Patents

Literature

58results about How to "Realize automatic peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

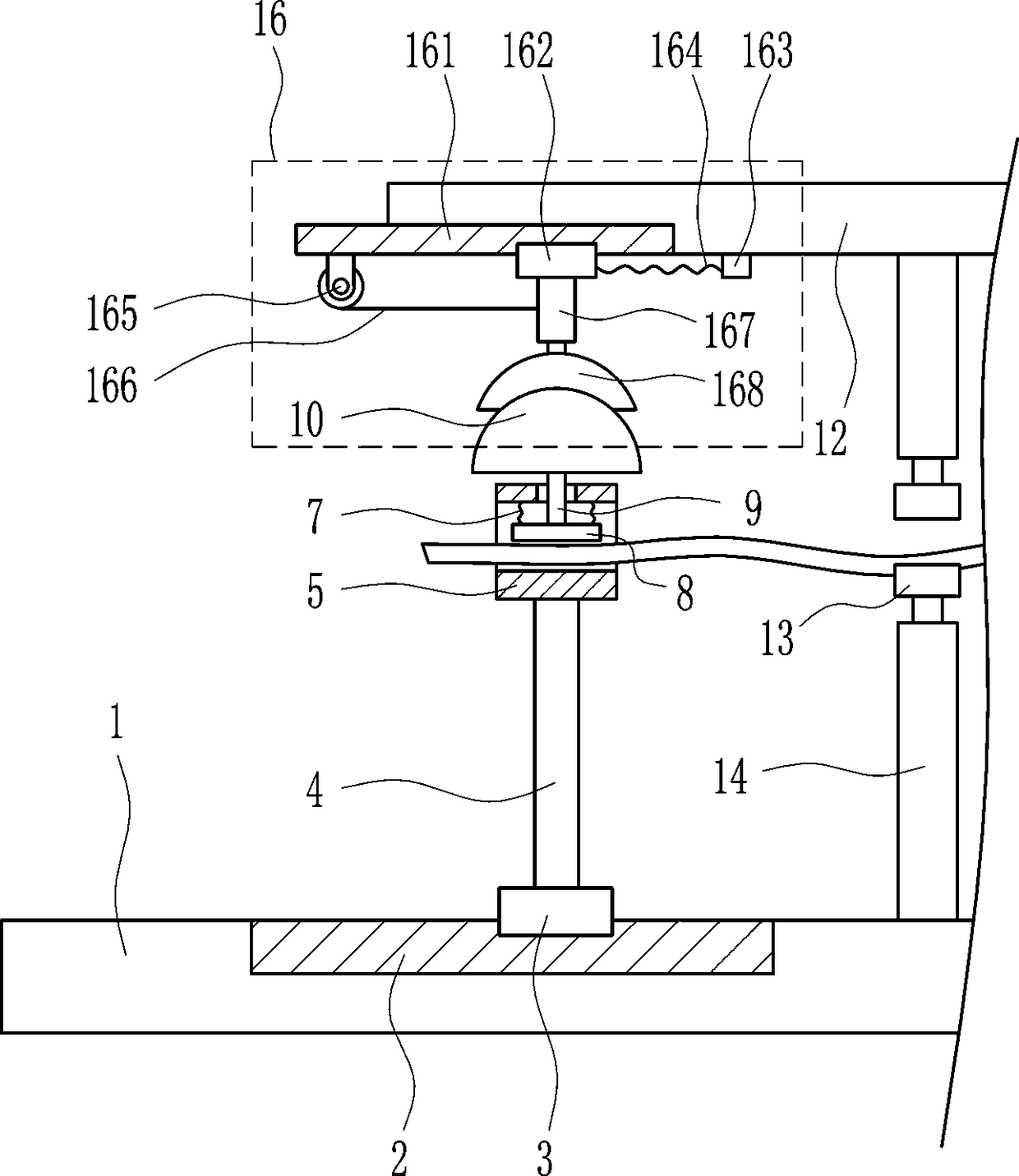

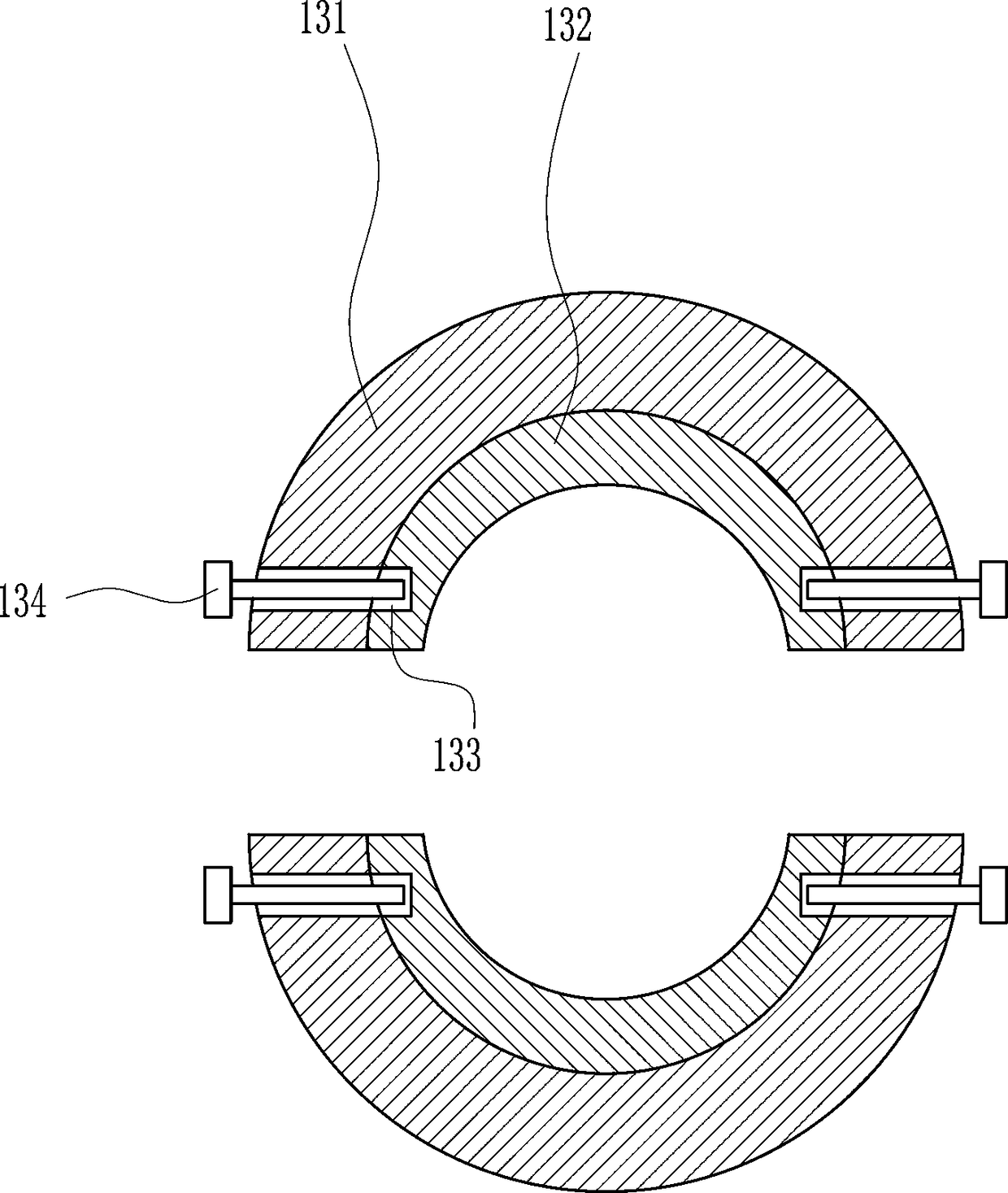

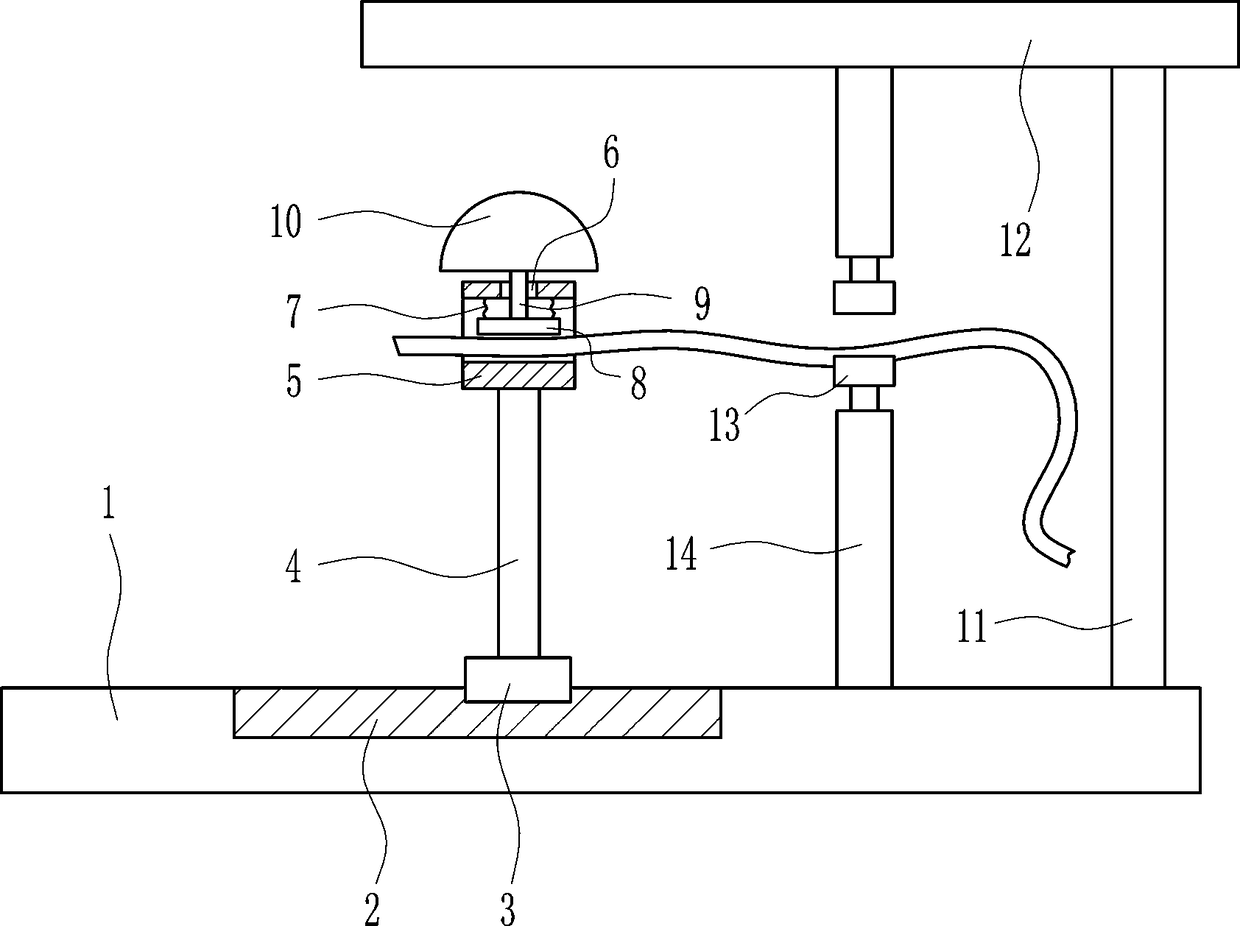

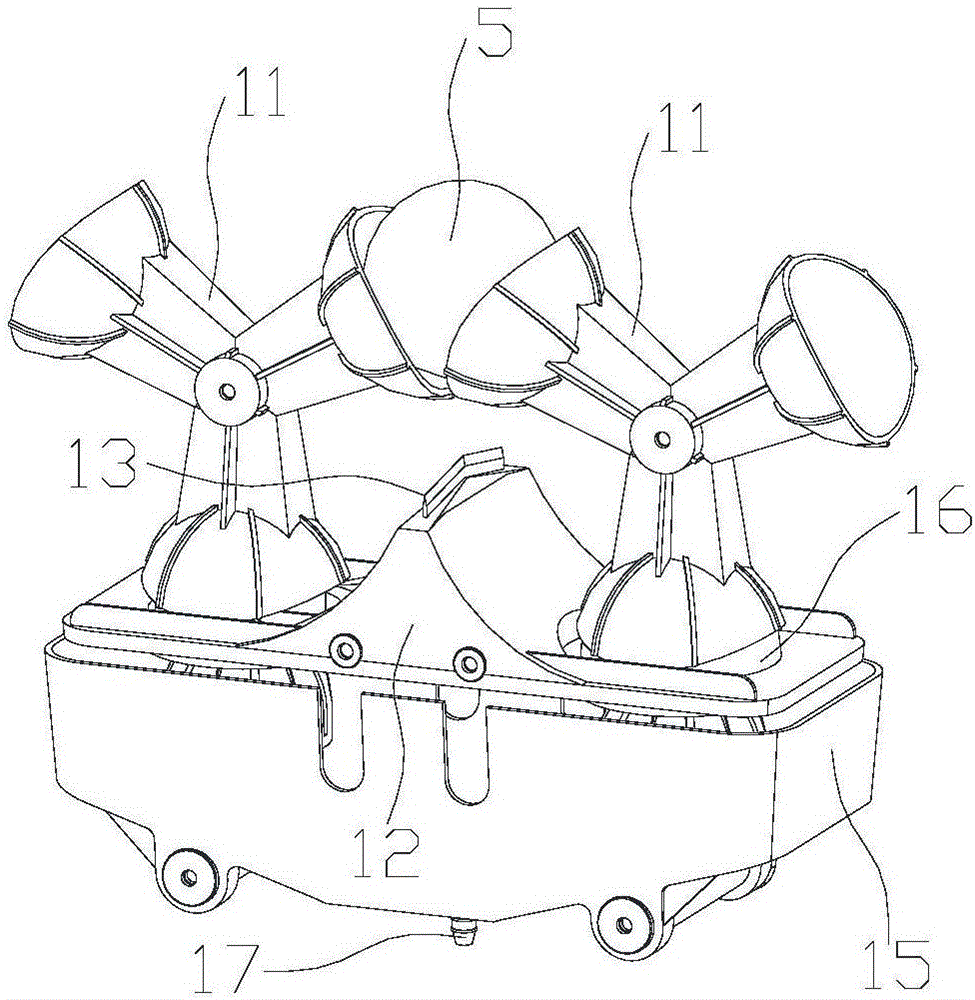

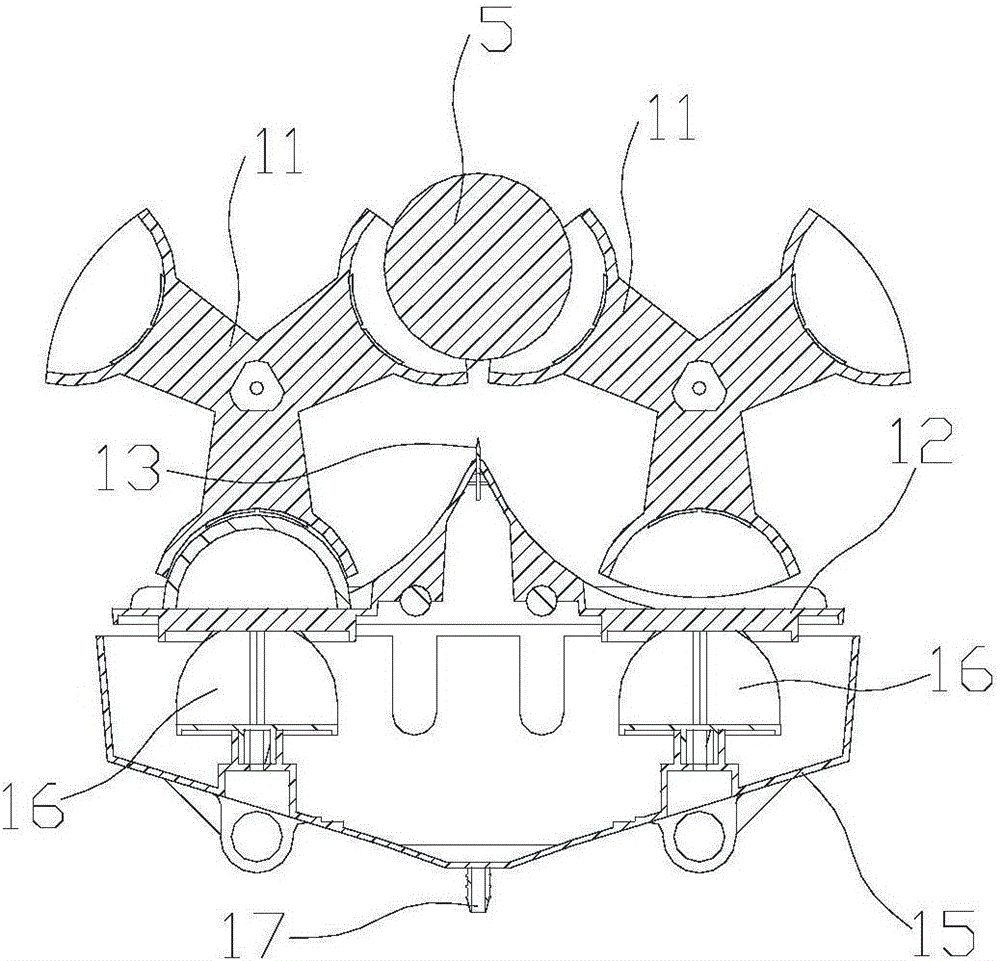

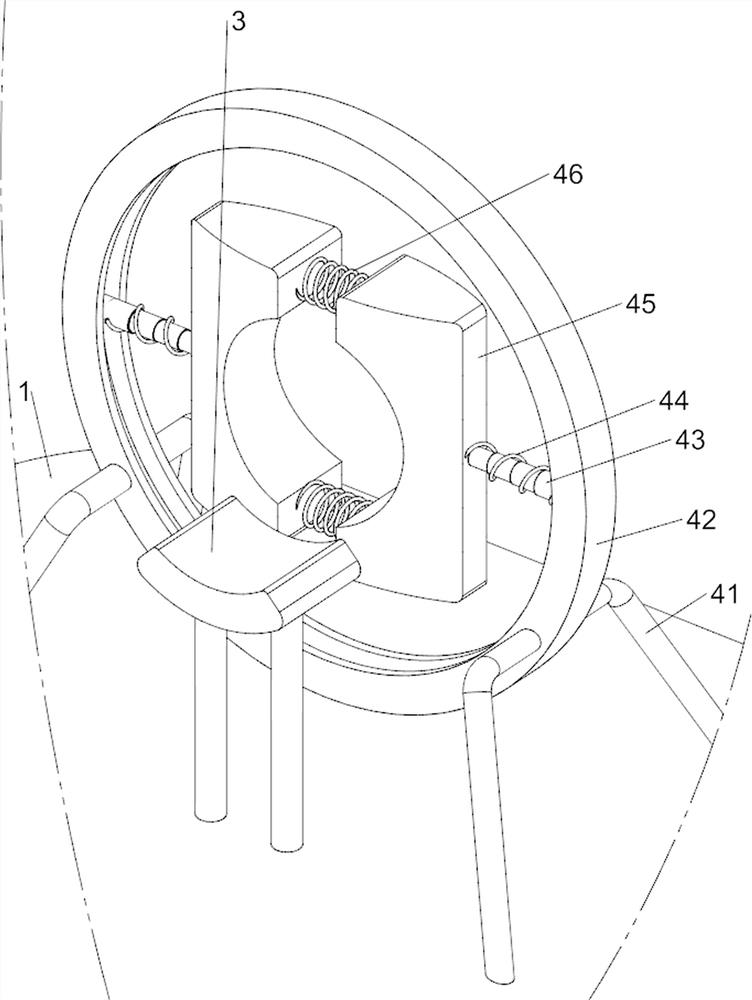

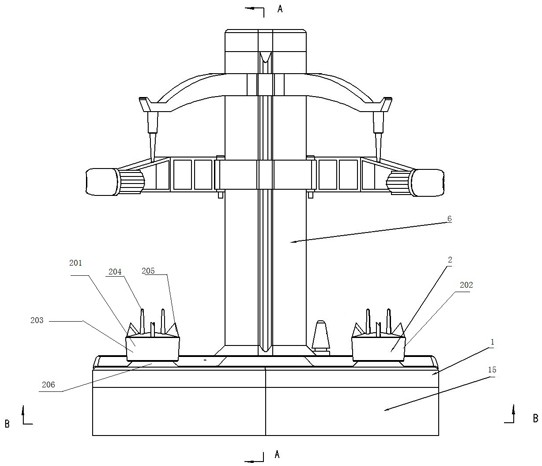

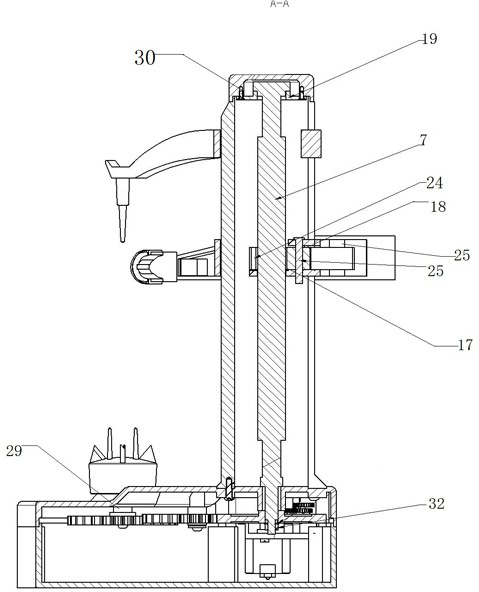

Cable stripping device

InactiveCN112421350ARealize automatic peelingAchieving circular cuttingLine/current collector detailsApparatus for removing/armouring cablesStructural engineeringElectric cables

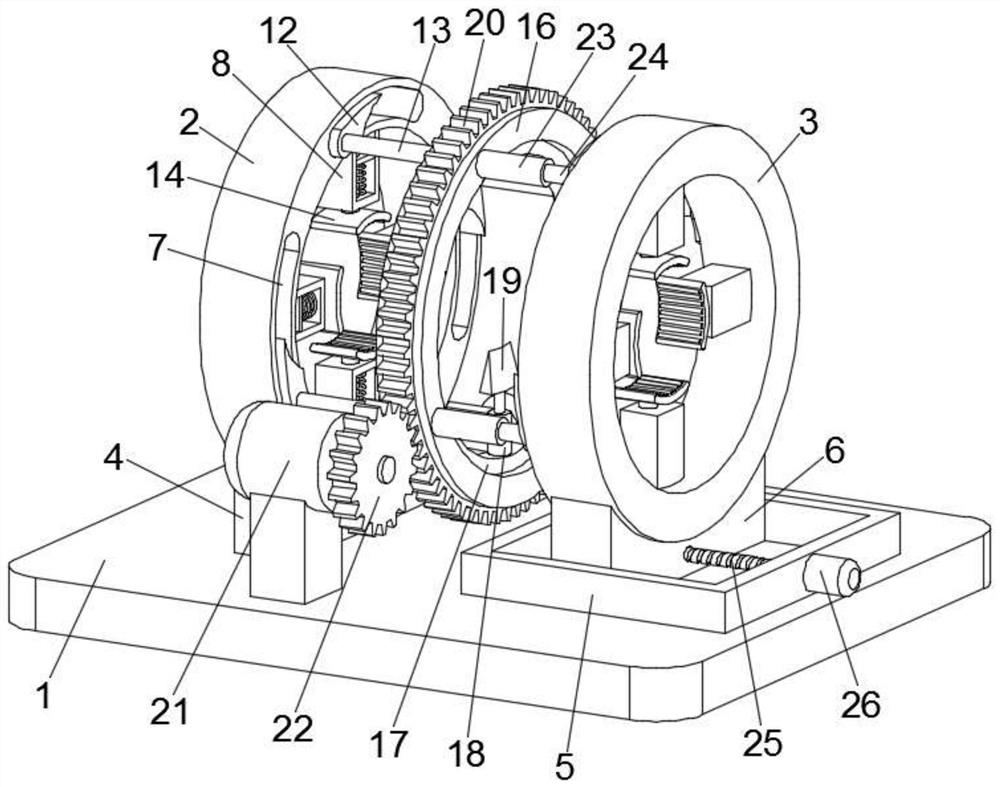

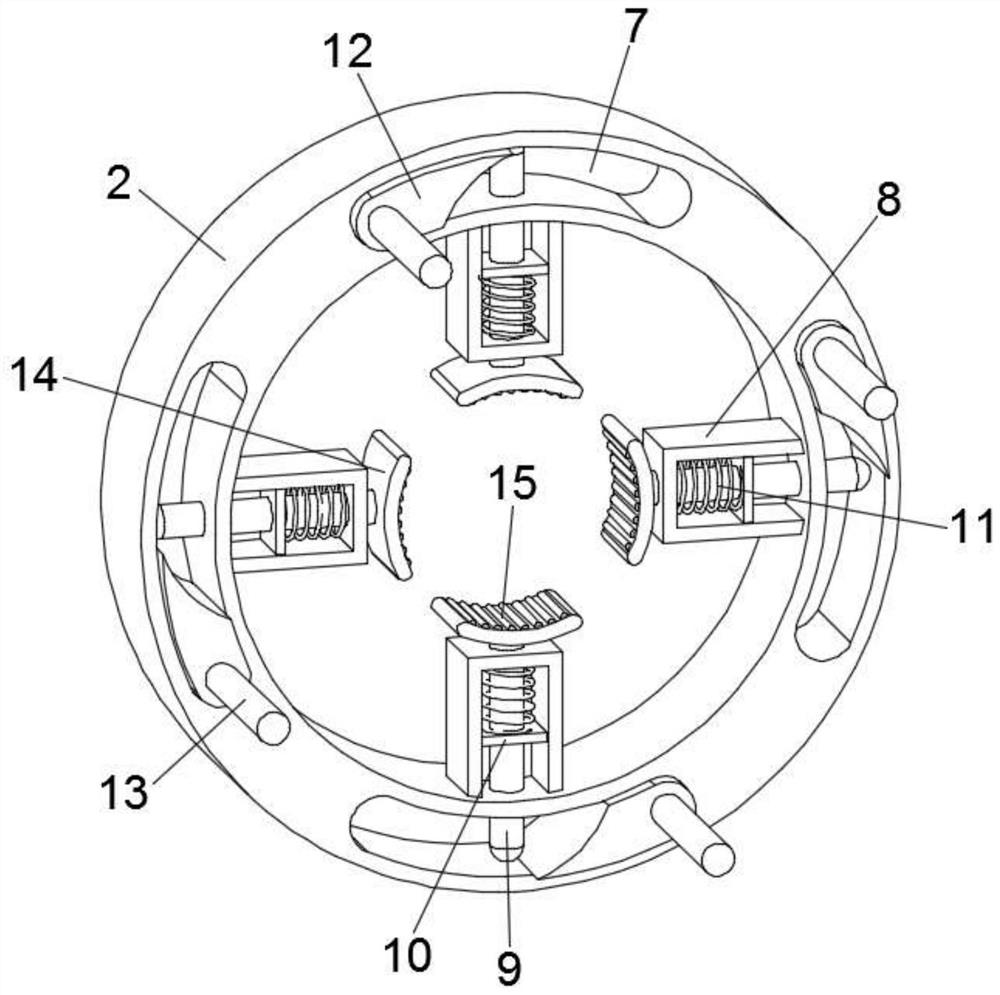

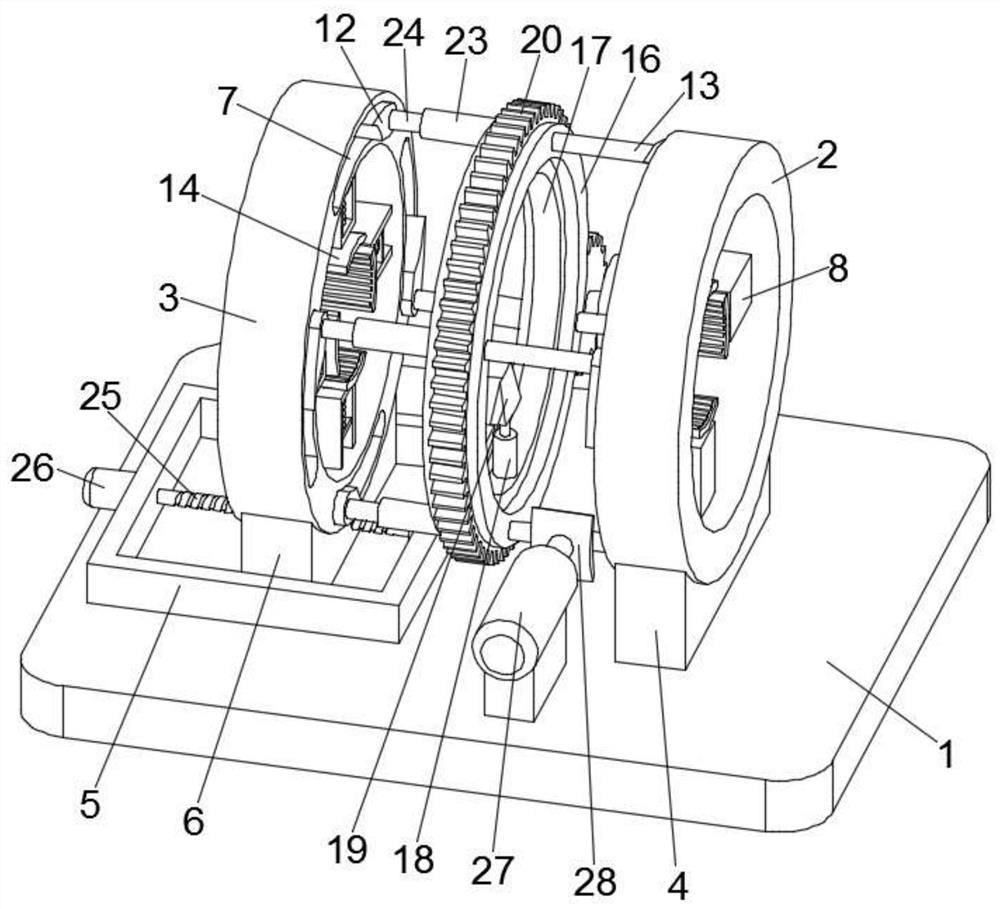

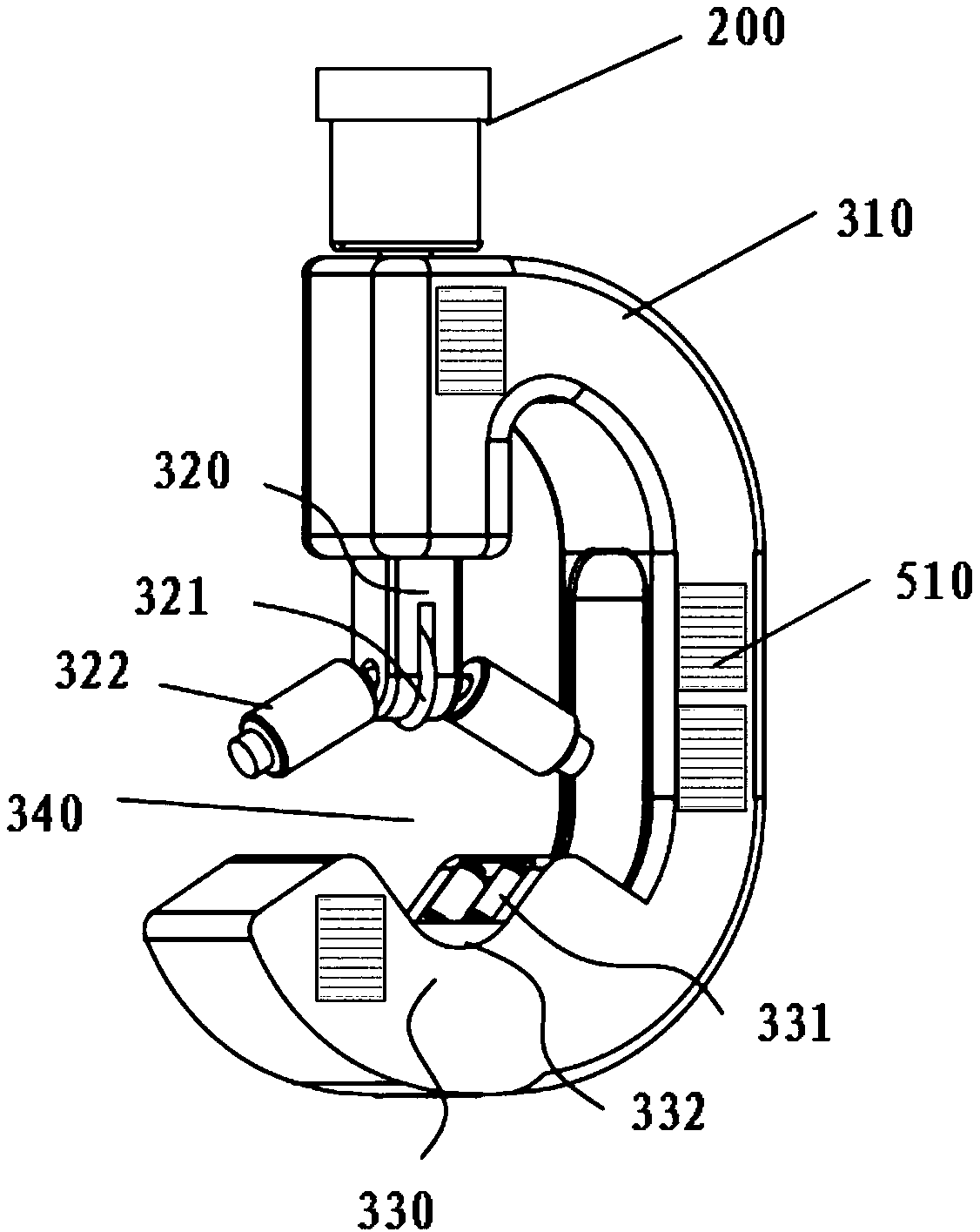

The invention discloses a cable stripping device, which comprises a base, a first support ring, a second support ring and a mounting ring; a plurality of sets of clamping assemblies are evenly distributed on the first supporting ring and the second supporting ring in the circumferential direction. A rotating ring is further rotationally embedded in the mounting ring, a telescopic column is mountedon the inner wall of the rotating ring, a blade is fixedly mounted at the extending end of the telescopic column, and a rotating mechanism for driving the rotating ring is arranged on the base. A push plate is used for pushing a first connecting rod to rotate in the circumferential direction, so that the multiple sets of clamping assemblies on the first supporting ring and the second supporting ring are driven to clamp and fix the two ends of a cable, the rotating mechanism drives the blades on the rotating ring to rotate in the circumferential direction, and annular cutting of the cable skinis achieved. And finally, the second supporting ring is driven by a translation mechanism to be far away from the first supporting ring, so that the cut cable skin is stripped from the cable core, the automatic stripping of the cable is realized, cables with different diameters can be stripped, the processing efficiency is high, and the stripping quality is stable and reliable.

