Patents

Literature

43results about How to "No manual contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

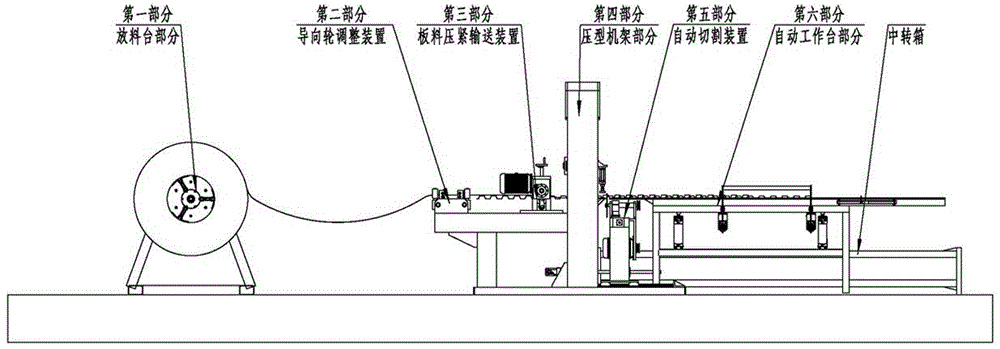

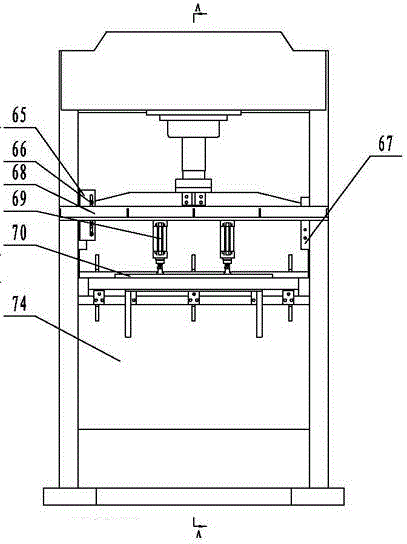

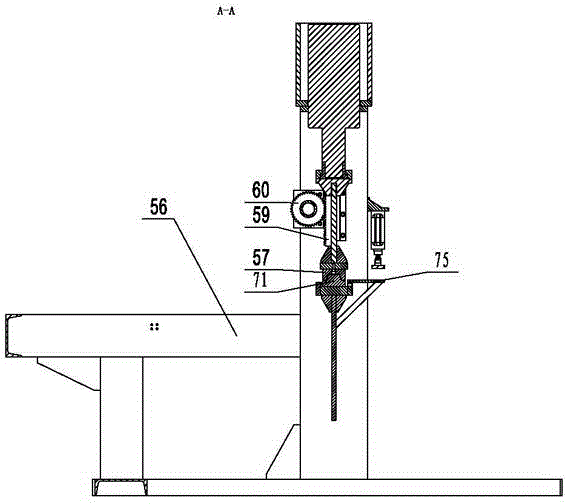

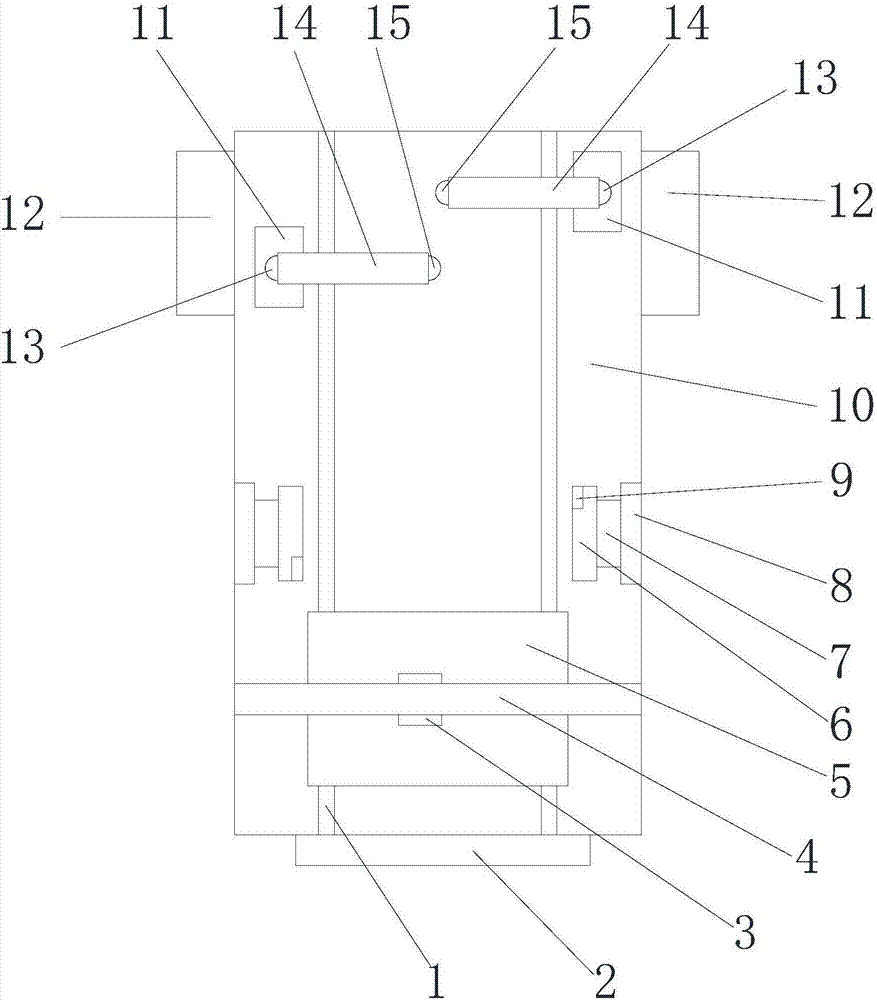

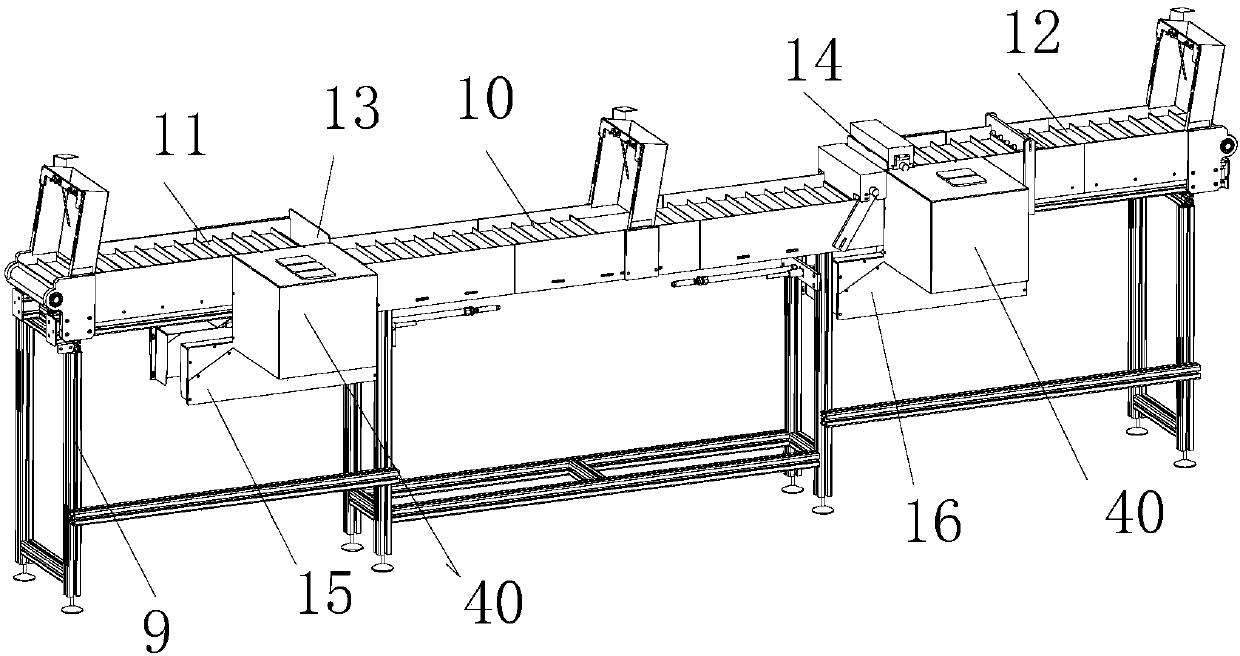

