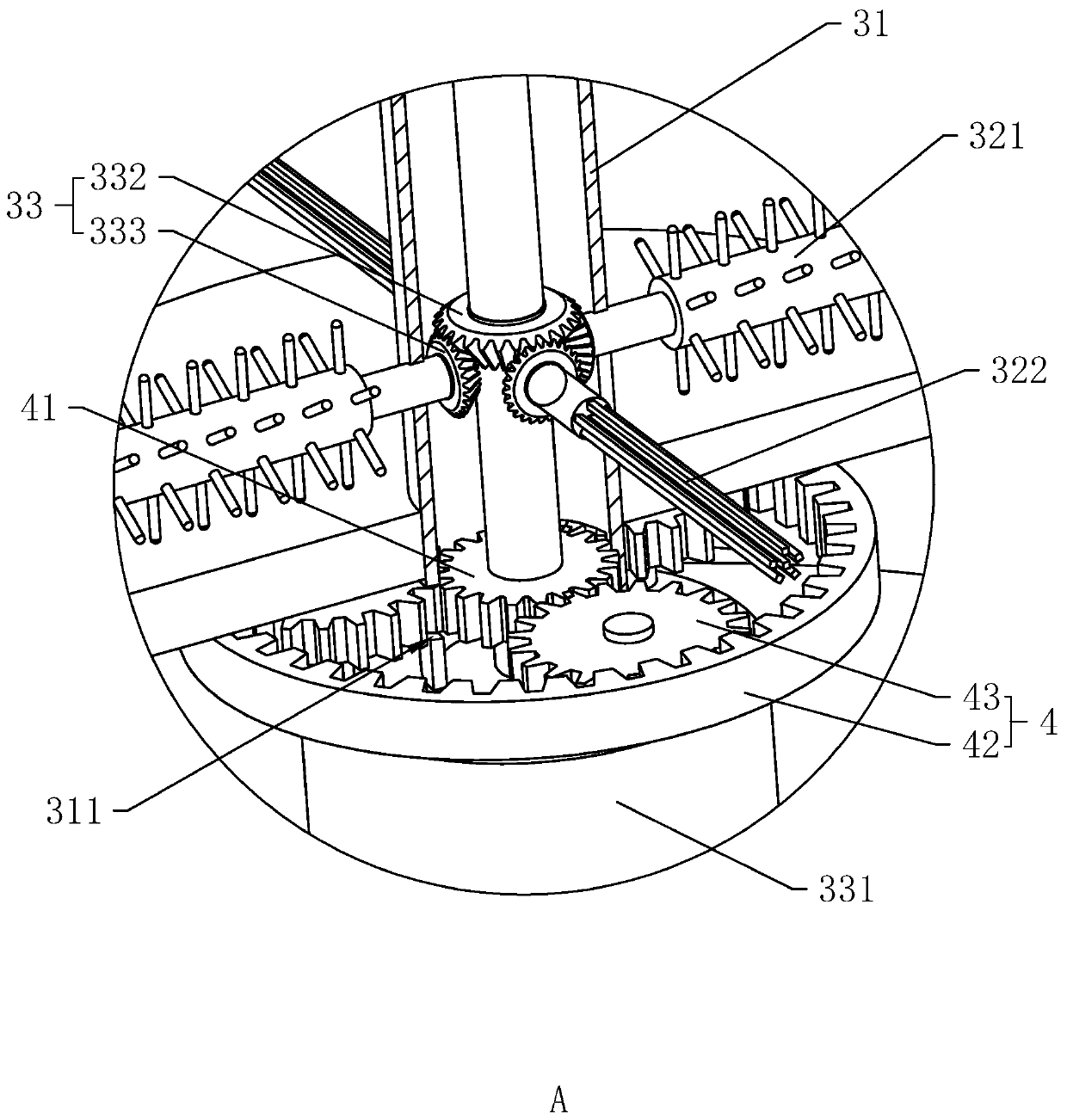

Berry peeling machine

ActiveCN109953354AReduce damageGood storage and transportVegetable peelingAgricultural engineeringAgricultural machinery

The invention discloses a berry peeling machine, which relates to the agricultural machinery, and is used to solve the problem that the ordinary peeling machines are easy to cause berry damage. The berry peeling machine includes an outer shell barrel, a material barrel disposed in the outer shell barrel, and a peeling mechanism disposed on the outer shell barrel. The peeling mechanism comprises atransmission cover, a soft peeling roller rotatably mounted on the transmission cover and used for rubbing the berries, and a transmission component disposed in the transmission cover for driving thesoft peeling roller to rotate. The berry peeling machine has the following advantages and effects that the soft peeling roller can reduce the damage to the berries while achieving the peeling of the berries, so that the berries can be better preserved and transported, and the cooperation between a soft brush and a silicone strip brush can better separate a film from the berries, so that the peeling machine has better peeling effect.

Owner:浙江双普工贸有限公司

Bean sprout peeling machine

The invention discloses a bean sprout peeling machine. The bean sprout peeling machine comprises at least two vibrating screens, turnover devices, blowing devices and an air suction device. In the conveying direction of bean sprouts, the tail ends of the screen faces of the vibrating screens are arranged obliquely downwards relative to the horizontal plane, and the turnover devices are arranged between the two adjacent vibrating screens. At least one blowing outlet is formed in the lower part of the screen face of each vibrating screen. The blowing devices enable blowing outlets of the blowingdevices to align with the screen faces of the vibrating screens through the blowing outlets, the air suction device is arranged on the upper part of the screen face of a last vibrating screen at thetail end, and the air suction device is connected with a collection net cage through an air duct. Therefore, compared with the prior art, the bean sprout peeling machine has the advantage of good peeling effects.

Owner:安徽绿色根据地农业科技有限公司

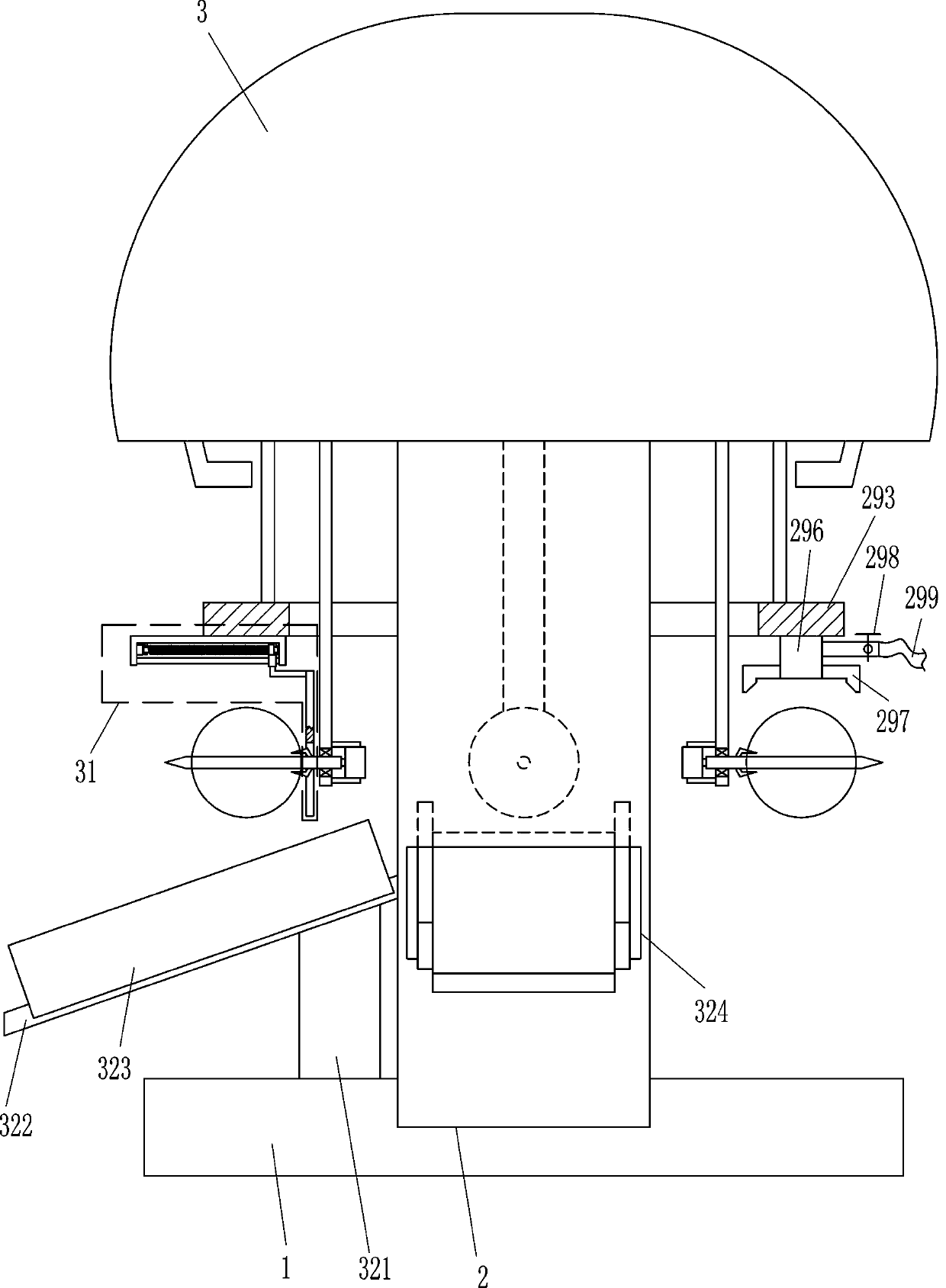

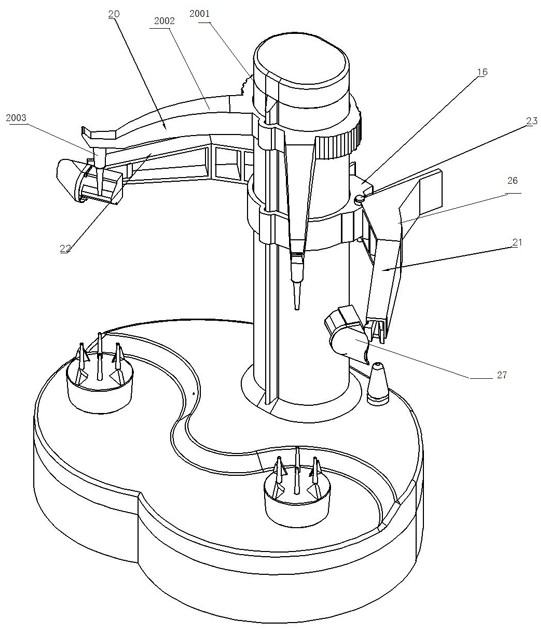

Coconut shelling and peeling machine

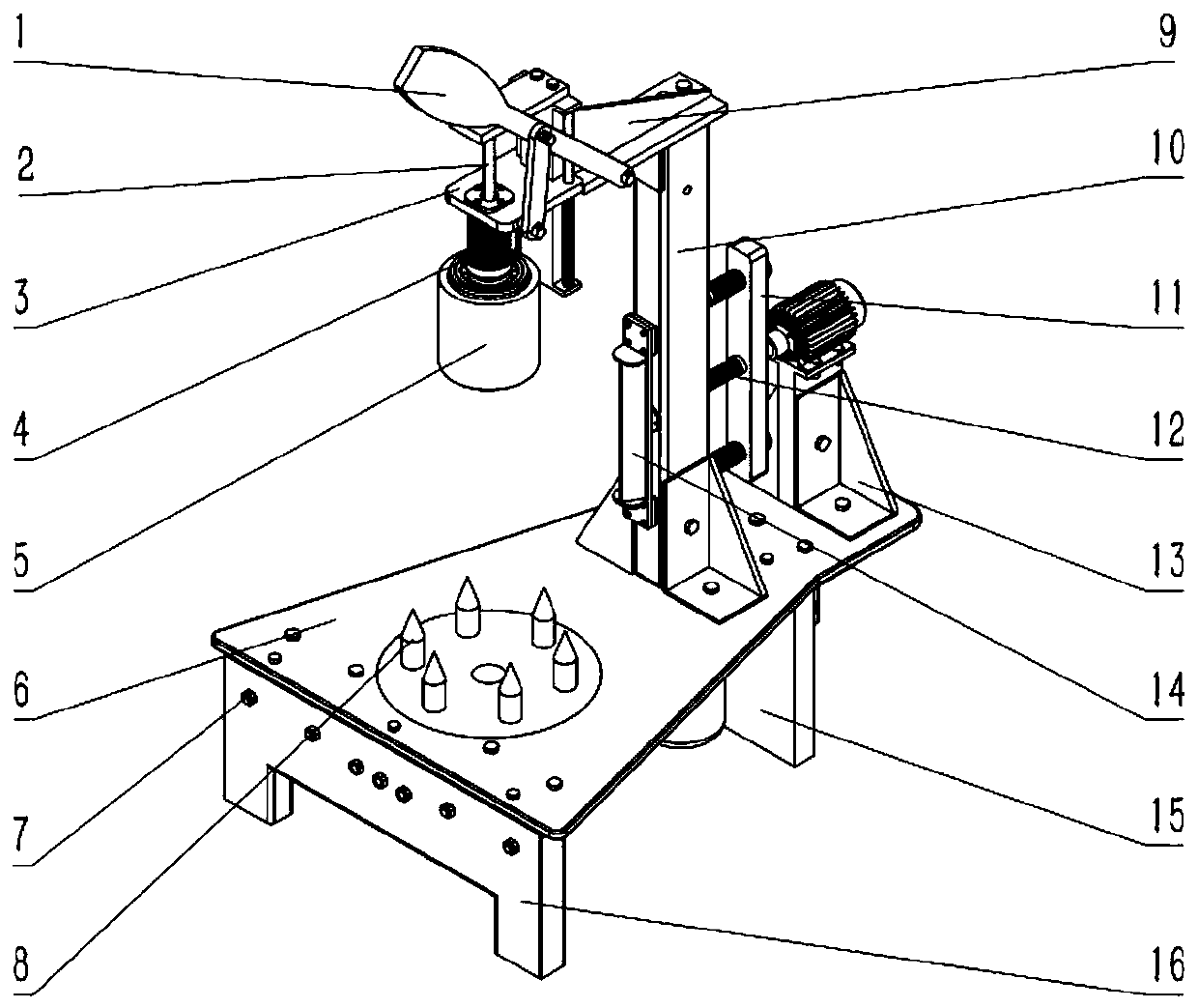

The invention discloses a coconut shelling and peeling machine, which comprises a rotating plate connected to a bottom plate. A front footing plate and a rear footing plate are arranged at the bottomof the bottom plate parallelly and perpendicular to the horizontal plane, a plurality of nails with upward tips are uniformly fixed to the rotating plate, a fixing mechanism is arranged at the bottomof the rotating plate, and a peeling mechanism is arranged on the bottom plate through a supporting frame. A shelling mechanism is arranged on a supporting plate which is vertically connected to the top of the supporting frame, a shelling tool of the shelling mechanism and the rotating plate are in vertically linear corresponding relationship, and a space formed by the shelling tool and the rotating plate corresponds to a side knife of the peeling mechanism. By the coconut shelling and peeling machine, problems of high potential safety hazards, complexity in operation, low efficiency and failure in guarantee of quality and sanitation in coconut peeling the prior art are solved.

Owner:XIAN UNIV OF TECH

Bean sprout peeling machine

The invention discloses a bean sprout peeling machine. The bean sprout peeling machine comprises a vibrating screen, a blowing device and an air suction device. In the conveying direction of bean sprouts, the tail end of the screen surface of the vibrating screen is arranged obliquely downwards relative to the horizontal plane, at least one blowing outlet is formed in the lower part of the screensurface of the vibrating screen. The blowing device enables blowing outlets of the blowing device to align with the screen surface of the vibrating screen through the blowing outlets, the air suctiondevice is arranged on the upper part of the screen surface of the vibrating screen, the air suction device is connected with a collection net cage through an air duct, and from the front end to the tail end of the vibrating screen, the blowing device and the air suction device are arranged in sequence. Therefore, compared with the prior art, the bean sprout peeling machine has the advantages of high working efficiency and good peeling effects.