Owner:王广飞

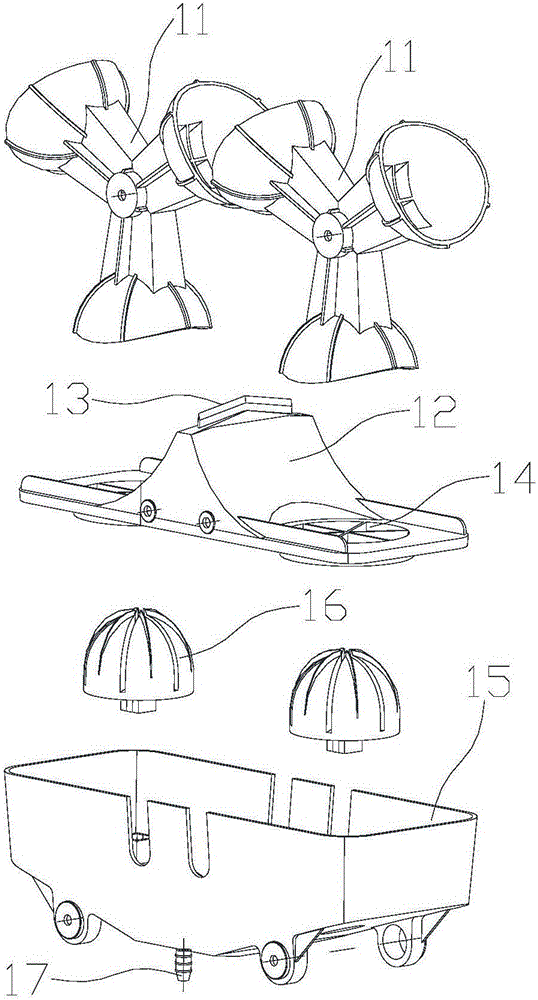

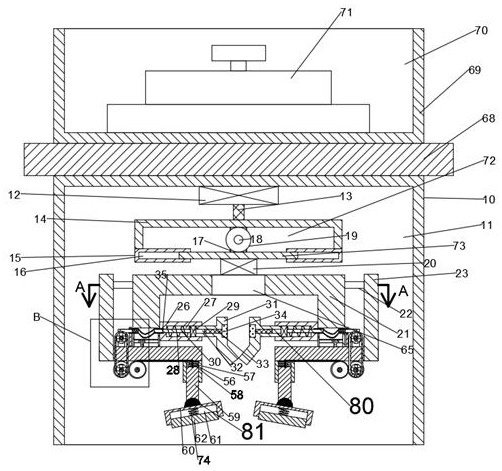

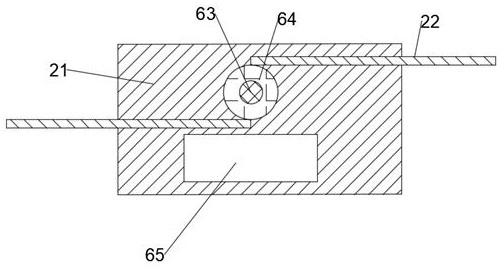

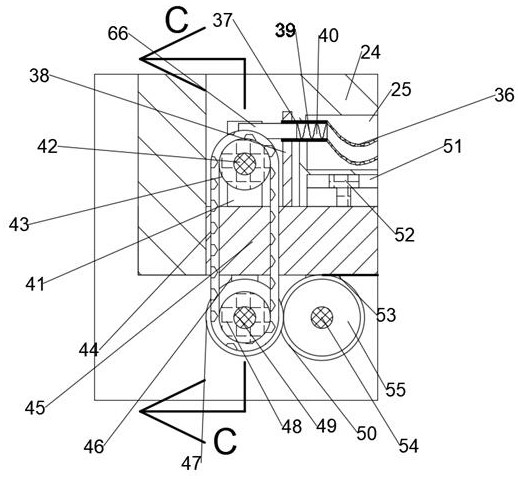

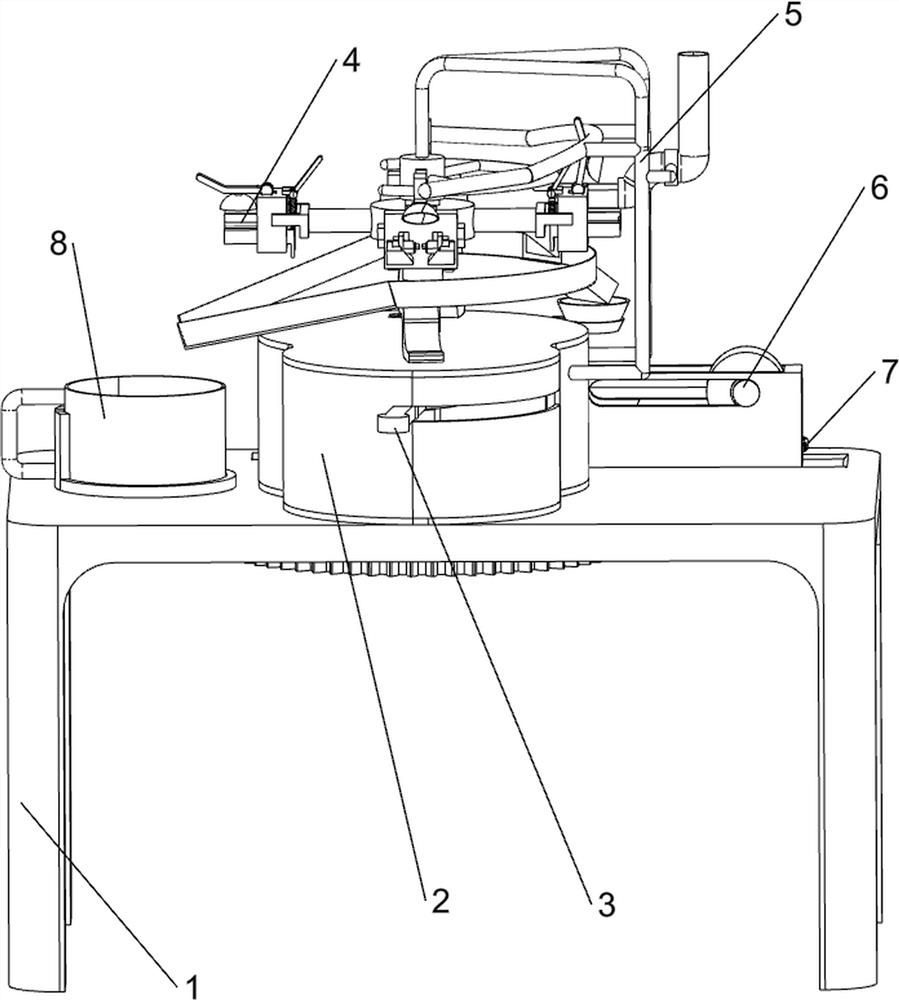

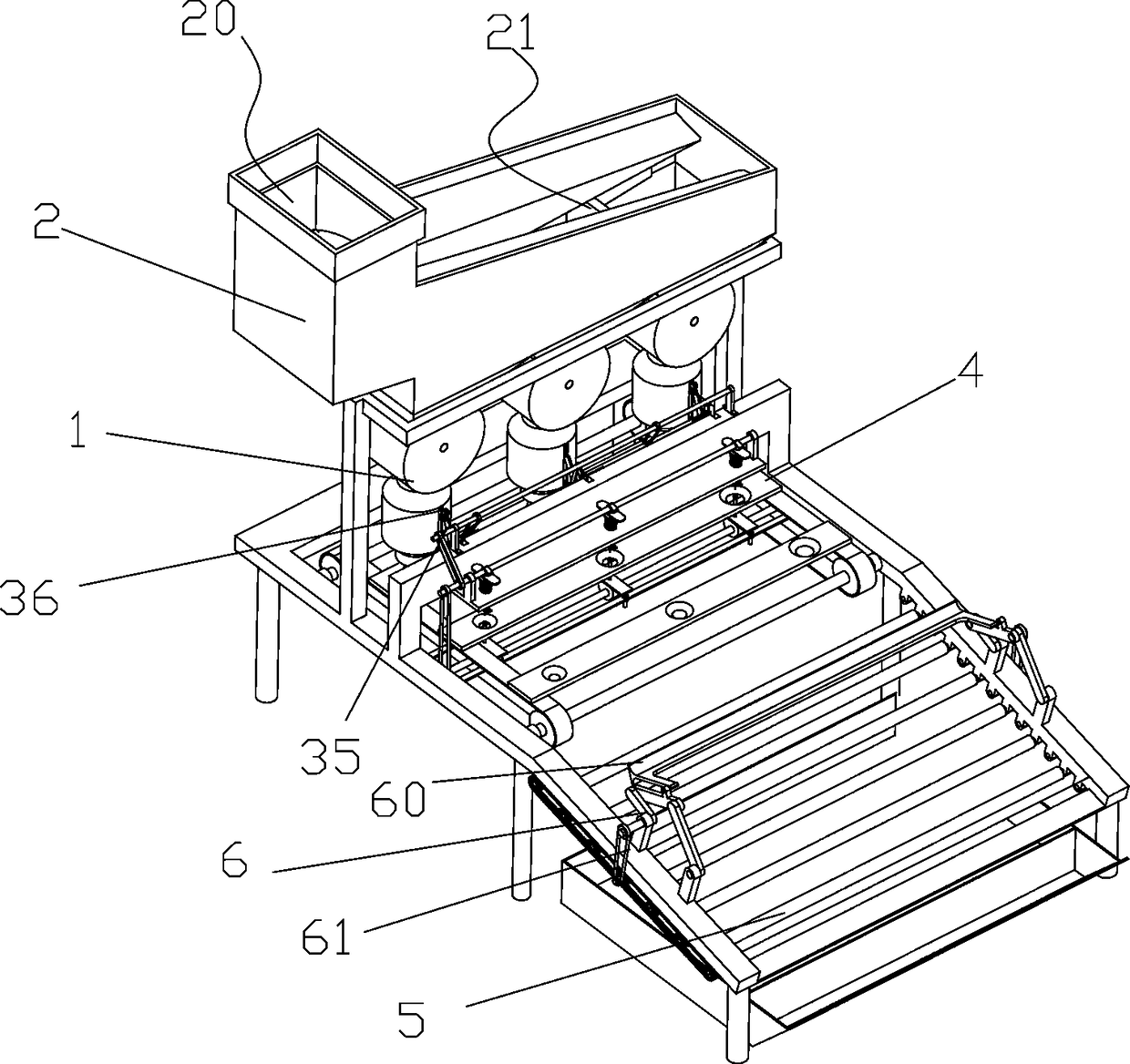

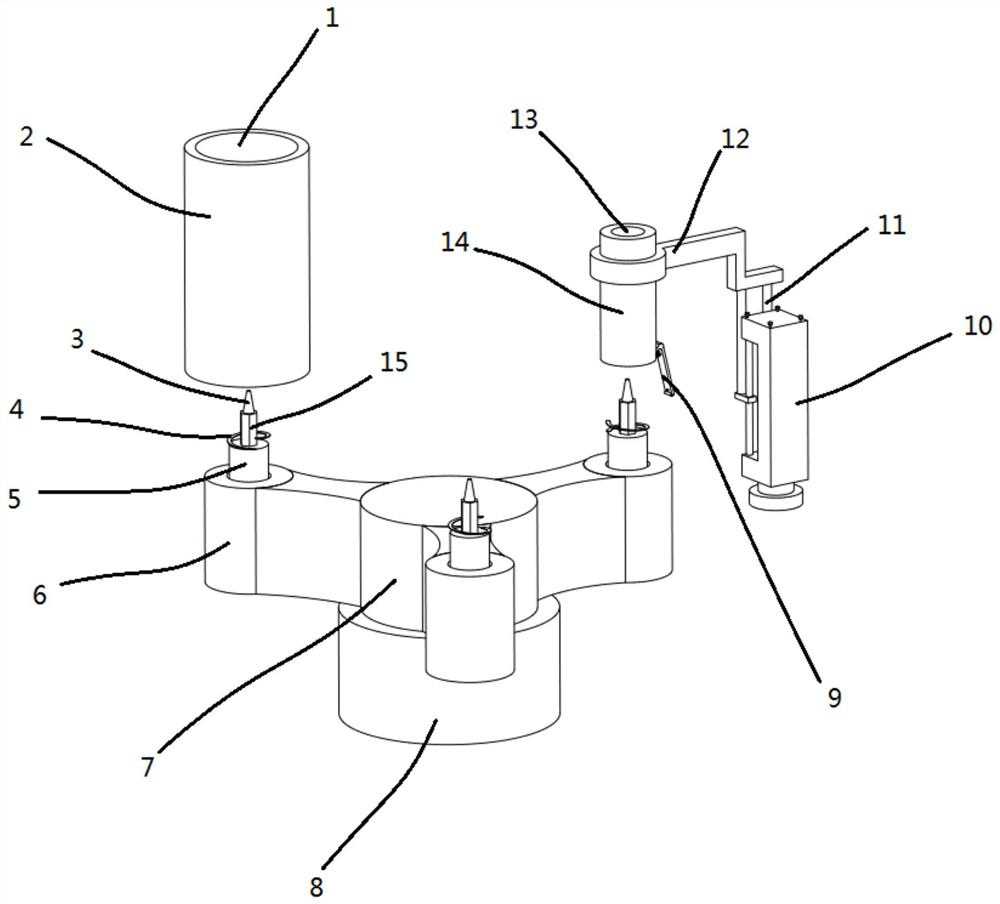

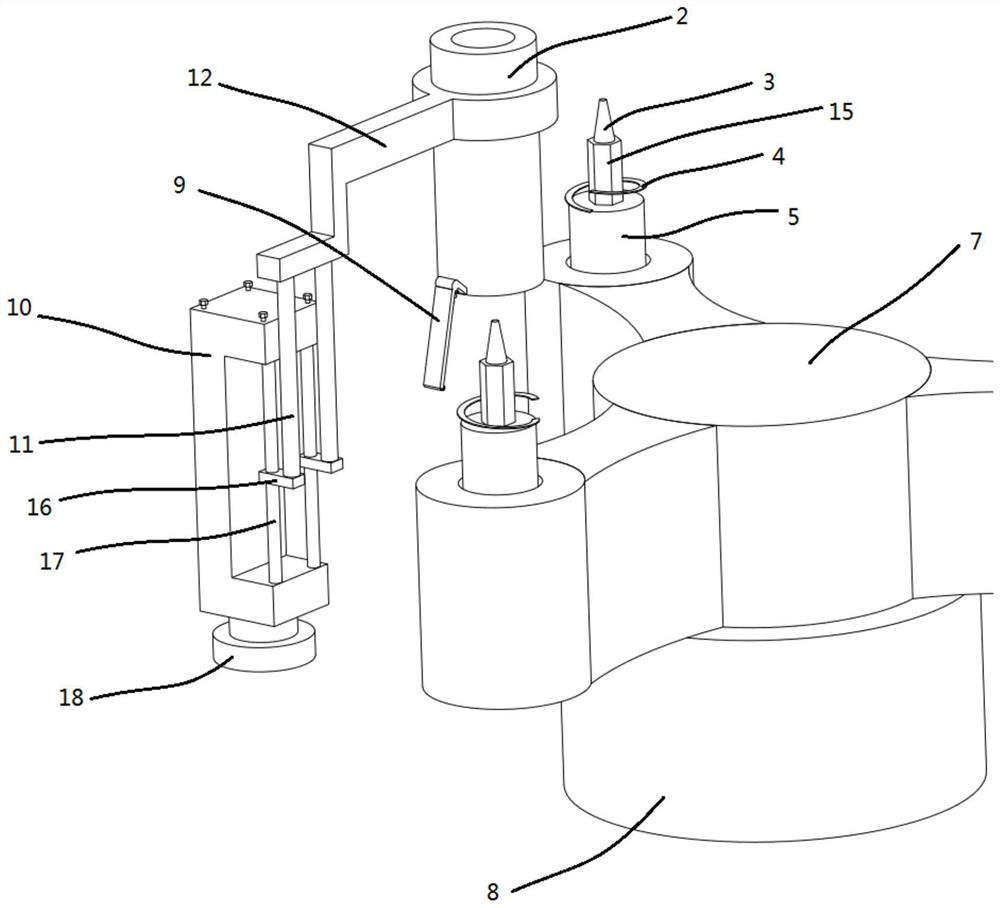

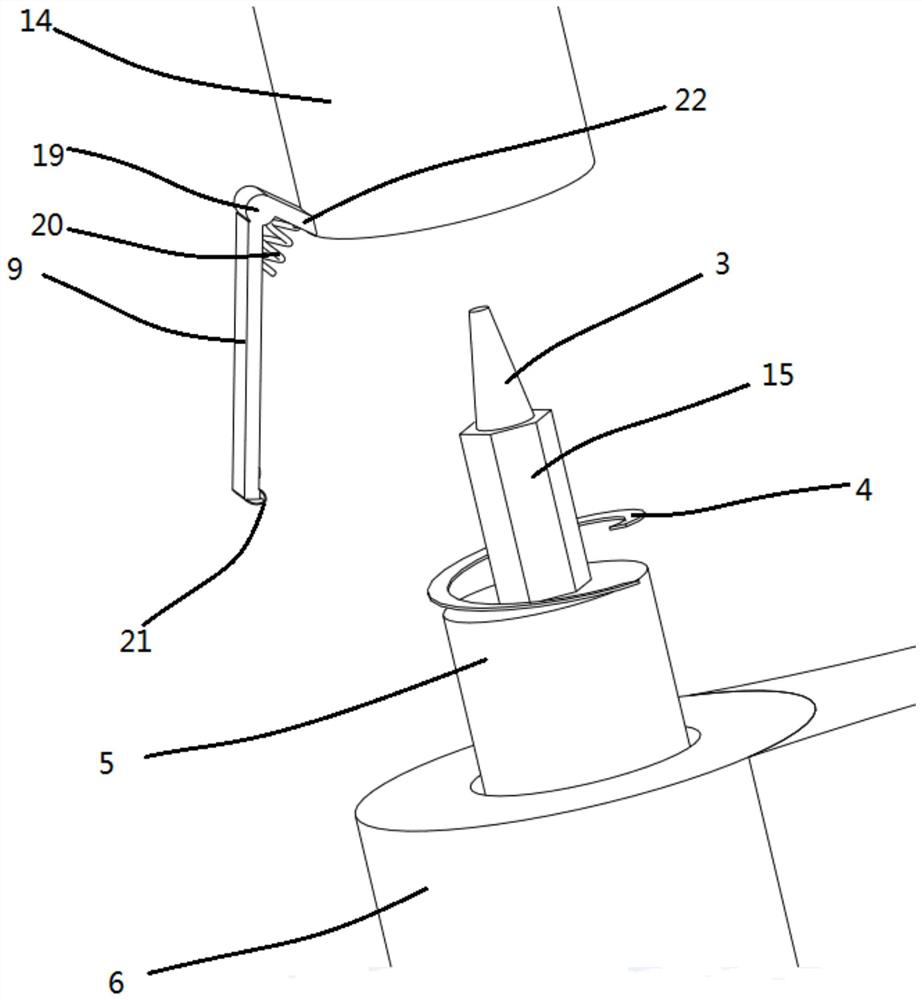

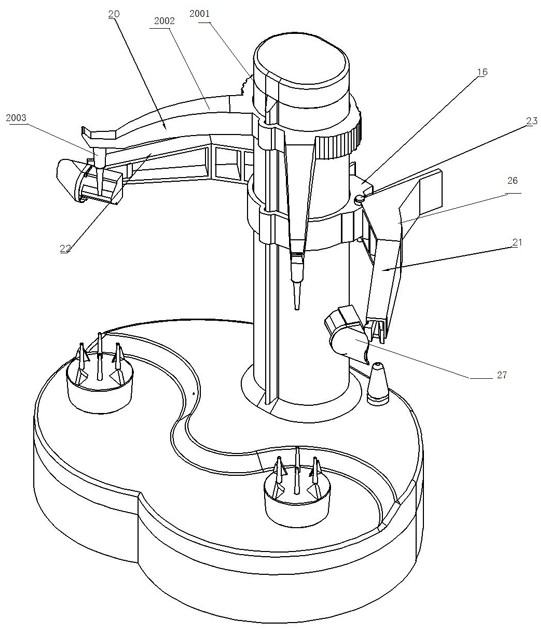

Manual-work-imitated melon/fruit peeling machine

InactiveCN106072693ARealize automatic peelingImprove peeling efficiencyVegetable peelingTransmission beltEngineering

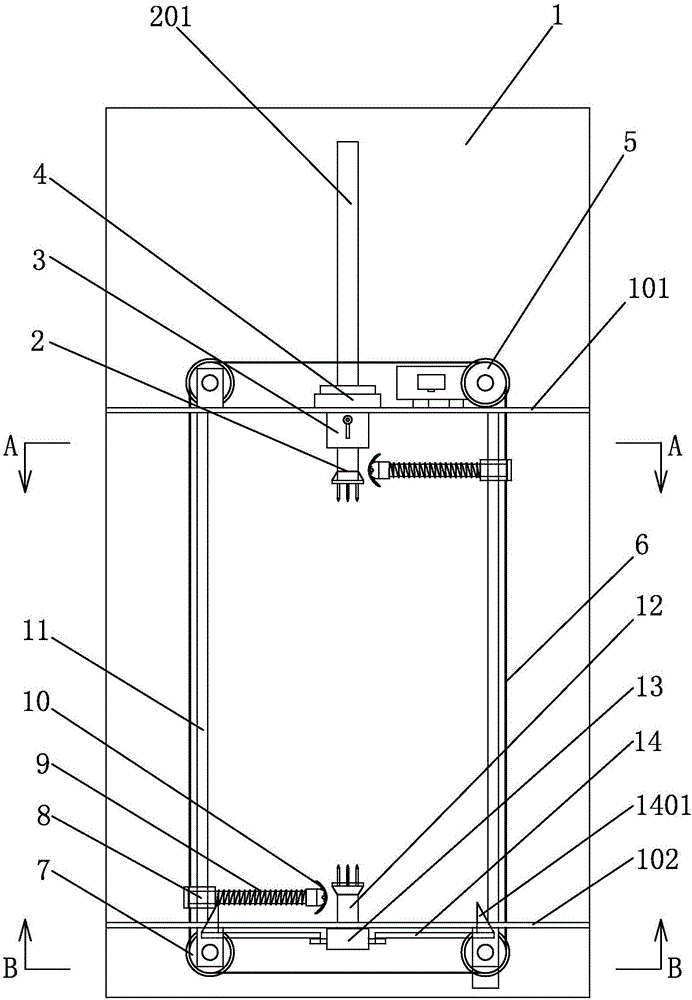

The invention relates to a manual-work-imitated melon / fruit peeling machine for peeling off fruits. The manual-work-imitated melon / fruit peeling machine comprises a rack, a clamping mechanism and a peeling mechanism, wherein the rack comprises an upper fixed plate and a lower fixed plate; a peeling working region is formed between the upper fixed plate and the lower fixed plate; an upper clamping part which rotates and can be adjusted in a lifting manner is arranged on the upper fixed plate; a lower clamping part capable of rotating in one direction is arranged on the lower fixed plate; an upper transmission belt wheel is arranged on the upper end face of the upper fixed plate and a lower transmission belt wheel is arranged on the lower end face of the lower fixed plate; the upper transmission belt wheel and the lower transmission belt wheel are connected through a transmission belt; the transmission belt vertically passes through the peeling working region; the peeling mechanism comprises a lifting bracket, an elastic bracket and a peeling knife; the transmission belt is fixedly connected with the lifting bracket; the lifting bracket is connected with the peeling knife through the elastic bracket, so that the peeling knife is self-adaptive to surfaces of melons and fruits in the peeling working region; and a guide rod which is used for limiting a lifting knife rest to slide in the vertical direction is arranged between the upper fixed plate and the lower fixed plate. The manual-work-imitated melon / fruit peeling machine is high in peeling efficiency, is safe and reliable, and is suitable for being used as peeling equipment for various types of fruits.