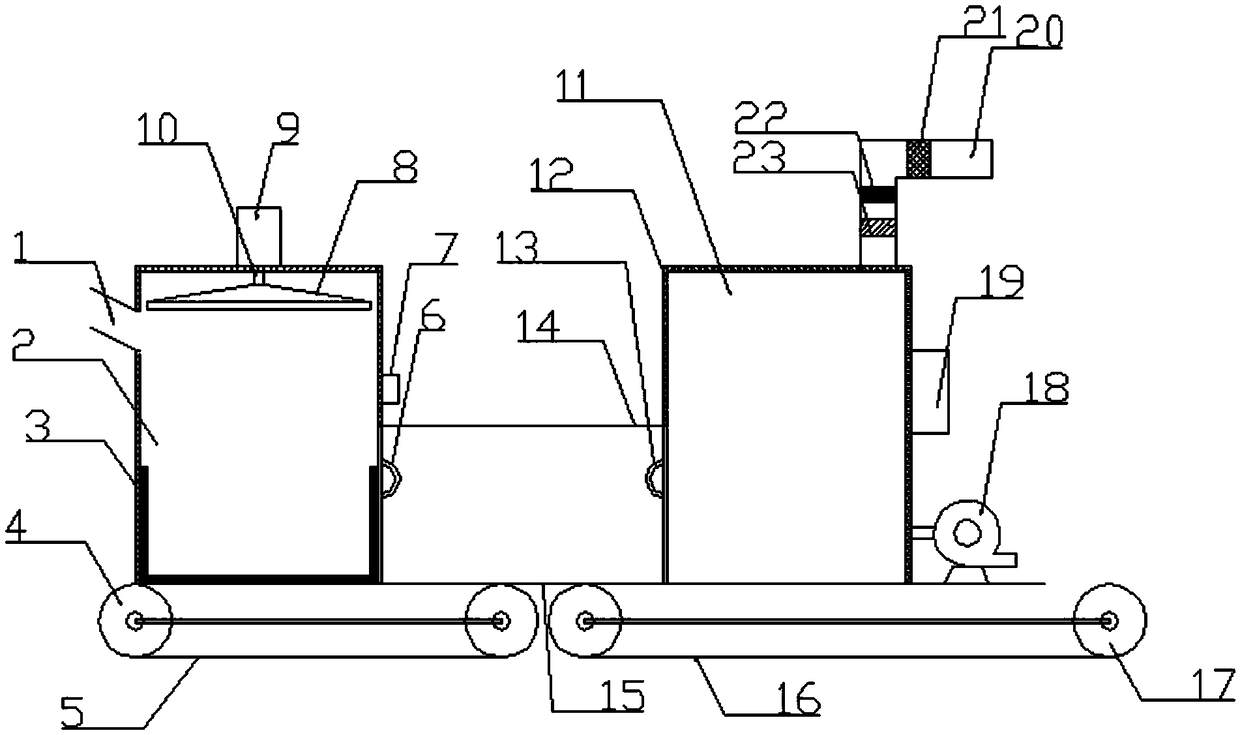

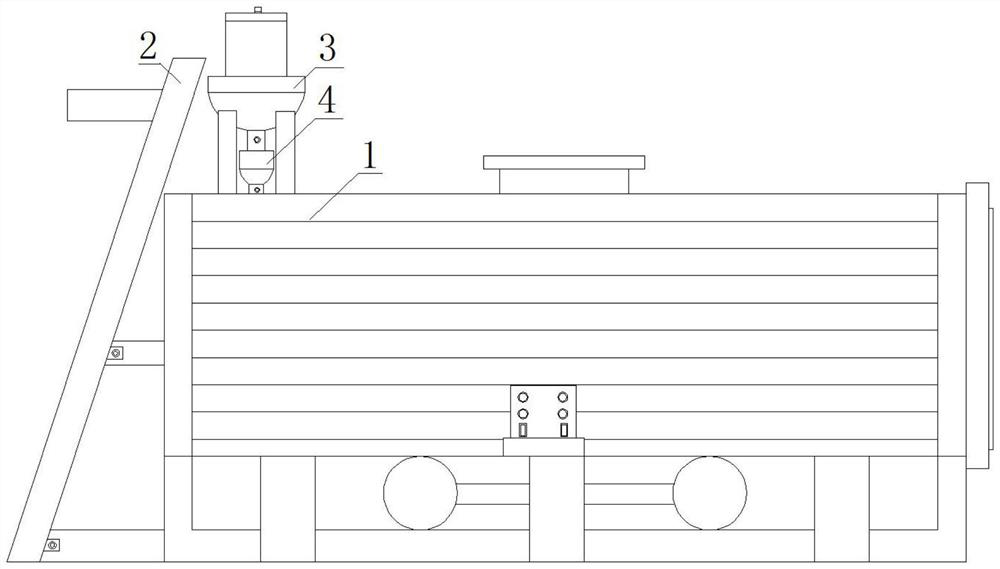

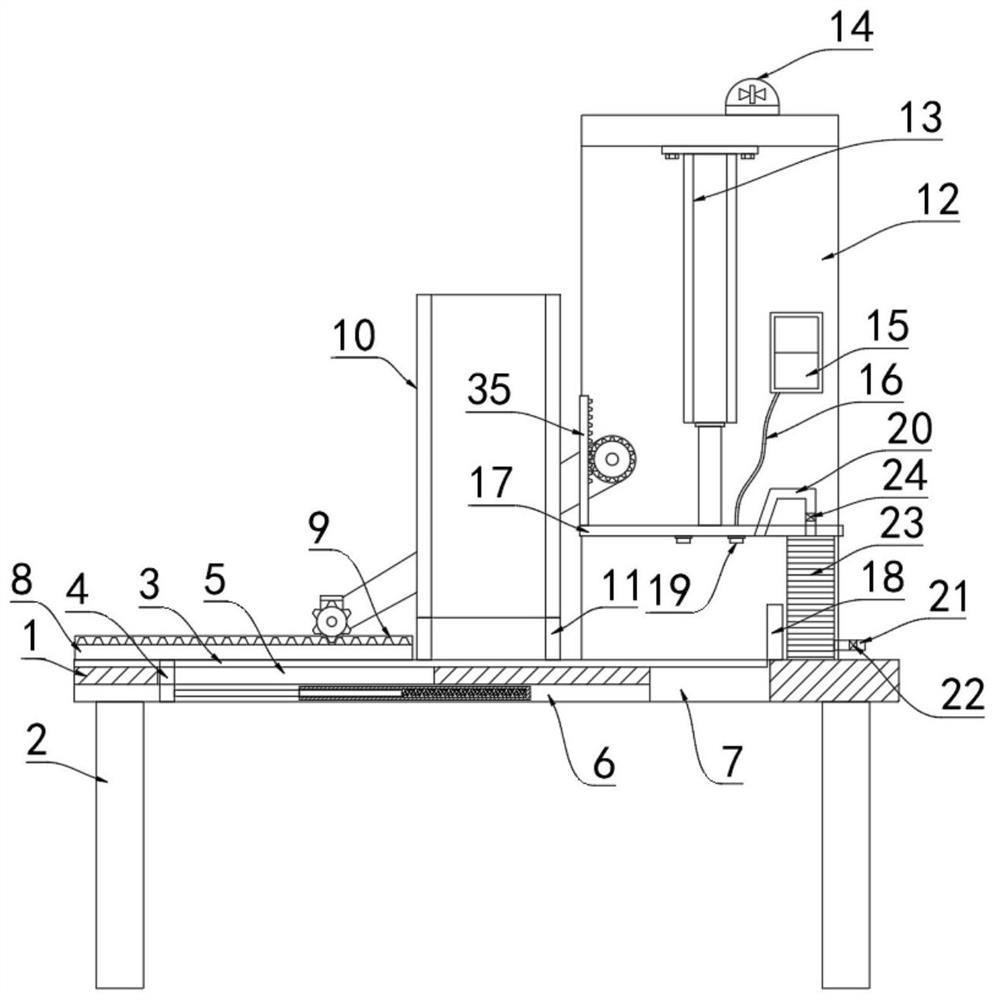

