Automatic vortex-jet machine for blowing garlic peel

A technology of garlic and vortex spraying, which is applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problems of low efficiency, time-consuming and laborious manual peeling, and achieve the reduction of floor space, convenient subsequent processing, and peeling good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

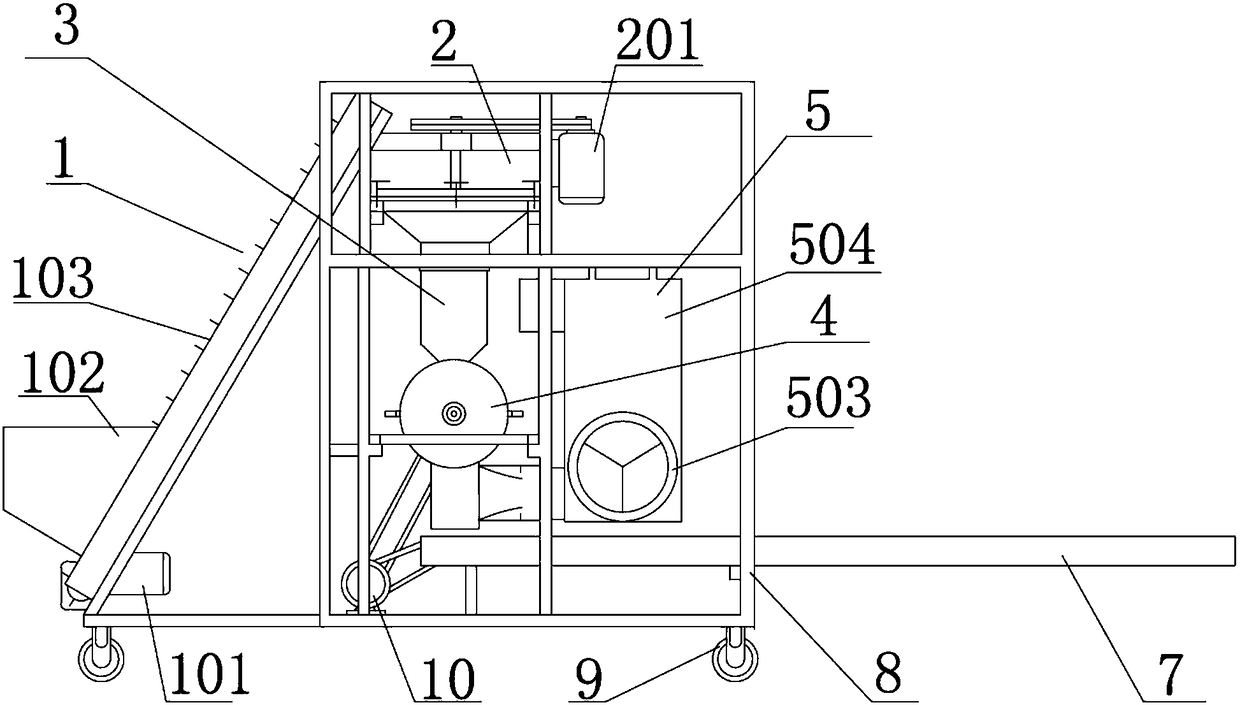

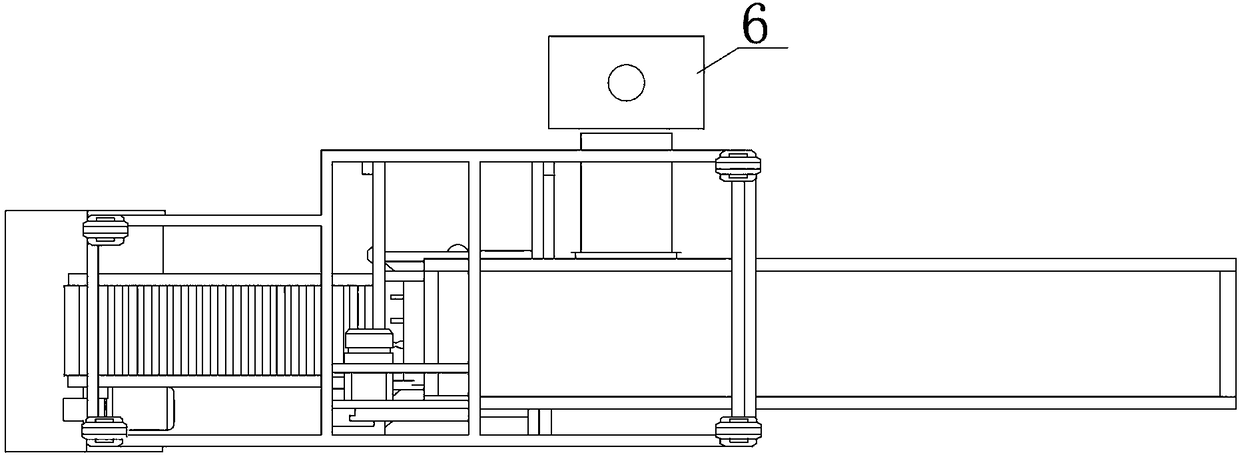

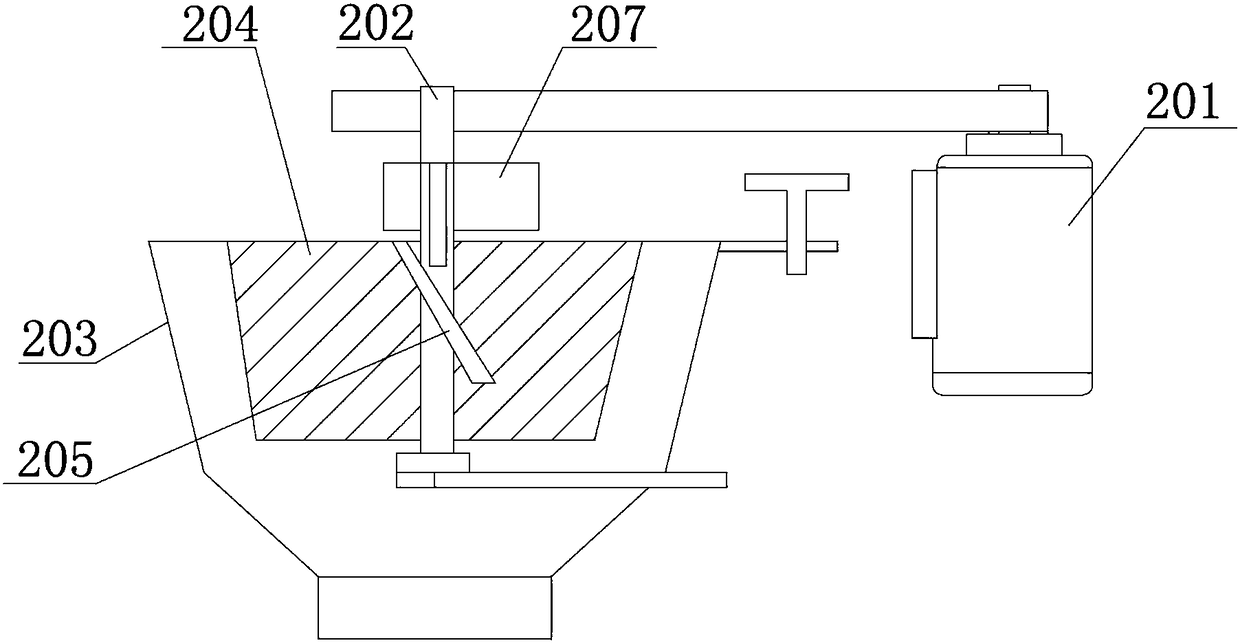

[0028] Such as figure 1 As shown, the automatic vortex jet garlic skin blowing machine of the present invention comprises a frame 8, a feeding mechanism 1, a splitting skin mechanism 2, a distributor 3, a peeling mechanism 4, a waste skin collection mechanism 5 and a waste skin extruding mechanism. Mechanism 6, feeding mechanism 1, skin splitting mechanism 2, distributor 3, peeling mechanism 4, waste skin collecting mechanism 5 and waste skin extruding mechanism 6 are all arranged on the frame 8, and the bottom of the frame 8 Casters 9 are provided, thereby realizing the movement of the frame 8 . One end of the feeding mechanism 1 is located above the split-flap skinning mechanism 2, and the peeling mechanism 4 is located below the split-flap skinning mechanism 2, and the split-flap skinning mechanism 2 and the peeling mechanism 4 are connected by a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com