Owner:宁波市奉化奇佳机械设备有限公司

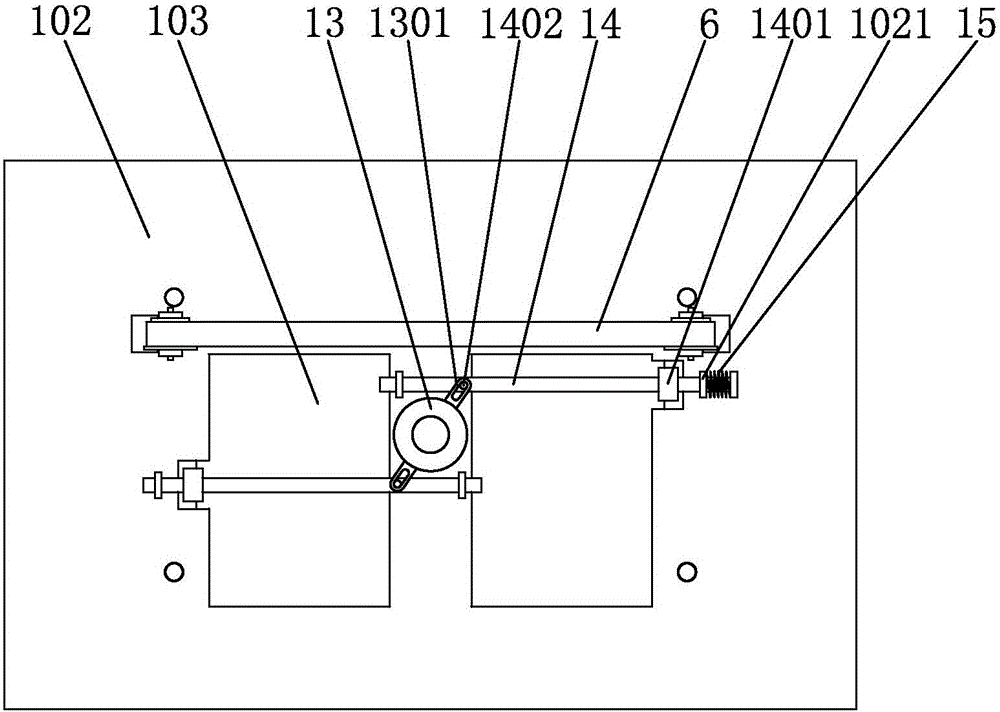

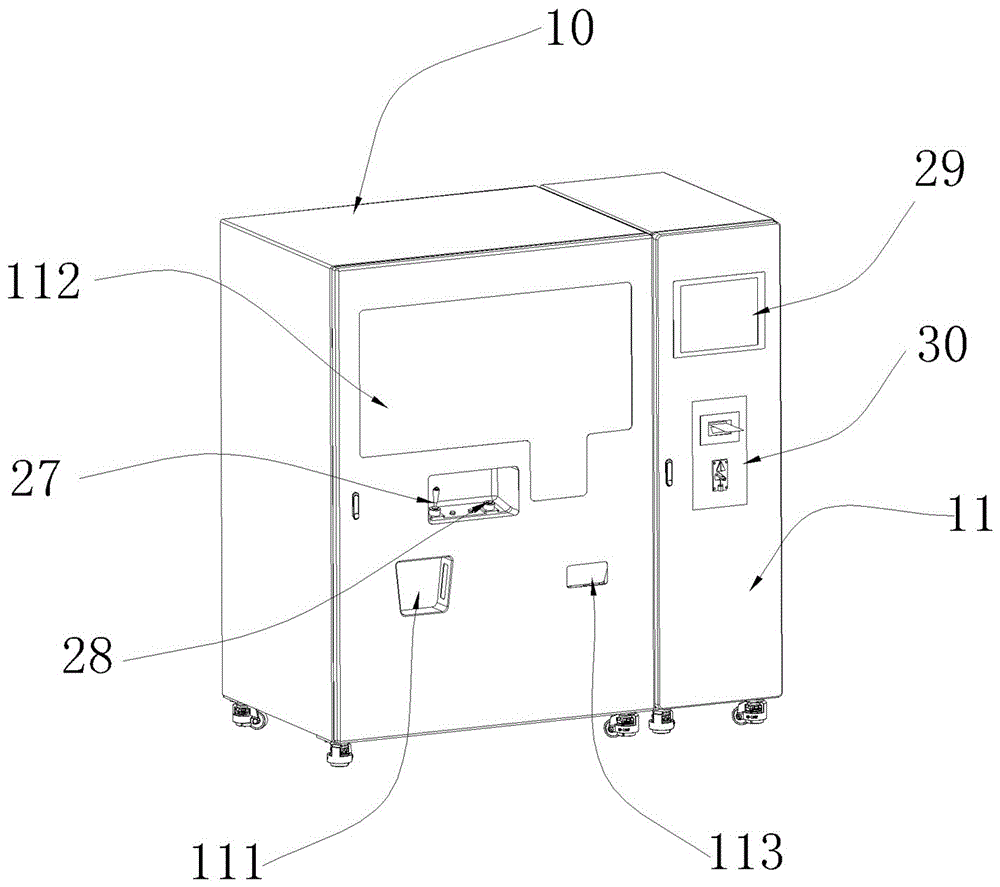

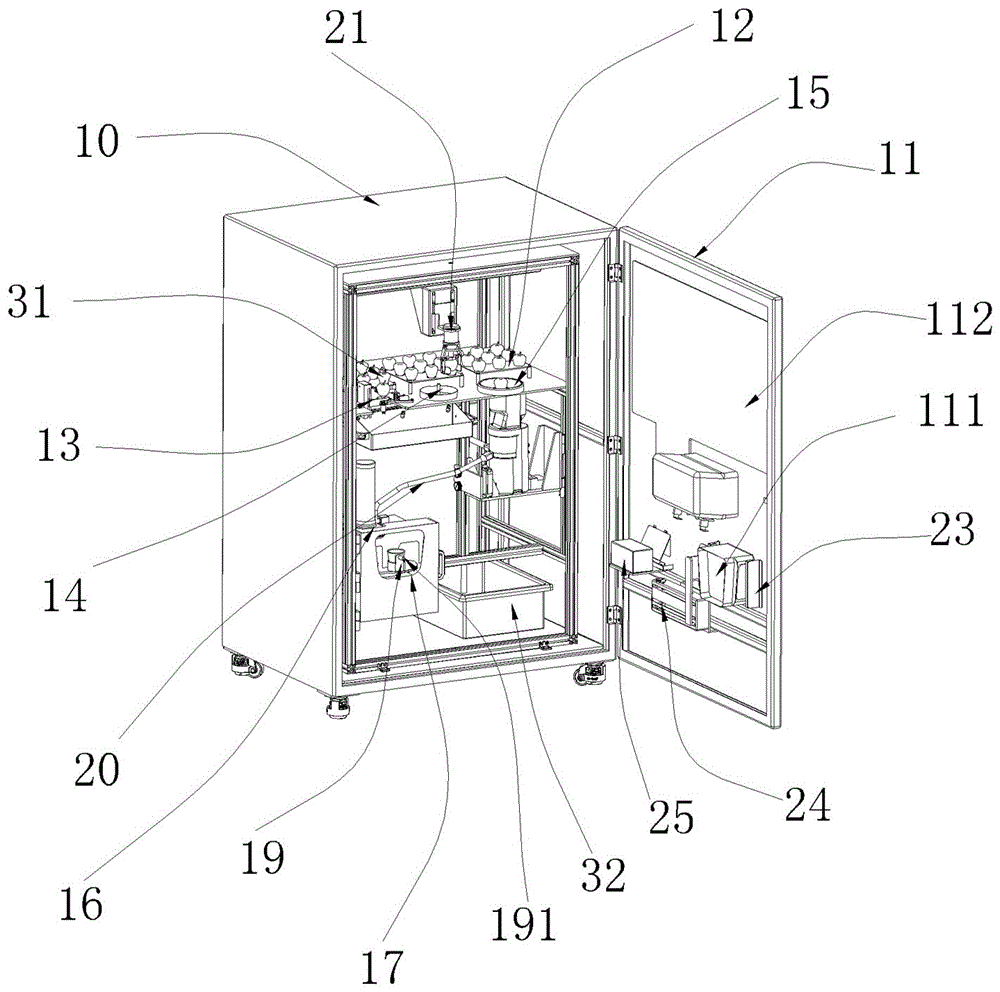

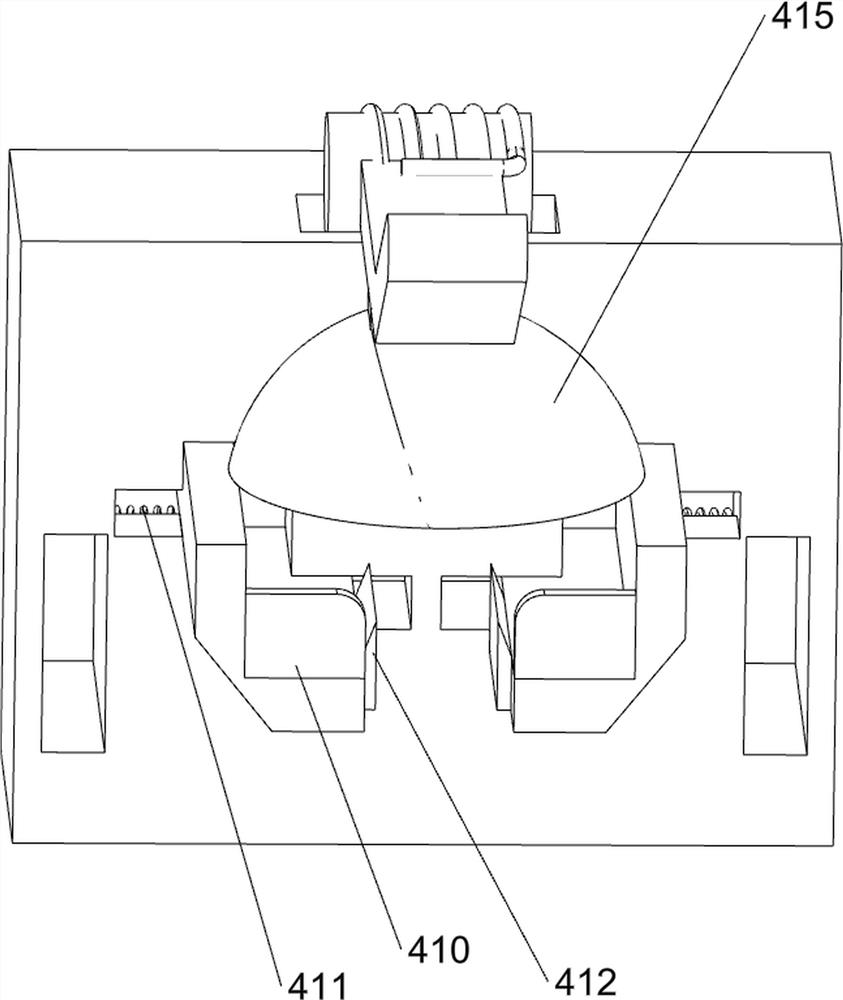

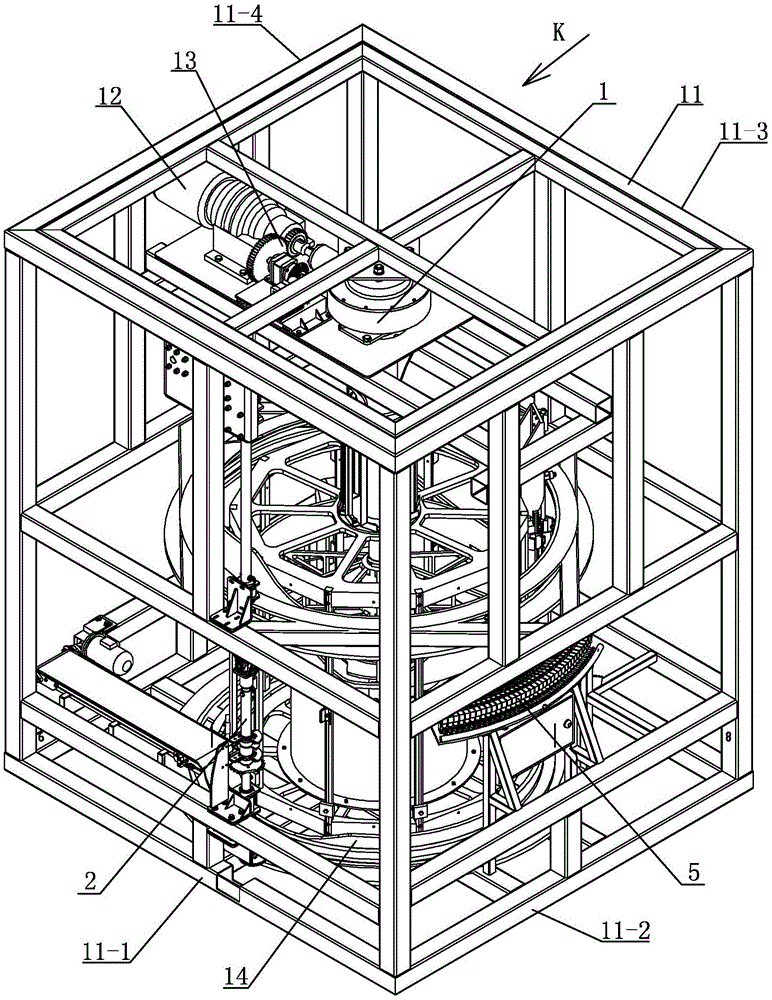

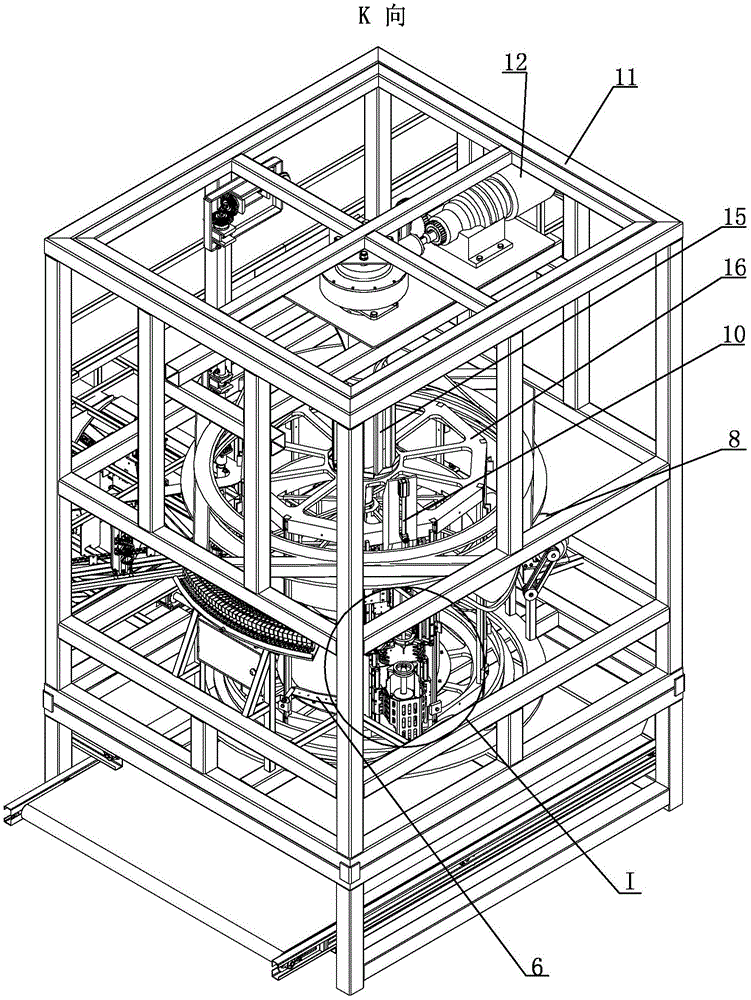

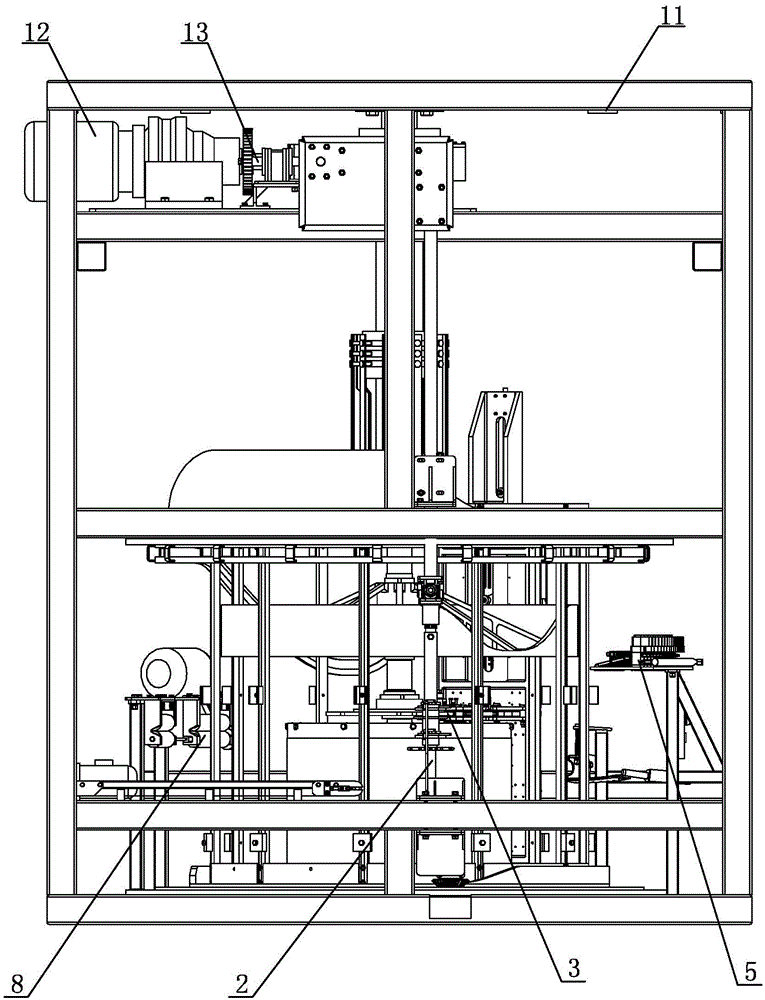

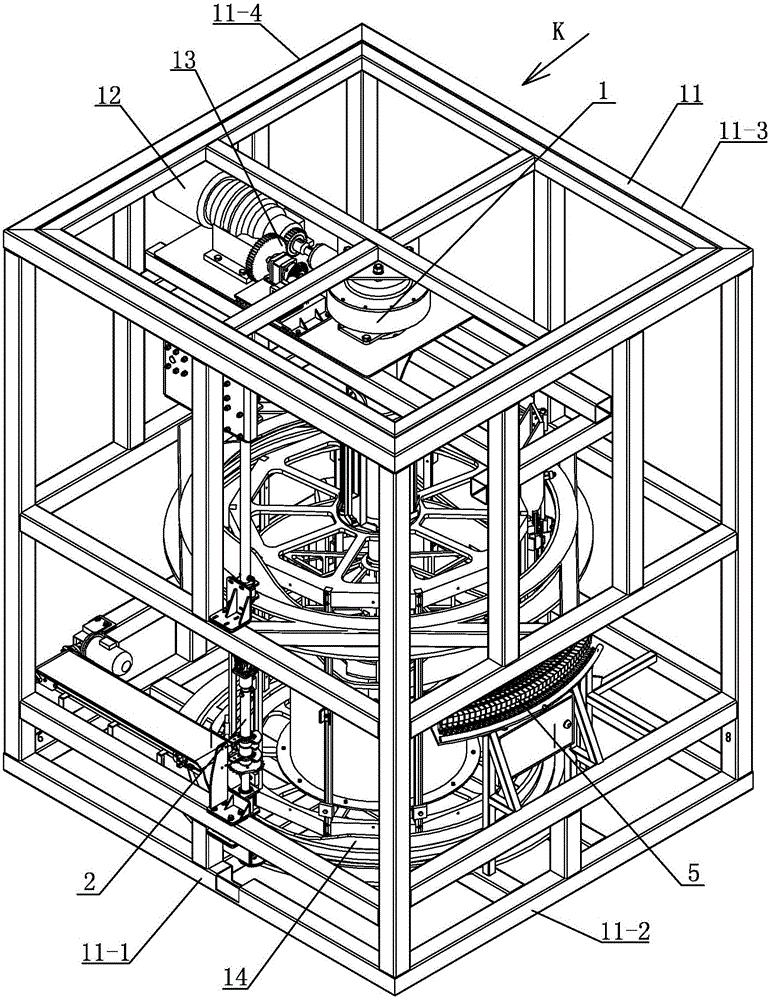

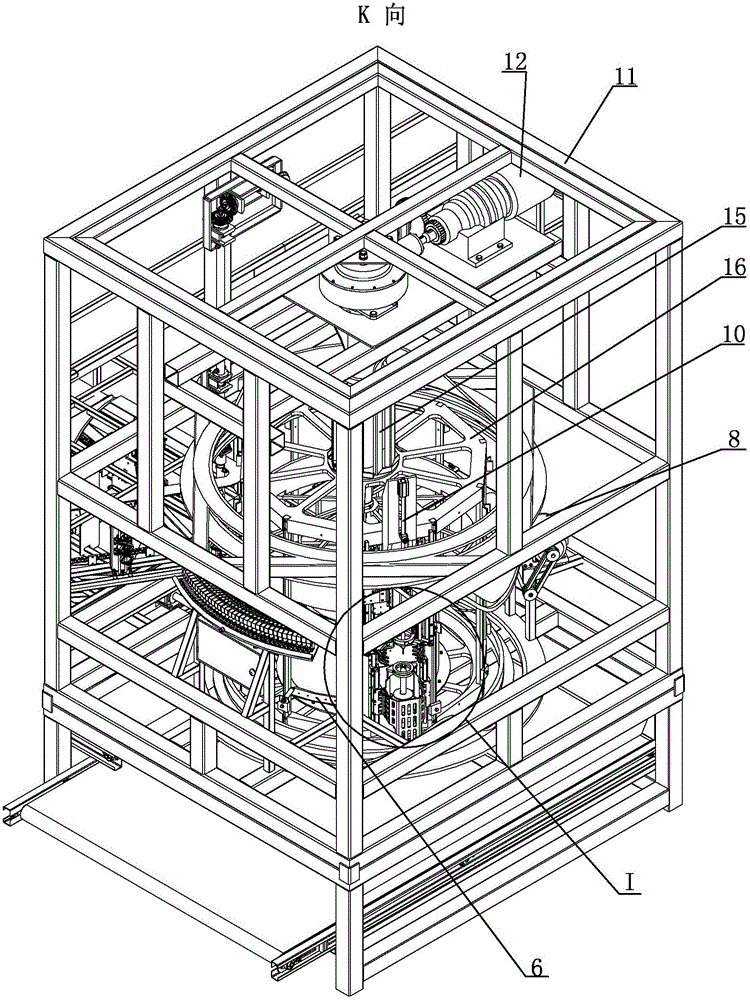

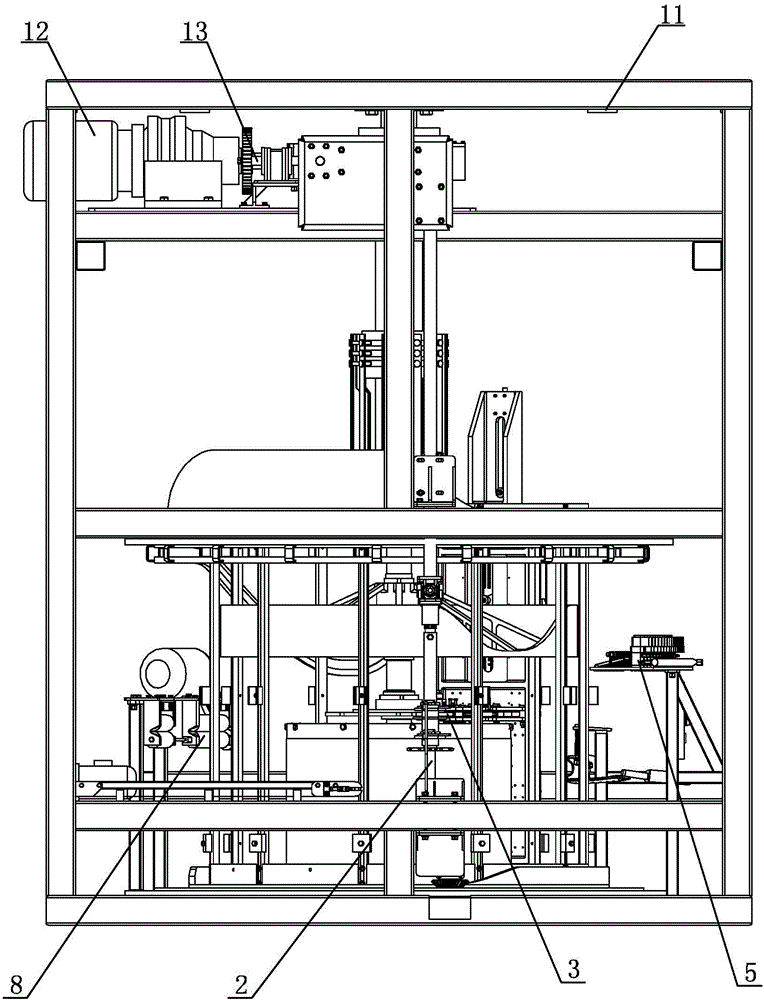

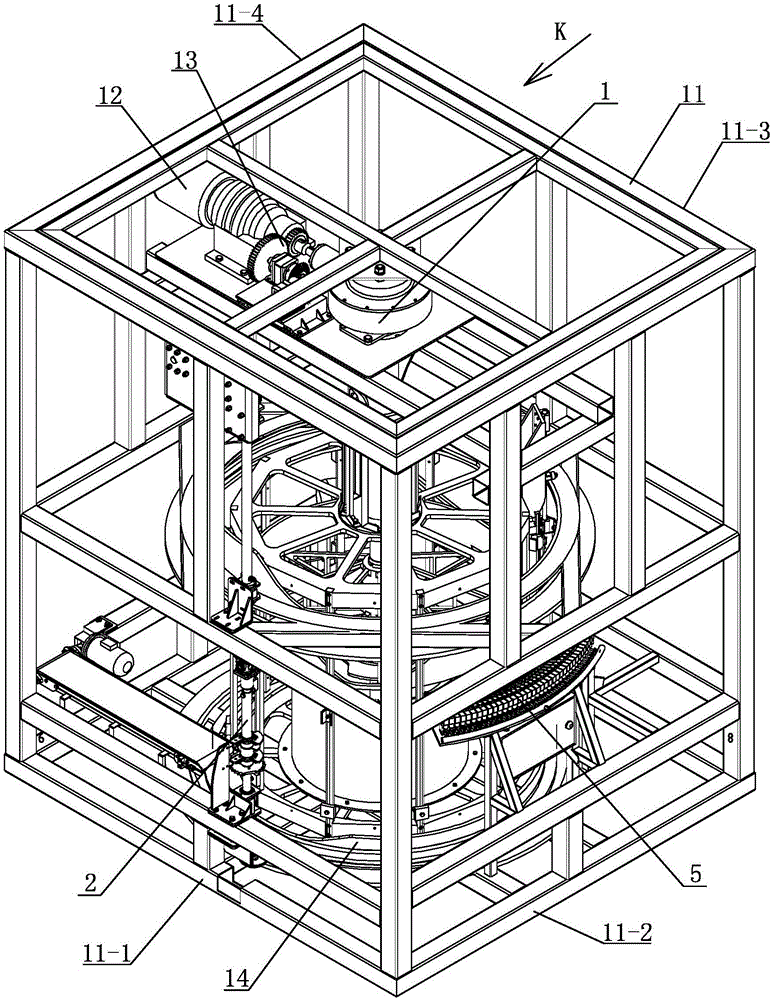

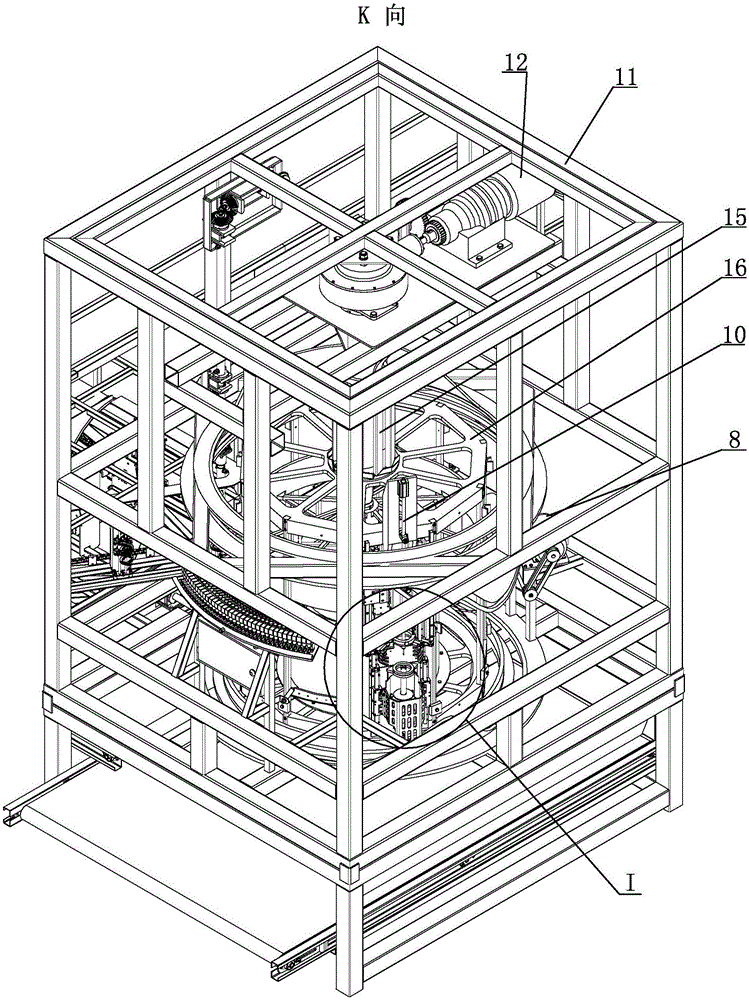

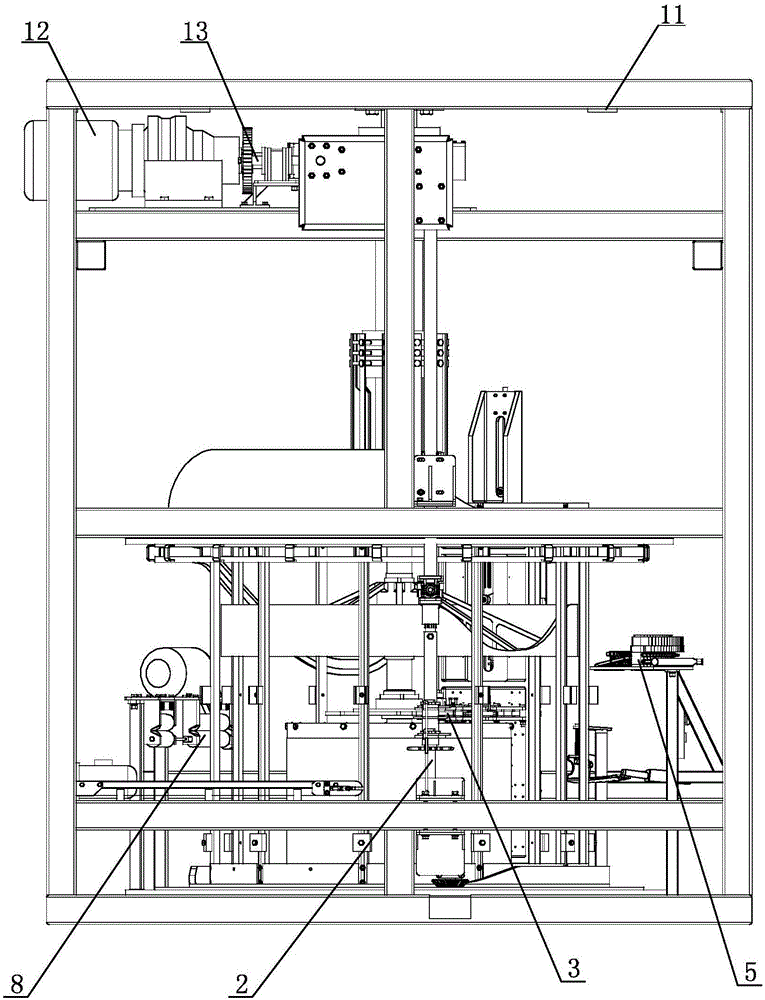

Automatic juicing and taking equipment of beverage dispenser and method thereof

ActiveCN105761361ASimple structureImprove convenienceKitchen fruit stoningApparatus for dispensing fluids/granular materialsEngineering

The invention discloses automatic juicing and taking equipment of a beverage dispenser and a method thereof. The equipment comprises a box, a box door connected with the box in a pivoting mode, a fruit storing area, a peeling device, a core removing device, a juicing device, a cup dropping device, a rotating cup conveying device, a residual juice collecting device and a juice level induction device, wherein the fruit storing area, the peeling device, the core removing device, the juicing device, the cup dropping device, the rotating cup conveying device and the residual juice collecting device are arranged in the box, and the juice liquid level induction device is arranged on the rotating cup conveying device. A mechanical hand used for grabbing fruit is arranged at the inner top end of the box. The peeling device, the core removing device and the juicing device are sequentially placed. The juicing device is communicated with a beverage outlet through a beverage pipe. The cup dropping device is located above the rotating cup conveying device. The residual juice collecting device is communicated with the beverage outlet. Automatic peeling, core removing and juicing can be achieved, labor is omitted, and juicing convenience is improved; in addition, the automatic beverage dispenser can drop the cups, convey the cups and collect residual juice automatically, and the problem that labor participation is needed in the using process is solved effectively.