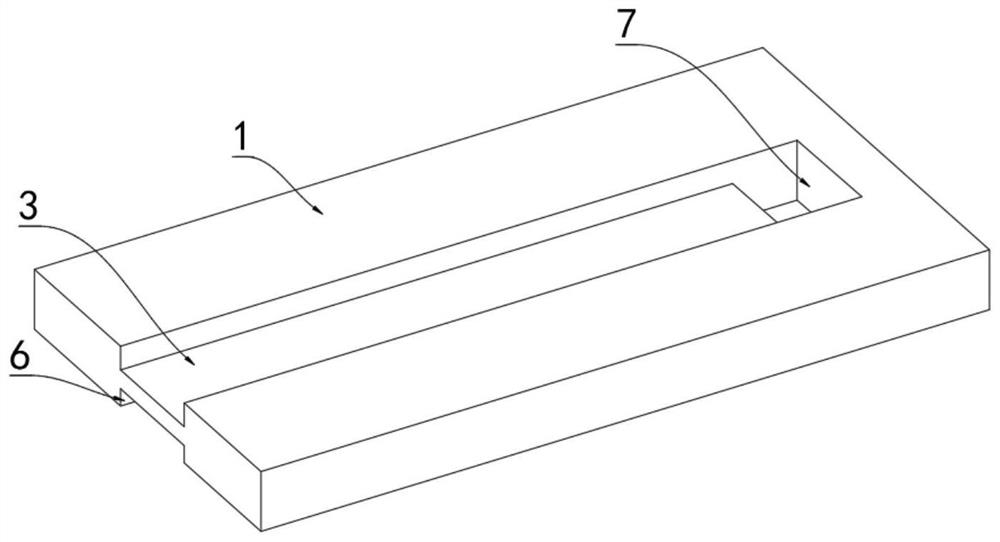

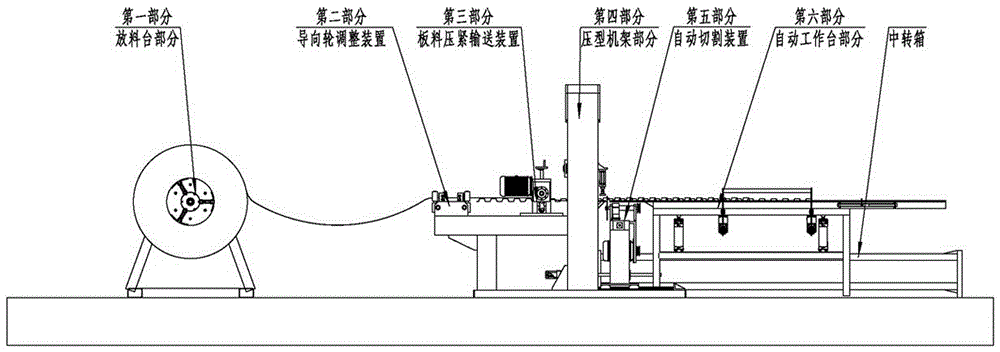

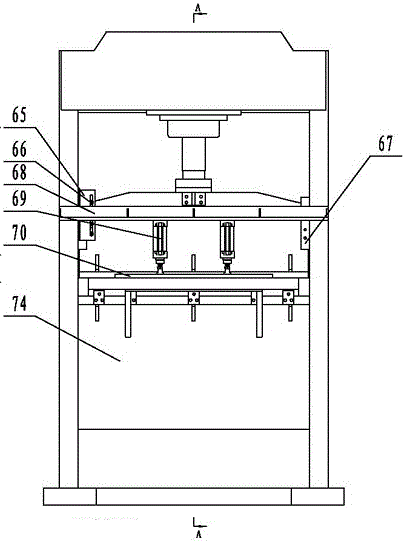

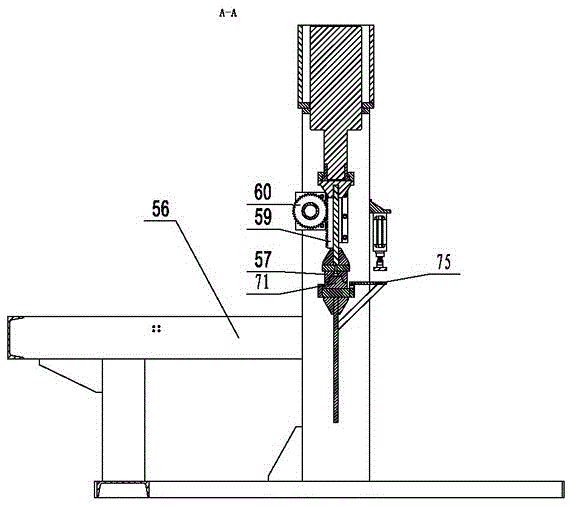