Owner:安徽绿色根据地农业科技有限公司

Novel machine for peeling potatoes

The invention discloses a novel machine for peeling potatoes. The machine comprises a slotting tool, one end of the slotting tool is connected to a driving mechanism, the periphery of the other end of the slotting tool is provided with a peeling mechanism comprising a peeling plate, the peeling plate is fixed to the pedestal in a floating mode, a side face close to the slotting tool of the peeling plate is provided with a peeling layer made from cleaning wire ball, the peel plate is made from plastic material, and the slotting tool has a cross section. According to the peeling device composed by the above technical scheme, a potato can be rotated by the slotting tool to be rubbed by the cleaning wire ball at the inner face of the peeling plate, to scrub the peel of the potato so as to peel the potato. The novel machine is high in peeling efficiency, low in damage to potato, high in production efficiency and low in production cost.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Complete peeling and separation device with opening function for lotus seeds

The invention provides a complete peeling and separation device with an opening function for lotus seeds. The device includes a shell; a large-particle opening device is fixedly connected to the middle of the top of the shell; a screen is fixedly connected to the lower side of the large-particle opening device inside the shell; the screen is obliquely arranged towards the lower right, and the right part of the screen is provided with a falling through hole; the left side of the falling through hole on the screen is fixedly connected to a first flow guide plate; the first flow guide plate is obliquely arranged towards the lower left, and the left end of the first flow guide plate is connected to a small-particle opening device; the inner side wall of the shell is fixedly connected to a second flow guide plate below the small-particle opening device; the second flow guide plate is funnel-shaped; and a peeling device is fixedly connected to the middle part of the lower side of the secondflow guide plate. The device has the following beneficial effects: firstly: a first rotating shaft drives a first rotating cylinder to rotate, and the first rotating cylinder drives first opening teeth to rotate, and the first opening teeth are exposed from a through groove so as to carry out opening treatment on superficial shells of the lotus seeds.

Owner:何小平

A kind of integrated corn harvesting device

The invention relates to the technical field of agricultural machinery, in particular to an integrated harvesting device for corn, which includes a box body, and a partition board is fixedly installed in the box body, and the partition board divides the inner cavity of the box body into a A peeling chamber and a threshing chamber located below, the peeling chamber is provided with a peeling mechanism, and the threshing chamber is provided with a threshing mechanism; the top of the box body is provided with a feed port communicated with the peeling chamber, The right side of the box body is provided with a discharge port that communicates with the threshing chamber, and the partition plate is provided with a port that communicates with the peeling chamber and the threshing chamber; the present invention drives the corn through the conveying roller. When the ear moves, it drives the ear of corn to rotate. When the conveying roller drives the ear of corn to move below the cutting shaft, the corn husk is chopped by the cutting knife, so as to realize the peeling of the ear of corn, and the peeling efficiency is high.

Owner:HENAN VOCATIONAL COLLEGE OF AGRI

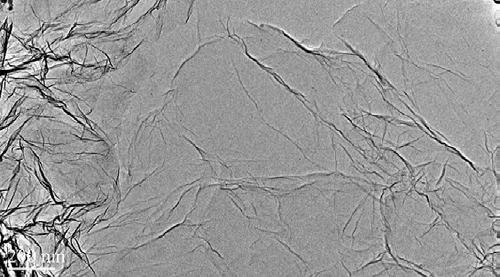

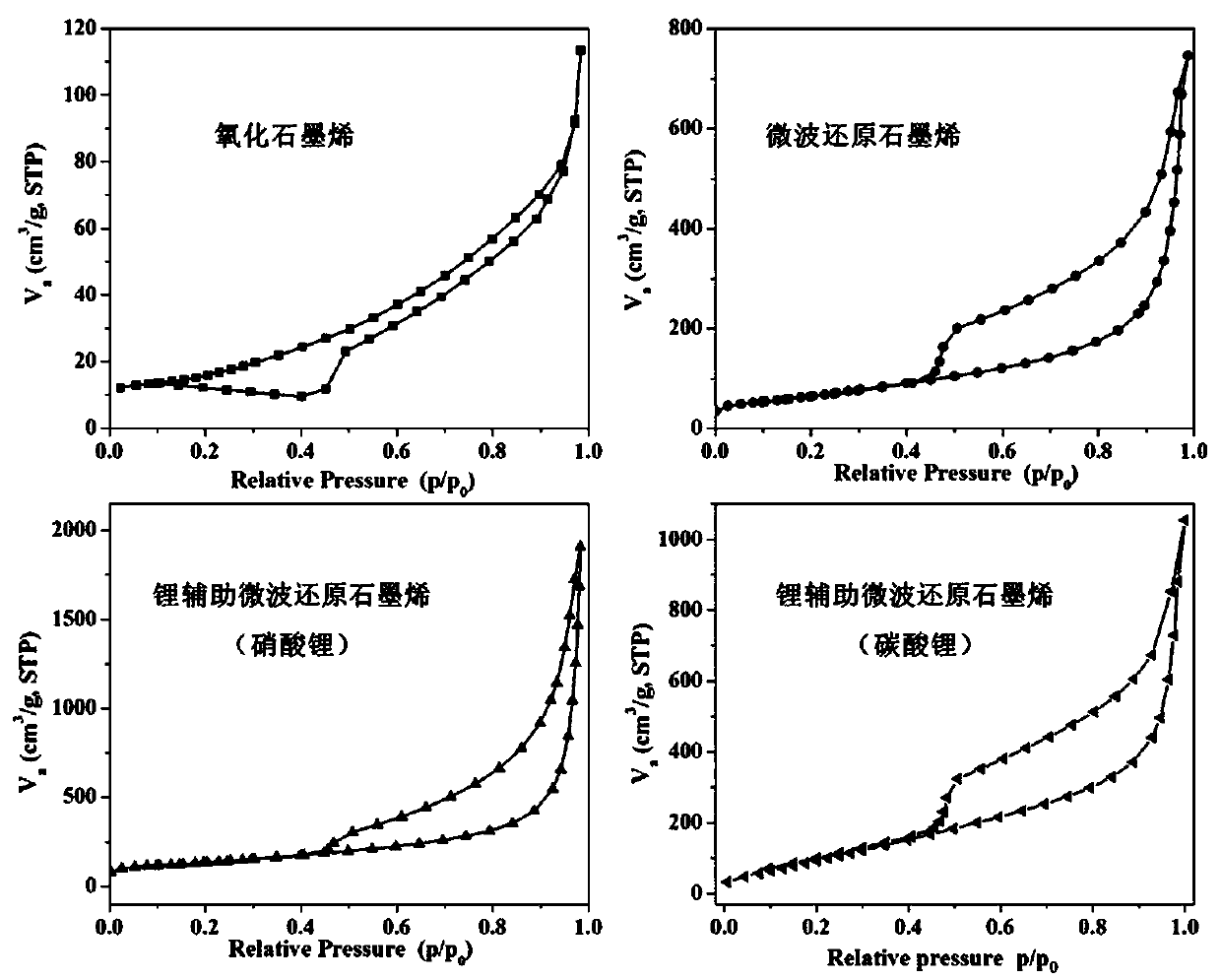

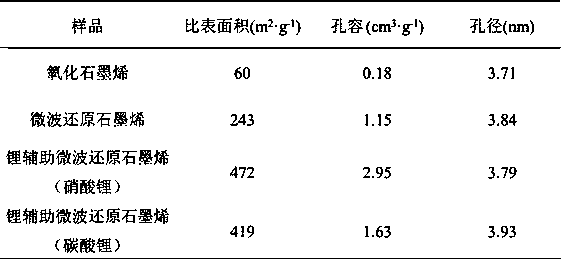

Method for reducing exfoliated graphene oxide by lithium-assisted microwave thermal expansion method

The invention relates to the field of nano carbon material preparation, in particular to a method for reducing exfoliated graphene oxide by a lithium-assisted microwave thermal expansion method. The preparation of lithium-assisted microwave reduction graphene is completed under the conditions of ultrasonic treatment, blast drying and microwave heating, in the microwave heating process, oxygen-containing functional groups on graphene oxide fall off to be released as gas, pressure is generated, thermal expansion occurs among graphene layers to peel off, and high-quality graphene is prepared at low temperature and normal pressure. In the microwave heating process, the decomposition rate of the oxygen-containing functional groups in the graphene oxide is higher than the diffusion rate of the generated gas, and the Van der Waals' force capable of overcoming the combination of graphene sheet layers is generated, so that reduction and exfoliation are achieved. The existence of lithium breaks an original electronic structure and is more beneficial to exfoliation of the graphene sheet layers. The preparation method is simple in process, high in preparation speed and low in cost and can be used for large-scale production, and the product is black floccules.