Owner:SHENZHEN QIANGRUI ELECTRONICS

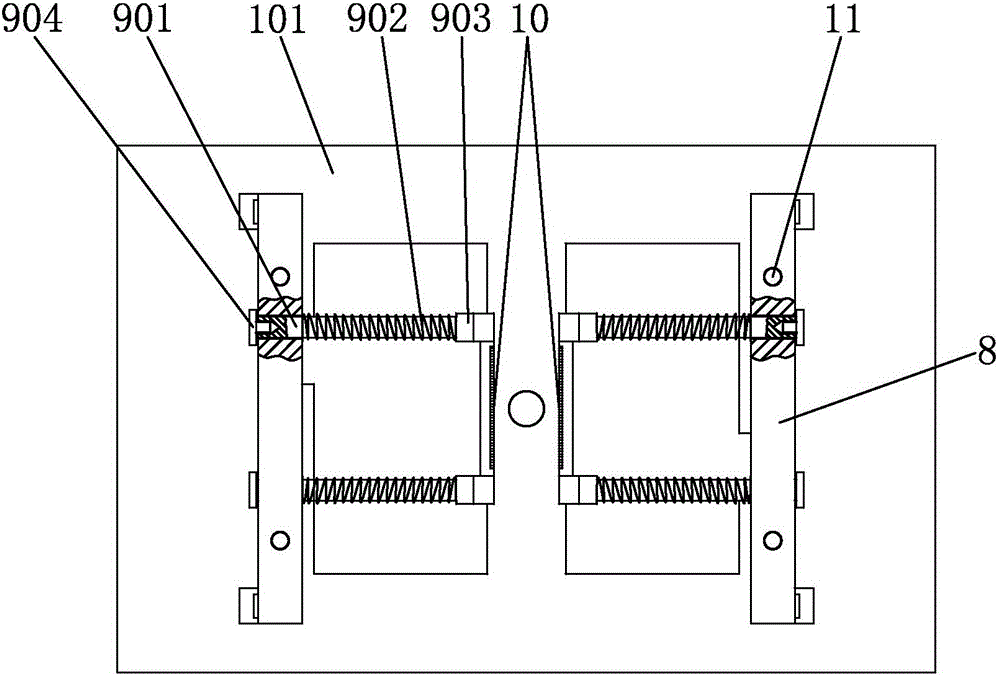

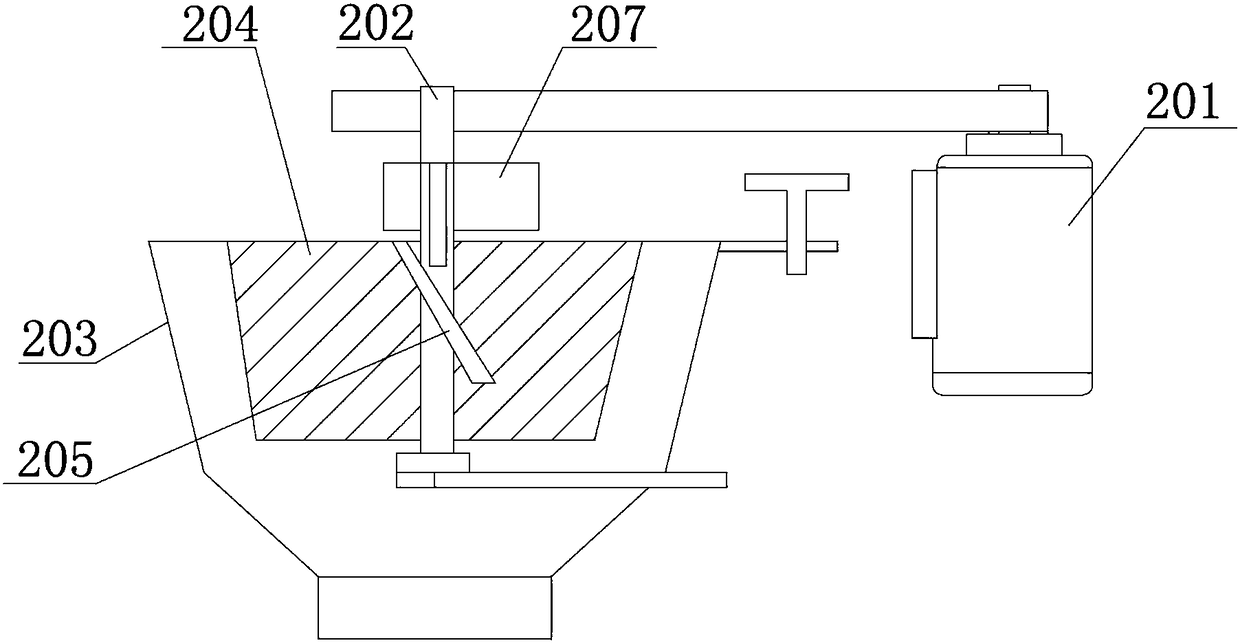

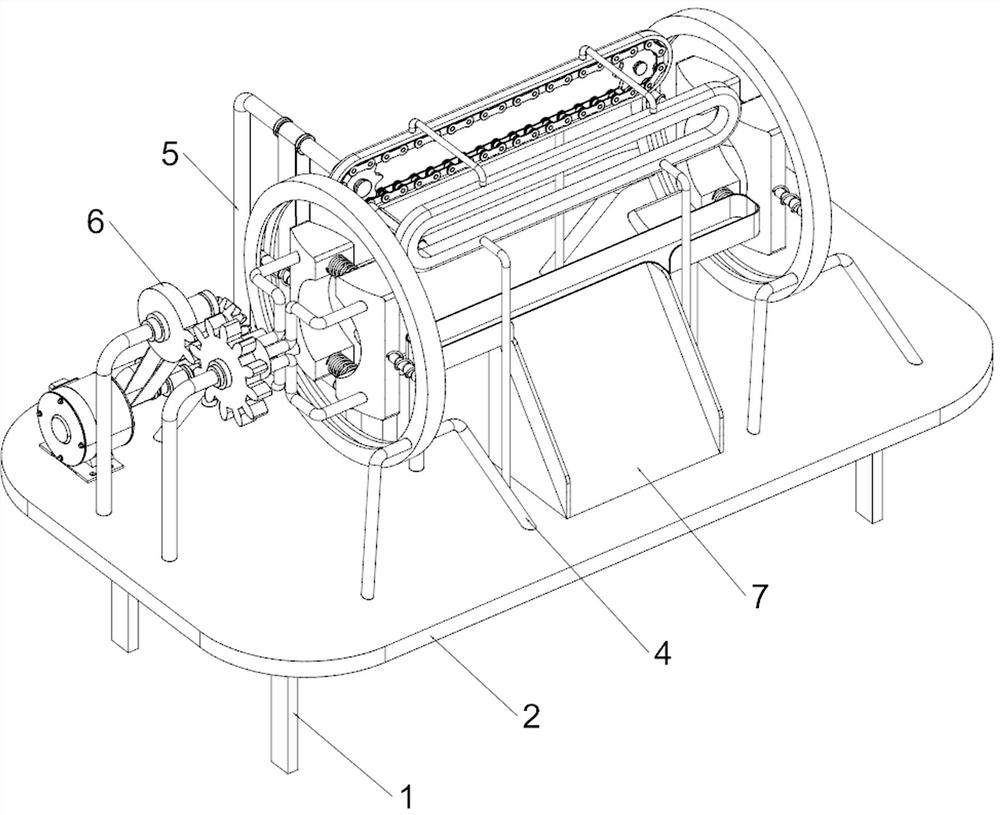

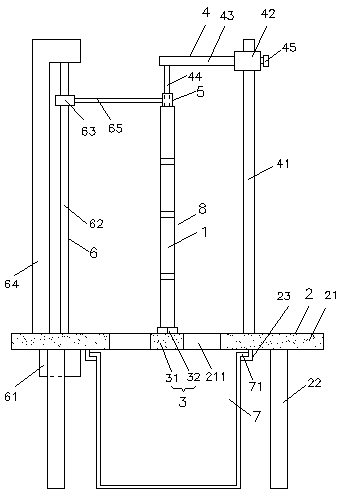

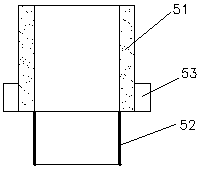

Mechanical peeling equipment for wire recycling

ActiveCN108899812AEasy to peelSo as not to damageApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention relates to mechanical peeling equipment, and particularly relates to mechanical peeling equipment for wire recycling. The technical problem of the invention is to provide mechanical peeling equipment for wire recycling which is high in working efficiency and does not damage conductors inside wires. The mechanical peeling equipment for wire recycling comprises a bottom plate, a firstsliding rail, a first sliding block, a support rod, a circular tube, a first spring, a pressing plate and the like; the left side of the top of the bottom plate is embedded with the first sliding rail, the first sliding block is arranged in a sliding manner on the first sliding rail, the support rod is arranged at the middle of the top of the first sliding block, the circular tube is arranged on the top end of the support rod, the upper wall of the circular tube is provided with a guide hole, and the both the left side and the right side of the inner wall of the circular tube are connected with the first spring. The mechanical peeling equipment achieves the effects of being high in working efficiency and not damaging conductors inside wires. The mechanical peeling equipment is enabled to perform peeling on the wires easily through the cooperation of a bulge and a cutting knife.

Owner:TIANCHANG TIANFENG MECHANICAL & ELECTRICAL TECH CO LTD

Small bamboo shoot peeling machine for food processing

ActiveCN111869895ARealize automatic peelingEasy to collectClimate change adaptationVegetable peelingBamboo shootEngineering

The invention relates to a peeling machine, in particular to a small bamboo shoot peeling machine for food processing, and provides the small bamboo shoot peeling machine for food processing, which can achieve automatic peeling and is high in efficiency. The small bamboo shoot peeling machine for food processing comprises a base, an inclined plate, a cutter, a pushing mechanism, a peeling mechanism and a collecting box, wherein two groups of supporting columns are arranged at the top of the base, and every two supporting columns form one group; the inclined plate is connected between the top ends of the supporting columns; the cutter is arranged at the middle of one end of the inclined plate; the pushing mechanism is arranged on one side of the top edge of the base; the peeling mechanism is arranged on the inclined plate; and the collecting box is arranged on the side away from the pushing mechanism, of the top of the base. Through cooperation of the pushing mechanism and the peeling mechanism, when a sliding block moves leftwards, a peeling rod rotates clockwise, then automatic peeling of the small bamboo shoots is achieved, the working difficulty of people is reduced, and the efficiency is improved; and then the peeled small bamboo shoots are better collected through the collecting box.

Owner:揭阳市青源农业种养基地有限公司

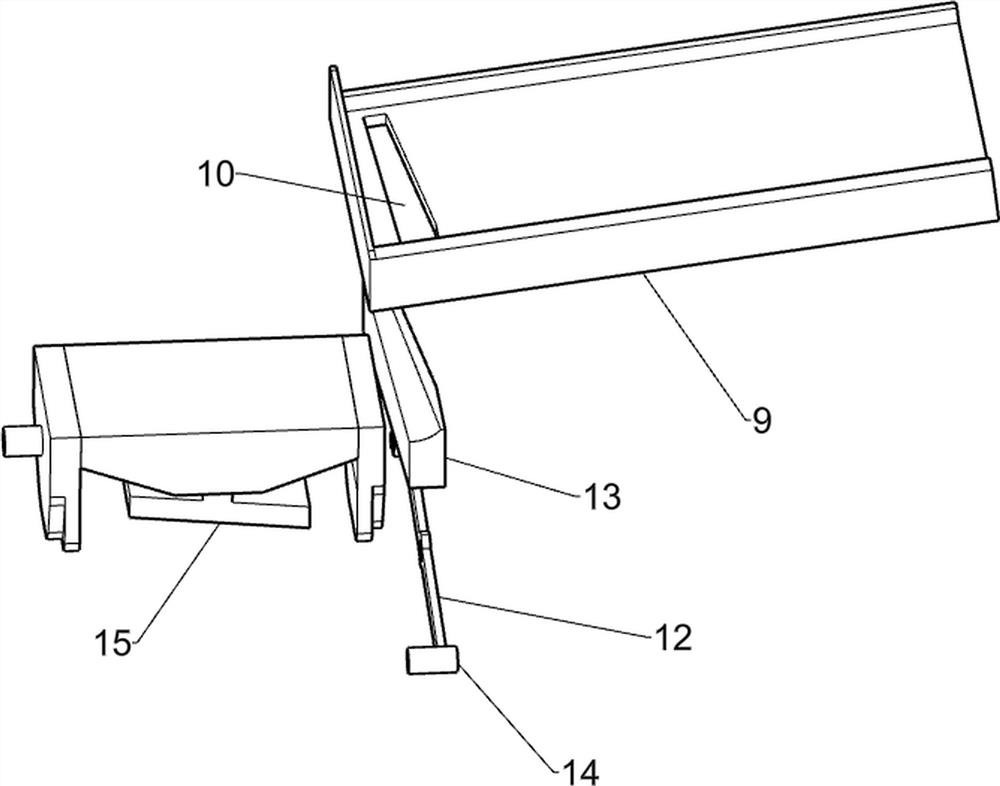

Cinnamomum cassia presl peeling cutter

PendingCN110962207ARealize automatic peelingReduce labor intensityTree debarkingTree trunkChinese cinnamon

The invention discloses a cinnamomum cassia presl peeling cutter. The cutter comprises a positioning mechanism and a peeling mechanism; the positioning mechanism is used for positioning a cinnamomum cassia presl and driving the cinnamomum cassia presl rotate; the peeling mechanism comprises a first driving device, a second driving device and a peeling cutter, wherein the first driving device drives the peeling cutter to move in a Y direction, and the second driving device drives the peeling cutter to move in an X direction; a trunk clamped by the fixing mechanism; the first driving device drives the peeling cutter to get close to the trunk in the Y direction to enable the peeling cutter to just abut against the trunk; the fixing mechanism drives the trunk to rotate, and at the same time, the second driving device drives the peeling cutter to move in the X direction to enable the peeling cutter to peel off bark in the axial direction of the trunk; and therefore, automatic peeling is achieved, labor intensity is reduced, and efficiency is improved.