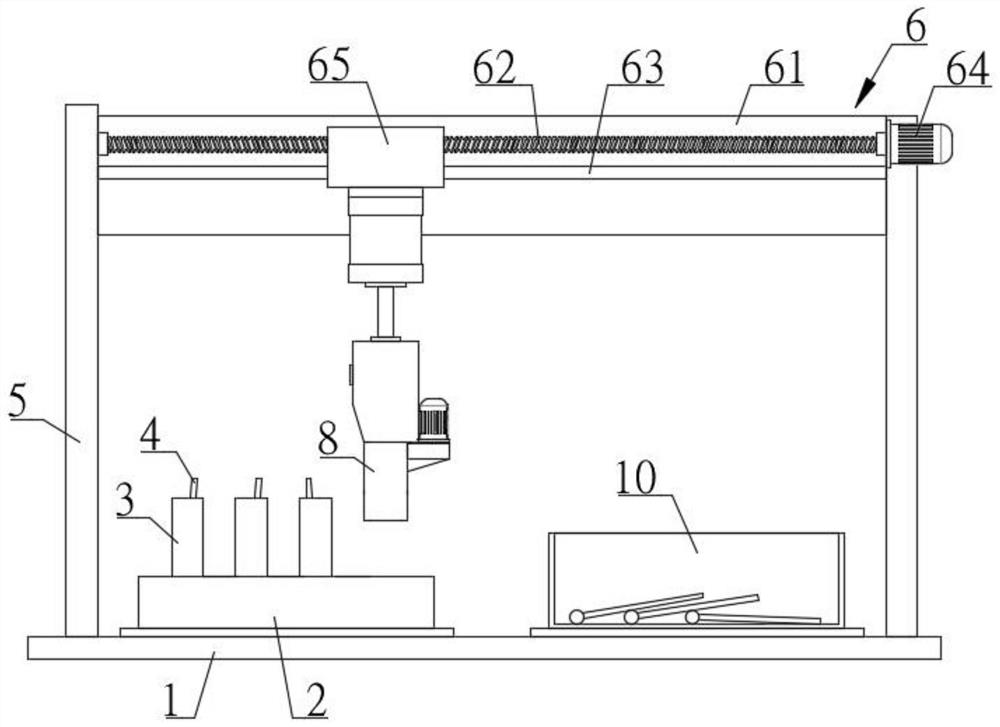

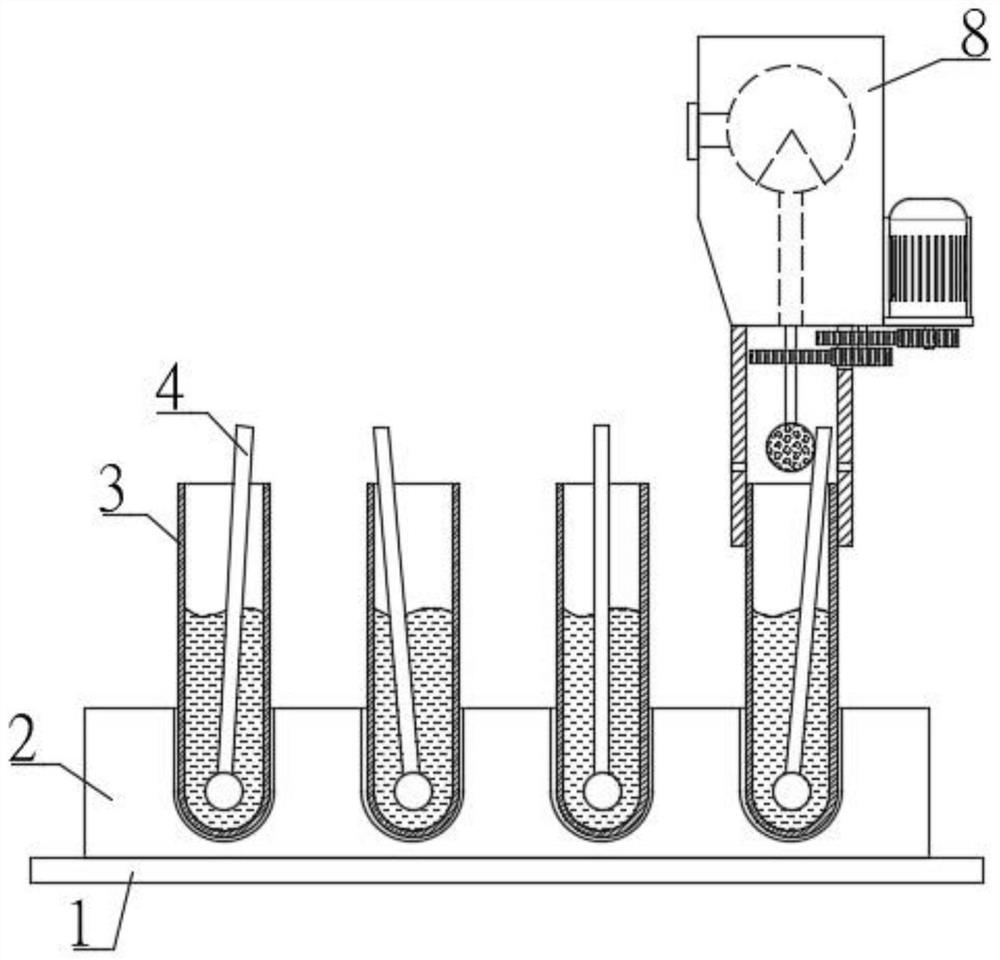

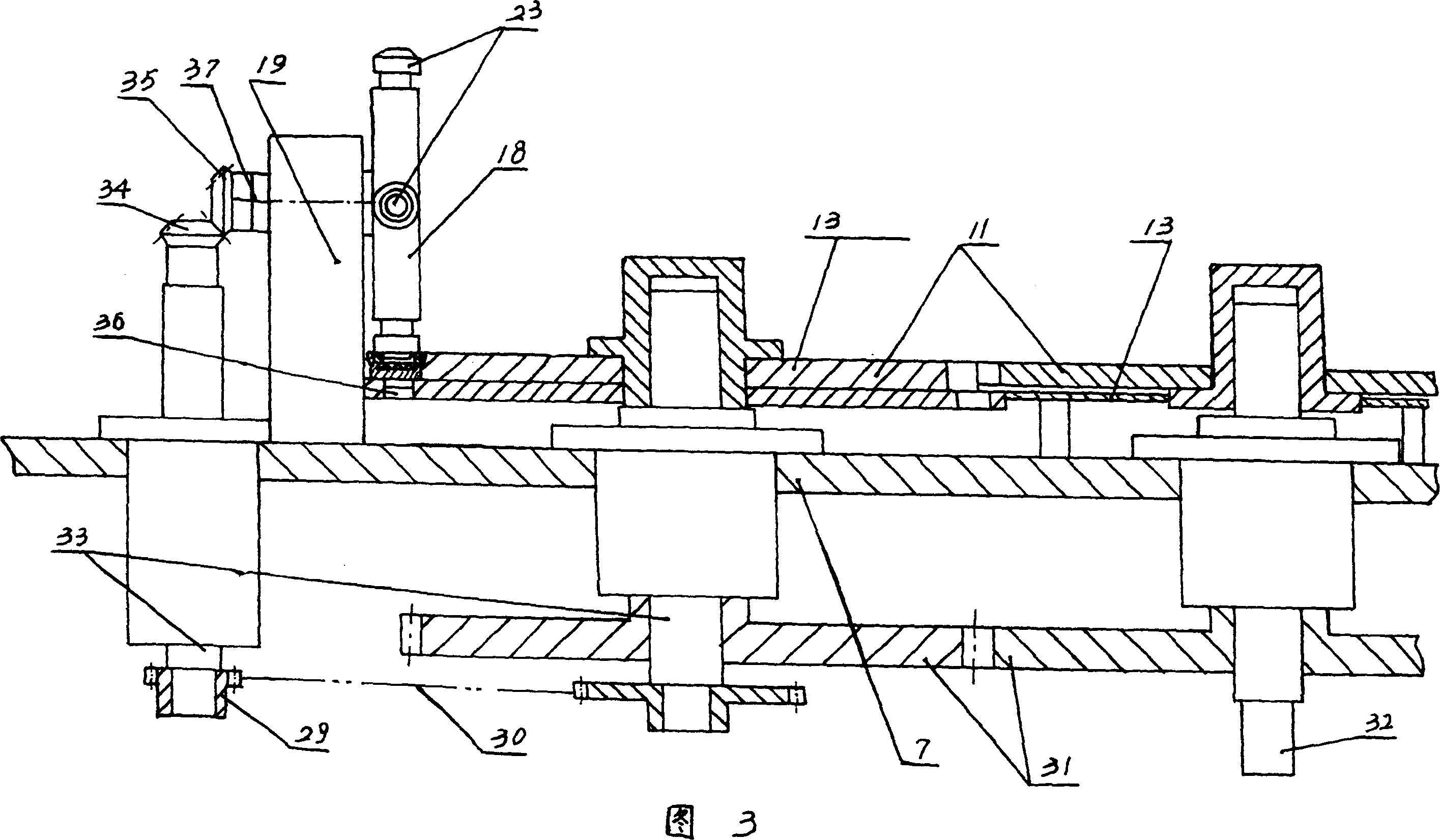

Full-automatic production line for forming corrugated boards

ActiveCN104607551ALoad accuratelyConsistent moldingShaping toolsMetal-working feeding devicesProduction lineEngineering