Owner:TAIYUAN UNIV OF TECH

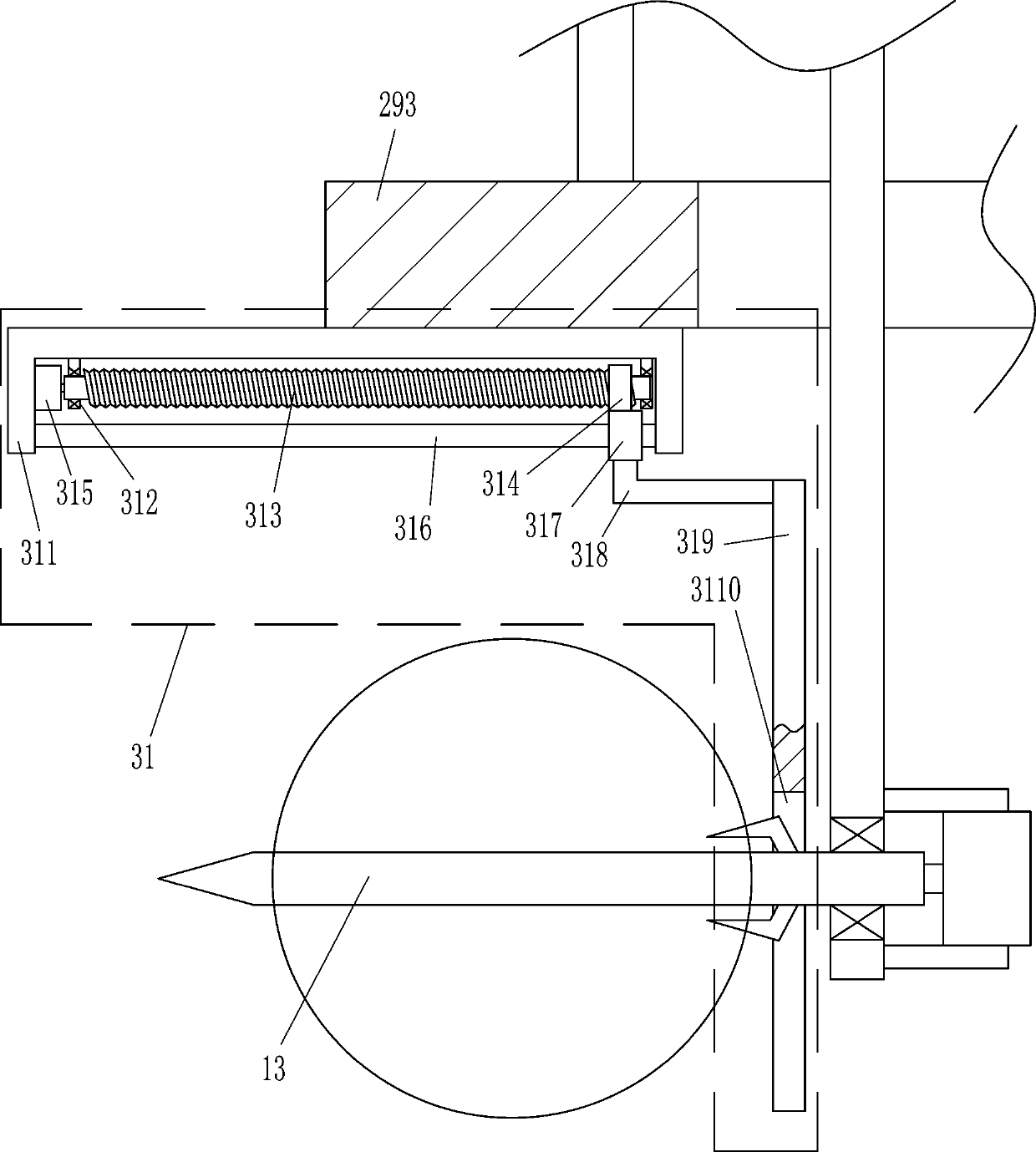

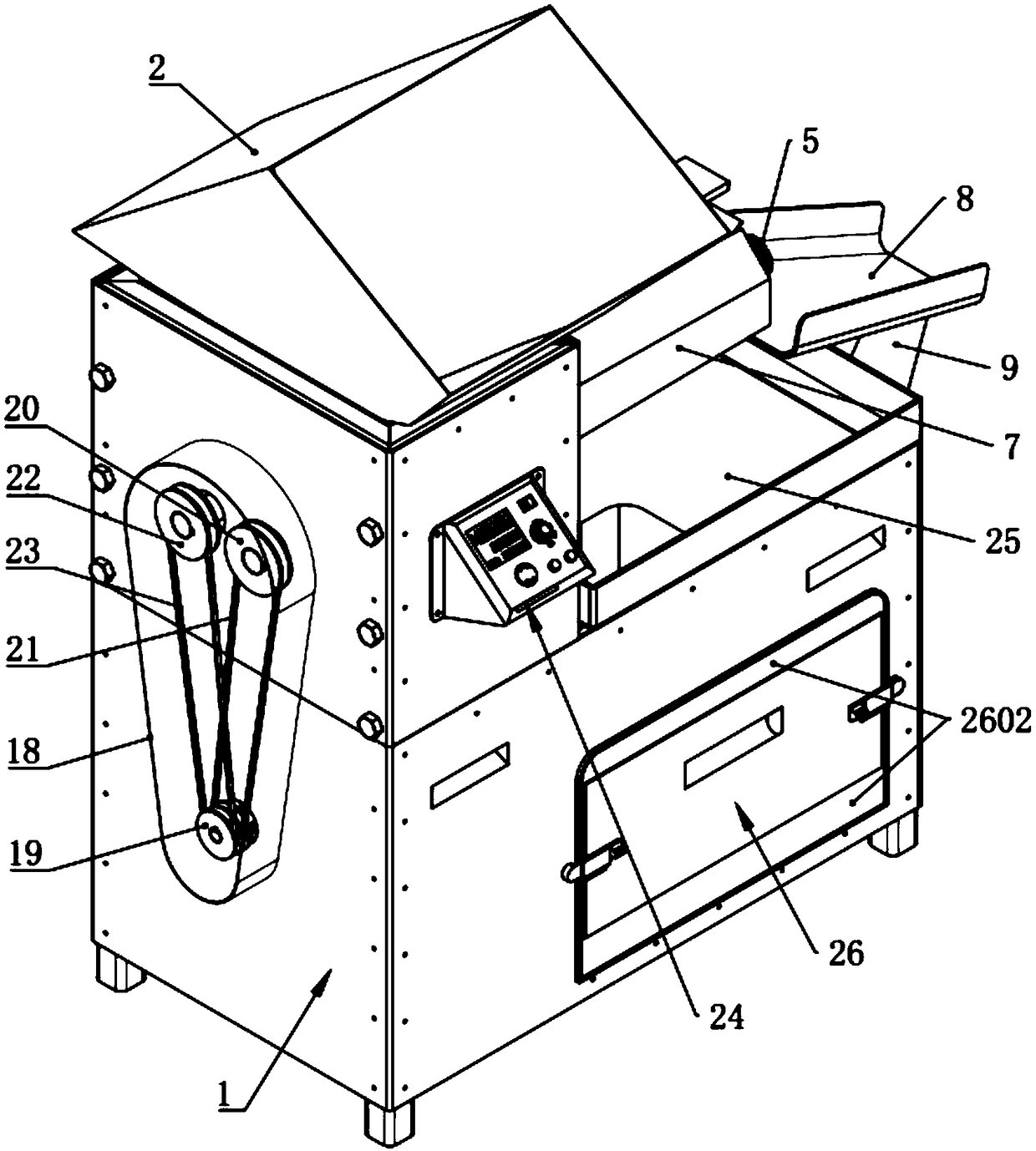

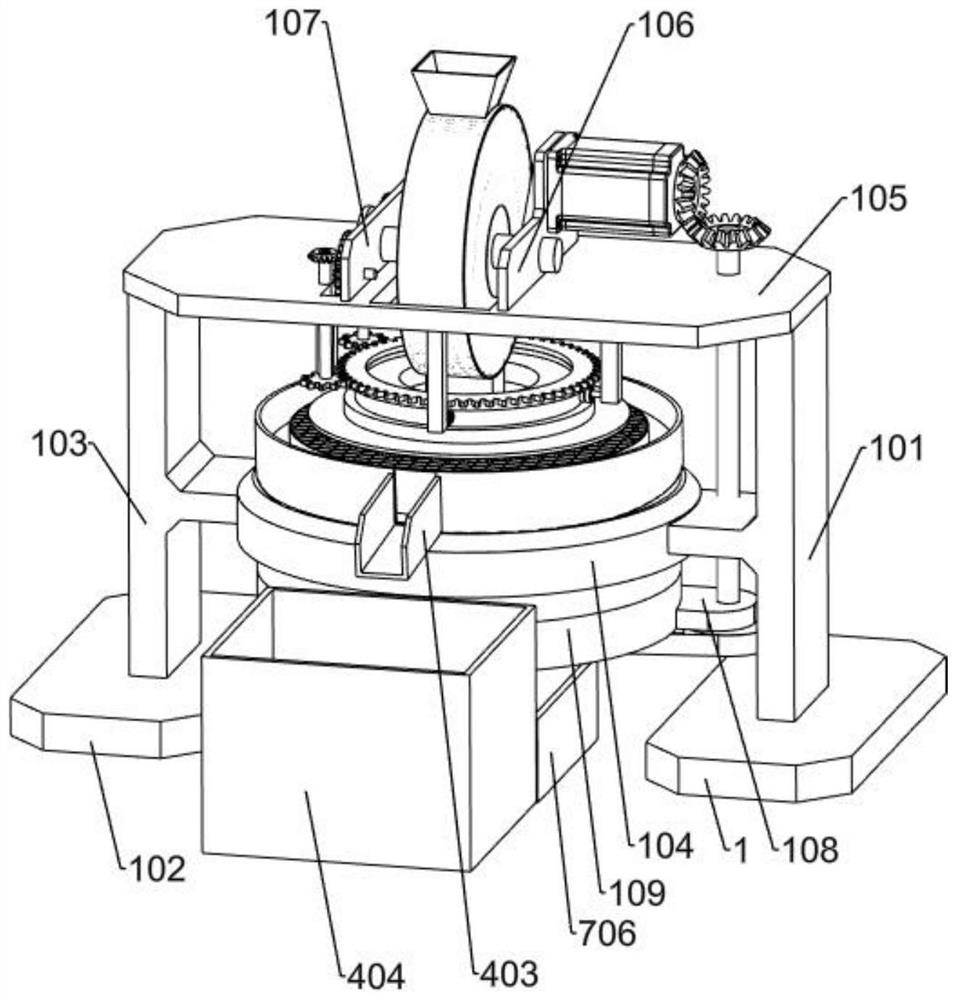

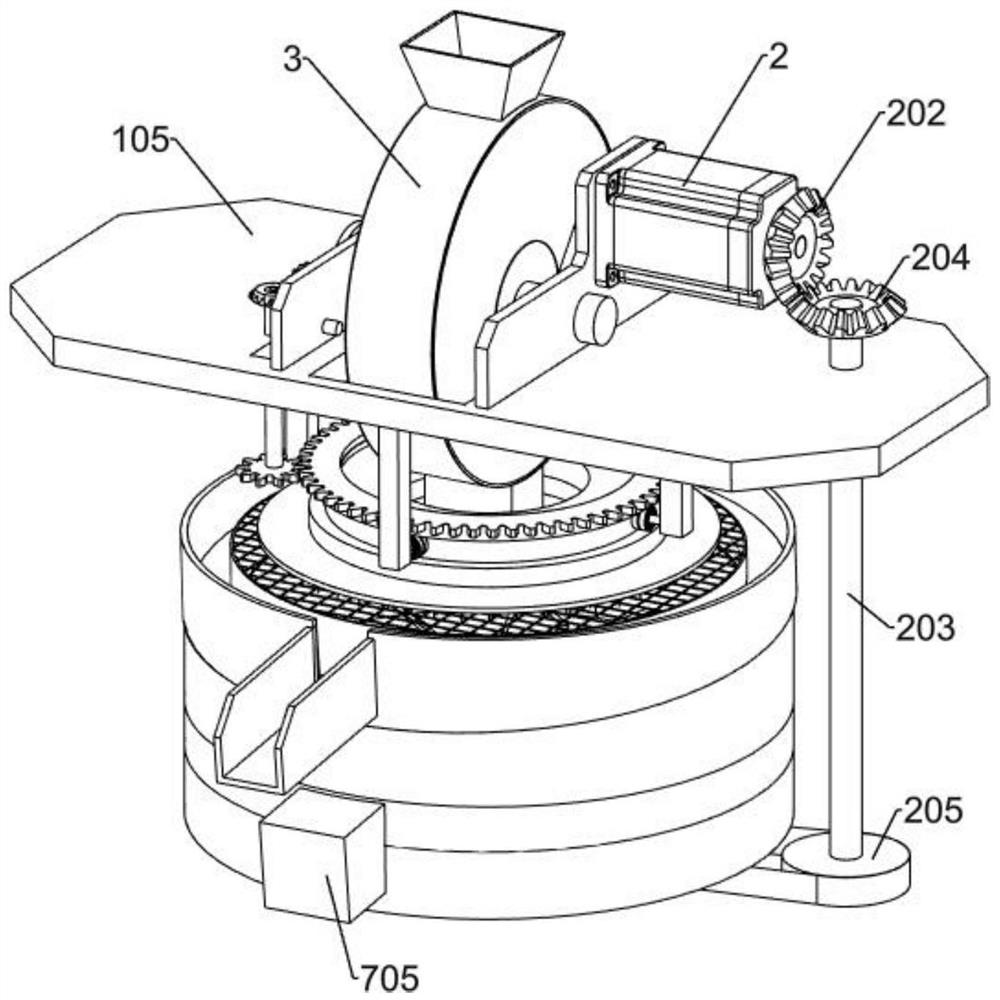

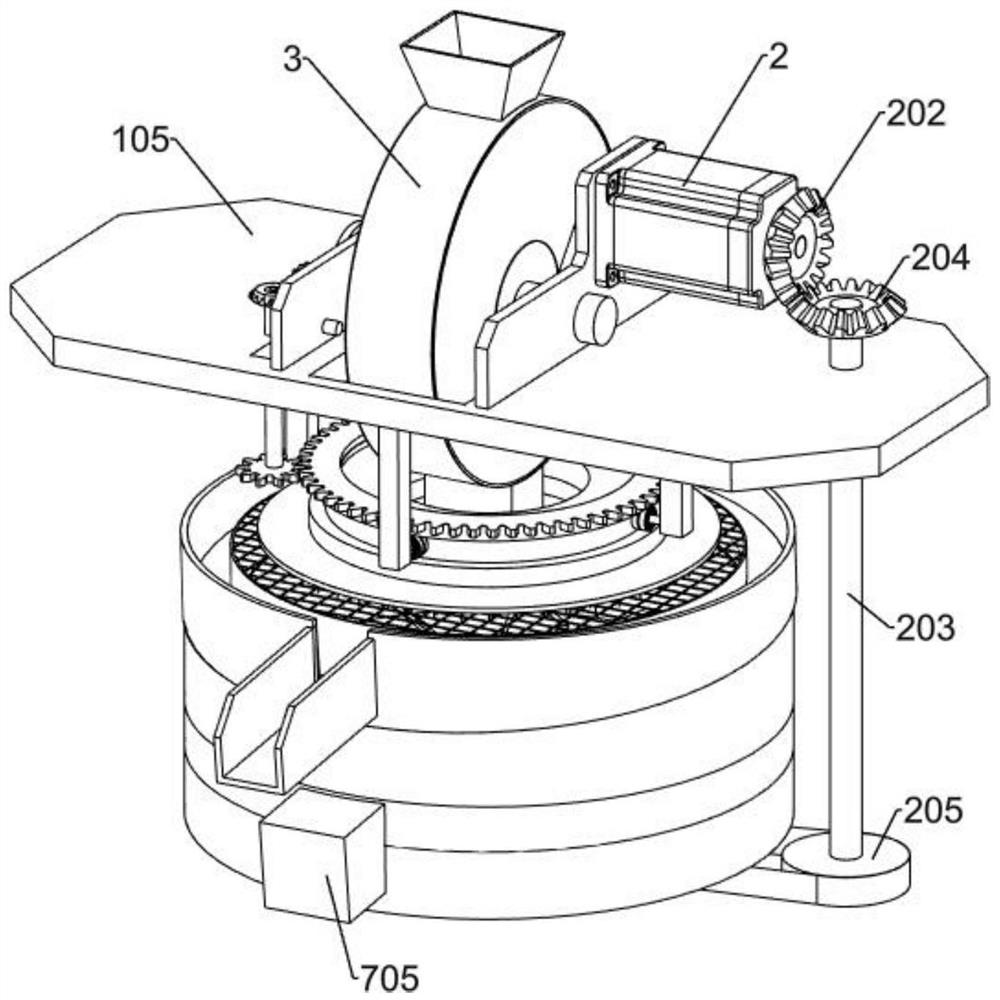

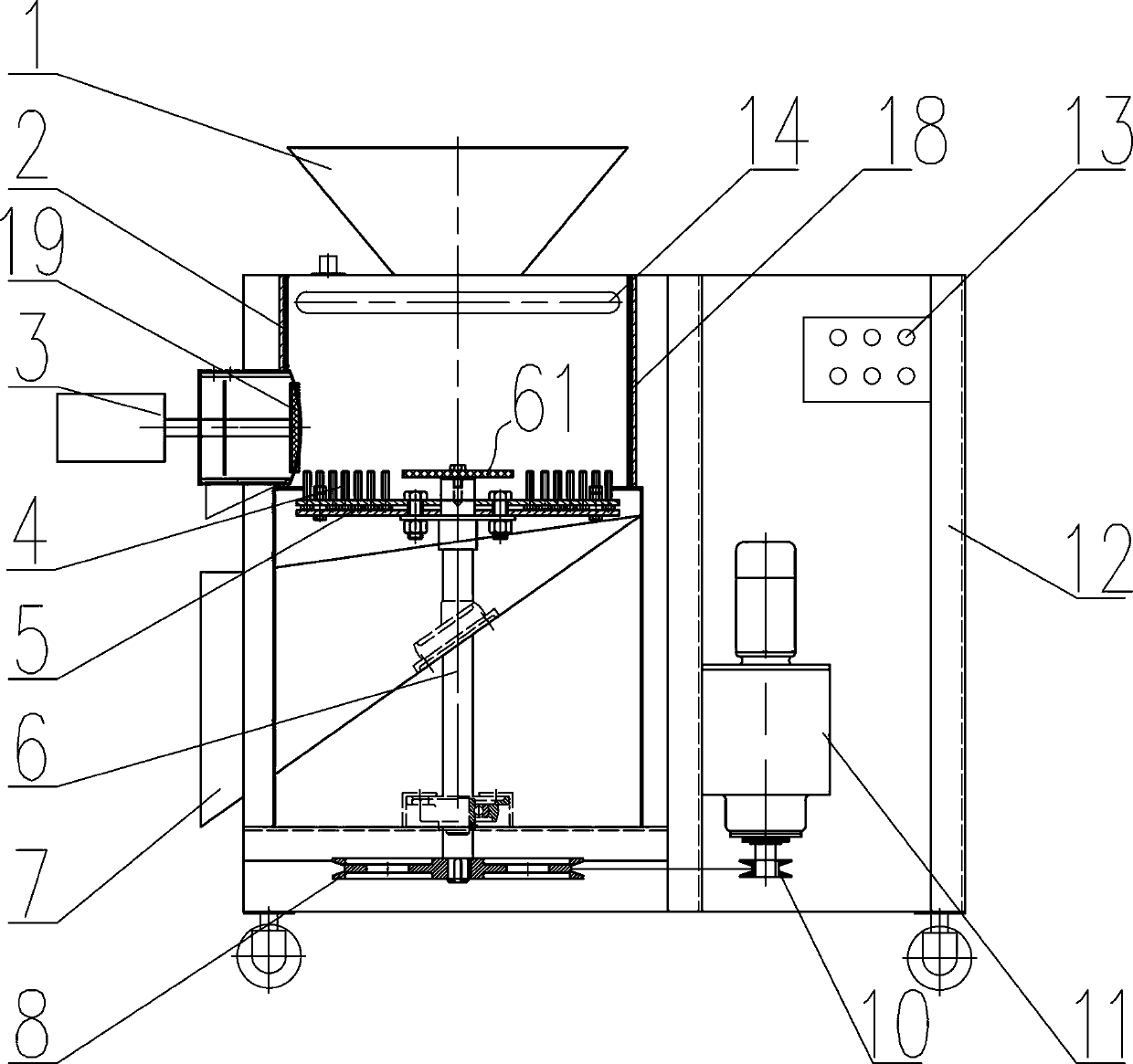

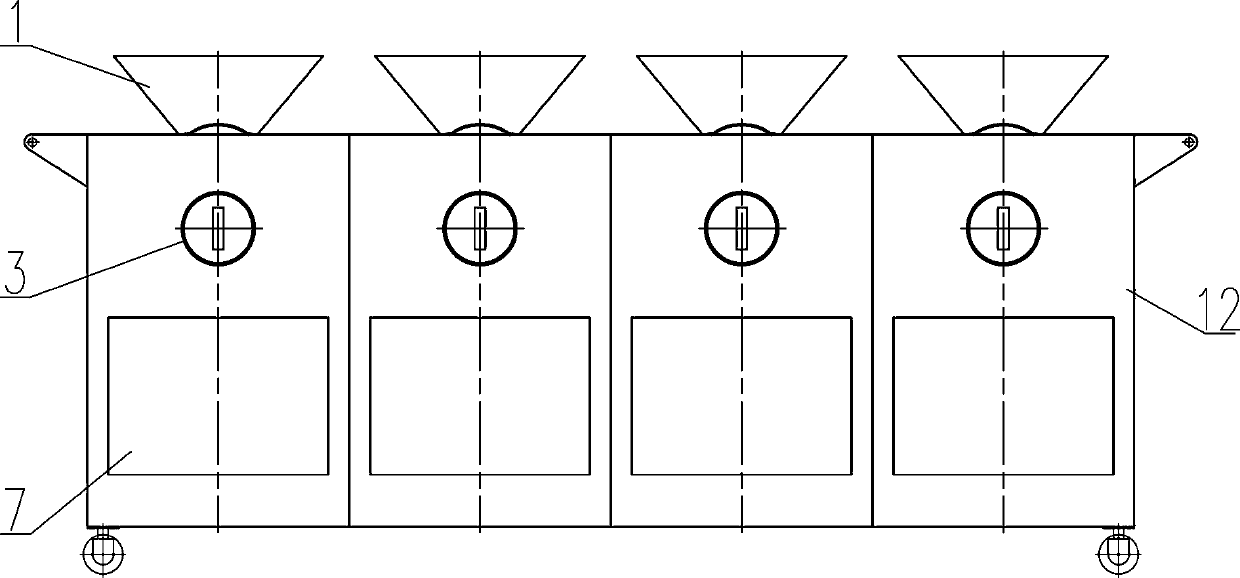

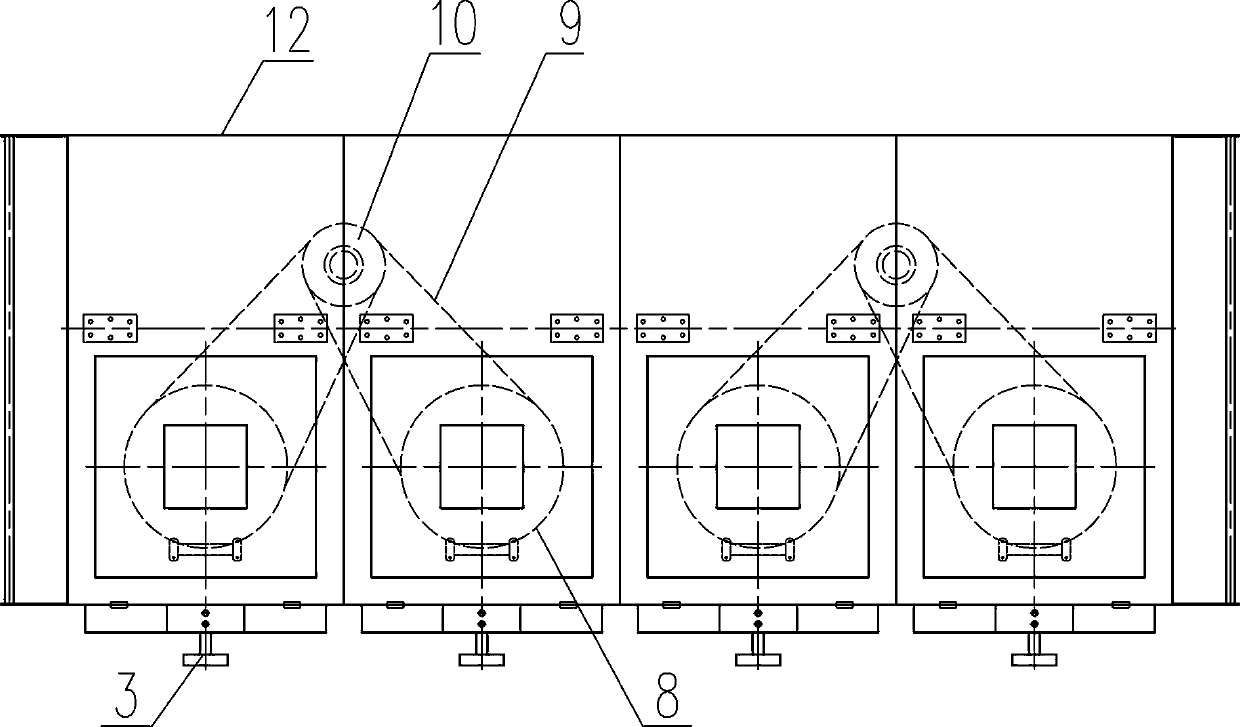

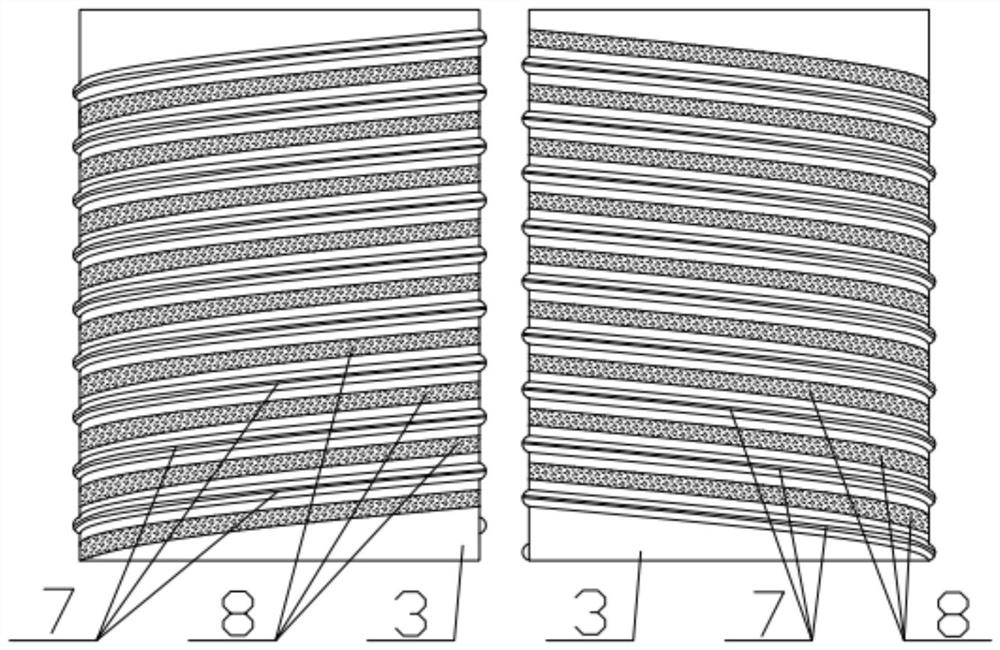

Conical roller grinding type green walnut peeling machine

The invention, which belongs to the technical field of walnut peeling, provides a conical roller grinding type green walnut peeling machine comprising a frame provided with a feeding hopper. A first conical roller and a second conical roller that are driven by a driving device are installed on the frame in a rotating manner; and the first conical roller and the second conical roller are arranged side by side and a mounting gap is arranged between the rollers. Cutting teeth for peeling off the green coat of the walnut are arranged on the wall of the first conical roller; and a rubber sleeve fordriving the walnut to make rotation sleeves the outside of the second conical roller. A discharge hole of the feeding hopper is arranged above the first conical roller and the second conical roller and is close to the thick ends of the first conical roller and the second conical roller. Under the effect of the driving device, the first conical roller and the second conical roller make rotation ina same direction. Compared with the traditional green walnut peeling equipment, the conical roller grinding type green walnut peeling machine has the following beneficial effects: the peeling efficiency and the peeling quality are greatly improved; the peeling is done completely; no manual secondary cleaning is needed; the damages on the walnut are reduced substantially; and the quality of the walnut after peeling processing is ensured effectively.