Owner:WUYI UNIV

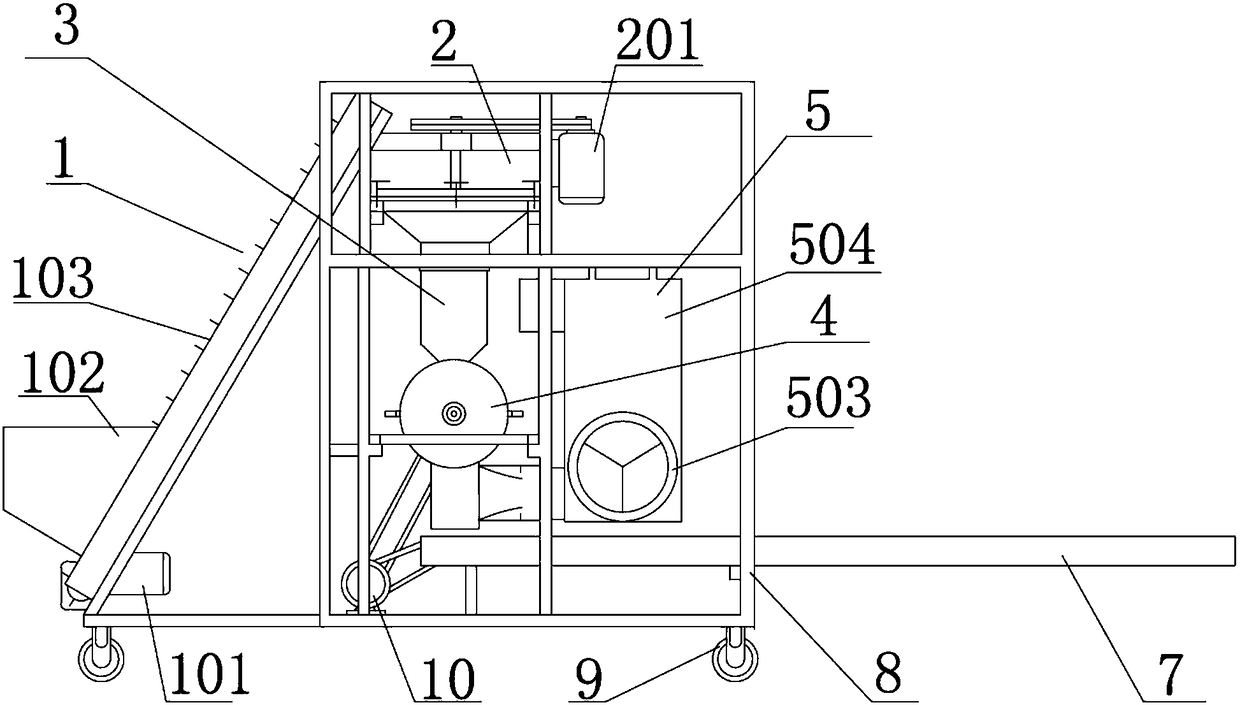

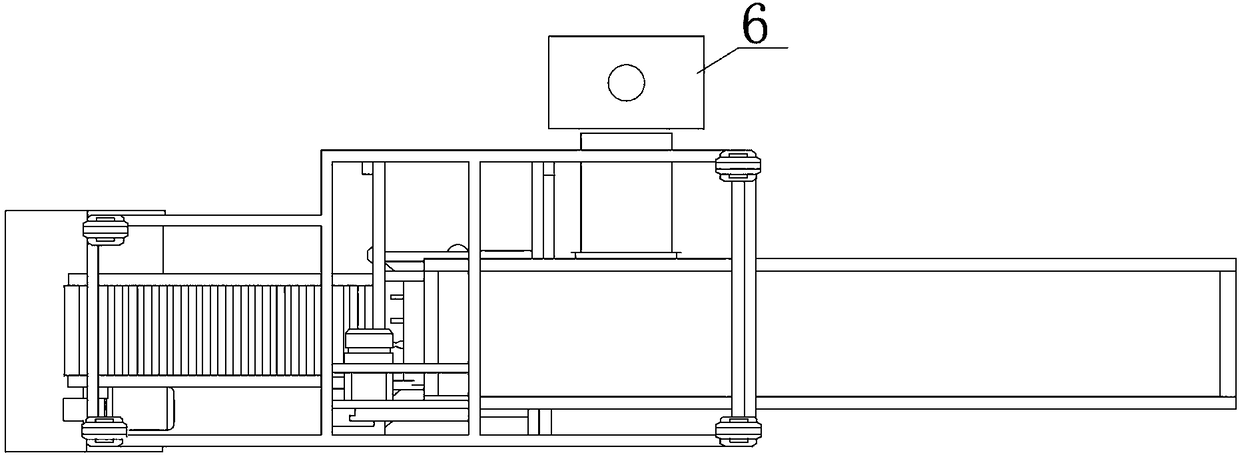

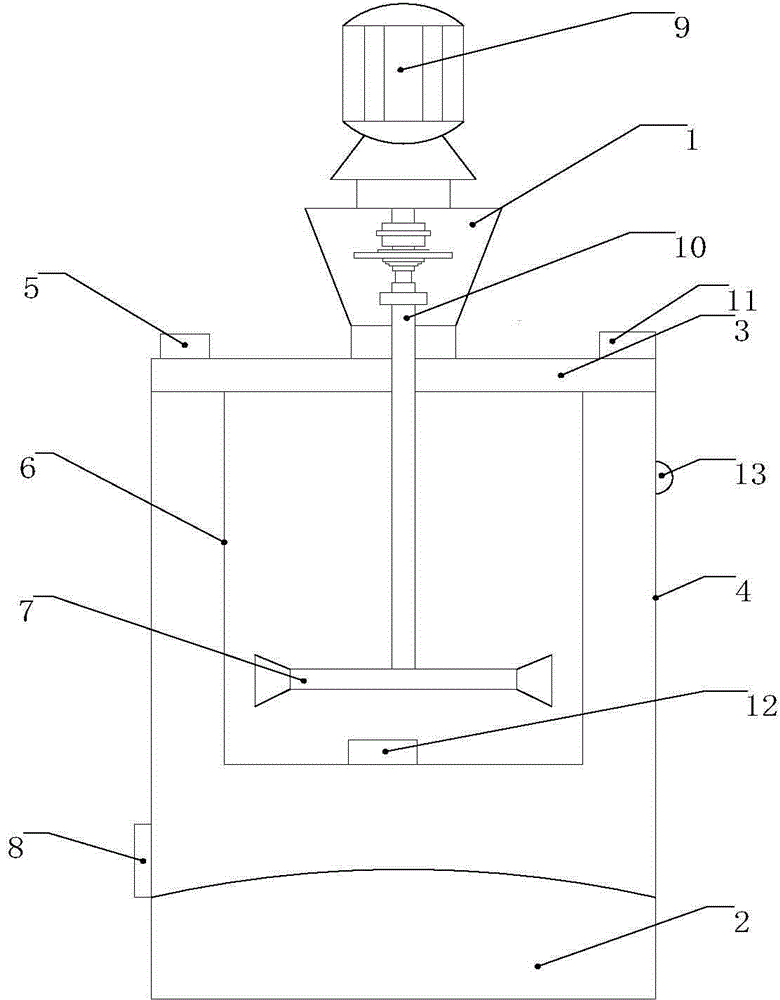

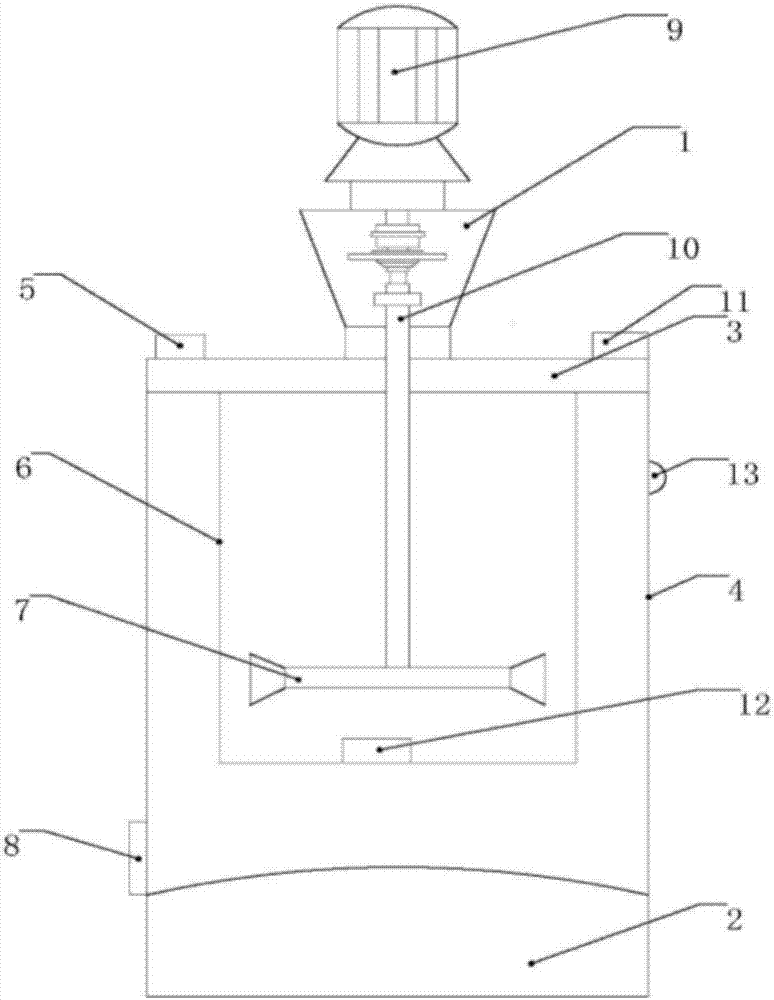

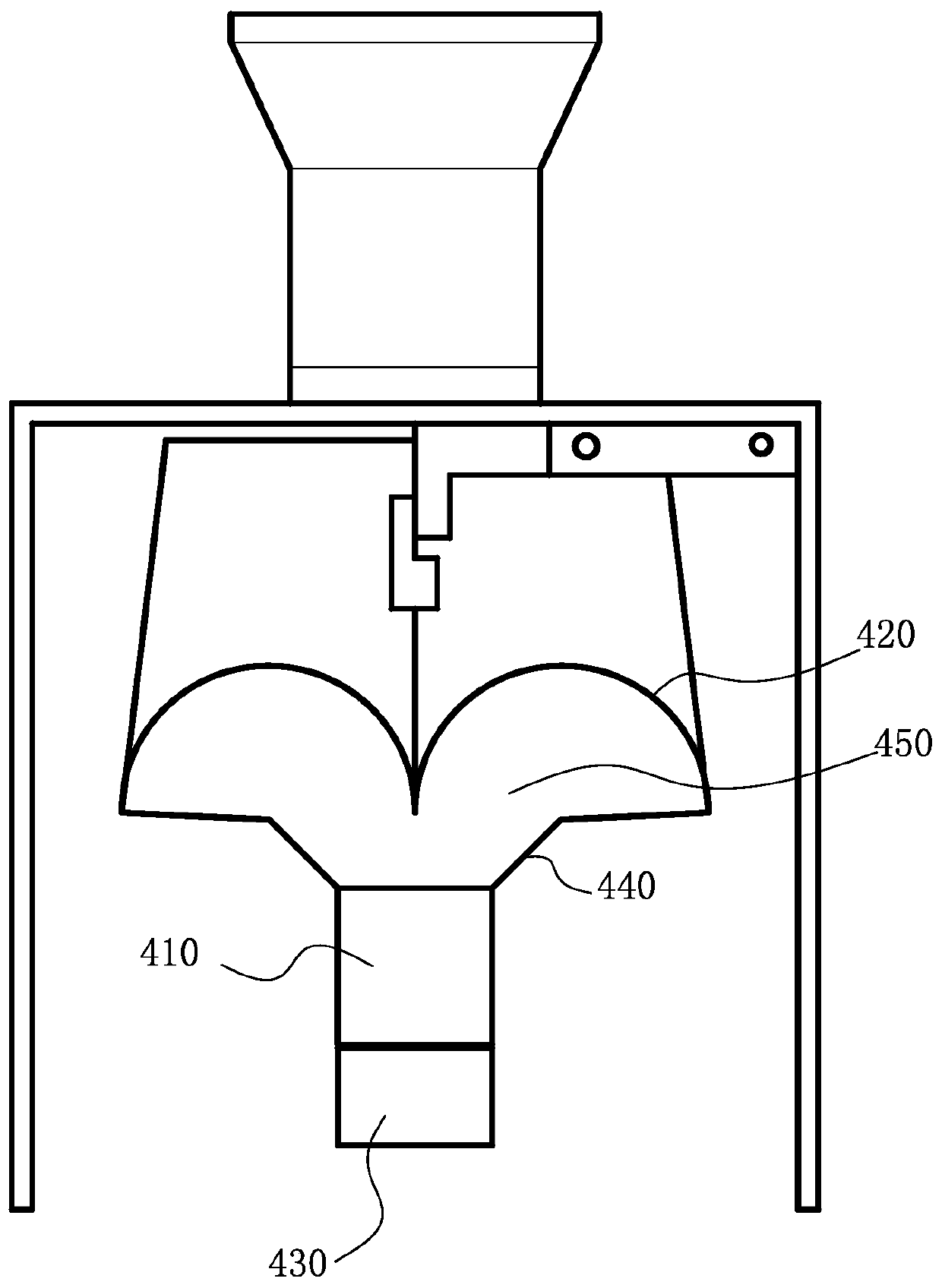

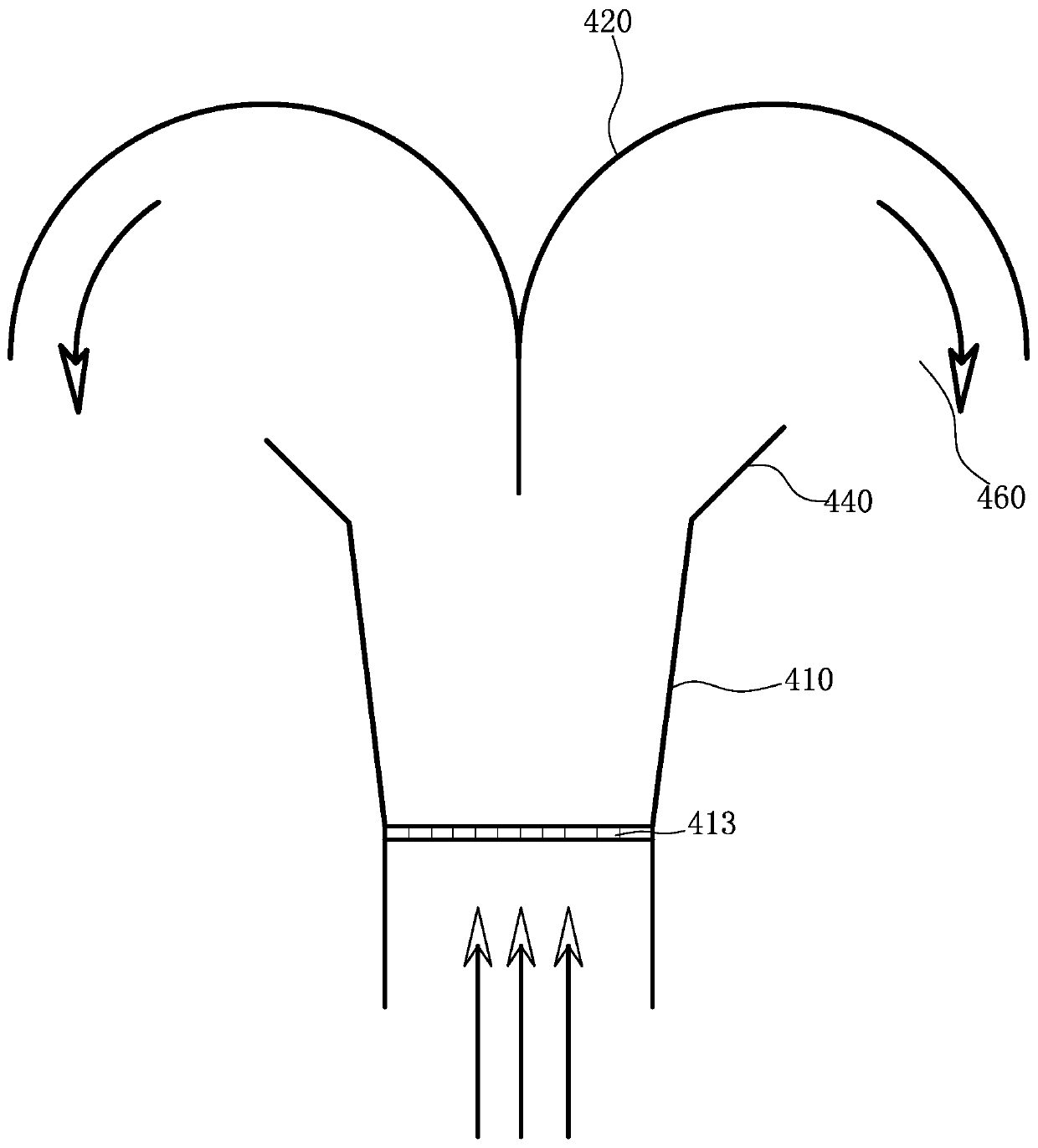

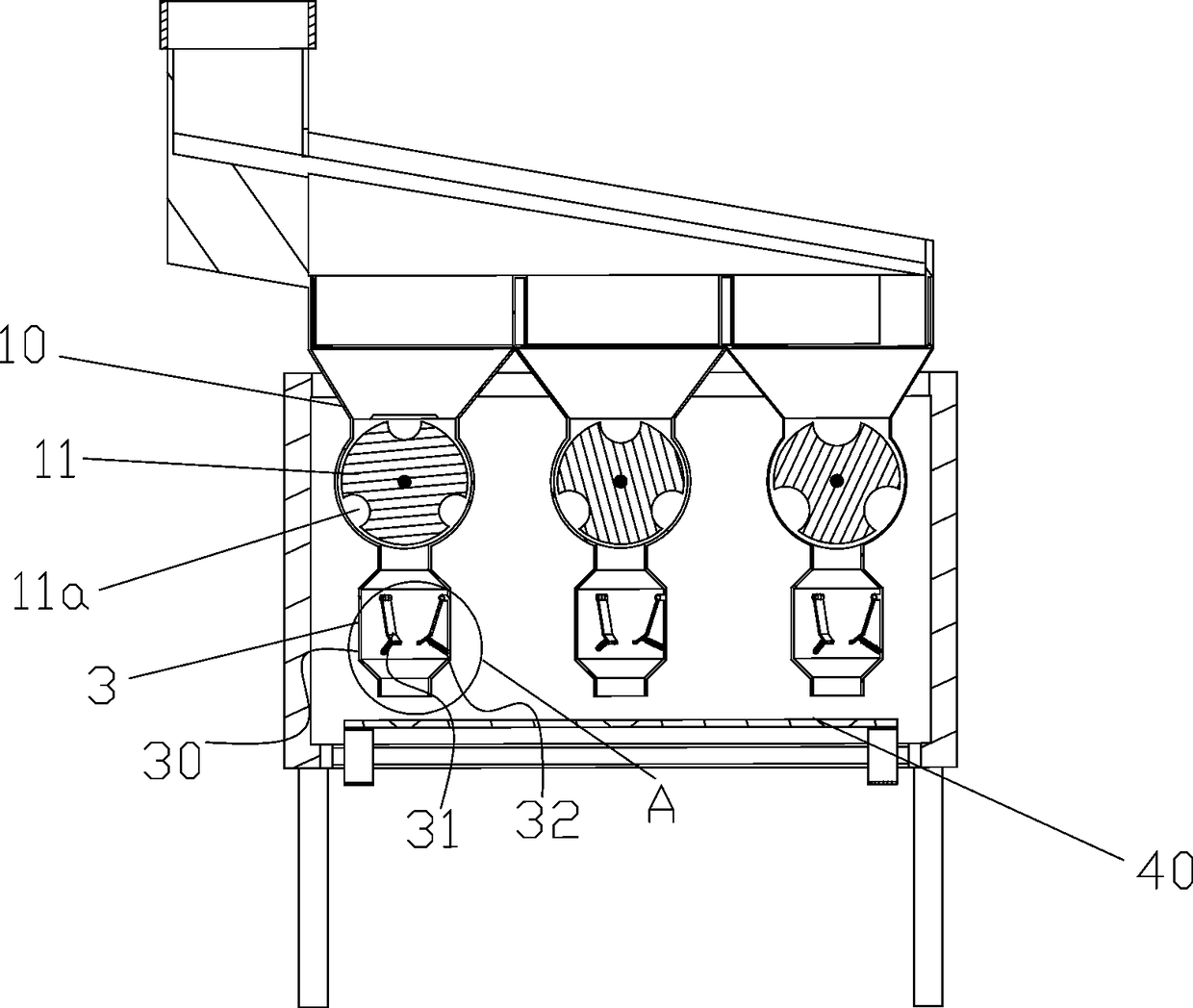

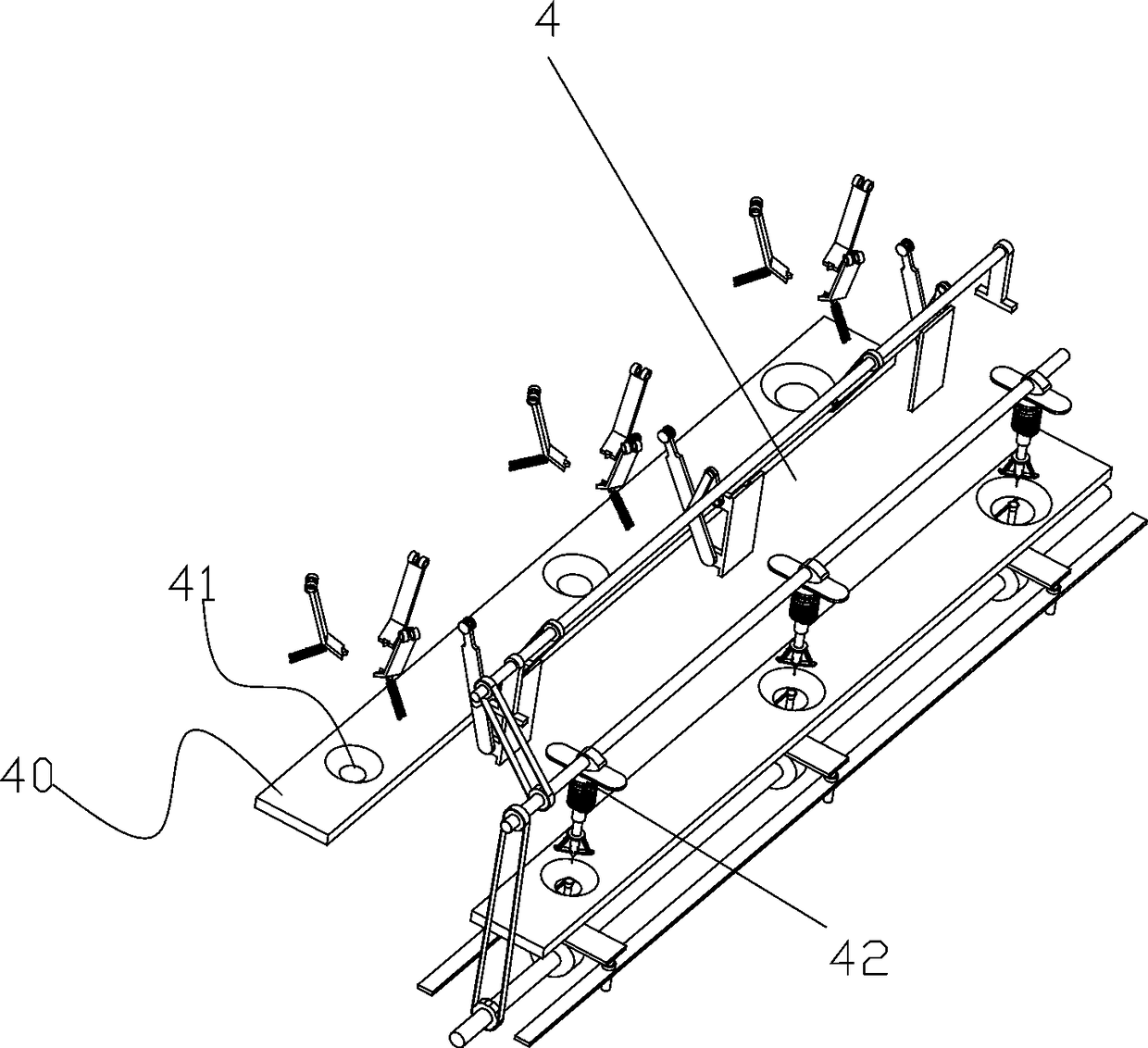

Automatic vortex-jet machine for blowing garlic peel

PendingCN108185454AGood peeling effectImprove peeling efficiencyVegetable peelingPulp and paper industry

The invention relates to a garlic peeling machine, in particular to an automatic vortex-jet machine for blowing garlic peel. The machine comprises a frame, a clove separation and peel cutting mechanism, a distributor, a peeling mechanism and a waste peel collection mechanism; the clove separation and peel cutting mechanism, the distributor, the peeling mechanism and the waste peel collection mechanism are all arranged on the frame; the peeling mechanism is positioned below the clove separation and peel cutting mechanism; the clove separation and peel cutting mechanism is connected to the peeling mechanism through the distributor; the peeling mechanism and the distributor are separately connected to the feeding port of the waste peel collection mechanism; and the discharging port of the waste peel collection mechanism is connected to a waste peel extruding mechanism. The machine realizes the automatic continuous peeling on garlic, has high working efficiency, and carries out recovery and treatment on the garlic peel.

Owner:青岛盛祺源工贸有限公司

Egg processing machinery

The present invention discloses an egg processing machinery and relates to the technical field of food processing. The egg processing machinery can automatically perform shelling and reduce labor intensity of operators, and is convenient and healthy. The egg processing machinery includes a transmission device, a mounting bracket, a cooker and a heating device. The cooker includes a pot lid and a pot body, wherein the pot lid is located at the top of the pot body. The transmission device is fixed at the upper surface of the mounting bracket, the mounting bracket is fixed at the upper surface of the pot lid, the pot body is located at the upper surface of the heating device, a material inlet is arranged at the pot lid and extends from the upper surface of the pot lid to the lower surface, a tube container is arranged at the lower surface of the pot lid, filter screens are arranged at the side wall and the bottom wall of the tube container, an output end of the transmission device passes through the mounting bracket and the pot lid extends into the interior of the tube container, and a paddle is arranged at the output end of the transmission device.

Owner:侯森

Juicing structure and juicer

The present invention discloses a juicing structure and a juicer and solves the problem that an existing juicer is complex to operate and is not good for ensuring food cleanliness and safety. the juicing structure comprises a juicing bowl part, a fixture, a juicing bowl raised head and a juice storage box, the juicing bowl part is provided with at least one juicing bowl concave head, and blades are fixed to the fixture; fruits are placed in the two juicing bowl concave heads, the juicing part rotates, the blades cut the fruits into halves, and the fruits are pushed to juicing holes; then, the juicing bowl part stops rotating, the juicing bowl raised head moves up and squeezes the halved fruits for juicing; finally, the juicing bowl raised heads move down and return, the juicing bowl part rotates to throw out peels. The juicer comprises the juicing structure, as well as a mounting fixing plate and a transmission mechanism, automatically performs a series of actions including halving, rotating, juicing and peel-throwing, is simple in overall structure, simple to control, good in operation stability, high in juicing efficiency, good for ensuring juice cleanliness, safety and taste.

Owner:四川长虹技佳精工有限公司

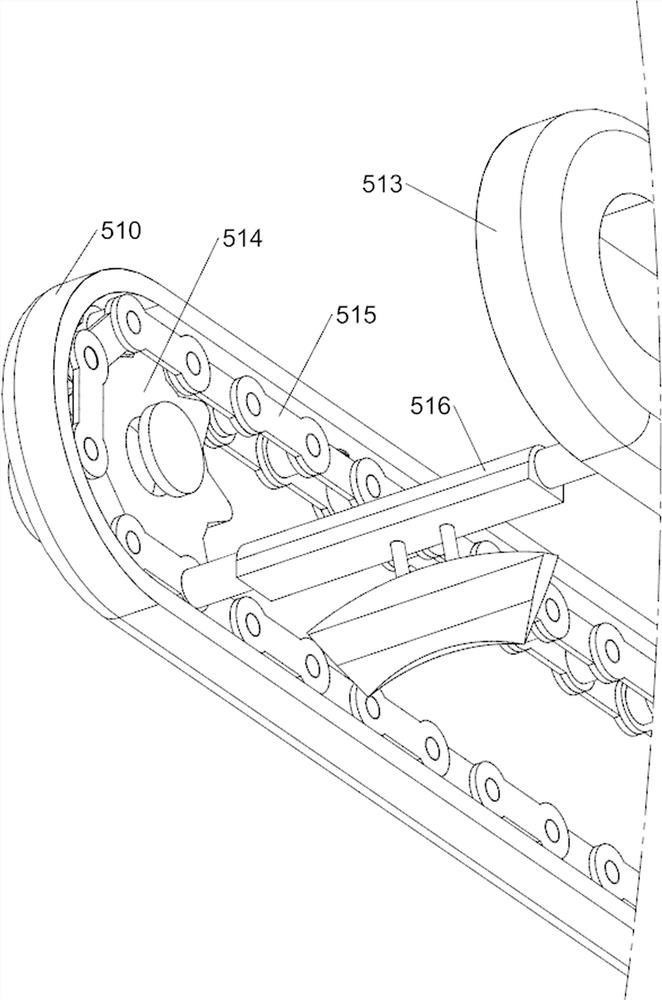

Automatic bamboo body peeling device

InactiveCN112060246ARealize automatic peelingGuaranteed work efficiencyCane mechanical workingWorkbenchEngineering

The invention relates to a peeling device, in particular to an automatic bamboo body peeling device. The invention provides the automatic bamboo body peeling device which is automatic in peeling and high in working efficiency. The automatic bamboo body peeling device comprises supporting supports, supporting plates, a fixing mechanism and a peeling mechanism, wherein the supporting supports are evenly arranged at the bottom of a workbench; the supporting plates are arranged on two sides of the top of the workbench; the fixing mechanism is arranged at the top of the workbench on the outer sidesof the supporting plates; and the peeling mechanism is mounted at the top of the workbench. Through the arrangement of a peel outlet, bamboo chips can conveniently fall on the ground along an obliqueplane of the peel outlet under the action of gravity, and the situation that the workbench is disordered due to the fact that the bamboo peels fall on the workbench in piles under the action of gravity can be avoided.