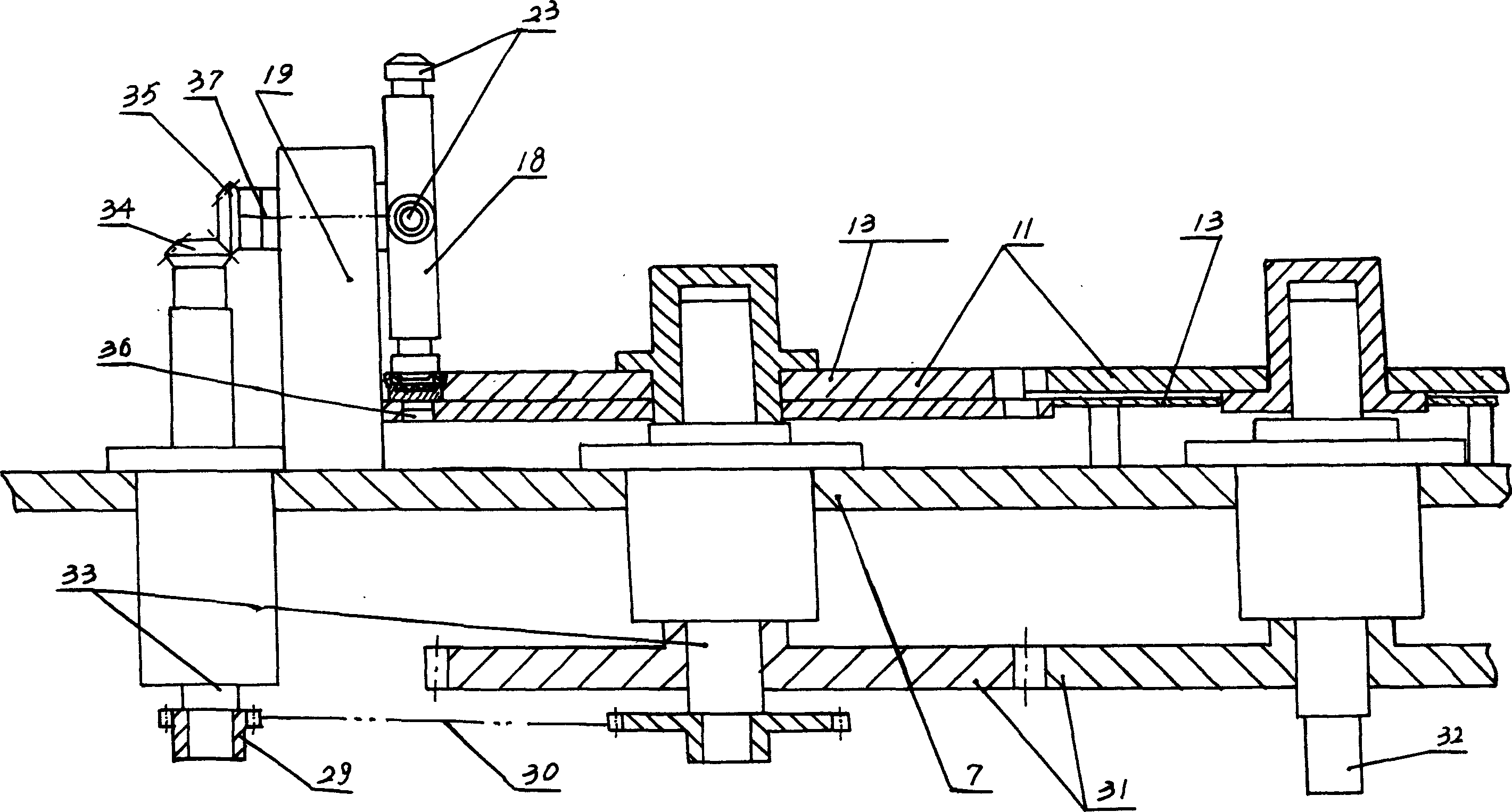

A full-automatic production line for forming corrugated boards comprises a forming press and a board conveying device. The forming press comprises an n-shaped support. Two upper mold guide seats are arranged on two transverse side stand columns of the n-shpaed support respectively, an upper mold is installed between the two upper mold guide seats, an upper mold installation plate is arranged on the upper mold, the upper mold is in sliding fit with the upper mold guide seats through the upper mold installation plate, a press forming oil cylinder is arranged on the upper portion of the n-shaped support, a piston rod of the press forming oil cylinder is connected with the upper mold installation plate, a lower mold fixing plate is arranged on the lower portion of the n-shaped support, a lower mold is arranged on the lower mold fixing plate, the upper mold and the lower mold vertically correspond to each other, and a rack is arranged on the feeding side of the n-shaped support. The board conveying device comprises two lifting frames, an upper pressing roller and a lower pressing roller are installed between the two lifting frames, the two ends of the upper pressing roller are movably connected with lifting components of the two lifting frames respectively, and one end of the upper pressing roller is connected with a driving device. The full-automatic production line has the advantages of being simple in structure, low in manufacturing cost and convenient to use.