Owner:WEIFANG VOCATIONAL COLLEGE

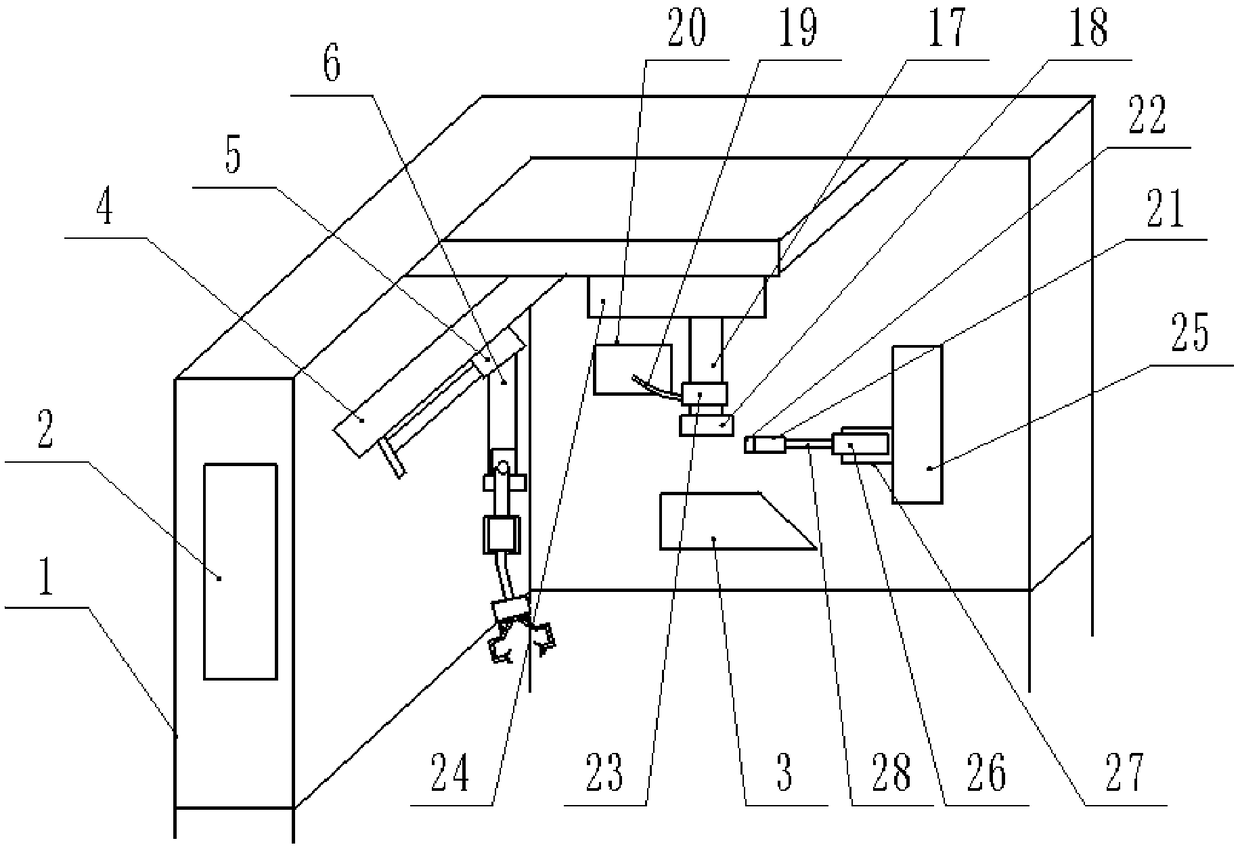

High-efficiency persimmon peeling machine

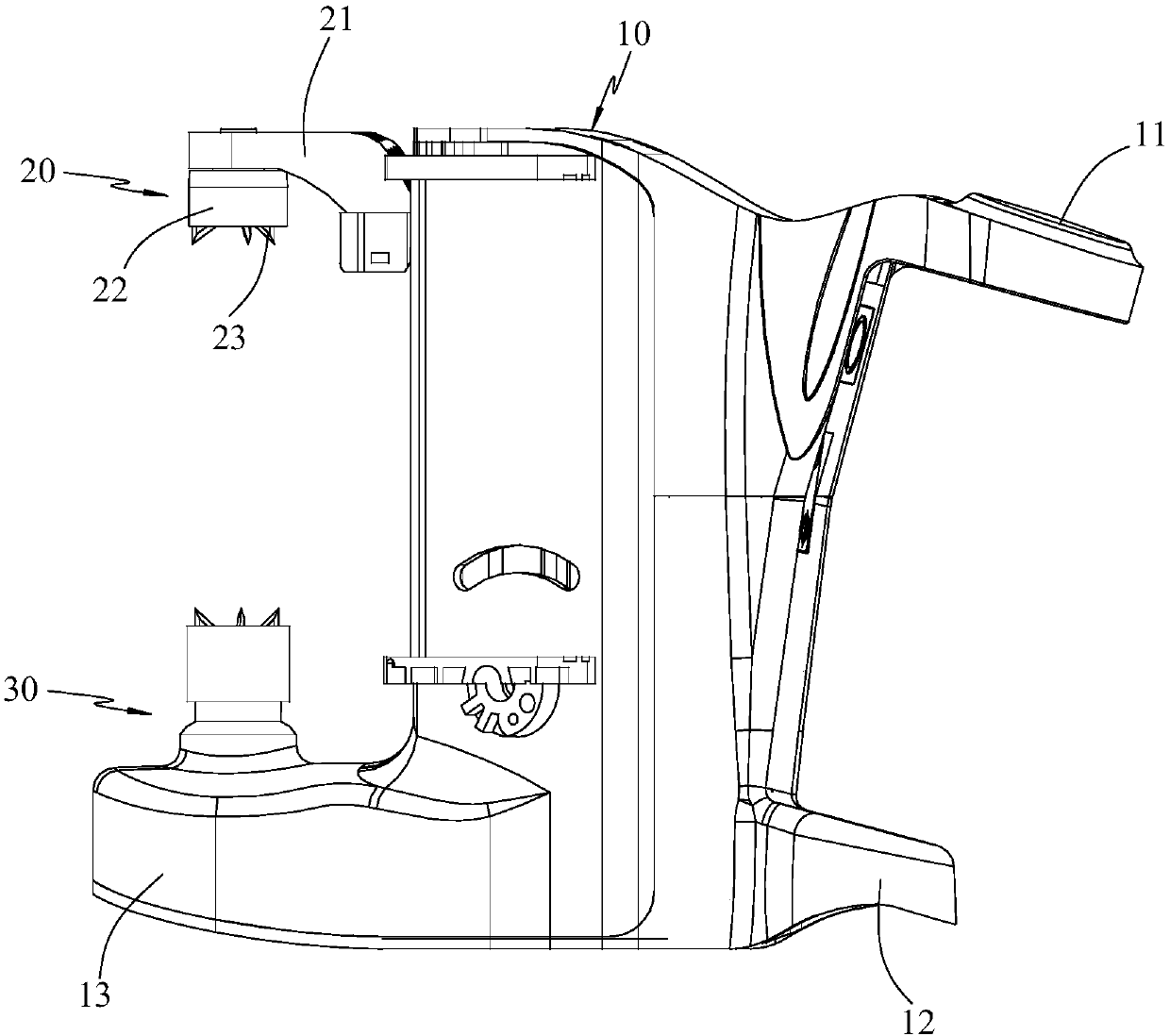

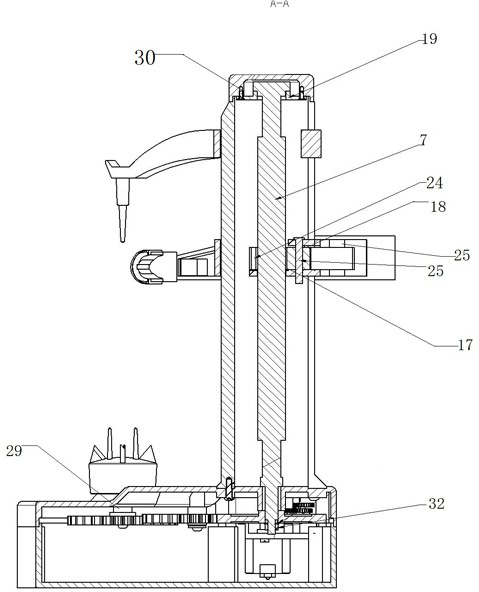

ActiveCN109222138AAchieve crawlingLarge grabbing rangeVegetable peelingElectric machineryEngineering

The invention discloses a high-efficiency persimmon peeling machine, and relates to the technical field of agricultural product processing equipment. The high-efficiency persimmon peeling machine comprises a rack, wherein the rack is provided with a controller, an automatic gripping device, an automatic peeling device and a collection hopper; the automatic gripping device comprises a bracket connected with the rack, the bottom of the bracket is connected with a first air cylinder, the first air cylinder is connected with a first motor base provided with a first rotating motor, the first rotating motor is connected with a first swing arm, the first swing arm is connected with a second motor seat provided with a second rotating motor, the second rotating motor is connected with a second swing arm, the second swing arm is connected with a manipulator, the manipulator cooperates with the automatic peeling device, and the manipulator is provided with a position sensor. The high-efficiency persimmon peeling machine has the advantages that persimmons can be peeled accurately, the peeling efficiency is high, the safety is good, the labor intensity is low, and the high-efficiency persimmonpeeling machine meets the standards of safety, hygiene and efficiency and is worth popularizing and applying vigorously.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

