Automatic efficient peeling line for small diameter logs

A high-efficiency technology for small-diameter wood, which is applied to high-efficiency automatic peeling of small-diameter wood. ,In the field of high-efficiency automatic peeling line for small-diameter timber, it can solve the problems of high wood loss of automatic peeling line and low efficiency of semi-automatic peeling line, and achieve the effect of solving high wood loss, simple maintenance and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

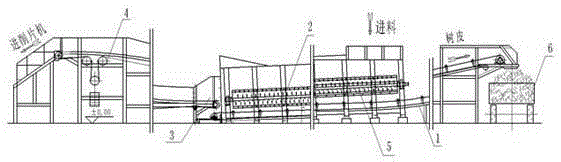

[0025] Such as figure 1 , the present invention mainly is made up of log car, toothed roller type peeling machine 2, discharge chute 3, discharge belt conveyor 4 and bark belt conveyor 1 and bark hopper 6. The rack in the toothed roller peeling machine is provided with a rotating roller at an inclination angle of 2.6°. Above the higher end of the rotating roller is the feed port of the toothed roller peeling machine 2500×1500. Below the rotating roller It is a bark belt conveyor, one end of the bark belt conveyor is provided with a bark hopper; the frame at the lower end of the rotating roller is provided with a discharge chute connected to the discharge belt conveyor.

[0026] The main technological process of the present invention: the wood grab car puts the small-diameter timber into the feed port of the toothed roller peeling machine 2500 × 1500, utilizes the toothed rotating roller in the toothed roller peeling machine and the equipment arranged at an inclination of 2.6°,...

Embodiment 2

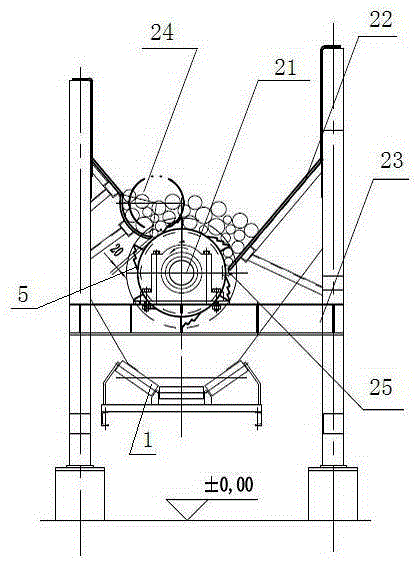

[0028] Such as figure 2 Shown, toothed roller type peeling machine mainly is made up of rotating drum 5, casing 22 and frame 23. The rotating roller is set on the rotating roller seat of the frame, and the top of the rotating roller is a tumbling area 24 for small-diameter materials; the two sides of the rotating roller are casings; there is a slag discharge gap 25 between the casing and the rotating roller ; The bottom of the rotating roller is provided with a bark belt conveyor 1.

Embodiment 3

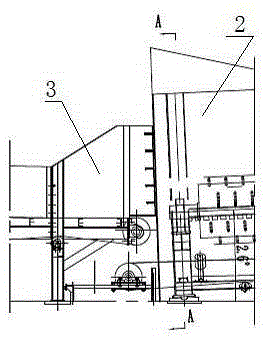

[0030] Such as image 3 , Figure 4 As shown, the discharge door 31 on the discharge chute 3 is controlled by a hydraulic cylinder 32 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com