Owner:万湘兰

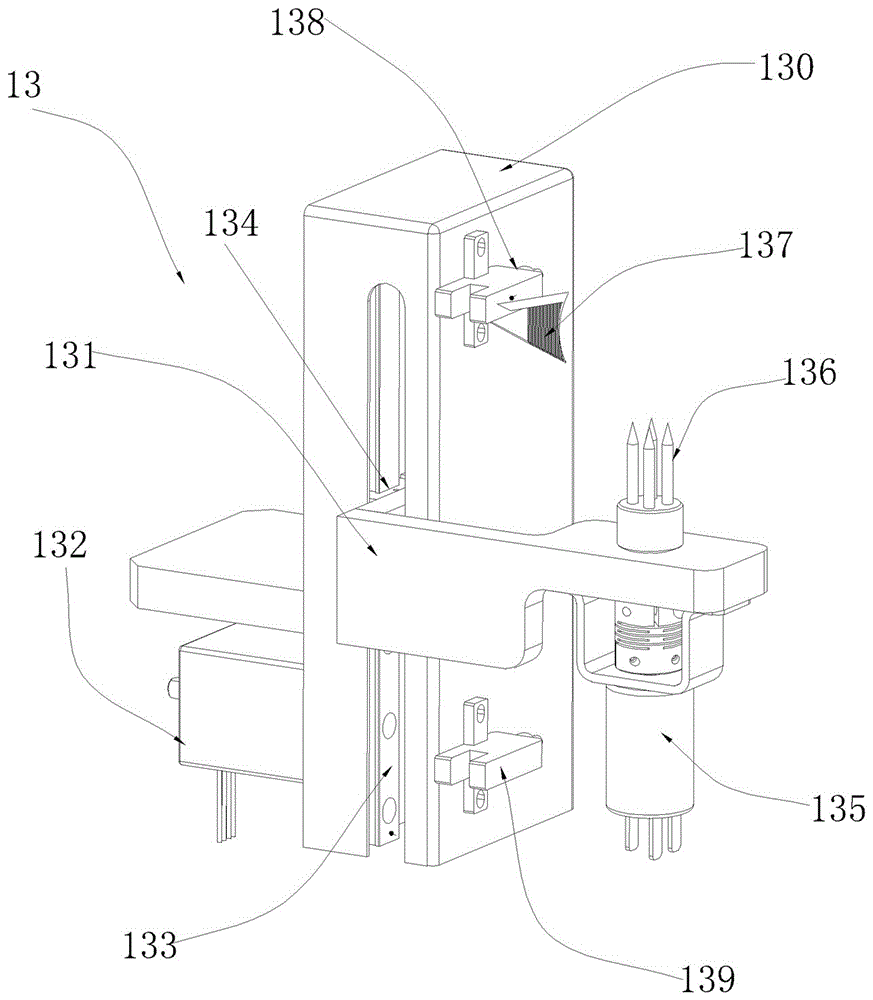

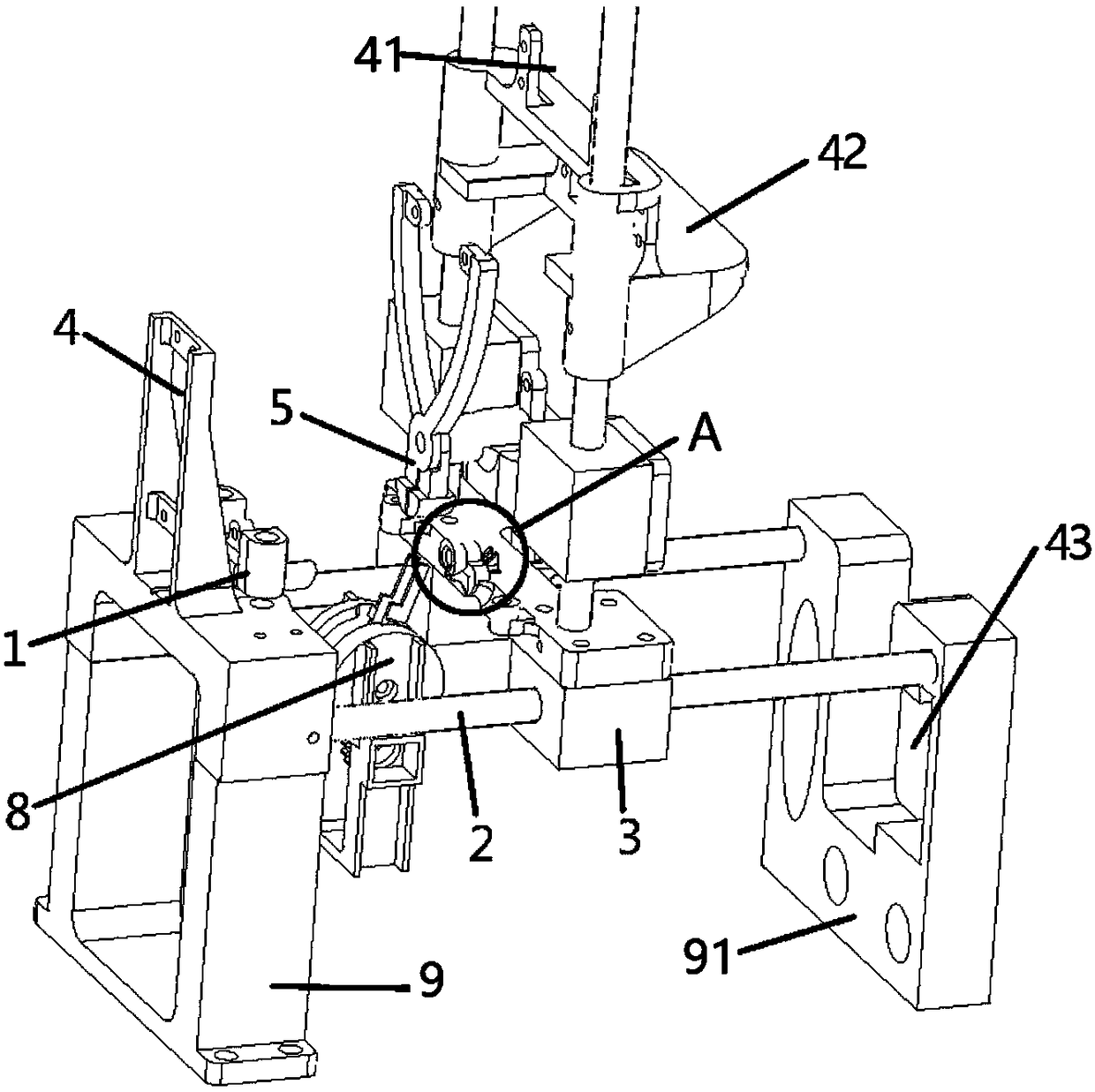

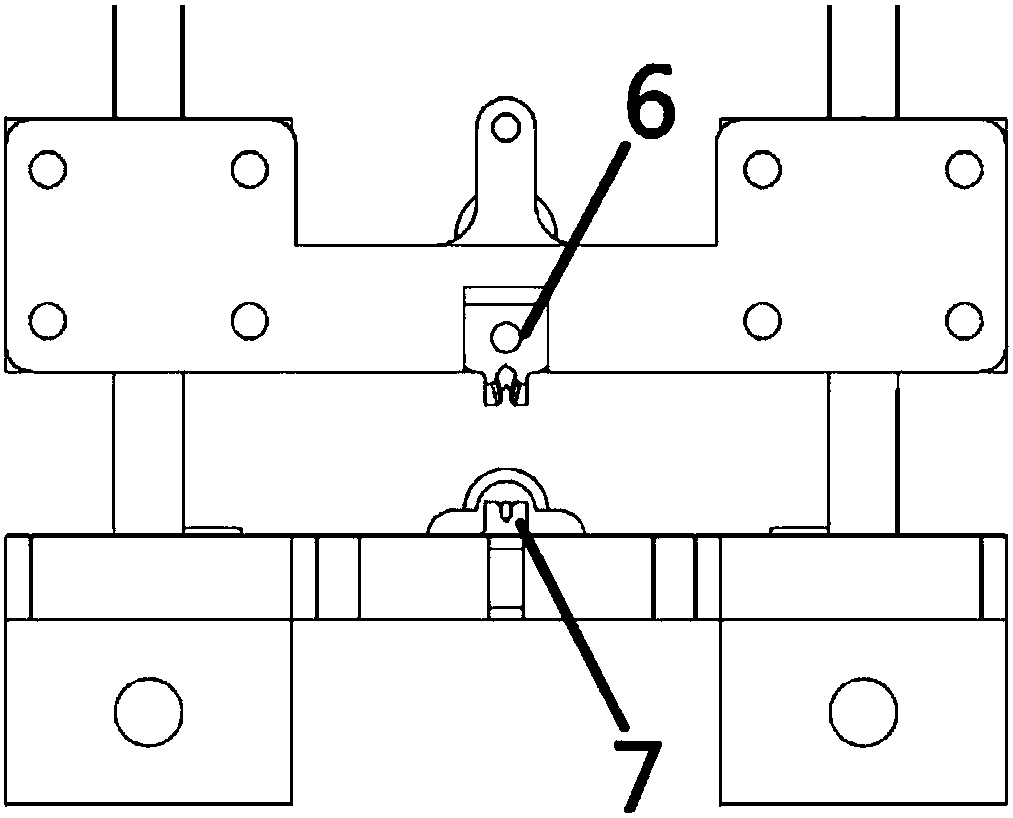

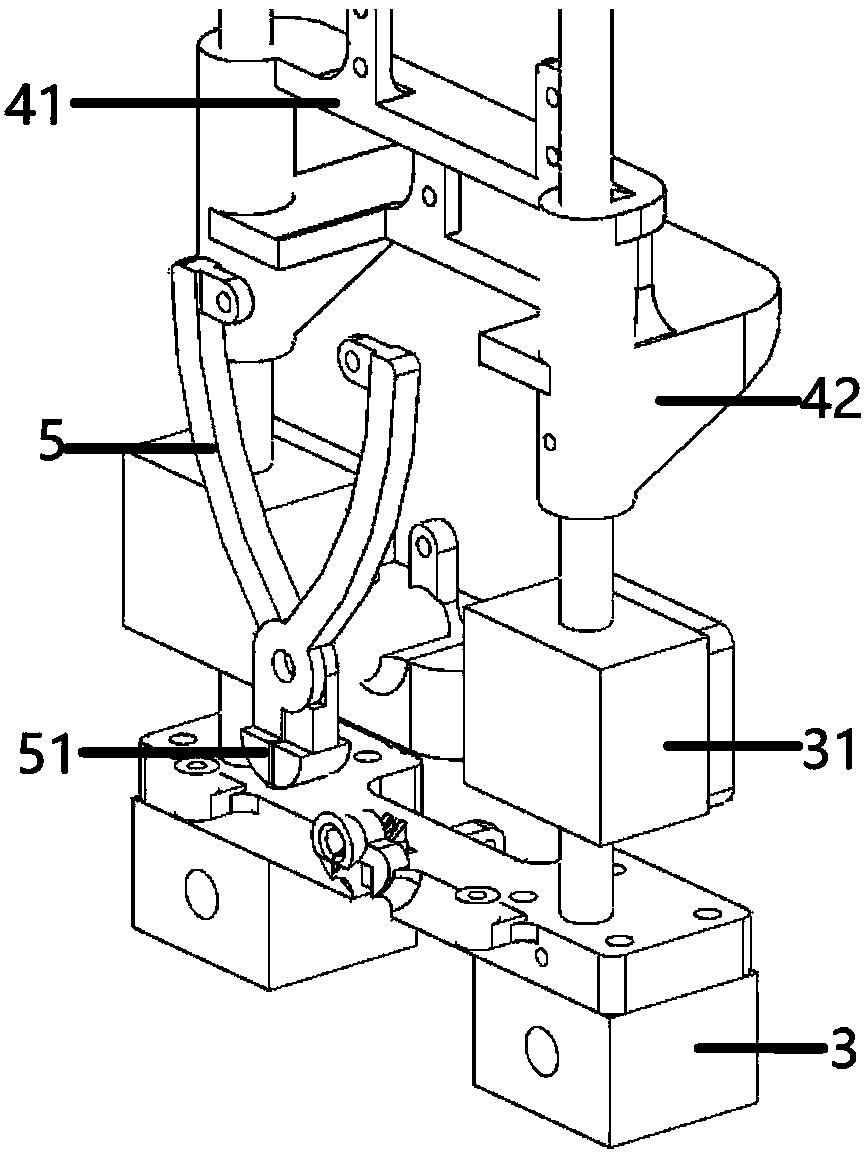

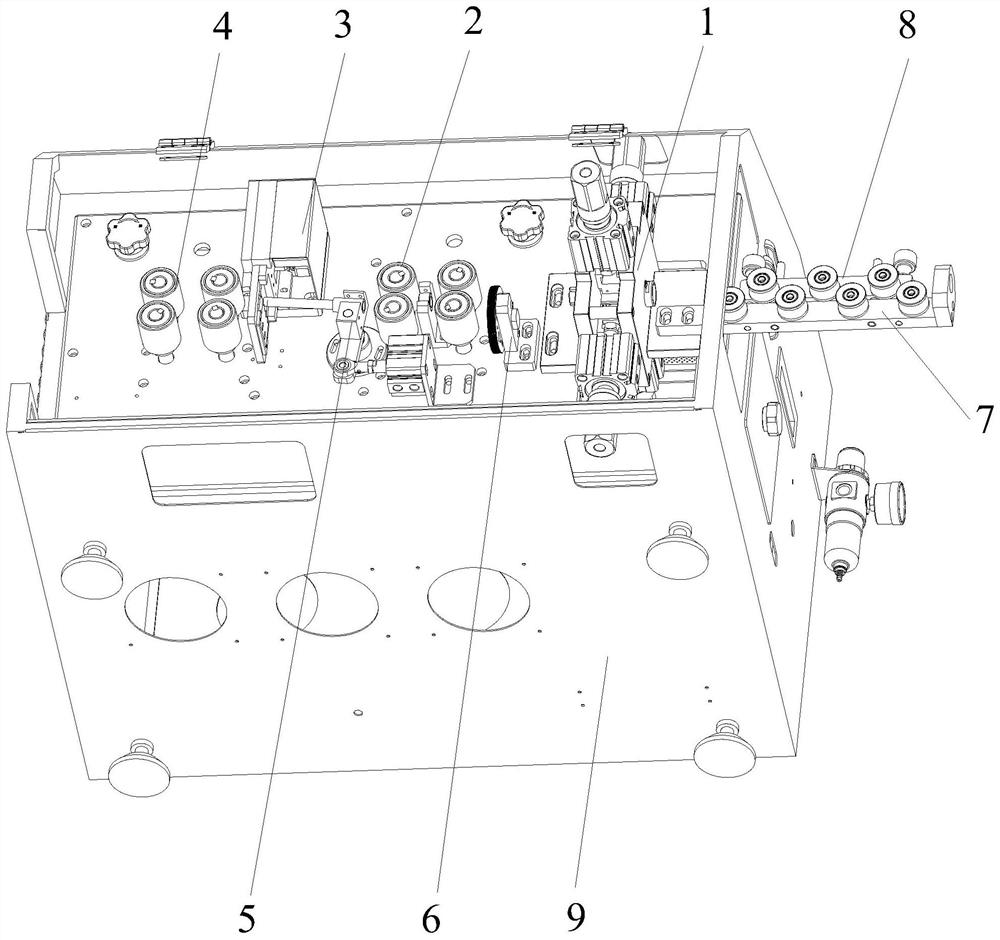

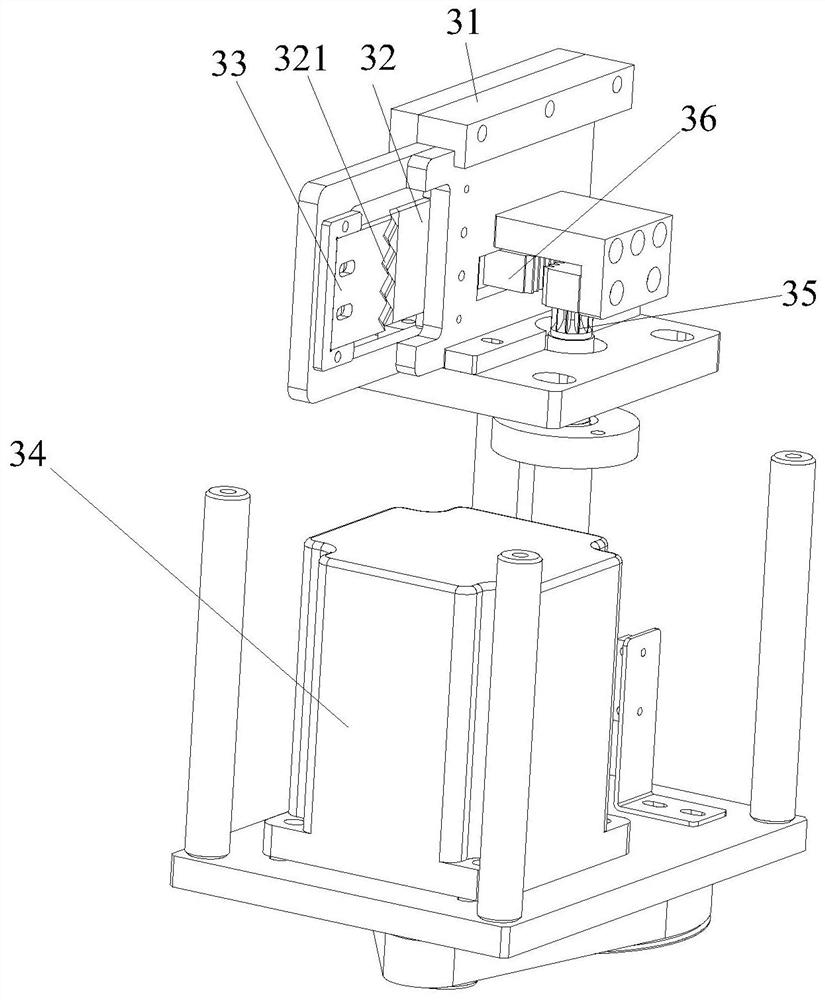

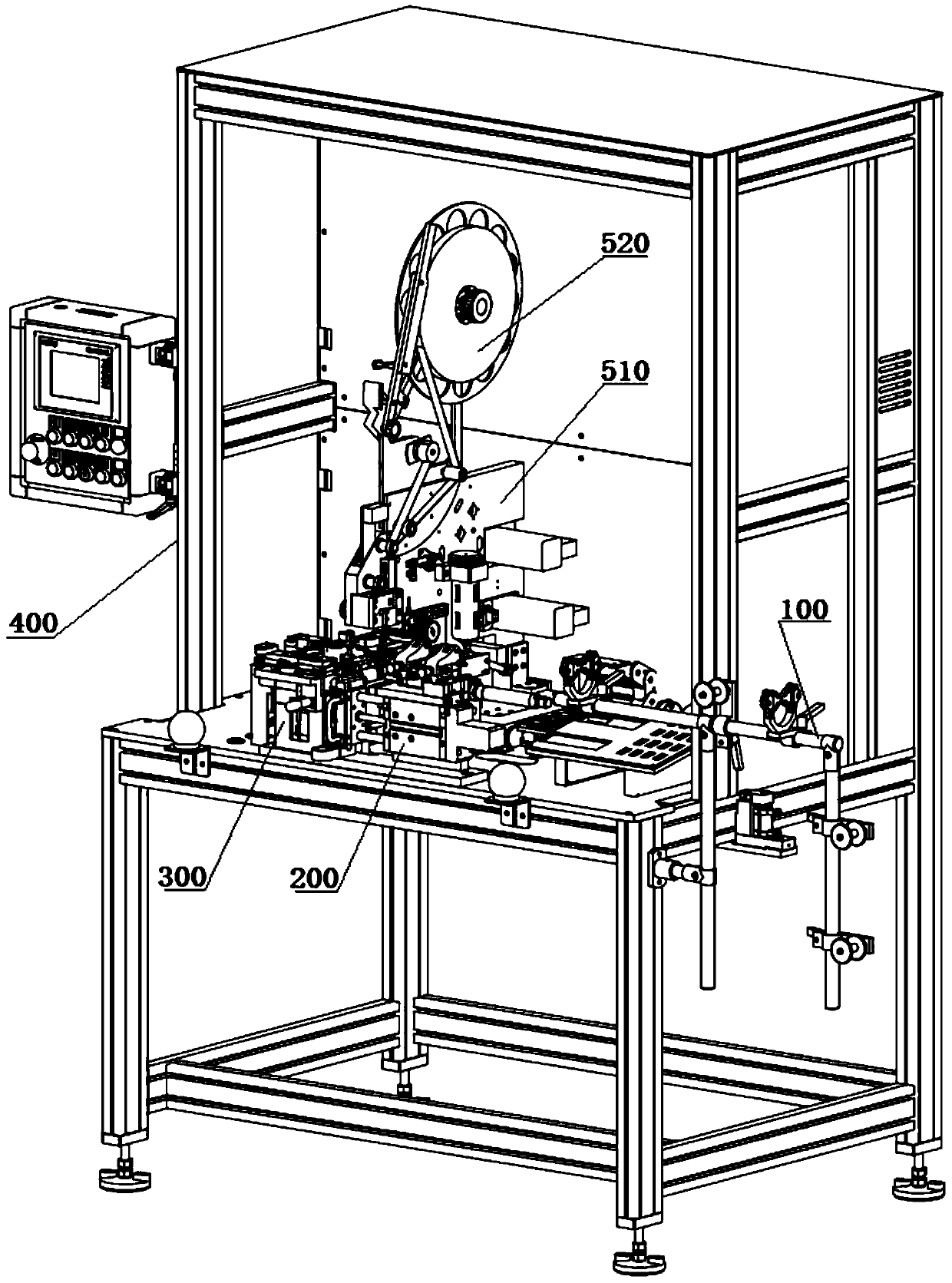

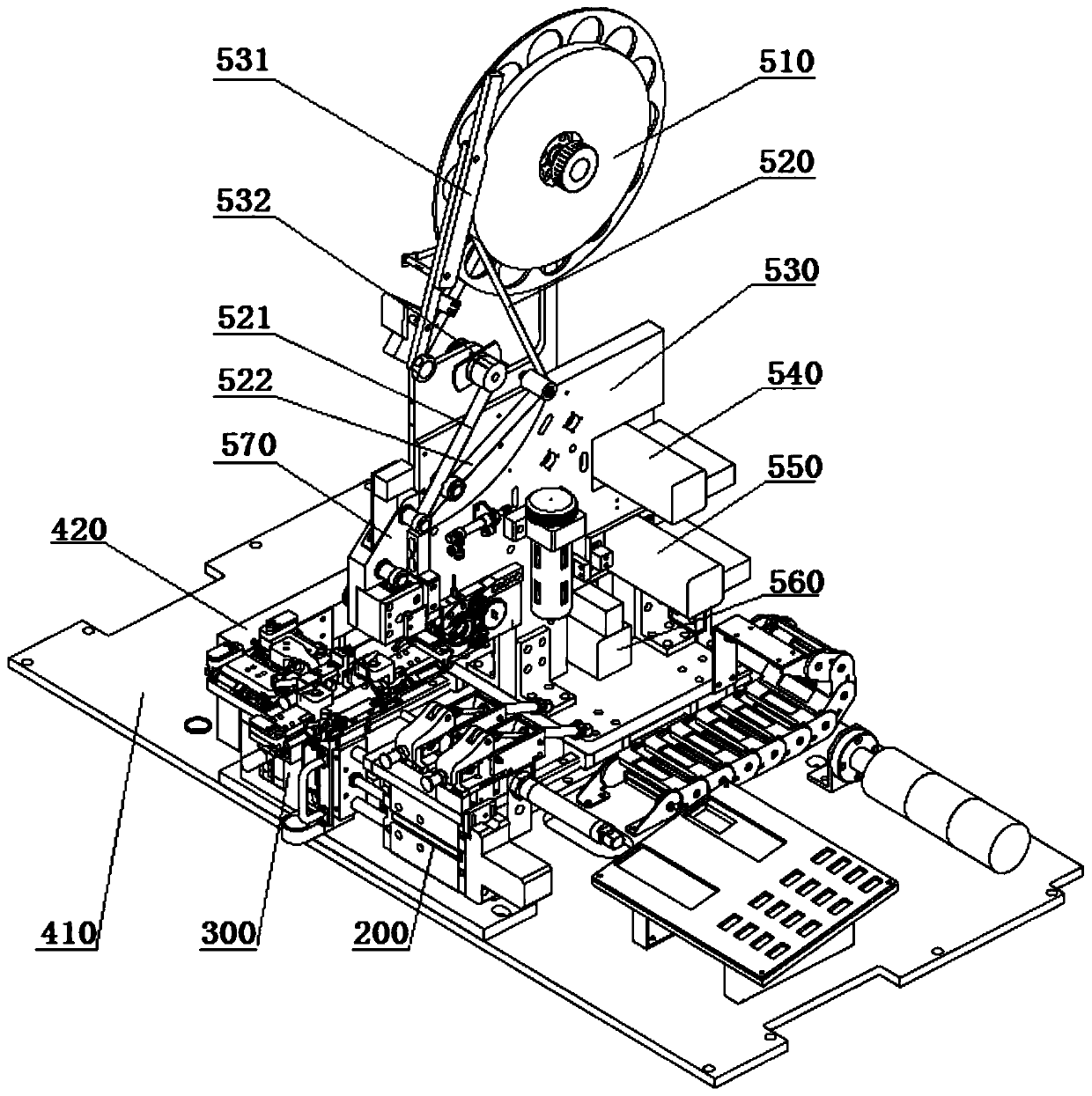

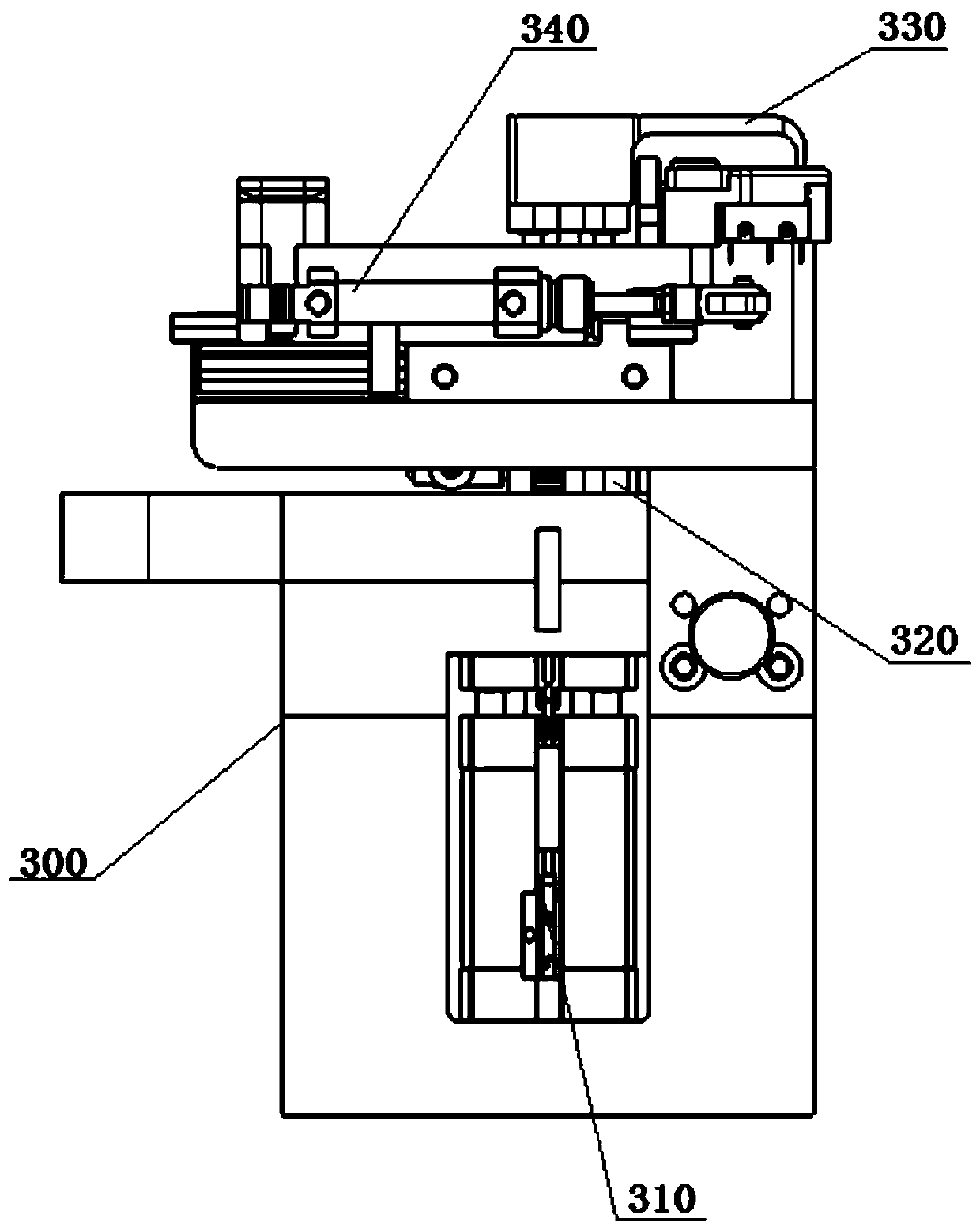

Automatic line stripping and cap pressing machine

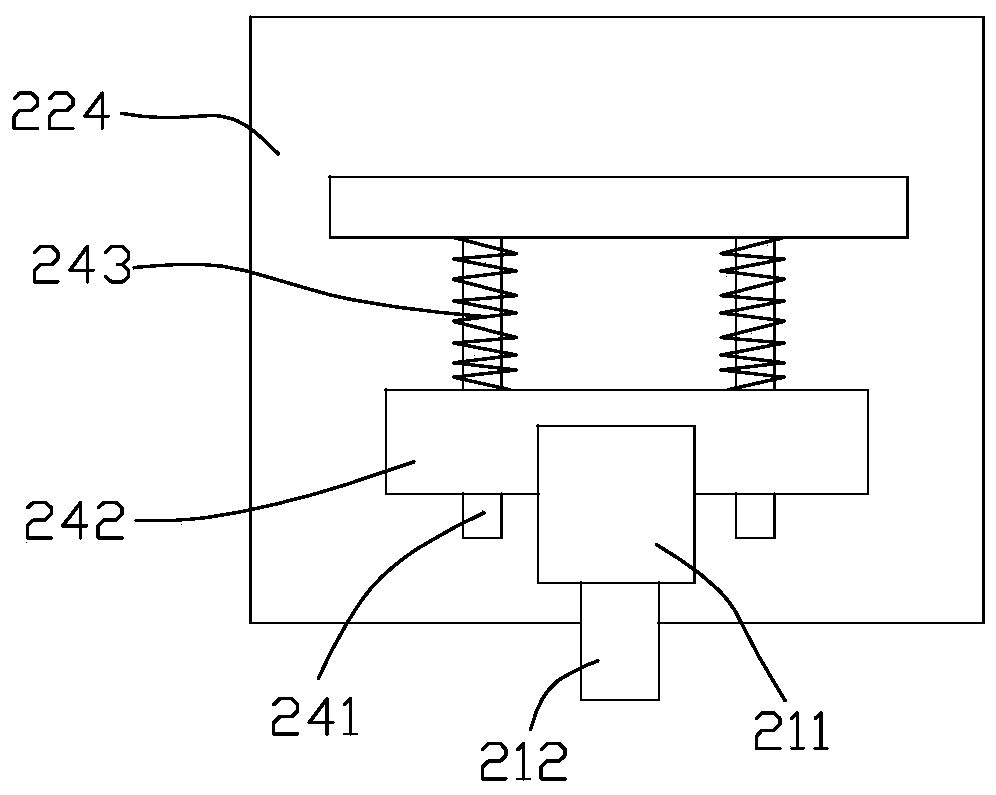

PendingCN108173099ARealize automatic peelingGood effectConnection formation by deformationElectronic waste recyclingMedium enterprisesEngineering

The invention discloses an automatic line stripping and cap pressing machine which is characterized in that the machine comprises a fixing device, a line stripping mechanism, a capping mechanism and acap pressing mechanism; the fixing device comprises a rack, a pressure block mounted on the frame and used for pressing a line, and a steering engine used for driving the pressure block; the line stripping mechanism comprises an upper jaw and a lower jaw equipped with blades, a sliding block connected to the frame and moving in a direction parallel to the line, a sliding frame fixedly connected with the upper jaw and moving in a direction perpendicular to the line, and a steering engine; the capping mechanism is a turntable mechanism located below the lower jaw; and the cap pressing mechanismcomprises a cap pressing clamp used for pressing a line cap, and the cap pressing clamp is fixed on the sliding frame and is in driving connection with a steering engine. The automatic line strippingand cap pressing machine has a simple structure and the functions of automatic line stripping, capping and cap pressing, costs low, is suitable for families and even small and medium enterprises, andovercomes the defects of the existing line stripper on the market such as complex structure, huge size and high price.