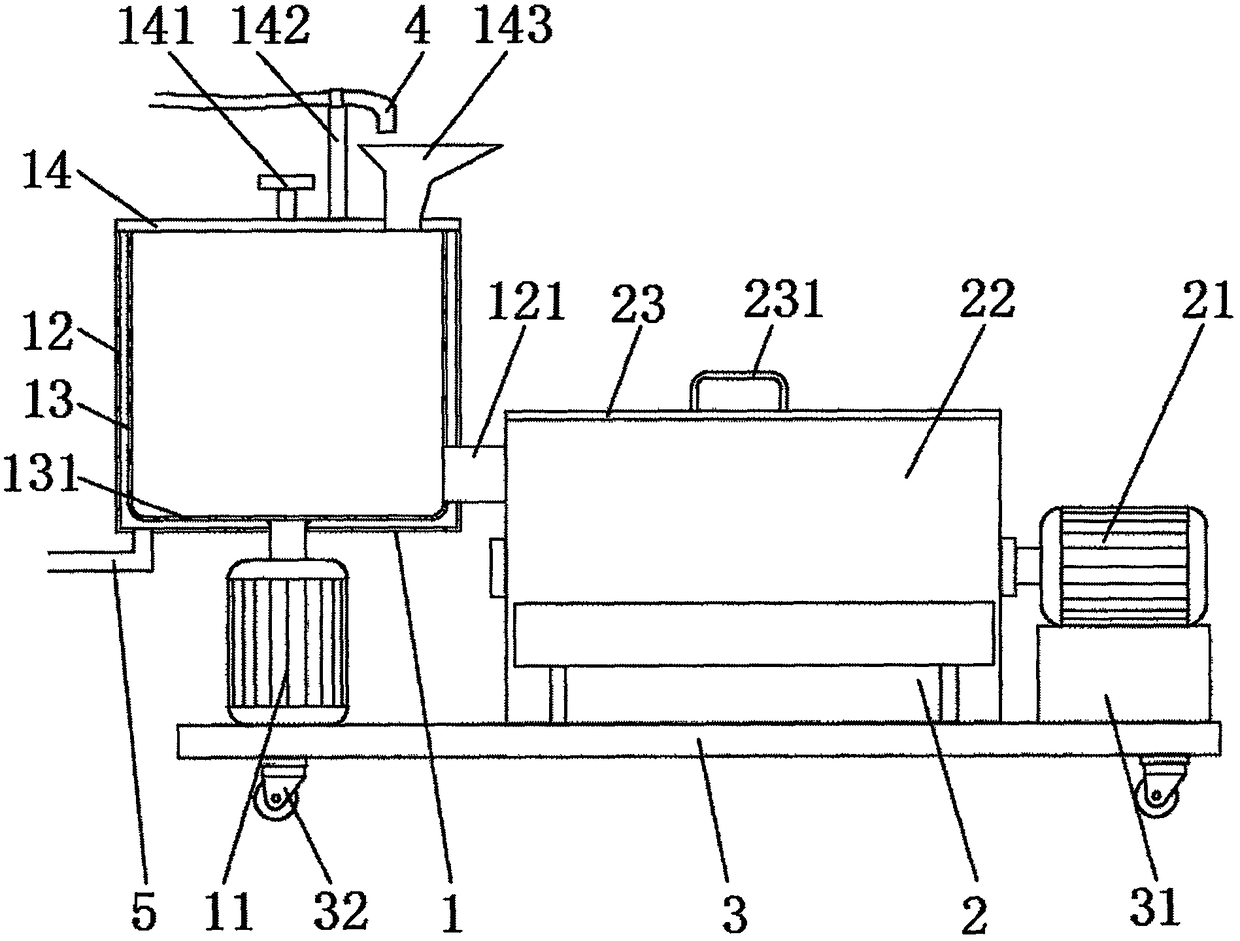

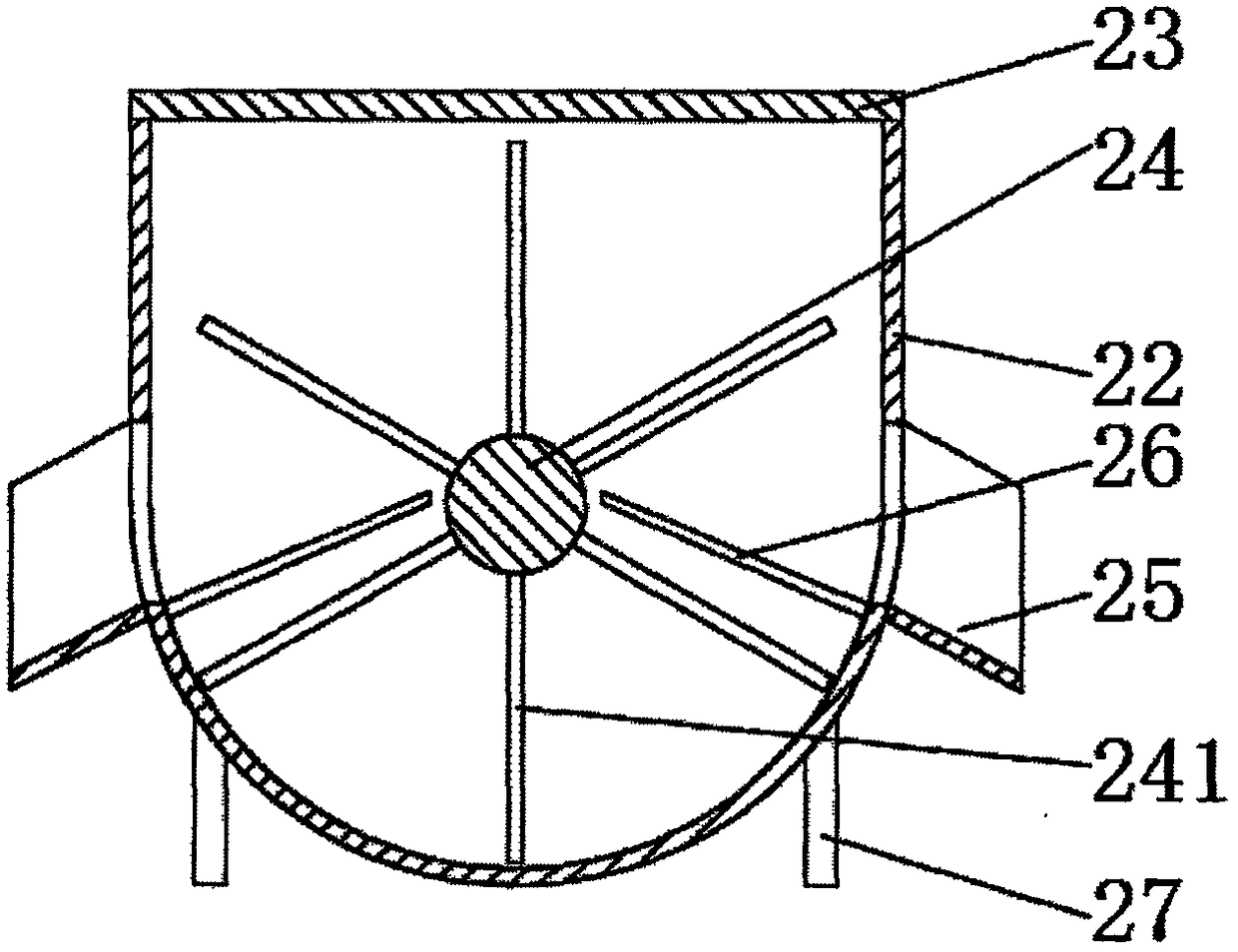

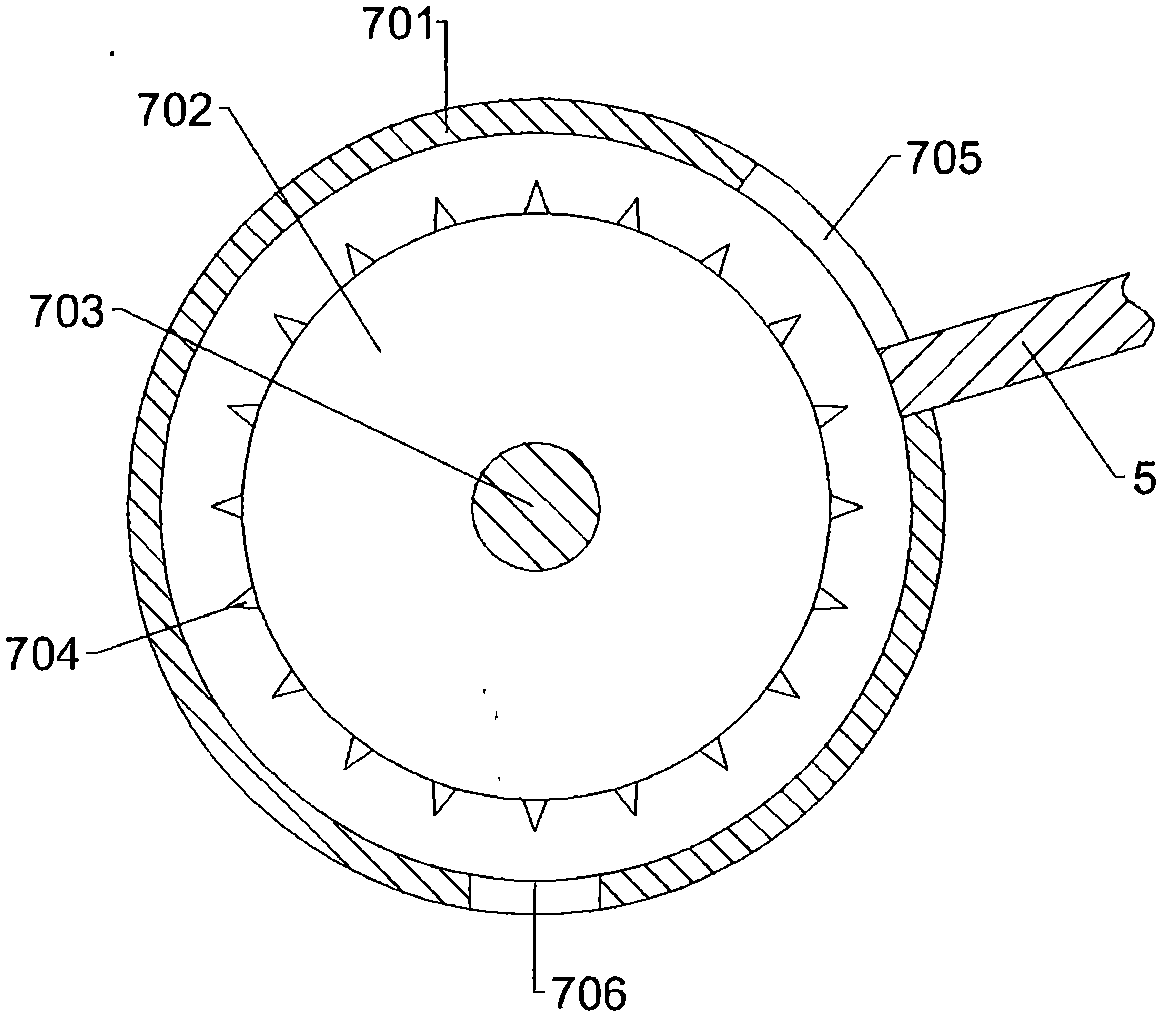

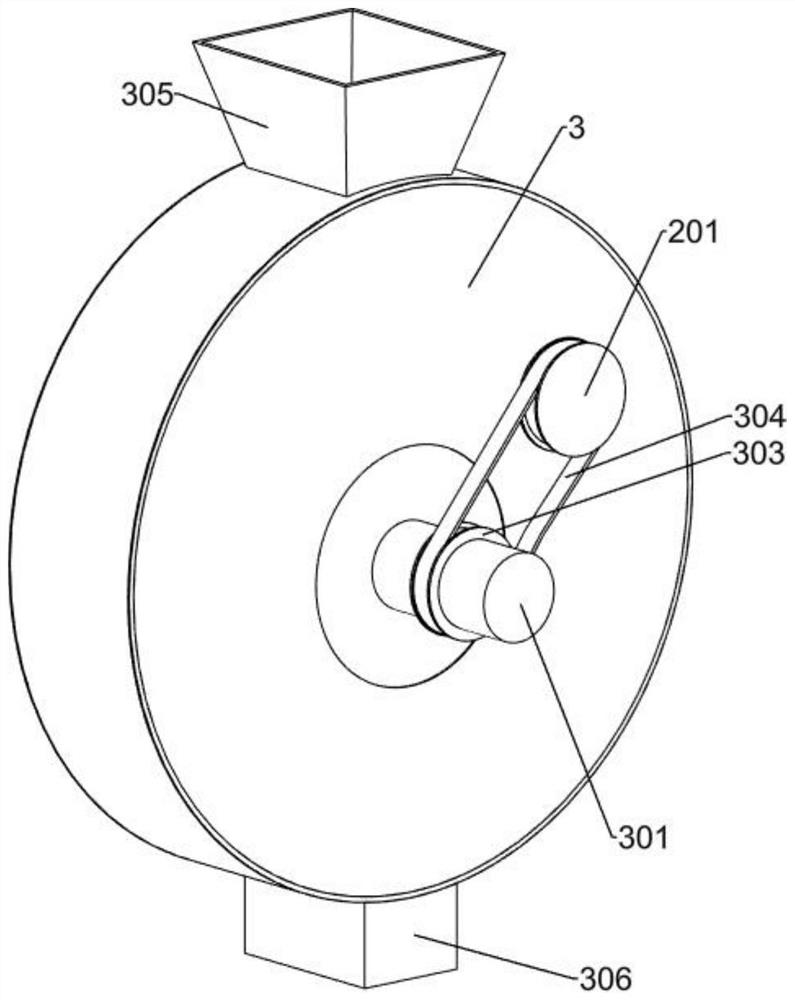

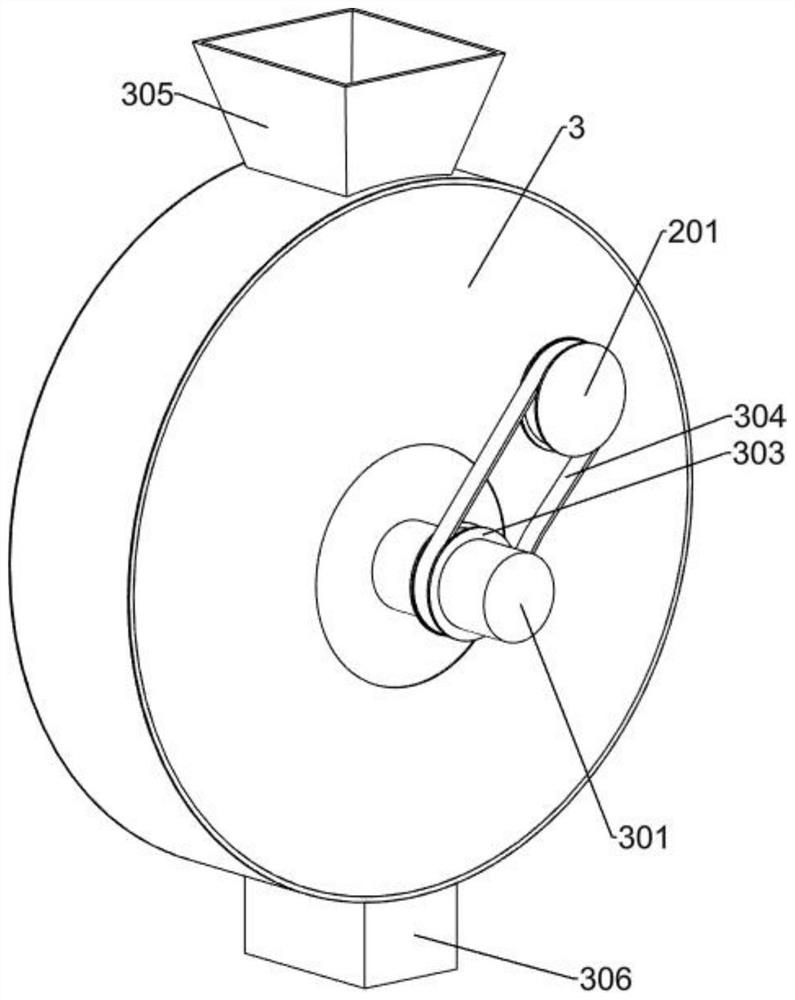

Sesame seed peeling equipment capable of performing drying

InactiveCN107865450AFast and efficient dryingImprove peeling efficiencyGas current separationVegetable peelingSesamum orientaleVertical tube

The invention discloses a sesame peeling device with drying, which includes a peeling device and a drying device. The peeling device includes a vertical cylinder and an inner cylinder. The turntable and the outer disk have the same center of circle, and the rotation direction of the turntable is opposite to that of the outer disk. The drying device includes a drying barrel, an air supply device, a collection chamber and an impurity chamber. Through the sesame peeling device with drying of the present invention, the sesame is thoroughly peeled, the efficiency of sesame peeling is improved, and the damage rate in the process of sesame peeling is reduced at the same time, the sesame is quickly and effectively dried, and the color and luster of the sesame are guaranteed. degree, to ensure the quality of the finished product.

