Grape peeling machine

A peeling machine and grape technology, which is applied in the peeling of vegetables or fruits, juice extraction, food science, etc., can solve the problems of low peeling efficiency, complicated process, affecting the taste and freshness of grape pulp, and improve the work efficiency. Efficiency and service life, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

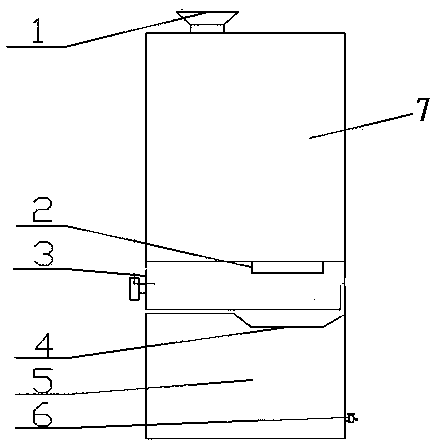

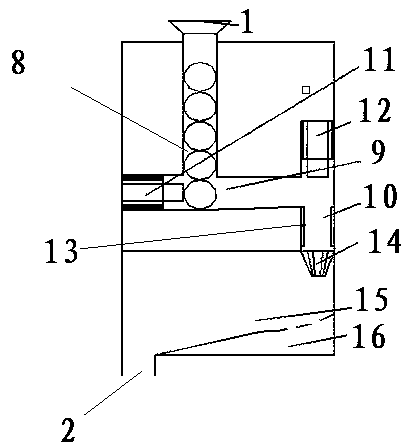

[0017] Embodiment one: if figure 1 and figure 2 As shown, the grape peeling machine of this embodiment includes a peeling box 7, the upper end of the peeling box 7 is provided with a grape inlet 1, and the lower end is provided with a pulp outlet 2, and a pulp collection box 3 is provided below the pulp outlet 2 , the pulp collection box 3 is detachably connected with the peeling box 7. The inside of the peeling box 7 is provided with a first vertical grape conveying chamber 8, a horizontal grape conveying chamber 9 and a second vertical grape conveying chamber 10, and the grape inlet 1 communicates with the first vertical grape conveying chamber 8 , the first vertical grape conveying chamber 8 communicates with the horizontal grape conveying chamber 9, the horizontal grape conveying chamber 9 communicates with the second vertical grape conveying chamber 10, and the horizontal grape conveying chamber 9 is provided with There is a horizontal cylinder plug 11, a vertical cyli...

Embodiment 2

[0018] Embodiment 2: The technical solution of this embodiment is basically the same as that of Embodiment 1. The only difference is that there is no pulp collection box 3 in this embodiment, but a funnel 4 is used instead, and the lower part of the pulp outlet 2 is directly facing the funnel 4. , the output end of the funnel 4 is connected to the input end of the juice extractor 5, and the output end of the juice extractor 5 is connected to the fruit juice outlet 6, wherein the funnel 4 and the juice extractor 5 are all installed in the peeling box 7, the juice outlet 6 is installed on the wall of the peeling box 7.

[0019] The operation principle of this device is: put the grapes after simple soaking into the grape inlet 1, and the grapes enter the first vertical grape conveying chamber 8 along the grape inlet 1 until the first vertical grape conveying chamber 8 is filled. Full of grapes, when peeling, the horizontal cylinder plug 11 pushes the grapes to the bottom of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com