Owner:SHANGHAI INST OF TECH

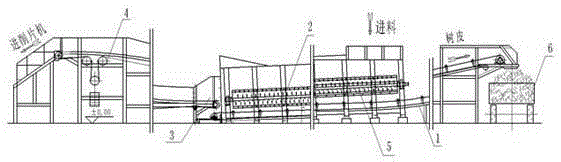

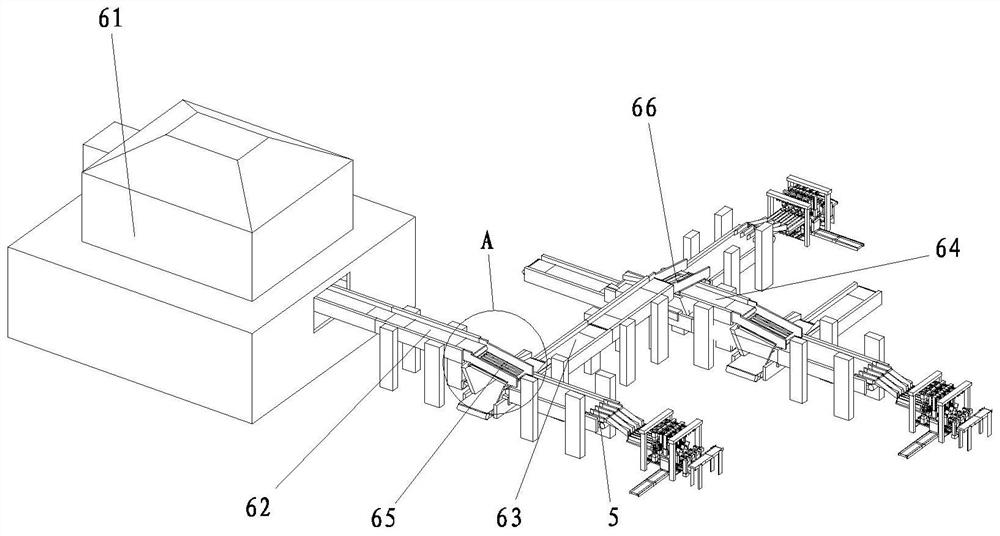

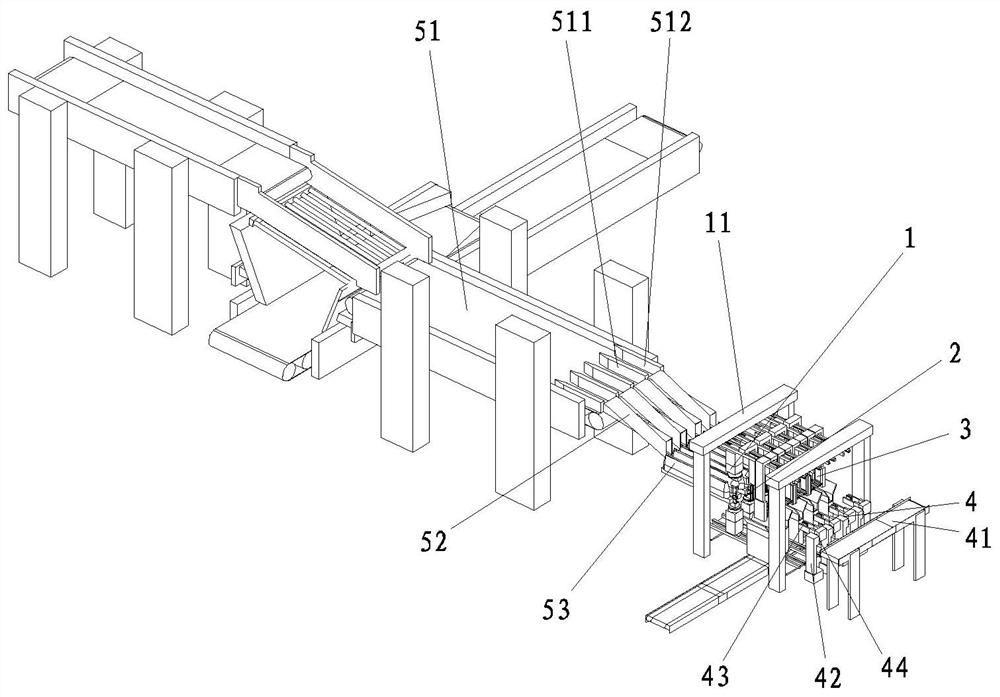

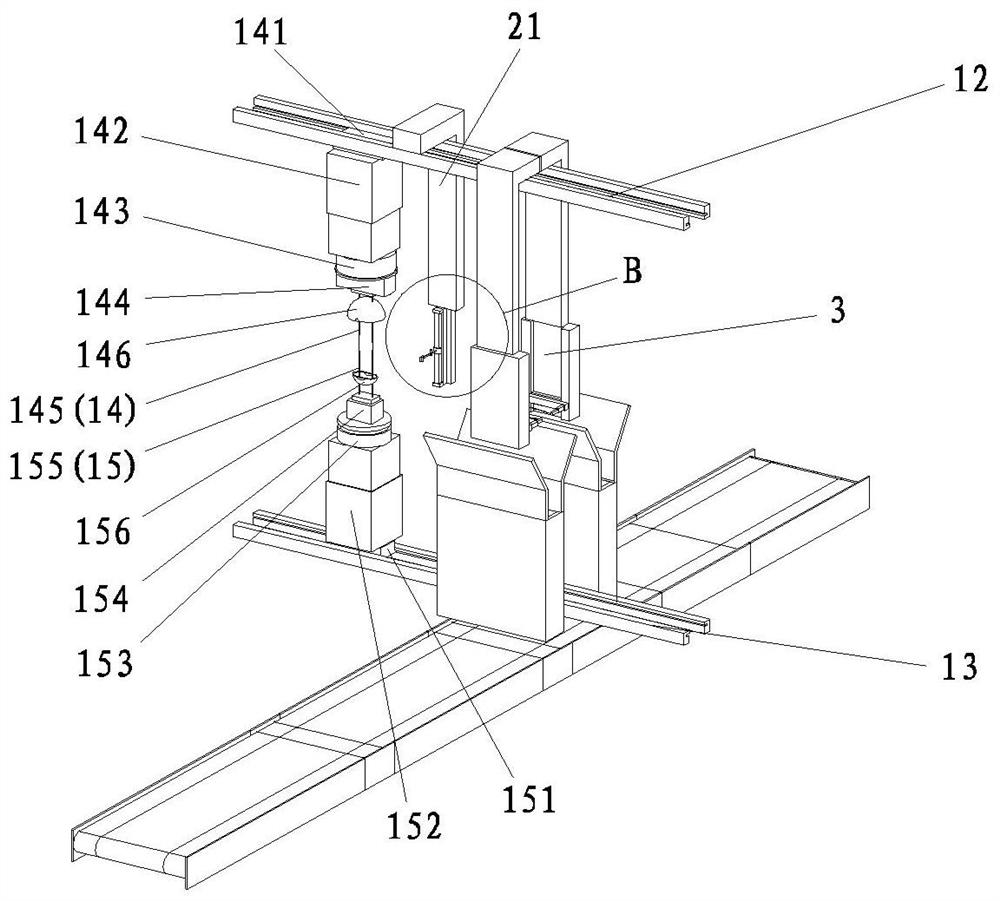

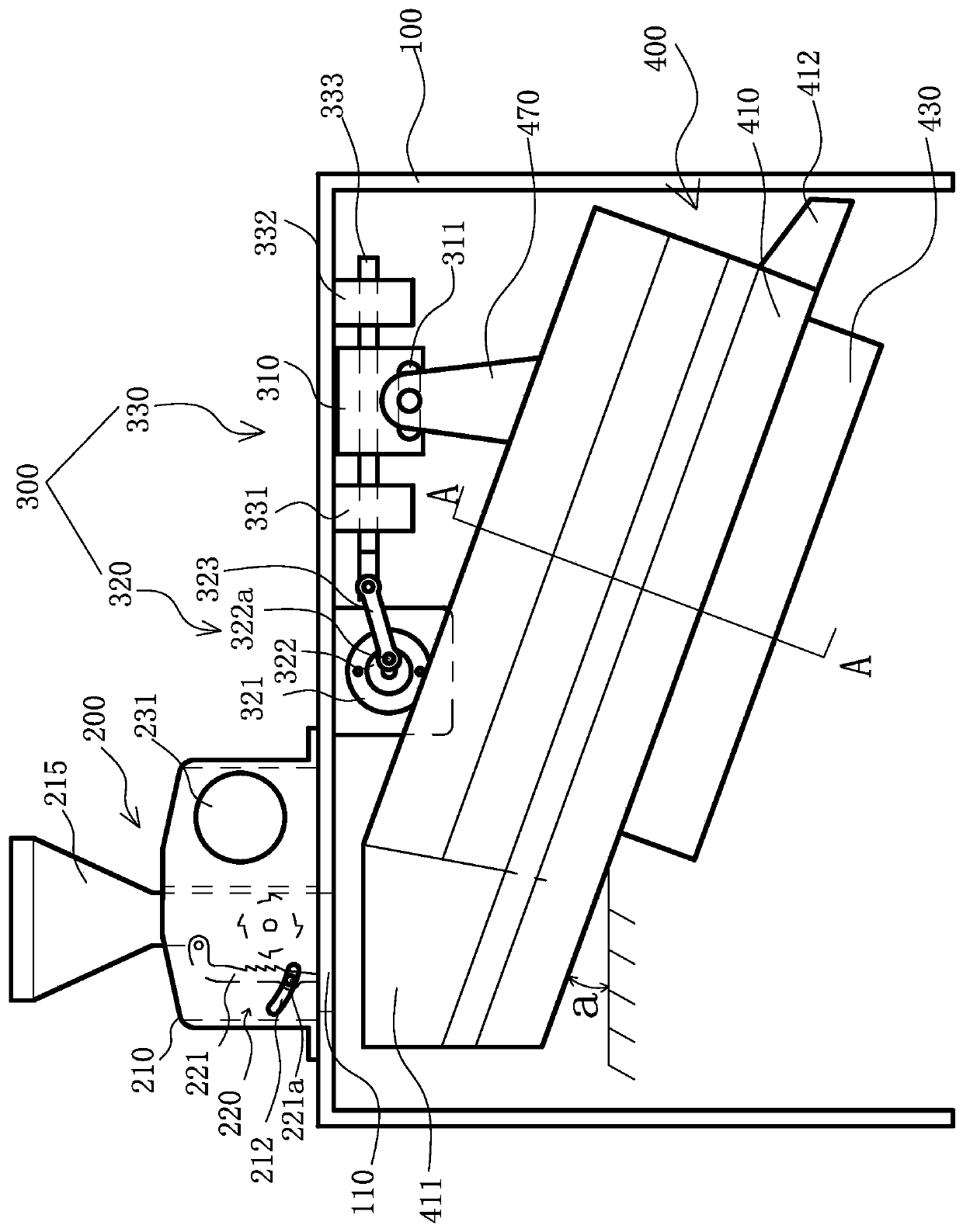

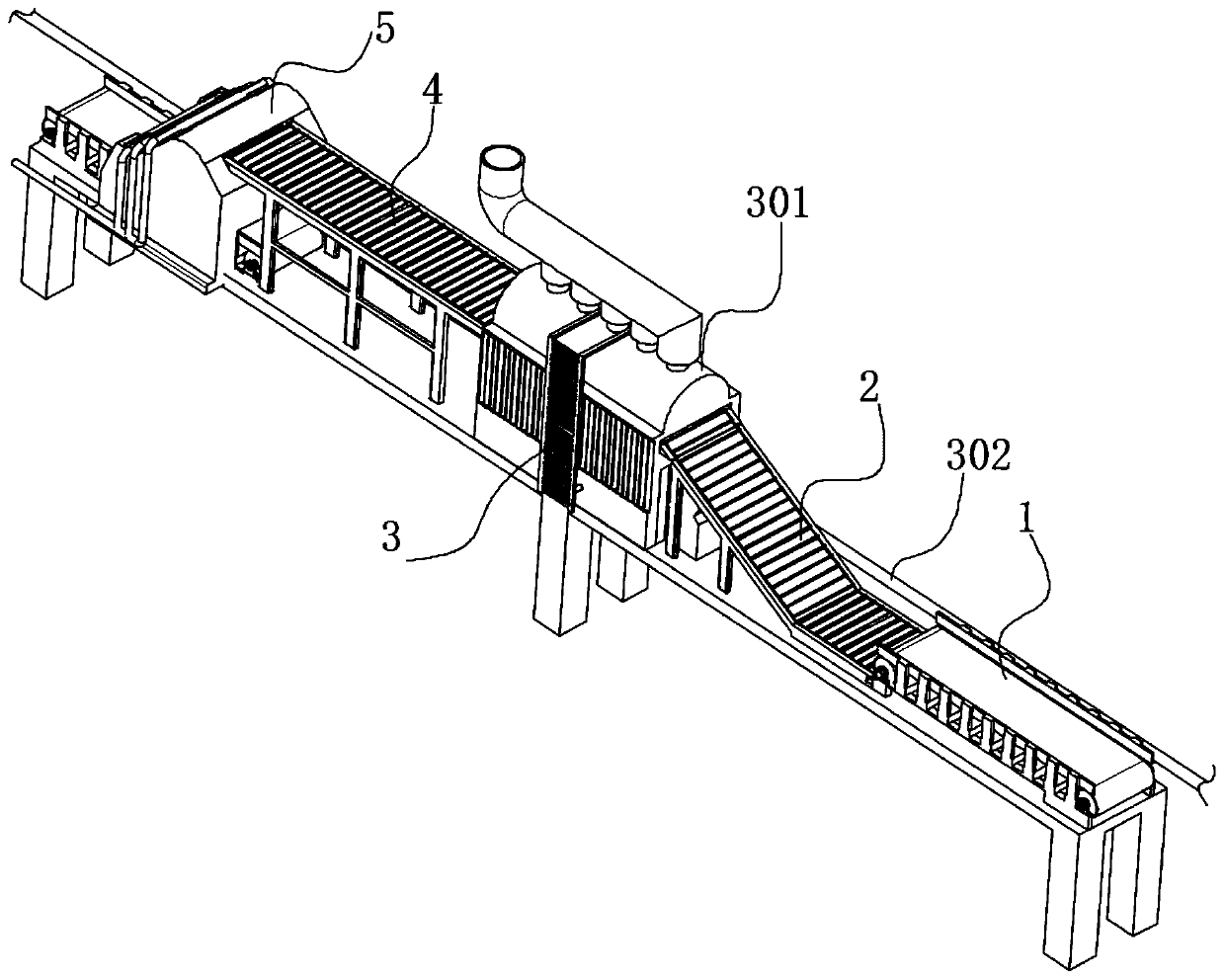

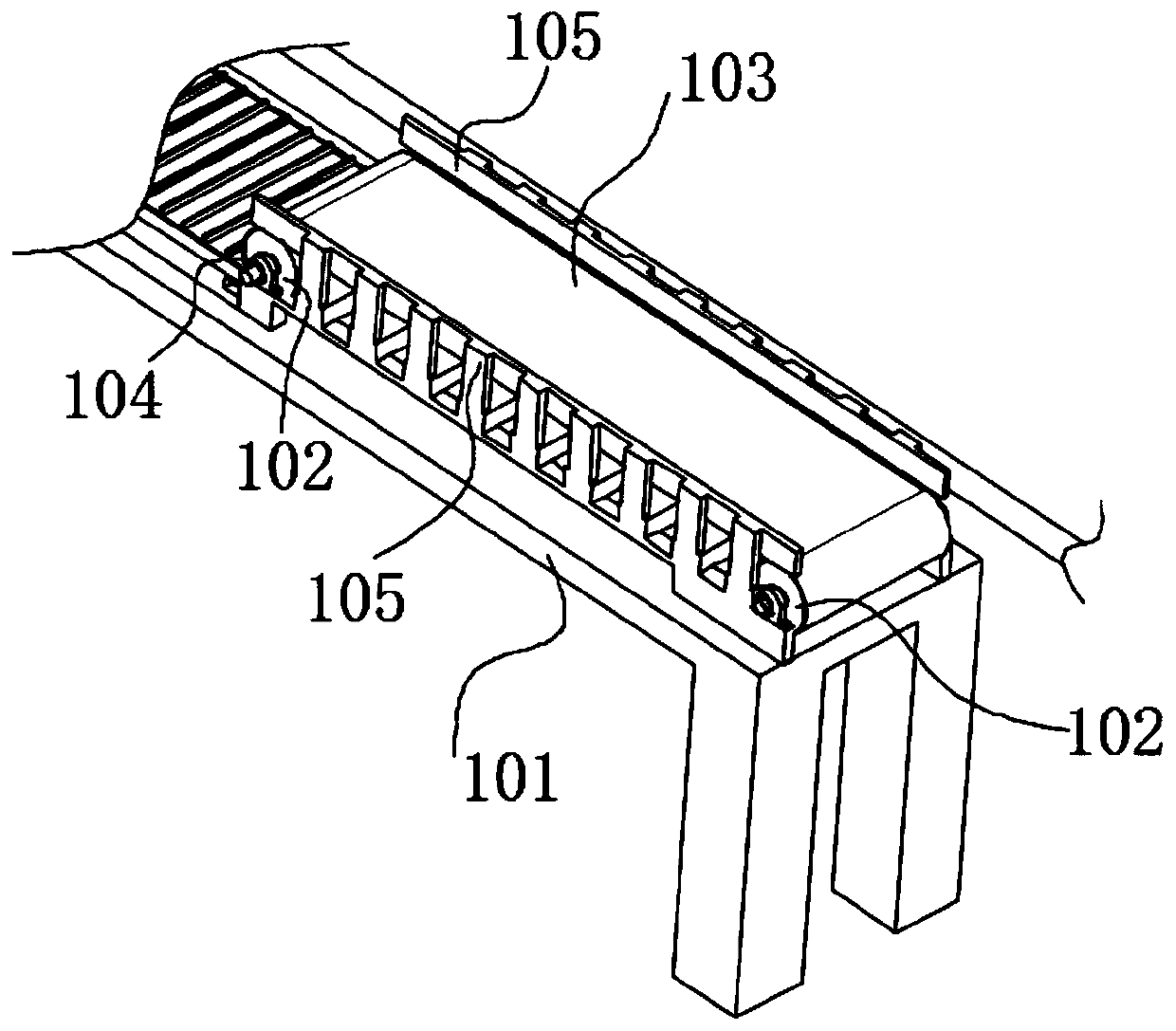

Automatic efficient peeling line for small diameter logs

InactiveCN105291227ASolve high wood damageSolve efficiency problemsTree debarkingVeneer manufactureProcess engineeringEnergy consumption

The invention discloses an automatic efficient peeling line for small diameter logs. The automatic efficient peeling line is characterized by mainly comprising a tooth roller peeling machine, a discharging chute, a discharging conveying belt, a log grabbing car, a chipping machine, a bark conveying belt and a bark hopper. Two principles of mechanical peeling and frictional peeling are organically combined, the purposes of saving energy and high efficiency are achieved, and the requirements for high peeling production capacity and low log damages of the small diameter logs are met. According to the automatic efficient peeling line for the small diameter logs, the process is simple, the equipment operation is safe and stable, the energy consumption is low, and the investment cost is low.

Owner:YUEYANG FOREST & PAPER CO LTD

Intelligent manufacturing equipment and method for canned fruits

ActiveCN113057348ARealize automatic peelingAchieve enucleationSievingGas current separationCanned fruitEngineering

The invention discloses intelligent manufacturing equipment and method for canned fruits, wherein the equipment comprises a mango conveying device and a kernel-pulp separating device; the discharging end of the mango conveying device is connected with the kernel-pulp separating device; and the kernel-pulp separating device comprises a positioning feeding mechanism, and a peeling mechanism, a kernel removing mechanism and a recycling mechanism that are sequentially arranged in the feeding direction of the positioning feeding mechanism. After the structure is adopted, compared with the prior art, automatic peeling and kernel removing of mangoes can be achieved, and mass production of canned mangoes is facilitated. In addition, the pulp carrying rate of mango kernels is low during kernel removal, and the phenomenon of waste of mango pulp is avoided.

Owner:FUJIAN HAISHAN FOODS

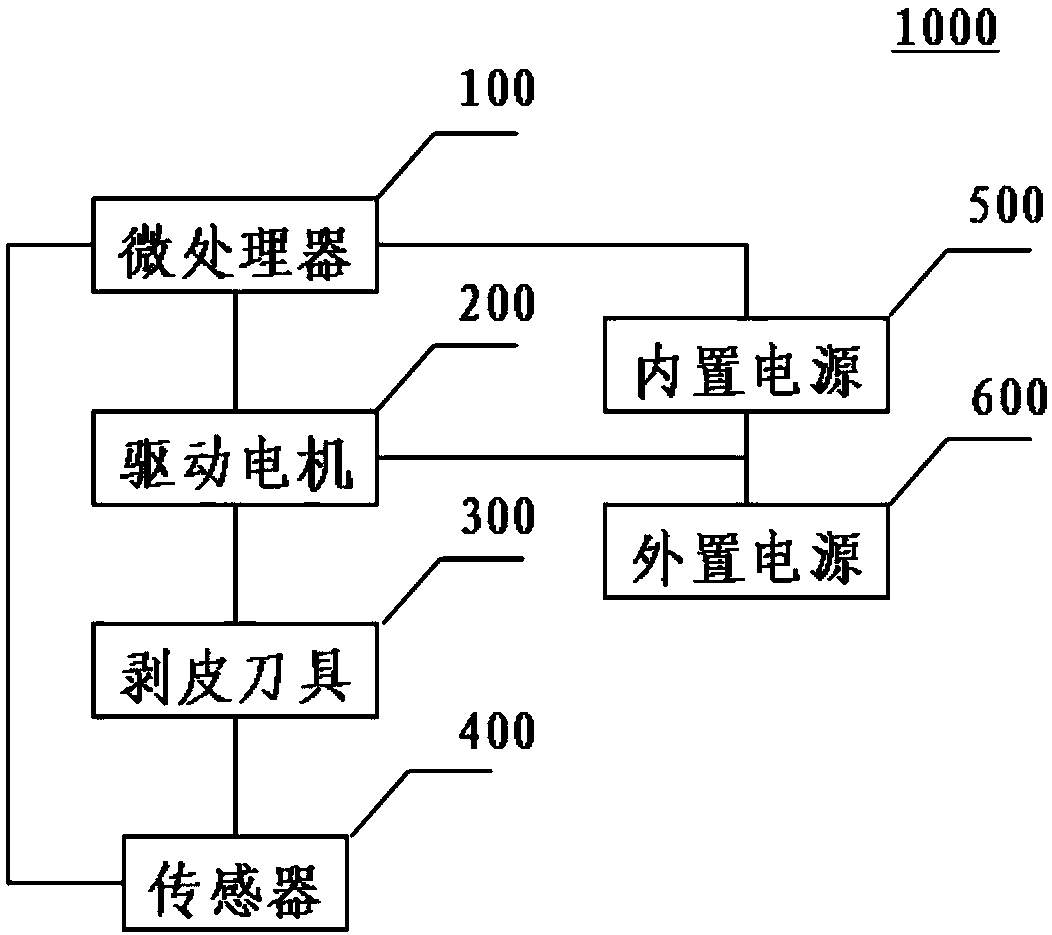

Eye massager with automatic eyedrop applying function

The invention discloses an eye massager with an automatic eyedrop applying function. The eye massager comprises a placement block, wherein a placement cavity with a downward opening is formed in the placement block, and an eye drop dripping mechanism is arranged in the placement cavity and comprises a moving motor connected with the inner wall of the upper side of the placement cavity in a slidingmanner. The invention is arranged on the eye massager, automatic eye drop application can be conducted on eyes, the whole device is arranged on the other side of the massager, automatic eye drop application can be conducted on the eyes before eye massage, and according to different eye positions of different people, a rack is driven by a gear to move the eye drop dripping device to conduct medicine applying positioning; and when the eye massager is used, only an eyedrop bottle needs to be automatically clamped, eyelids can be automatically pushed open, eyedrops can be dripped into the eyelids, and when the eyelids are pushed open, a buffer pad is arranged, so that the eyelids are prevented from being injured due to improper force application of the device, and the situation that bacterialinfection of the eyes is caused by inaccurate positioning during manual eyedrop driping is avoided.

Owner:南京百世扬服装有限公司

Egg processing machine

InactiveCN107343752ARealize automatic peelingAchieve separationTable equipmentsEgg-cookersEngineeringUltimate tensile strength

The invention discloses an egg processing machine and relates to the technical field of food processing. The egg processing machine disclosed by the invention can automatically peel the shell, can relieve the labor intensity of an operator and is convenient and hygienic. The egg processing machine comprises a driving device, a mounting bracket, a cooking pot and a heating device; the cooking pot comprises a pot cover and a pot body; the pot cover is located at the top of the pot body; the driving device is fixedly arranged on the upper surface of the mounting bracket; the mounting bracket is fixed on the upper surface of the pot cover; the pot body is located on the upper surface of the heating device; a material inlet is formed on the pot cover; the material inlet extends to the lower surface from the upper surface of the pot cover; a tubular container is arranged on the lower surface of the pot cover; filter nets are arranged on the side wall and bottom wall of the tubular container; an output end of the driving device is penetrated through the mounting bracket and the pot cover and stretches into the tubular container; and a paddle is arranged at the output end of the driving device.

Owner:郭继安

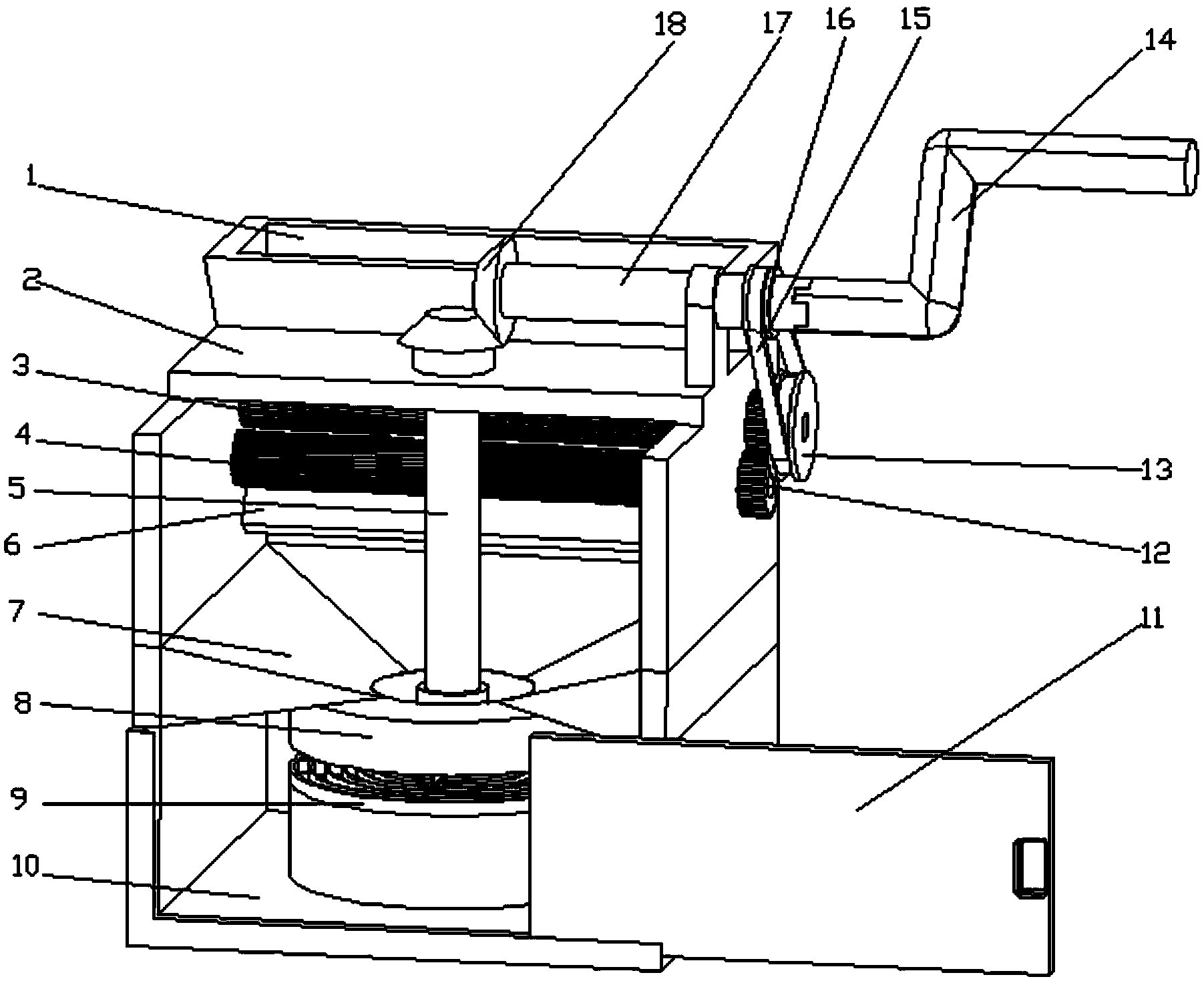

Household hand-operated Chinese chestnut peeling machine

The invention relates to a household hand-operated Chinese chestnut peeling machine and belongs to the field of household products. The household hand-operated Chinese chestnut peeling machine comprises a feed inlet, an upper tank, an upper cylindrical cutter, a lower cylindrical cutter, a vertical shaft, an inclined retaining plate, a middle shell, a rotary grinding disc, a mesh type grinding disc, a lower tank, a chestnut baffle, two gears, a large belt pulley, a small belt pulley, a rocking handle, a cross shaft and bevel gears, wherein the inclined retaining plate is mounted in the upper tank, the cylindrical cutters are parallelly mounted in the upper tank, the vertical shaft is vertically mounted in the middle of the upper surface of the upper tank, the rotary grinding disc is mounted at the lower end of the vertical shaft, the mesh type grinding disc is arranged in the lower tank, the gears are mounted on shafts of the cylindrical cutters respectively, the large belt pulley is mounted on the shaft of the upper cylindrical cutter and outside the gears, the small belt pulley is mounted on the cross shaft, the bevel gears are mounted on the cross shaft and the vertical shaft, the cross shaft is mounted on a shaft platform of the upper surface of the upper tank, and the rocking handle is mounted at one end, with a crisscrossed slot, of the cross shaft. The household hand-operated Chinese chestnut peeling machine has the advantages that husk of chestnuts can be automatically peeled off.

Owner:徐州携创智能科技有限公司

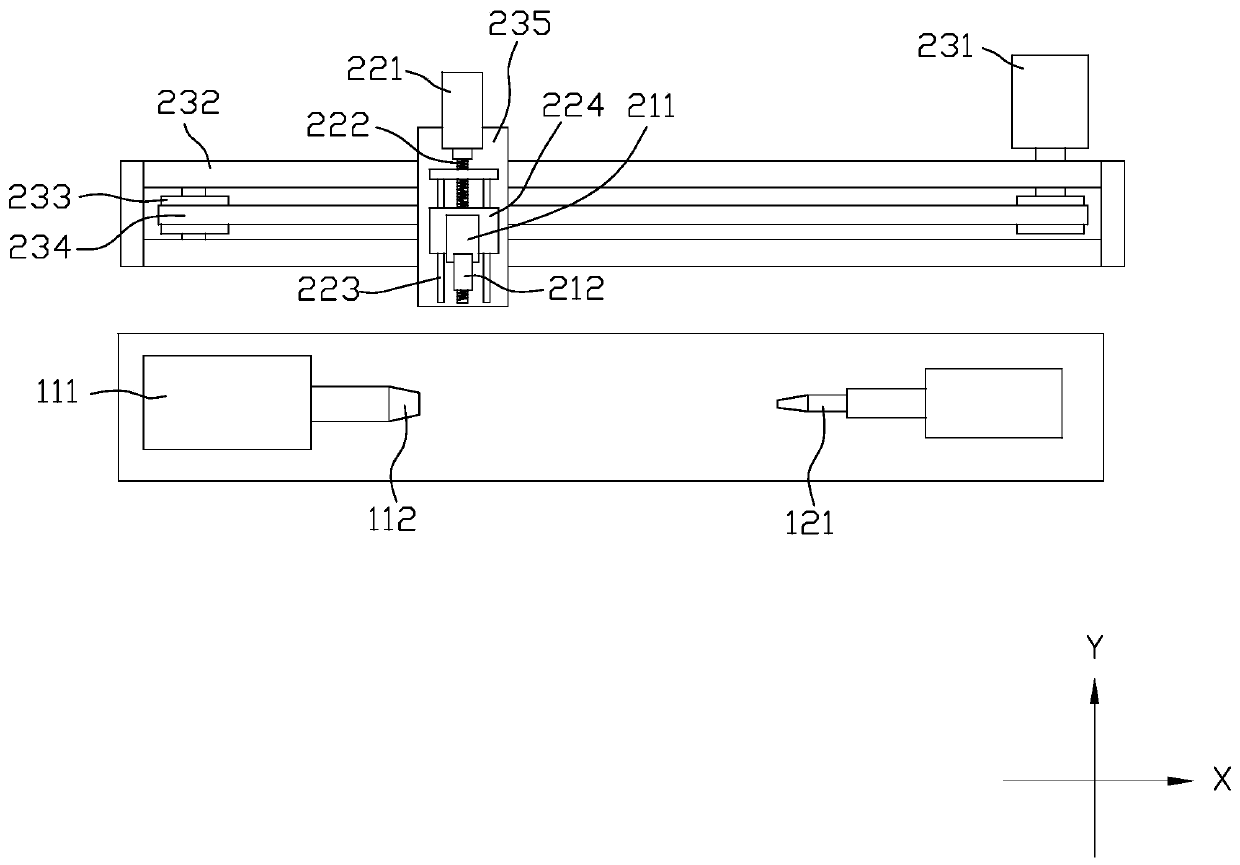

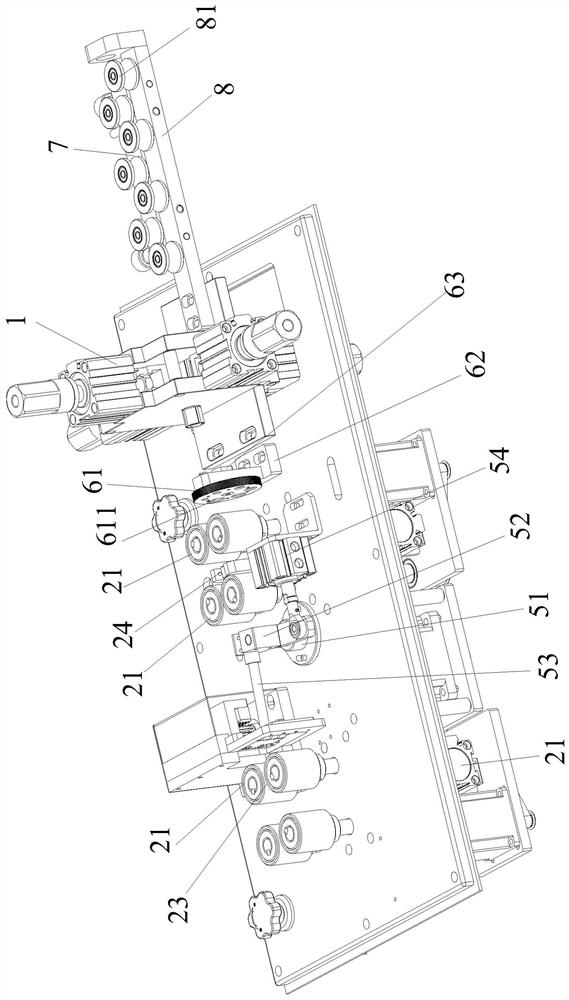

Automatic peeling device

PendingCN113363885ARealize automatic peelingAvoid stickingApparatus for removing/armouring cablesElectronic waste recyclingWire rodEngineering

The invention belongs to the field of wire peeling, and particularly relates to an automatic peeling device. The peeling device is characterized in that the peeling device comprises a transverse cutting mechanism for transversely cutting the surface of an electronic wire, a first traction rolling mechanism for pulling the electronic wire and rolling the electronic wire, a vertical cutting mechanism which is used for vertically cutting the surface of the electronic wire rod, and a second traction rolling mechanism which is used for pulling the electronic wire rod and rolling the electronic wire rod; the transverse cutting mechanism, the first traction rolling mechanism, the vertical cutting mechanism and the second traction rolling mechanism are sequentially arranged, and a peeling path used for conducting traction peeling on the electronic wire is formed among the transverse cutting mechanism, the first traction rolling mechanism, the vertical cutting mechanism and the second traction rolling mechanism. According to the invention, the automatic stripping of the electronic wire can be realized, and the inner core of the electronic wire cannot be damaged while the smooth stripping of the wire skin can be ensured.

Owner:深圳市明源鑫机械有限公司

Small environment-friendly multifunctional egg shelling machine

InactiveCN112401694ARealize automatic peelingNo manual contactKitchen equipmentEggshellProcess engineering

The invention relates to an egg shelling machine, in particular to a small environment-friendly multifunctional egg shelling machine. The technical problem to be solved is to provide the small environment-friendly multifunctional egg shelling machine capable of automatically shelling eggs, separating egg white from eggshells and automatically stirring the egg white. The small environment-friendlymultifunctional egg shelling machine comprises a supporting frame and a supporting cylinder, wherein the top of the supporting frame is connected with the supporting cylinder; a power mechanism whichis connected into the supporting cylinder; a power mechanism which is connected with the husking mechanism; and a supporting cylinder which is connected with the discharging mechanism. Through cooperation of the power mechanism, the husking mechanism and the discharging mechanism, automatic husking of eggs can be achieved, egg white and eggshells are separated, manual contact is not needed, and sanitation and convenience are achieved.

Owner:唐召志

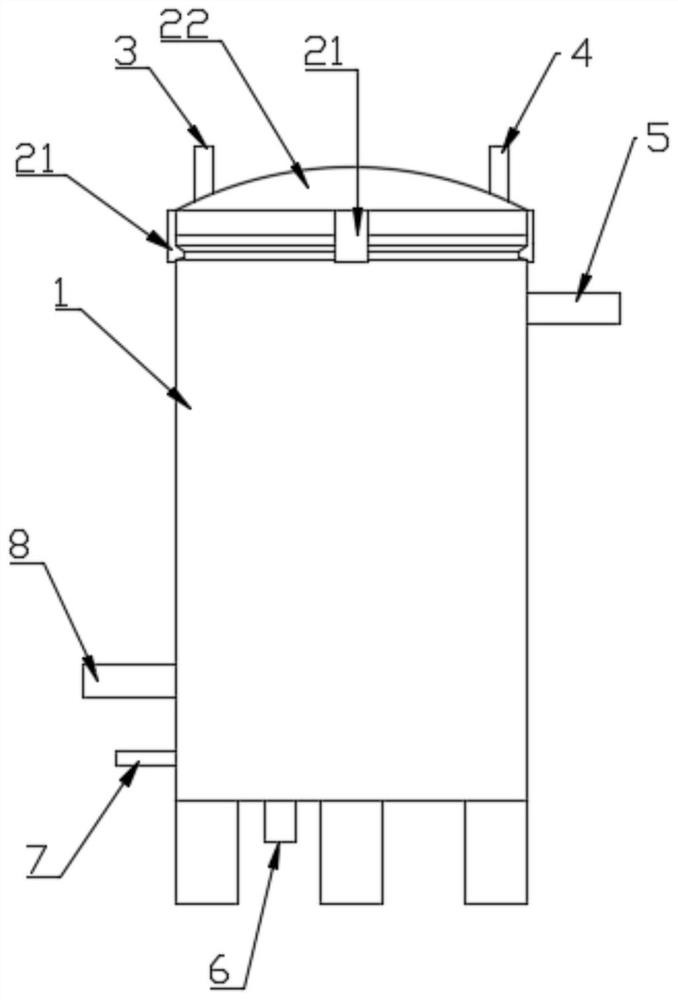

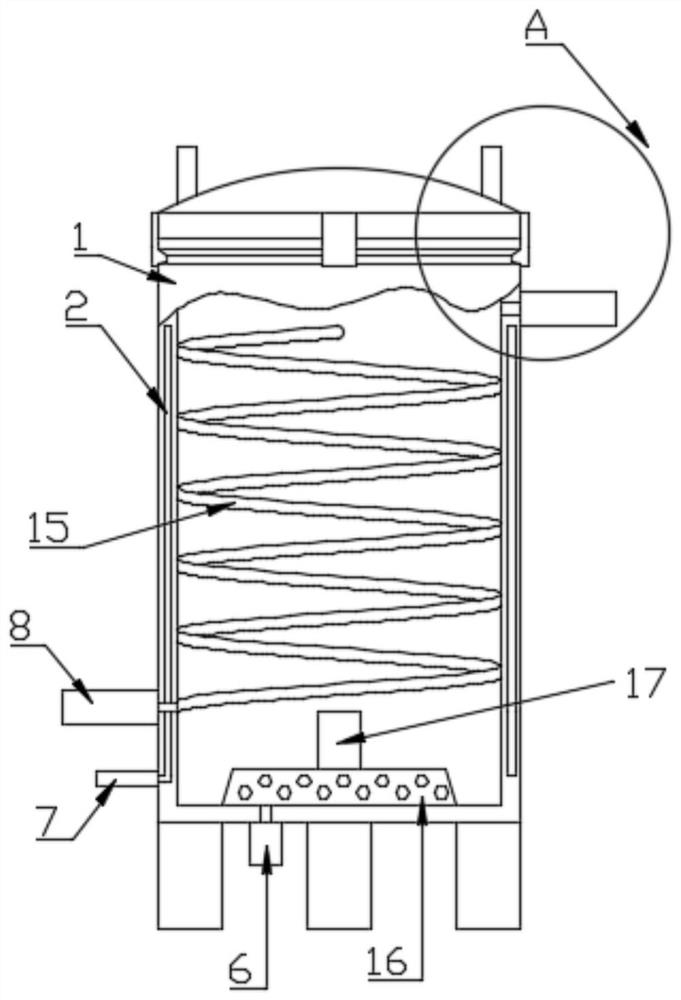

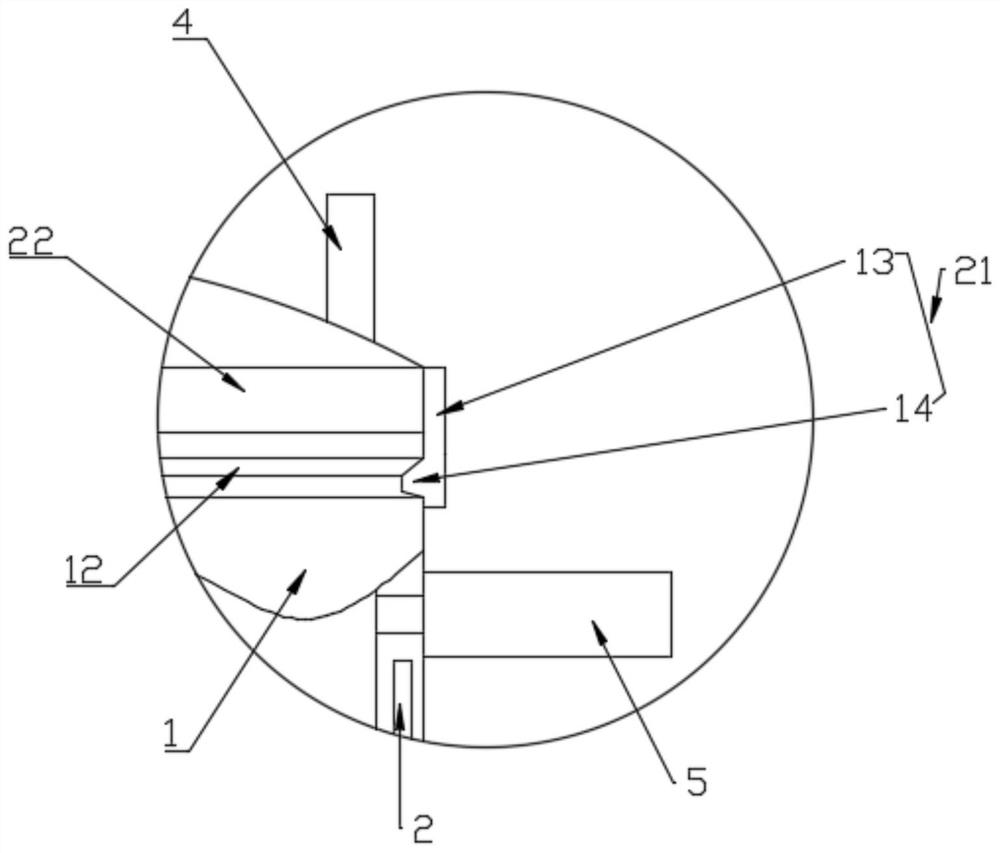

Evacuation pot capable of assisting citrus sinensis in peeling, and citrus sinensis peeling technology

ActiveCN111789268AAvoid burnsDecreased blanching temperatureFood shapingVegetable peelingMechanical engineeringBiotechnology

The invention provides an evacuation pot capable of assisting citrus sinensis in peeling. The evacuation pot comprises a pot body, wherein the pot body is provided with an interlayer; a sealing coveris buckled on the pot body and is provided with an exhaust pipe and a pressure pipe, which communicate with the inside of the pot body; the pot body is also provided with a liquid feeding pipe positioned on the upper end of the pot body, and a liquid discharging pipe arranged on the lower end of the pot body; the interlayer communicates with a gas inlet pipe and a liquid outlet pipe, which are arranged on the pot body; and the liquid feeding pipe and the liquid discharging pipe body both communicate with the inside of the pot body. The evacuation pot also comprises a hanging basket used for containing the citrus sinensis, wherein the upper end of the hanging basket is provided with an opening, and the opening is in threaded connection with a hole plate. The invention also provides a citrussinensis peeling technology which adopts the evacuation pot. According to the citrus sinensis peeling technology, a high temperature can be lowered, in addition, an operation is carried out in a sealed pot body, and employees can be prevented from being scalded. Meanwhile, under the assistance of enzyme treatment, the processed citrus sinensis has a high pulp separation degree, then, the citrus sinensi is added into a roller to be subjected to rolling processing, the pulp is separated, then, the citrus sinensi is introduced out to be subjected to manual separation, and a pulp damage rate is lowered to 5%.