Owner:黄林海

A device for removing green skin of walnut processing

The invention relates to a walnut processing device, in particular to a walnut processing green peel removal device. The technical problem of the present invention is to provide a walnut green skin removal device with high working efficiency and walnut polishing function. The technical embodiment of the present invention is: a walnut processing green peel removal device, including a support frame, etc.; the support frame includes a first bottom plate, a first vertical support, a second bottom plate, a second vertical support, a ring frame, and an upper horizontal plate , the first support plate, the second support plate, the fixed plate and the drum frame, the upper side of the first bottom plate and the second bottom plate are fixedly connected with the first vertical support and the second vertical support, and the outer side of the ring frame is fixedly connected with the first The inner side of the vertical support and the second vertical support, and the drum frame are fixedly connected to the inner side of the ring frame. The present invention realizes the removal of the green skin of the walnut through the power mechanism and the peeling mechanism, and saves manual removal of the green skin.

Owner:甘肃陇小南电子商务有限公司

Green seedcase removing device for walnut processing

The invention relates to a walnut processing device, in particular to a green seedcase removing device for walnut processing. The invention aims to solve the technical problem of providing a walnut green seedcase removing device which is high in working efficiency and has a walnut polishing function. According to the technical scheme, the green seedcase removing device for walnut processing comprises a supporting frame and the like, wherein the supporting frame comprises a first bottom plate, a first vertical bracket, a second bottom plate, a second vertical bracket, an annular frame, an upper transverse plate, a first supporting plate, a second supporting plate, a fixing plate and a barrel frame, the first vertical bracket and the second vertical bracket are fixedly connected to the upper side of the first bottom plate and the upper side of the second bottom plate, the outer side of the annular frame is fixedly connected to the inner side of the first vertical bracket and the inner side of the second vertical bracket, and the barrel frame is fixedly connected to the inner side of the annular frame. According to the green seedcase removing device, green seedcase removing of walnuts is achieved through a power mechanism and a peeling mechanism, and manual green seedcase removing is omitted.

Owner:甘肃陇小南电子商务有限公司

A kind of coconut shell peeling machine

The invention discloses a coconut shelling and peeling machine, which comprises a turntable connected to a base plate. A front foot plate and a rear foot plate are arranged on the bottom of the base plate. For nails with the nail tip facing upwards, a fixing mechanism is provided at the bottom of the turntable, a peeling mechanism is also provided on the bottom plate through a support frame, a support plate is vertically connected to the top of the support frame, and a shell opening mechanism is arranged on the support plate. The shell cutter and the turntable are in an up-and-down linear correspondence, and the space formed by the shell cutter and the turntable is horizontally corresponding to the side cutter of the peeling mechanism. The invention solves the problems in the prior art that the coconut peeling has great potential safety hazards, complicated operation, low efficiency and cannot guarantee quality and sanitation.

Owner:XIAN UNIV OF TECH

Novel rapid bamboo shoot peeling device

The invention relates to a peeling device, in particular to a novel rapid bamboo shoot peeling device. The novel rapid bamboo shoot peeling device can peel bamboo shoots safely, efficiently and rapidly. The novel rapid bamboo shoot peeling device comprises: a mounting table and a mounting block, wherein the mounting block is arranged on the right side of the top of the mounting table; a peeling mechanism which is rotatably connected to the mounting block; a motor which is arranged in the middle of the rear side of the top of the mounting table; and a missing gear, wherein the output shaft of the motor is connected to the missing gear, and the missing gear is meshed with a part of the peeling mechanism. When people need to peel the bamboo shoots, the bamboo shoots can be poured into a feeding box in batches, the bamboo shoots slide down along the sliding slope in the feeding box, and when a feeding rod acts, the feeding rod feeds the bamboo shoots into a peeling rod, so that high-efficiency bamboo shoot peeling is realized.

Owner:龚艳红

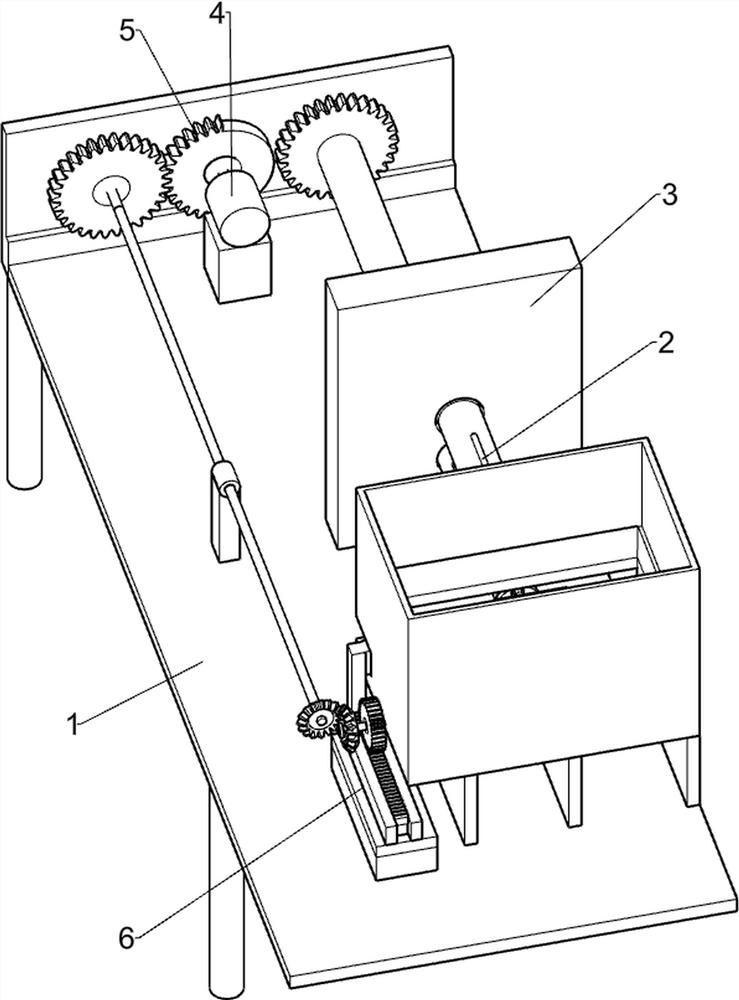

A kind of multifunctional fruit peeling machine

ActiveCN108888084BPeeling achievedEasily brokenKitchen fruit stoningMetal working apparatusElectric machineryEngineering

The invention discloses a multifunctional fruit peeling machine, which belongs to the technical field of fruit peeling machines, and comprises a frame, a support plate, a lead screw, a peeling knife, a cutting mechanism and a juice extraction mechanism. The nut installed inside the support plate passes through the The threaded screw is connected, and the peeling knife is composed of a fixed shaft, a torsion spring, a front peeling knife and a rear peeling knife, and the sides of the front peeling knife and the rear peeling knife are provided with a cutting mechanism fixedly installed on the top of the frame; The dicing mechanism includes a dicing frame and a dicing knife, and a dicing knife is installed in the groove at the upper end of the dicing frame. The juice extracting mechanism is composed of a container, a blade and a driving mechanism. The second gear, the first half tooth, the second half tooth, the third gear and the fourth gear, the first half tooth and the second half tooth are fixedly installed on the shaft where the second gear is located from bottom to top, and the fourth gear is located Two identical blades are installed forward and backward on the rotating shaft. The present invention can integrate the functions of peeling, pitting and squeezing, etc., so as to realize diversified functions.

Owner:广西宝酱园食品有限公司

Sweet potato peeling device

InactiveCN110679968APeeling achievedReduce collisionVegetable peelingStructural engineeringCylinder block

The invention discloses a sweet potato peeling device. According to the invention, a vertical shaft is mounted at the bottom in a cylinder body; one end of the vertical shaft extends out of the cylinder body and is connected with a first motor; the other end of the vertical shaft is fixedly connected with a horizontally-arranged transverse shaft; the transverse shaft is in threaded connection witha vertically-arranged first peeling shaft, the first peeling shaft wraps a peeling brush by a circle, a connecting shaft is installed at the top in the cylinder body, one end of the connecting shaftextends out of the cylinder body and is provided with an output shaft of a second motor, the other end of the connecting shaft is in threaded connection with a vertically-arranged second peeling shaft, and the second peeling shaft wraps the peeling brush by a circle; a feeding hole is formed in the upper section of the side wall of the cylinder body; a water outlet is formed in the lower section of the side wall of the cylinder body; according to the sweet potato peeling device, sweet potatoes are peeled through rotation of the upper peeling shaft and the lower peeling shaft, each peeling shaft is wrapped with a layer of the peeling brush, and the peeling brushes rub against the sweet potatoes, so that peels of the sweet potatoes in different shapes can be removed.

Owner:冯学明

Novel device for peeling potato

The invention discloses novel device for peeling a potato. The novel device comprises a slotting tool, wherein one end of the slotting tool is connected with a drive mechanism, a peeling mechanism is arranged on the periphery of the other end of the slotting tool and comprises peeling plates, the peeling plates are fixed on a base in a floating manner, and peeling layers composed of cleaning ball wires are arranged on plate surfaces, close to the slotting tool, of the peeling plates; each peeling plate comprises an arc-shaped plate piece, and the curvature center of each arc-shaped plate piece is located on the side close to the slotting tool. The peeling plates are arranged along the two opposite sides of the periphery of the slotting tool, and a to-be-peeled potato fixed on the slotting tool is located in an area defined by the peeling plates. With the adoption of the peeling device formed according to the scheme, the potato is rotated through the slotting tool to rub with the cleaning ball wires on the inner plate surfaces of the peeling plates, a potato peel is rubbed and falls off, and the potato is peeled. The peeling efficiency of the device is high, loss of potato flesh is low, the production efficiency is improved, and the production cost is reduced.

Owner:NANTONG HECHENG TEXTILE CO LTD

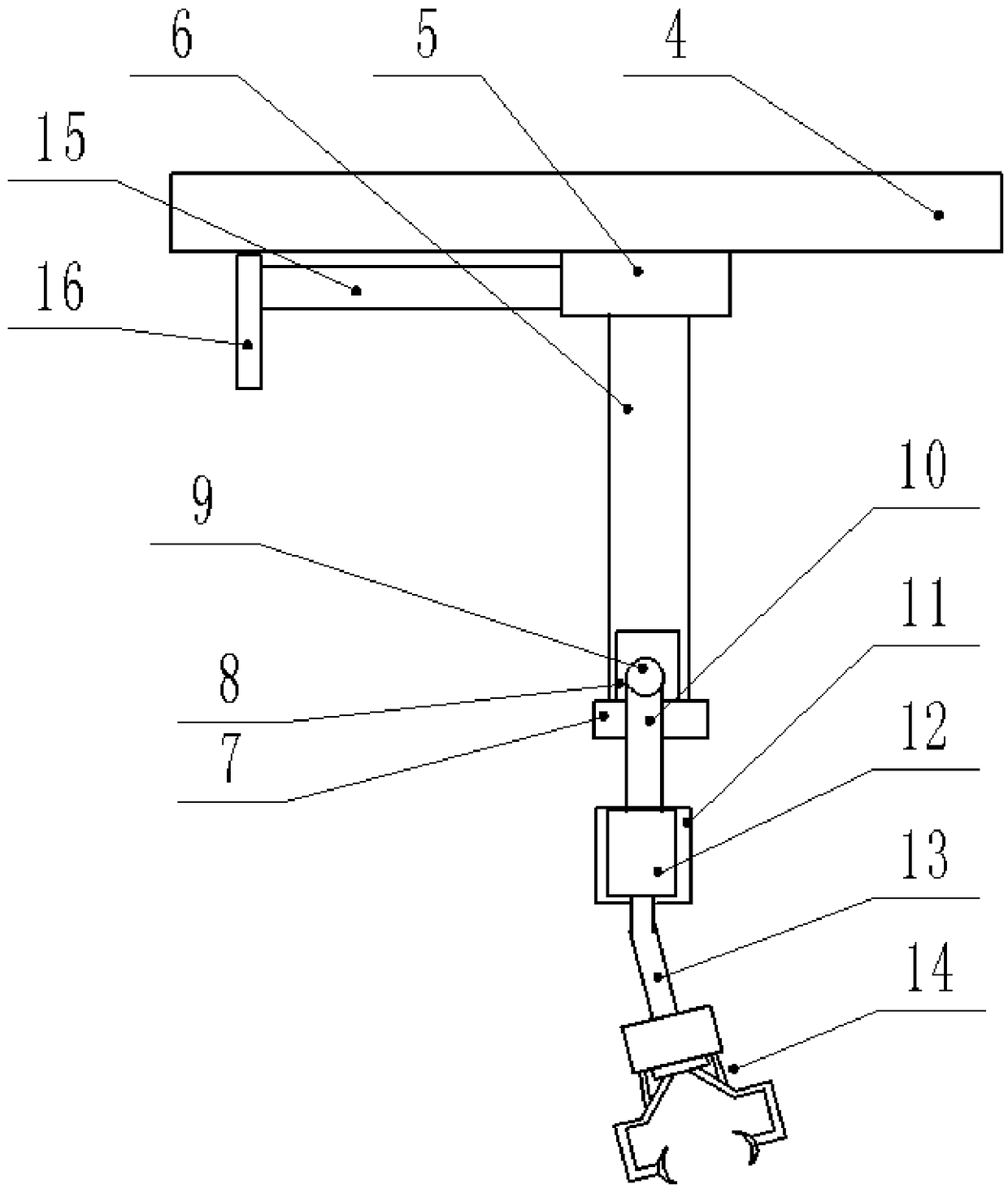

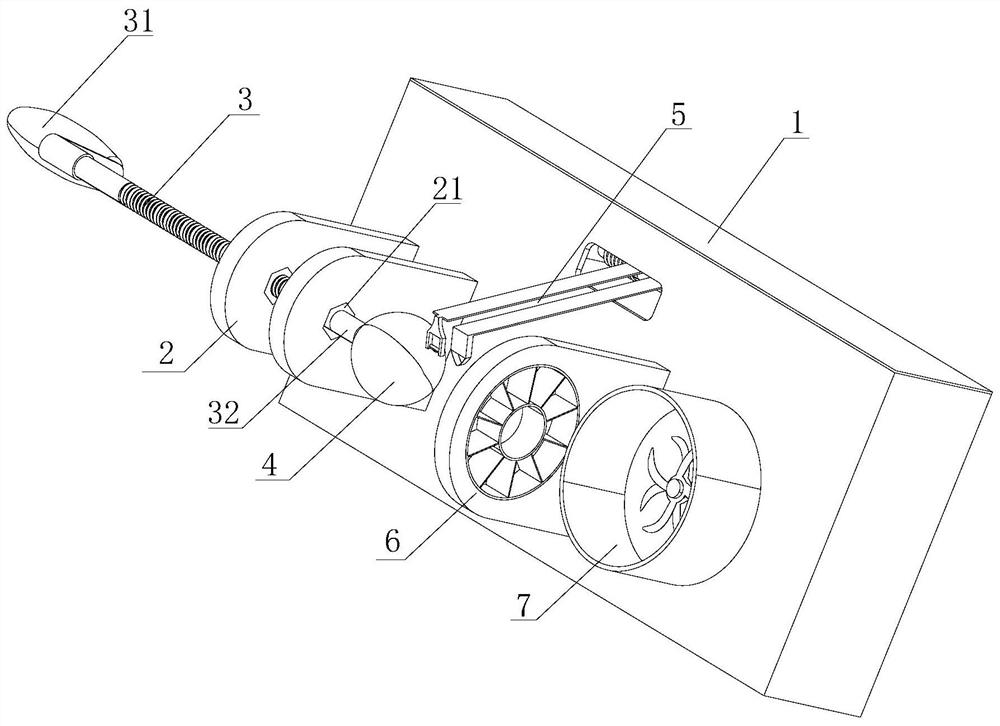

Fruit paring clamping device

The invention relates to a fruit paring clamping device. The device comprises an installation support, upper and lower clamping jaw assemblies arranged in one side of the installation support correspondingly, a first driving module driving the upper clamping jaw assembly to move up and down relative to the lower clamping jaw assembly, and a second driving module for driving the lower clamping jawassembly to rotate. The device is characterized in that the lower clamping jaw assembly is rotationally installed in a soleplate which is extended out of the lateral side of the installation support,and includes upper and lower rotation units arranged coaxially up and down and an elastic member driving the upper rotation unit to move far from the lower rotation unit, and the lower end of the upper rotation unit and the upper end of the lower rotation unit include engagement structures which are engaged with each other. The fruit paring clamping device can realize the whole fruit clamping, swinging and rotating process via a very compact structure, and is reliable and stable.