Owner:YICHANG HAITONG FOOD

Sunflower seed huller

PendingCN110839908ARealize automatic peelingEasy to eatGas current separationHuskingHorticultureFood processing

The invention provides a sunflower seed huller, belongs to the technical field of food processing and solves the problem that hulling sunflower seeds by people is insufficient. The sunflower seed huller comprises a rack, a hulling mechanism, a vibrating mechanism and a sorting mechanism. According to the invention, sunflower seed hulls are crushed by the hulling mechanism, so that the melon seed hulls no longer cover sunflower seed kernels, and then the vibrating mechanism cooperates with the sorting mechanism to separate the melon seed hulls from the melon seed kernels; therefore, sunflower seeds are automatically hulled by the sunflower seed huller to make it convenient for people to eat the sunflower seeds.

Owner:叶华阳

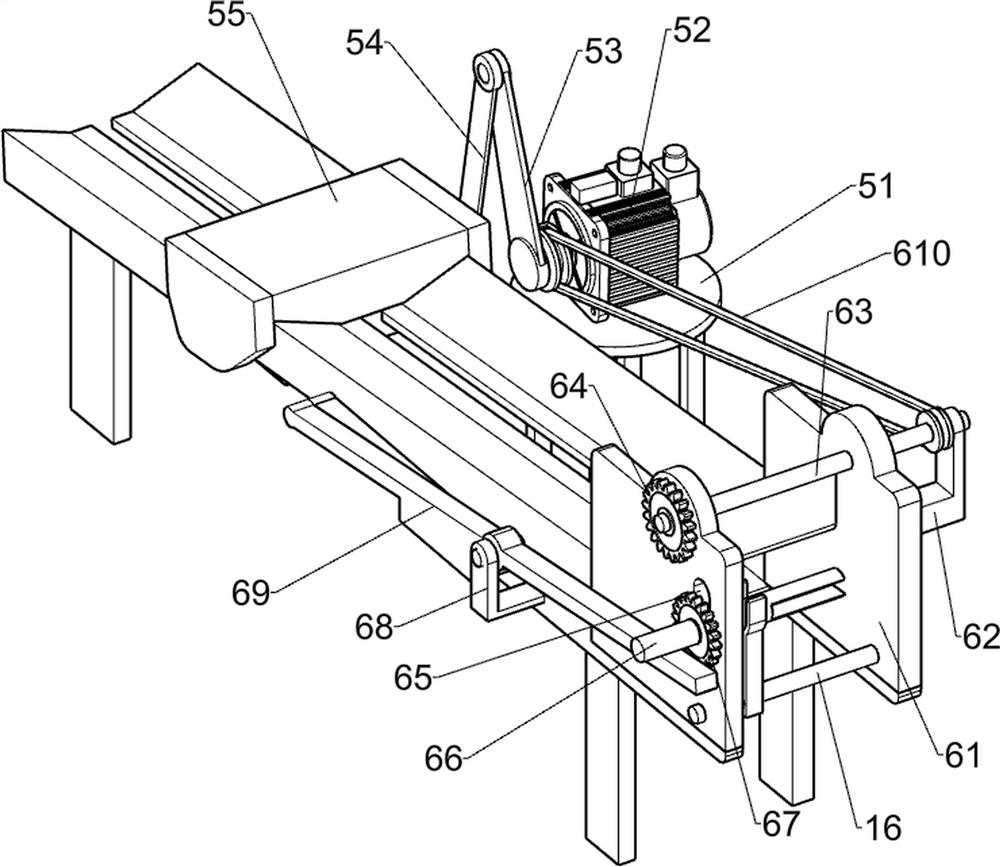

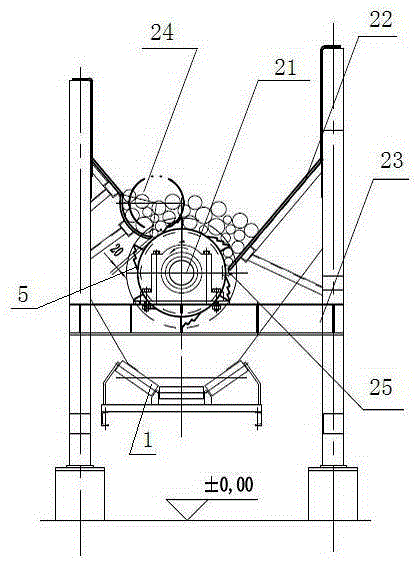

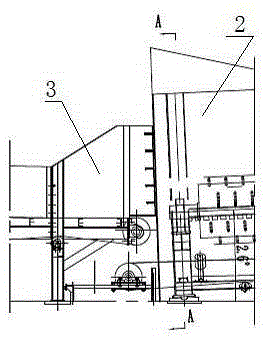

Bellows seal winding device

The invention discloses a bellows seal winding device. The bellows seal winding device comprises an operation platform, a long bellows storage mechanism arranged on one side of the operation platform,a pressure head fixture assembly arranged on the other side of the operation platform, a bellows stretching assembly arranged between the long bellows storage mechanism and the pressure head fixtureassembly, a supporting plate slidably arranged on the operation platform, a first driving mechanism arranged on the lower portion of the supporting plate, a cylindrical gear arranged on one side of the first driving mechanism and capable of being driven by the first driving mechanism to rotate, and a V-shaped pressing sheet fixed to the inner wall of the cylindrical gear, wherein the top of the supporting plate is provided with a sealing belt; the sealing belt covers the opening of the gear, the V-shaped pressing sheet sequentially makes contact with the sealing belt and an inner bellows by moving the supporting plate, and winding is conducted on the inner bellows along with rotating of the V-shaped pressing sheet. Through the bellows seal winding device, fixed-length winding of the bellows is achieved, and the winding precision is high.

Owner:JILIN WONDERFUL SCI & TECH CO LTD

Centrifugal type wind-blowing-off and pressing-ring tearing-off method of fresh corn husk

Provided is a centrifugal type wind-blowing-off and pressing-ring tearing-off method of fresh corn husk. The method comprises steps that 1) a corn clamping mechanical arm clamps corn on a spinning knife; 2) driven by the rotary knife, the corn begin to rotate and are scattered outwards in a slightly opened state; 3) when the rotary knife rotates to a blowing mechanism along with a main shaft, the blowing mechanism is started, affected by air pressure, a vertical air nozzle and a side air nozzle blow away the corn husk, and after being blown away, the corn husk are in a horizontally opened state; 4) a stop mechanism stops inertially rotating rotary knife from rotating; and 5) a pressing ring tearing-off part continuous to rotate along with the main shaft. When an upper pressing ring and a lower pressing ring clamp the corn husk and walk to a big wave trough from a small wave trough, the corn husk will be torn off from the corn after being imposed on downwards tearing force by the upper pressing ring and the lower pressing ring. When an upper pressing ring frame and a lower pressing ring frame continuous to enter and go out of the big wave trough, the upper pressing ring is gradually separated from the lower pressing ring, so the corn husk will fall off. Thus, wind-blowing-off and pressing-ring tearing-off for fresh corn husk is finished. The method is used for corn husk stripping.

Owner:HARBIN YONGYU POWER STATION EQUIP

Centrifugal method for husking fresh edible corns through air blowing and rubber roller peeling

The invention discloses a centrifugal method for husking fresh edible corns through air blowing and rubber roller peeling,the method comprising steps of: 1. a corn clamping manipulator clamps a corn to a rotation cutter; 2. the corn is driven to rotate by the rotation cutter, and the husks of the corns play outwardly in a slightly spreading manner; 3. the rotation cutter rotates along an upper cam circular orbit and lower cam circular orbit along with a main shaft. A plurality of vertical-air nozzles on an air blowing means are arranged above the corn, and a plurality of side-air nozzles on the air blowing means are positioned on side faces of the corn. When the rotation cutter rotates to the air blowing means along with the main shaft, the air blowing means is actuated. Under the action of the air pressure, the plurality of vertical-air nozzles and the plurality of side-air nozzles blow open the skins of the corn, and the skins of the corn assume a horizontal spreading status; 4. when the rotation cutter rotates to a rubber roller peeling means, since the corn is arranged perpendicular to the axes of an upper roller and a lower roller of the rubber roller peeling means, the horizontal plane of the root portion of the corn and the boundary between the upper roller and a lower roller are within the same horizontal plane.The upper roller and the lower roller rotate to peel away the residual husks of the corn clean. The method is applicable to husking corn.

Owner:HARBIN YONGYU POWER STATION EQUIP

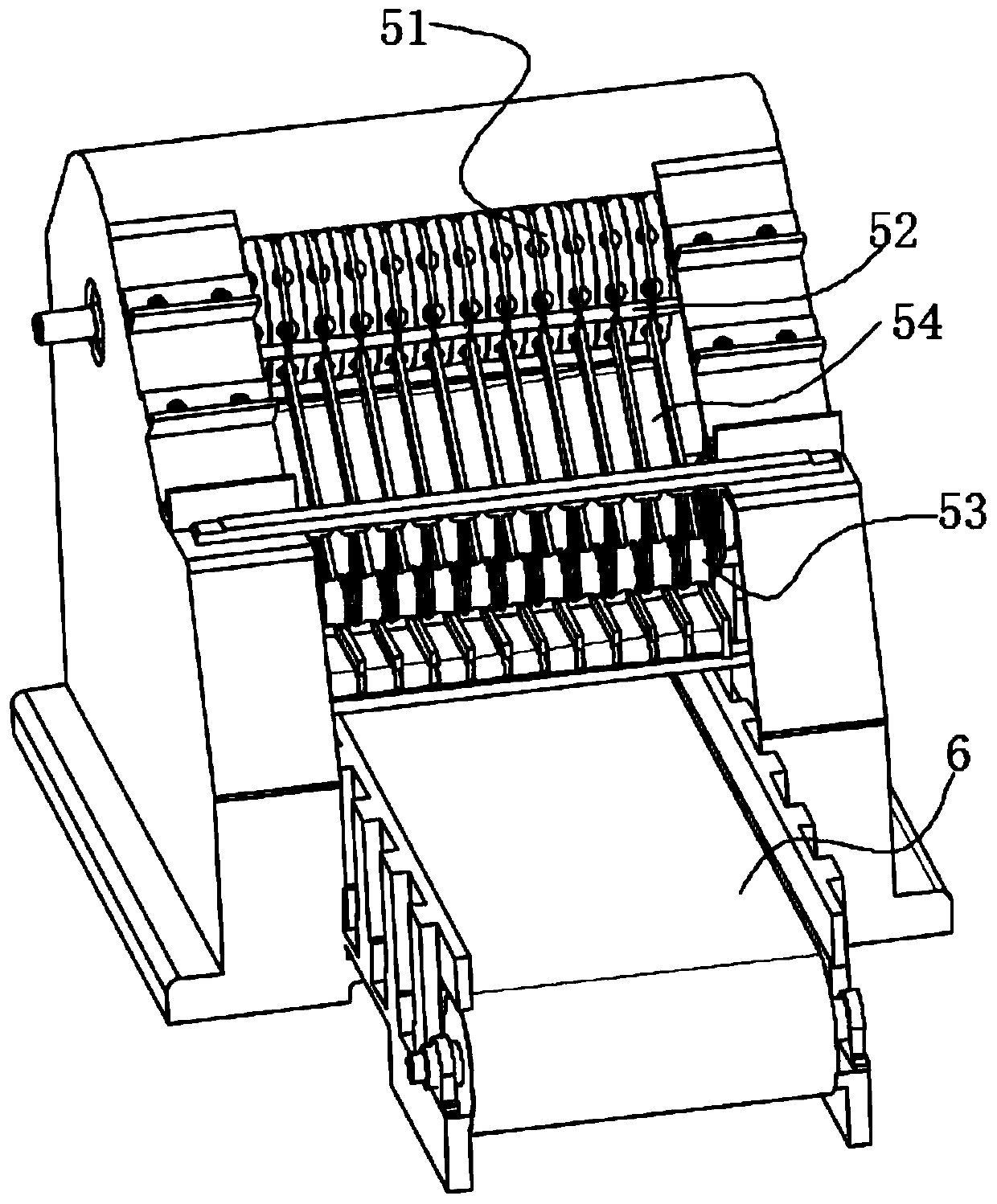

Multi-section synchronous orange peeling machine

InactiveCN108713771ARealize automatic peelingNot easy to damageVegetable peelingFood treatmentSocial benefitsEconomic benefits

The invention discloses a multi-section synchronous orange peeling machine. The machine comprises a delivery mechanism, a peel scratching mechanism, a breaking mechanism and a peeling mechanism, oranges are delivered to the peel scratching mechanism through the delivery system, the oranges are scratched in the peel scratching mechanism, then enter the breaking mechanism to be broke apart and enterthe peeling mechanism to be peeled. By means of the machine, automatic peeling of the oranges is achieved, peeling effect is stable, pulps are not easily damaged, the machine can be widely popularized and used, the market application prospect is wide, and excellent economic benefit and social benefit can be brought.

Owner:宁波市鄞州实验中学

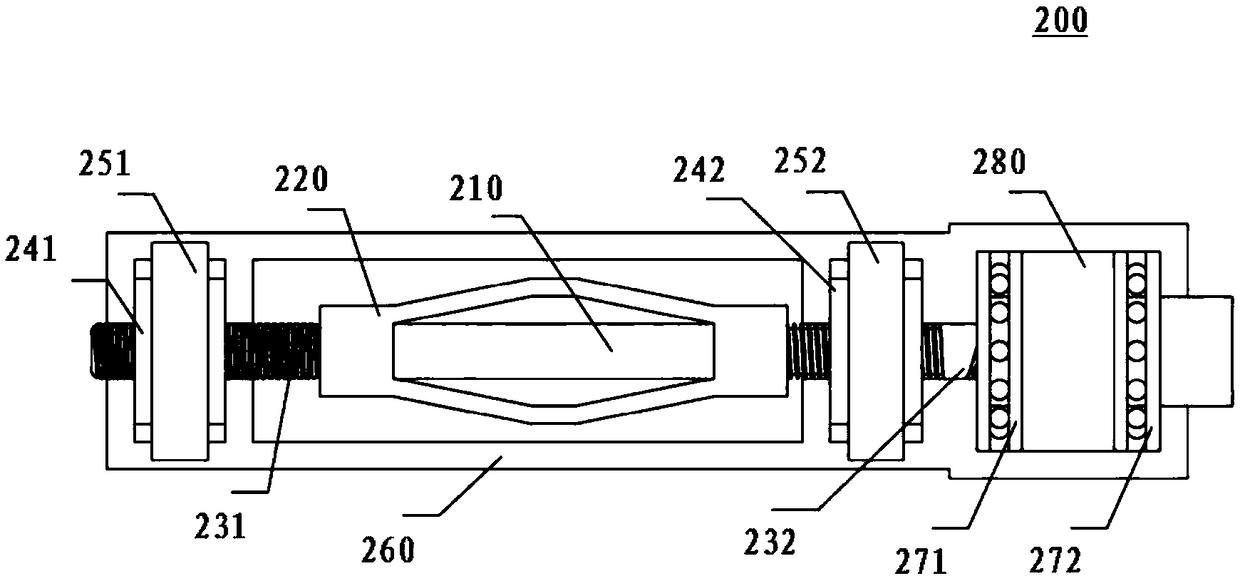

A practical device for cables

InactiveCN107017541BReduce energy consumptionHigh resolutionLine/current collector detailsImage resolutionClosed loop

Owner:STATE GRID SHANDONG ELECTRIC POWER CO SHOUGUANG POWER SUPPLY CO +2

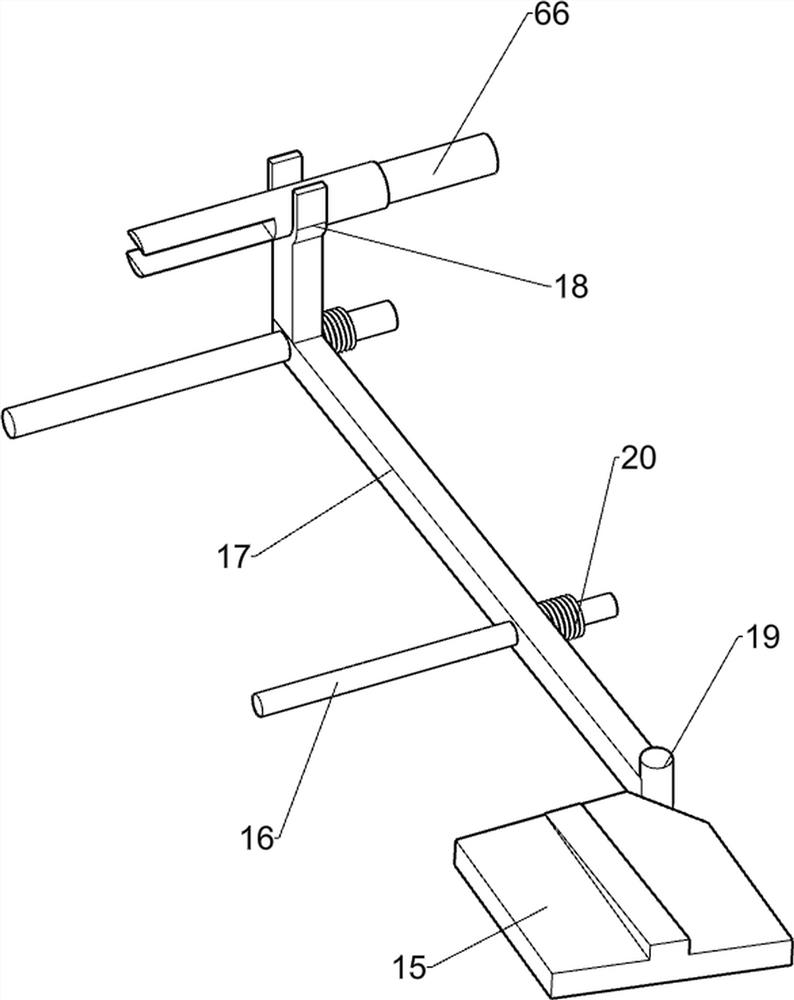

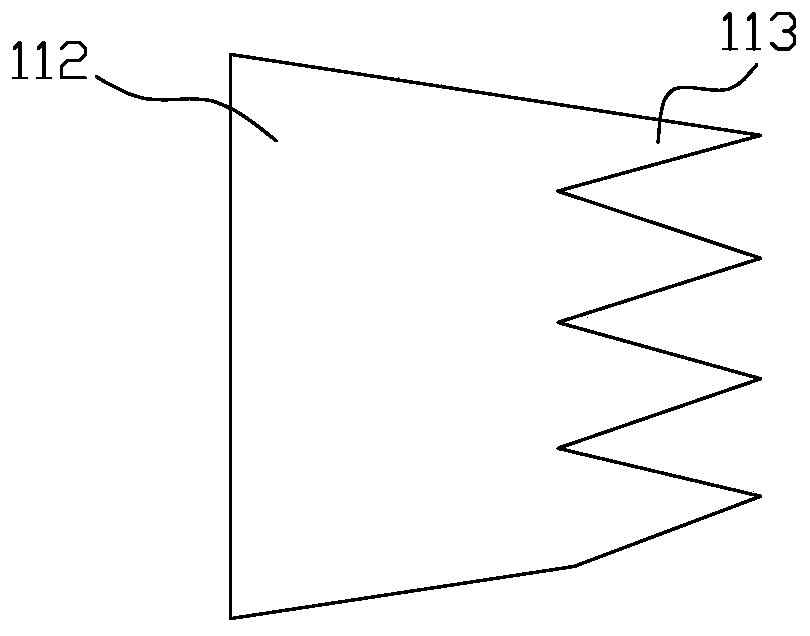

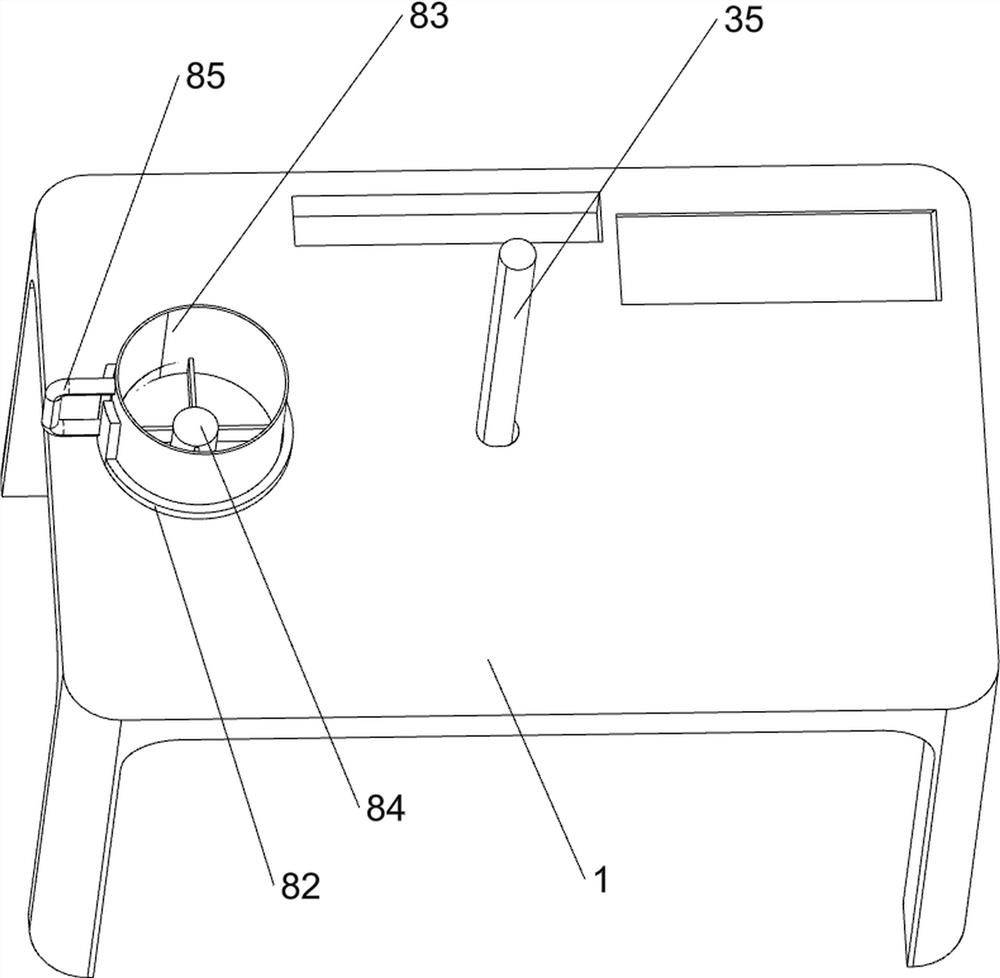

sugar cane peeler

ActiveCN106360756BImprove peeling efficiencyImprove applicabilityVegetable peelingLinear motionEngineering

The present invention relates to a sugar cane peeler. The sugar cane peeler comprises an operation table, a sugar cane bottom fixing device, a sugar cane top fixing device, a peeling cutting tool, a movable driving device for driving the peeling cutting tool to conduct a vertical reciprocating linear motion, and a sugar cane peel collection box; a through groove is arranged at the middle part of the table surface of the operation table and the sugar cane peel collection box is located under the through groove; the sugar cane bottom fixing device comprises a fixing plate and a fixing seat, and the fixing plate is fixed within the through groove; the sugar cane top fixing device comprises a stand column, a movable sleeve, a connecting rod and an extruding rod, the extruding rod is located over the fixing seat, and a containing space for containing the sugar canes is formed between the extruding rod and the fixing seat; and the peeling cutting tool comprises a fixing barrel, a peeling cutting blade, and cutting blades, the peeling cutting blade is fixed at the bottom surface of the fixing barrel, the four cutting blades are evenly fixed at the bottom end of the outer side wall of the fixing barrel, and the fixing barrel sleeves the extruding rod. The sugar cane peeler is convenient in use, automatic in peeling, high in peeling efficiency and diverse in functions.

Owner:徐州五果液果酒有限公司

Shared platform food material processing device based on Internet of Things

The invention relates to a shared platform food material processing device based on the Internet of Things. The shared platform food material processing device comprises a discharging barrel, a base,a first rotating mechanism and a peeling assembly matched with a rotating assembly. The first rotating mechanism is arranged at the top of the base in a matched mode, a plurality of clamping pieces are arranged on the outer side of the first rotating mechanism at intervals in the circumferential direction, second rotating mechanisms are connected to the tops of the clamping pieces in a matched mode, contact pins are arranged at the tops of the second rotating mechanisms, the discharging barrel is located above the contact pins, and the first rotating mechanism and the second rotating mechanisms can rotate. The peeling assembly comprises an abutting mechanism. The abutting mechanism is provided with a kernel channel in the axis direction in a penetrating mode. A second patch is arranged onthe outer side of the abutting mechanism, the end of the second patch is connected with a first patch in a matched mode through a rotating shaft, elastic pieces are arranged on the inner sides of thefirst patch and the second patch in a matched mode, a peeling knife is arranged at the end of the first patch, and a sensor is arranged on the inner side of the first patch and used for monitoring peel state information.

Owner:XUZHOU LIANGHAN AGRI DEV CO LTD

Efficient apple peeling device

The invention discloses an efficient apple peeling device, which comprises a rotary mechanism, a lifting mechanism, a follow-up lifting assembly, a rotary fixing assembly, a limiting column, an upperlimiting assembly, a first-stage peeling cutter assembly and a second-stage peeling cutter assembly. The rotary mechanism drives apples at the upper end of the rotary fixing assembly to rotate, and meanwhile the lifting mechanism converts rotary motion of the rotary mechanism into lifting linear motion, so that the lifting mechanism drives the follow-up lifting assembly, the first-stage peeling cutter assembly and the second-stage peeling cutter assembly to ascend and descend up and down. Then the first-stage peeling cutter assembly and the second-stage peeling cutter assembly move up and downto peel apples, cutters make contact with fruit cutting point positions for cutting, a power source provides power to drive fruits and vegetables to rotate, and automatic peeling is achieved; two apples can be peeled at the same time through double stations of the first-stage peeling cutter assembly and the second-stage peeling cutter assembly. In the aspect of power source, a motor, gear transmission and lead screw transmission are adopted, so that the efficiency is high, and the cost is low.

Owner:TAIZHOU POLYTECHNIC COLLEGE

A method of centrifugal fresh corn husk water blowing and rubber roller peeling

A centrifugal fresh corn bran water blowing and rubber covered roller peeling method. The method comprises steps that a corn is clamped to a rotary cutter by a corn clamping mechanical arm; the corn is driven by the rotary cutter to rotate; corn bran is external scattered to form a micro-open state; the rotary cutter rotates with a main shaft along an upper cam periphery track and a lower cam periphery track; a plurality of vertical nozzles on a water-blowing mechanism are arranged over the corn; a plurality of lateral water nozzles of the water blowing mechanism are arranged on the side surface of the corn; when the rotary cutter rotates to the water blowing mechanism with the main shaft, the water blowing mechanism is started; with an action of water pressure, the corn bran is blown away by the vertical water nozzles and the lateral water nozzles; the corn bran after the blowing are remained at a horizontal expansion state; when the rotary cutter rotates to a rubber covered roller peeling mechanism, a horizontal plane of the root of the corn and an intercross line of an upper roller and a lower roller are placed on the same horizontal plane due to a vertical arrangement between the corn and an axis of the upper roller and an axis of the lower roller of the rubber covered roller peeling mechanism; and residual leaves on the corn can be peeled and cleaned by the rotary upper and lower rollers. The centrifugal fresh corn bran water blowing and rubber covered roller peeling method is applied to corn peeling.

Owner:HEILONGJIANG YANDING MACHINERY EQUIP MFG CO LTD

A kind of citrus automatic peeling machine

ActiveCN107373698BRealize automatic peelingEnsure hygiene and safetyVegetable peelingEngineeringConveyor belt

The invention discloses an automatic citrus peeling machine. The machine comprises a conveying device, a steam skin-scalding device and a peeling device. The conveying device comprises a feeding device, a skin-scalding conveyor belt and a peeling conveyor belt. The feeding device comprises a rack, two rollers, a feeding conveyor belt and a feeding motor. The peeling device comprises a large roller, a cutting knife device and a roller skin device. A plurality of annular notches are formed in the large roller. A hemispherical groove is formed in each annular notch. The cutting knife device comprises a fixed shaft and a plurality of annular knives arranged on the fixed shaft. The fixed shaft is installed at the downstream side of the large roller. The annular knives on the fixed shaft extend into the annular notches of the large roller in a one to one correspondence mode. The roller skin device is arranged at the downstream of the large roller. After entering the feeding device, the citrus is conveyed to the steam skin-scalding device through the conveying device, then sent to the peeling device, and then peeled by utilizing a small roller, wherein peel is scratched by utilizing the hemispherical grooves and the annular knives. The automatic citrus peeling machine is high in peeling efficiency, and labor cost is drastically saved.

Owner:HUBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com