Owner:SHENZHEN PRAFLY TECH

Grape peeling machine

InactiveCN108669579ASimple structureImprove work efficiency and service lifeJuice extractionVegetable peelingKnife bladesEngineering

The invention relates to a grape peeling machine which comprises a peeling box. A grape inlet is formed in the upper end of the peeling box, and a pulp outlet is formed in the lower end of the peelingbox. A first vertical grape conveying cavity, a horizontal grape conveying cavity and a second vertical grape conveying cavity are formed in the peeling box, the grape inlet is communicated with thefirst vertical grape conveying cavity, the first vertical grape conveying cavity is communicated with the horizontal grape conveying cavity, and the horizontal grape conveying cavity is communicated with the second vertical grape conveying cavity. A horizontal air cylinder plug is arranged in the horizontal grape conveying cavity, a vertical air cylinder plug is arranged in an upper cavity body ofthe second vertical grape conveying cavity, a blade and a human-hand-shaped peeling claw are arranged in a lower cavity body of the second vertical grape conveying cavity in sequence, and a grape pulp conveying channel is arranged below the human-hand-shaped peeling claw and communicated with the pulp outlet. According to the grape peeling machine, by means of a simple mechanical structure, the function of completely stripping grape peel is achieved without influencing the completeness of grape pulp.

Owner:JIANGSU UNIV

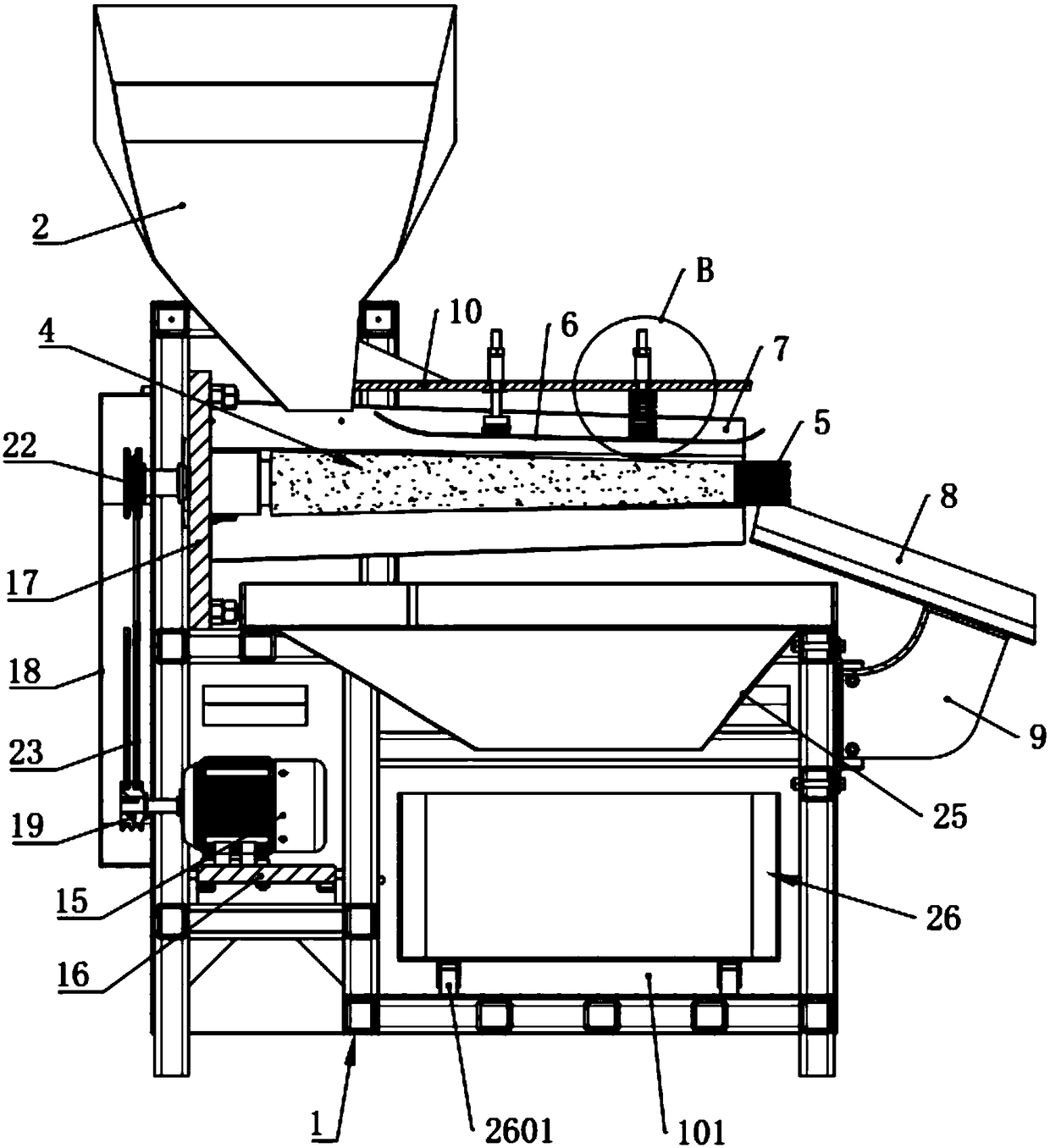

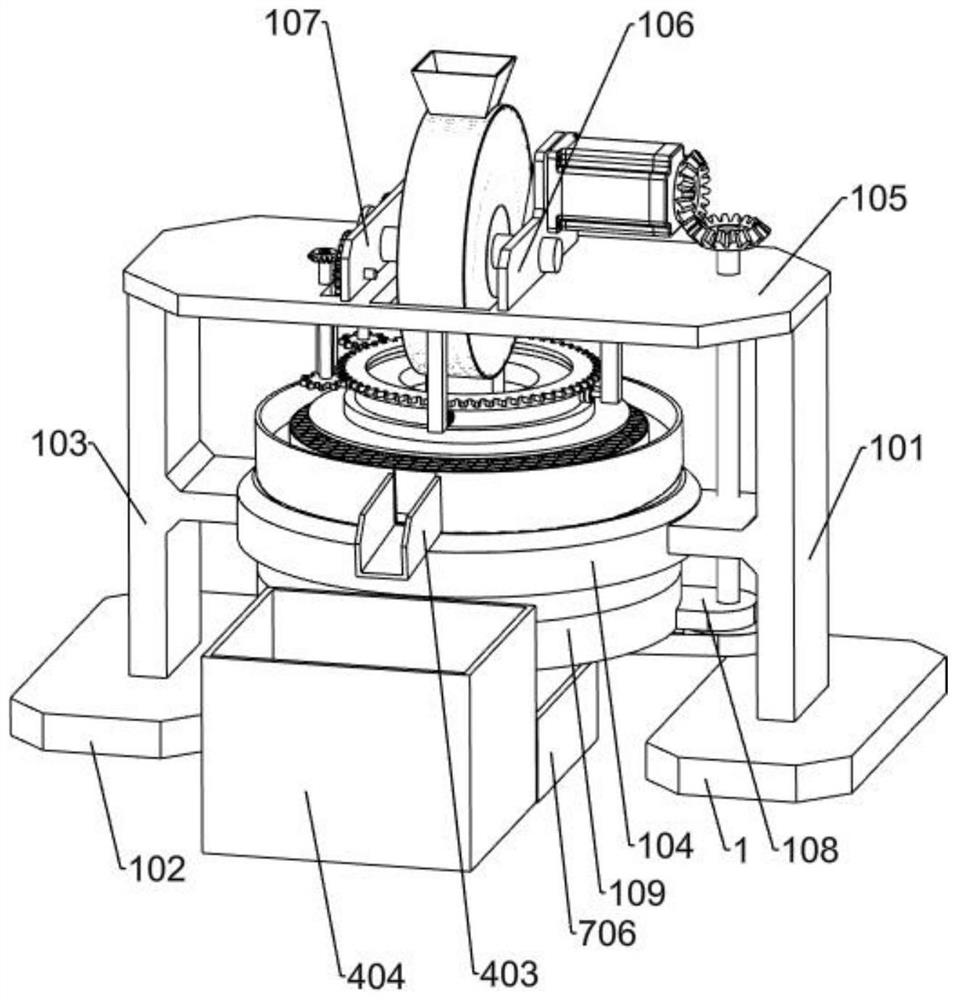

Full-automatic green walnut huller

The invention provides a full-automatic green walnut huller which comprises a hulling chamber arranged in a rack. A feeding hopper is arranged above the hulling chamber. A hulling rotary disc driven by a driving device to rotate is arranged at the bottom of the hulling chamber, and a plurality of hulling screws approximately perpendicular to the hulling rotary disc are arranged on the hulling rotary disc. An automatic water spraying device is further arranged below the feeding hopper. According to the green walnut hulling device, the structure of the horizontally-arranged hulling rotary disc and the approximately-perpendicular hulling screws is adopted, green walnuts are pushed by the hulling screws to rotate at the bottom of the hulling chamber, hulling is achieved in the process of rubbing with the inner wall, the requirement for the boundary dimension of the green walnuts is not high, the adaptability is wide, and a cleaning procedure can be completed at the same time. The steps ofautomatic hulling, automatic washing and automatic spin-drying are achieved, the labor cost is reduced, the production cost is reduced, and the damage rate of walnuts is low and is 0.1% or below during green hull removing. The yield is high, 300kg of green walnuts can be processed per hour by the hulling chamber with the diameter of 400CM, and automatic production is realized.

Owner:东方红集团(湖北)粮食机械股份有限公司

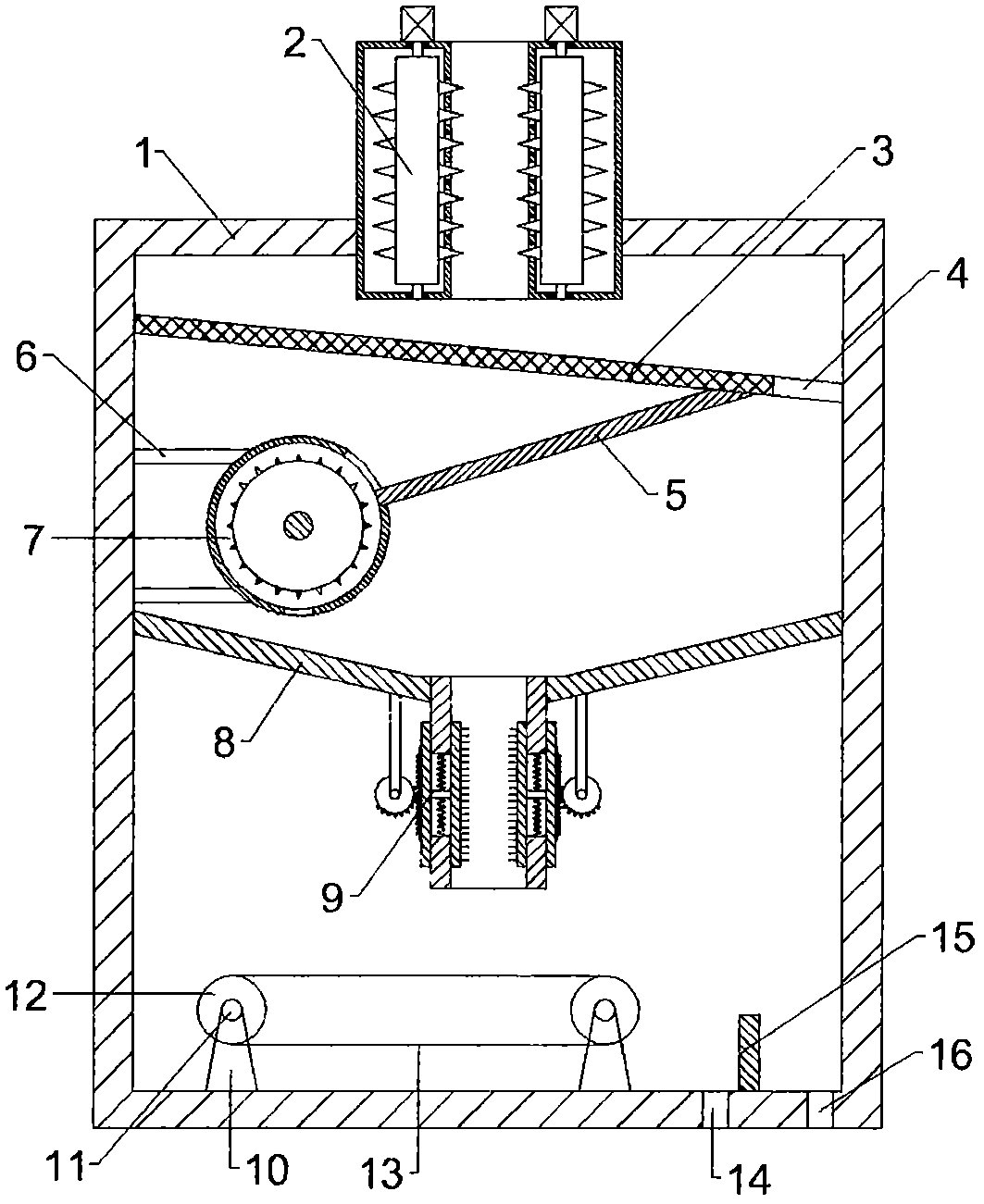

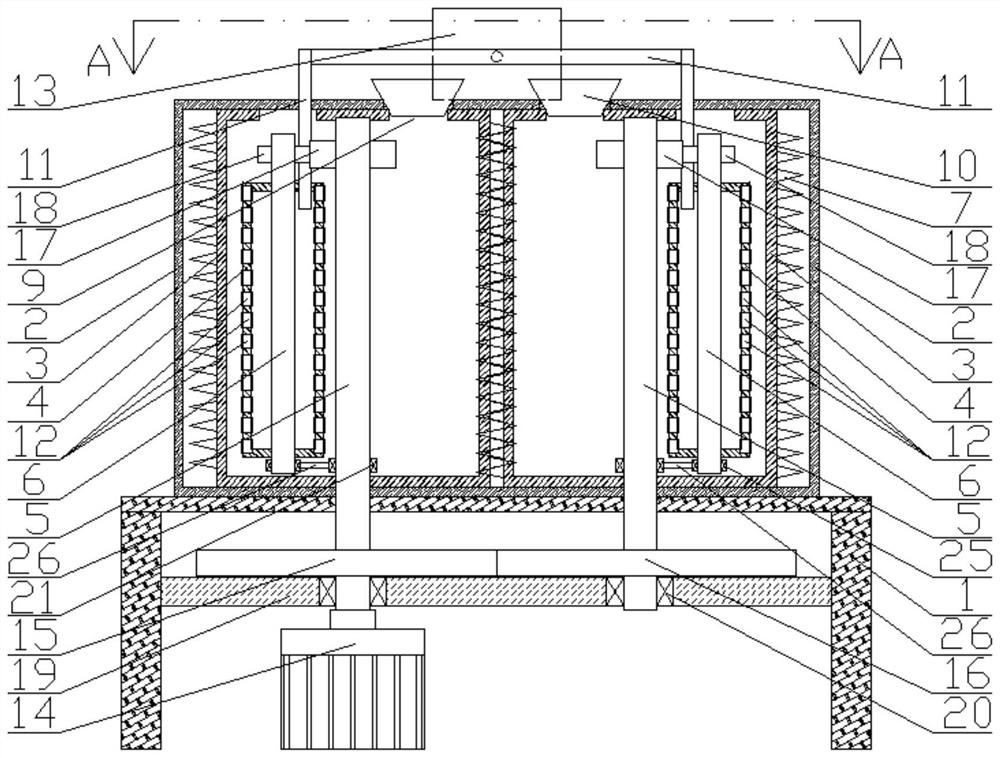

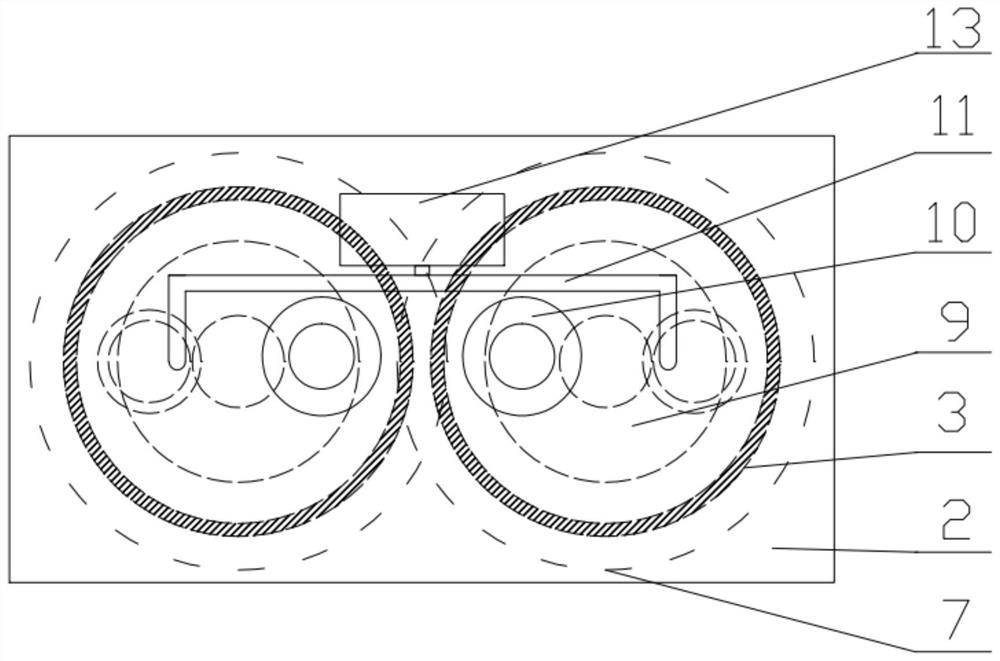

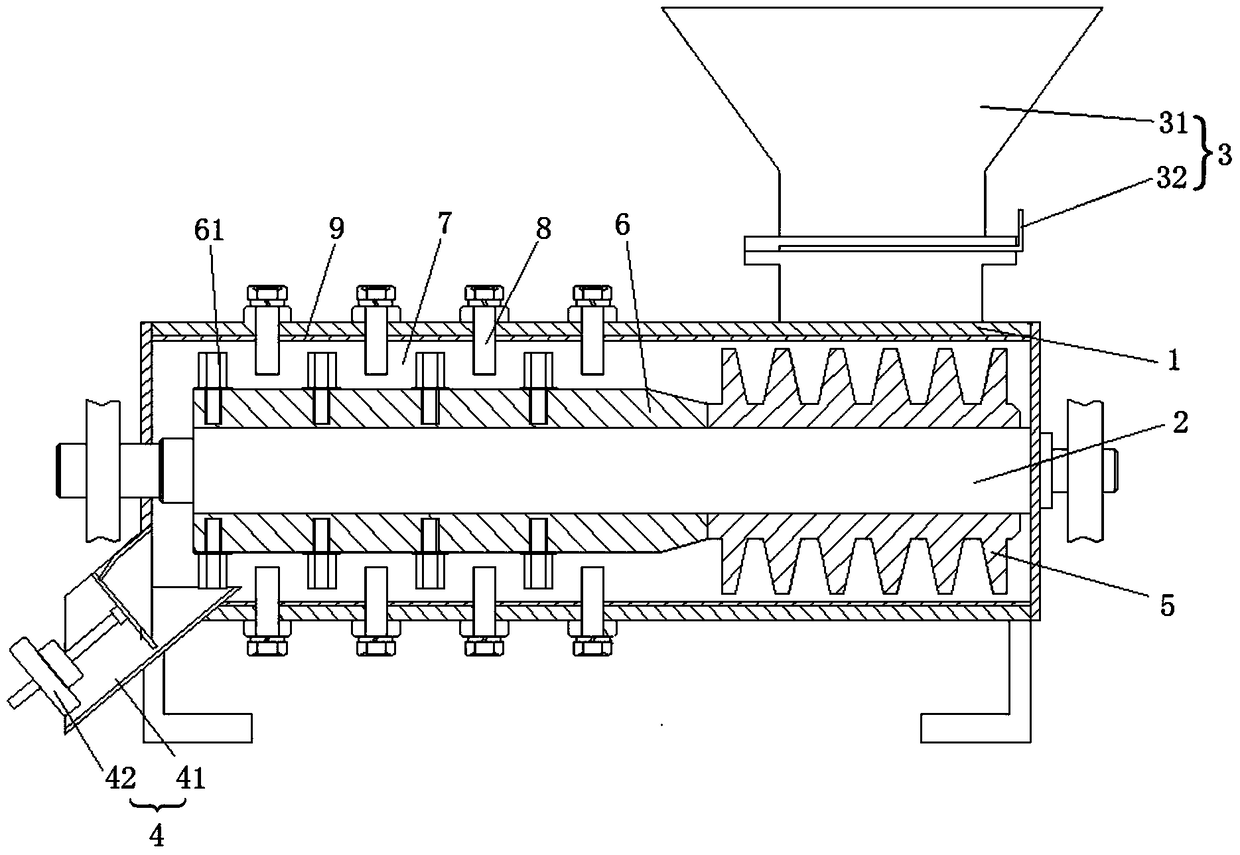

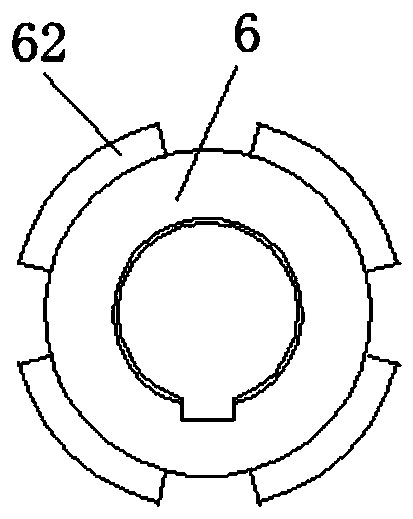

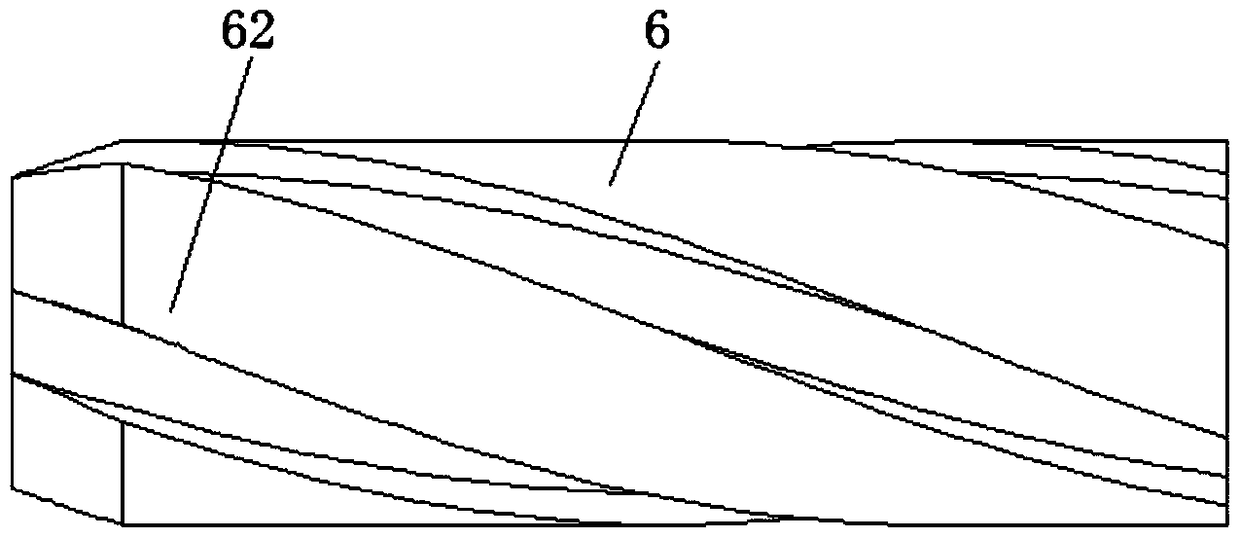

Chinese herbal medicine peeling machine

The invention discloses a traditional Chinese medicinal material peeling machine, which belongs to the field of traditional Chinese medicine processing equipment, and comprises an action box and two double-tube peeling mechanisms arranged in the action box. The double-tube peeling mechanism includes an outer barrel and an inner barrel The inner cylinder on the side, the central axis of the outer cylinder and the inner cylinder are respectively fixed with rotating shaft one and rotating shaft two; the side wall of the outer cylinder is a spiral structure, and a cutting tool is fixed on its outer surface, and the spiral structure of the outer cylinder side wall A helical perforation is formed in the gap; the top of the outer cylinder is provided with a circular feeding port, and a feeding hopper is provided on the opposite side of the feeding port to the inner cylinder, and an air inlet pipe connected to the inner cylinder is provided at the upper end of the inner cylinder. Air vents are evenly distributed on the side of the inner barrel. The present invention can simultaneously realize the cutting and peeling of Chinese medicinal materials, frictional peeling, relatively complete peeling, and good peeling effect; it can also realize cutting and crushing of the detached skins, which facilitates the separation and discharge of the skins and medicinal materials; and the multiple functions can be Simultaneously, the control operation is simple.

Owner:陕西康城药业股份有限公司

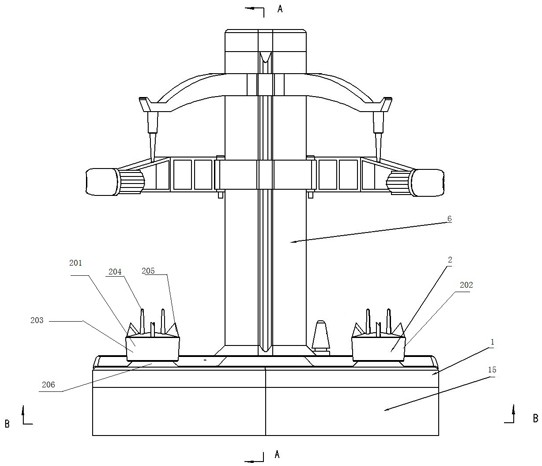

Efficient apple peeling device

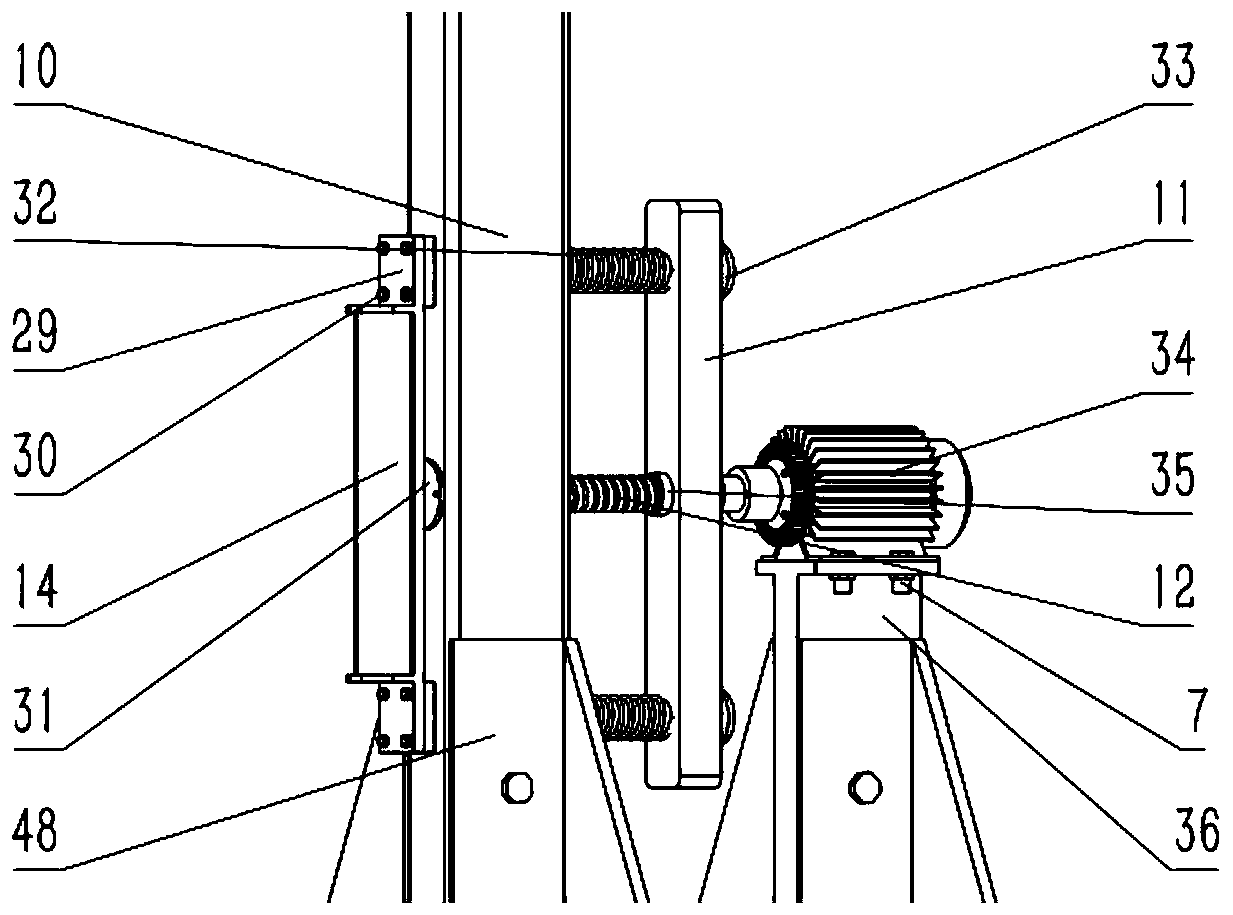

The invention discloses an efficient apple peeling device, which comprises a rotary mechanism, a lifting mechanism, a follow-up lifting assembly, a rotary fixing assembly, a limiting column, an upperlimiting assembly, a first-stage peeling cutter assembly and a second-stage peeling cutter assembly. The rotary mechanism drives apples at the upper end of the rotary fixing assembly to rotate, and meanwhile the lifting mechanism converts rotary motion of the rotary mechanism into lifting linear motion, so that the lifting mechanism drives the follow-up lifting assembly, the first-stage peeling cutter assembly and the second-stage peeling cutter assembly to ascend and descend up and down. Then the first-stage peeling cutter assembly and the second-stage peeling cutter assembly move up and downto peel apples, cutters make contact with fruit cutting point positions for cutting, a power source provides power to drive fruits and vegetables to rotate, and automatic peeling is achieved; two apples can be peeled at the same time through double stations of the first-stage peeling cutter assembly and the second-stage peeling cutter assembly. In the aspect of power source, a motor, gear transmission and lead screw transmission are adopted, so that the efficiency is high, and the cost is low.

Owner:TAIZHOU POLYTECHNIC COLLEGE

A kind of oat peeling machine

ActiveCN104785316BPeeling achievedSmooth peelingGrain huskingGrain polishingEngineeringDeep processing

Owner:CHINA NAT PACKAGING & FOOD MACHINERY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com