Owner:SHANDONG SHUIBO WELDING & CUTTING EQUIP MFG CO LTD

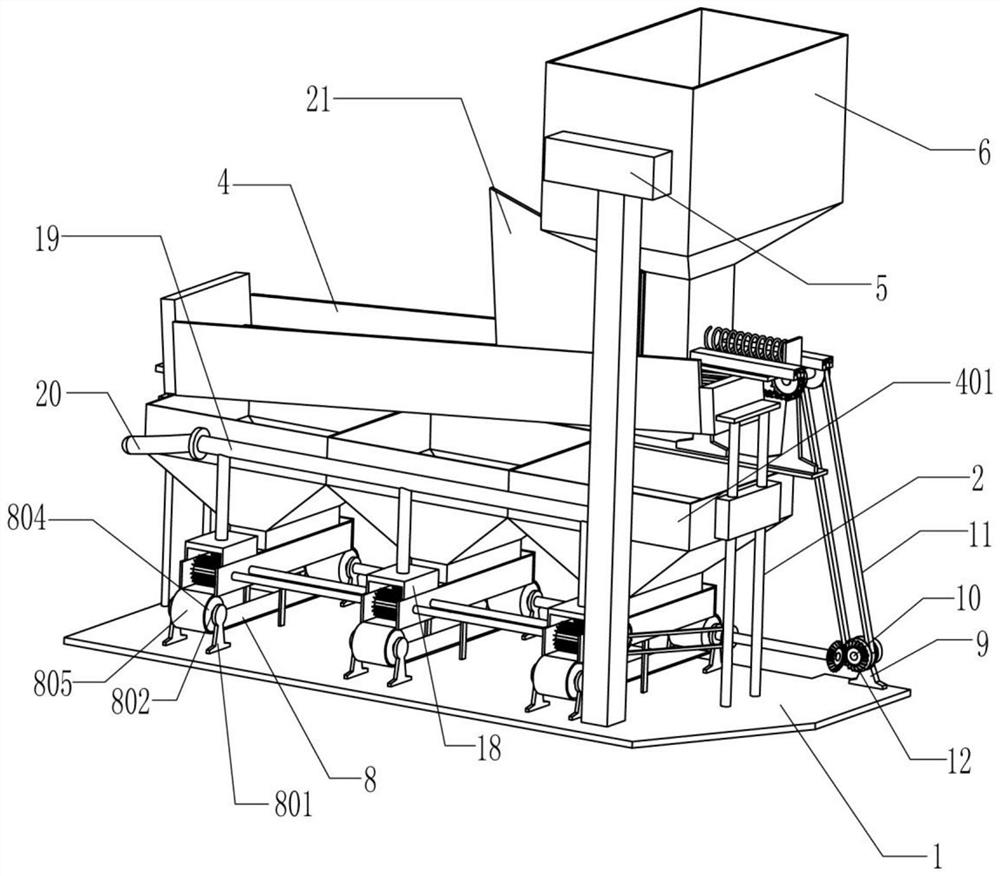

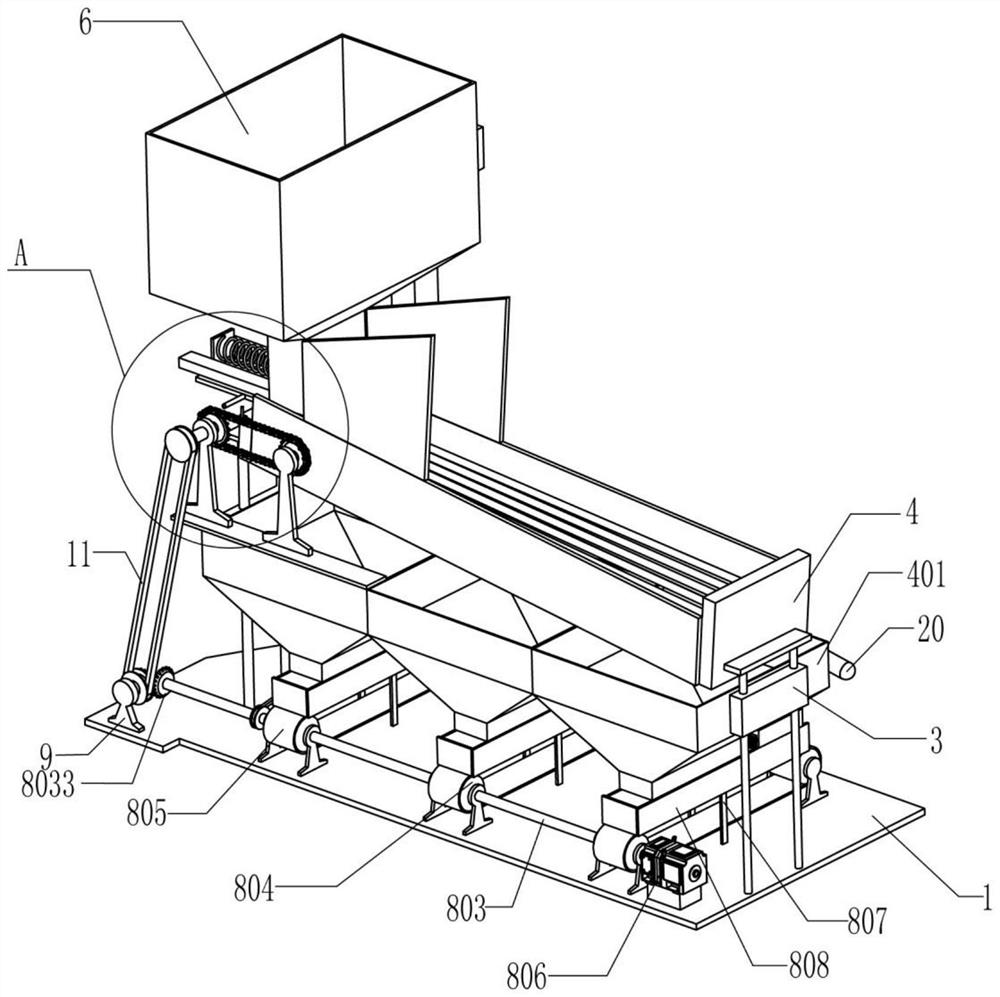

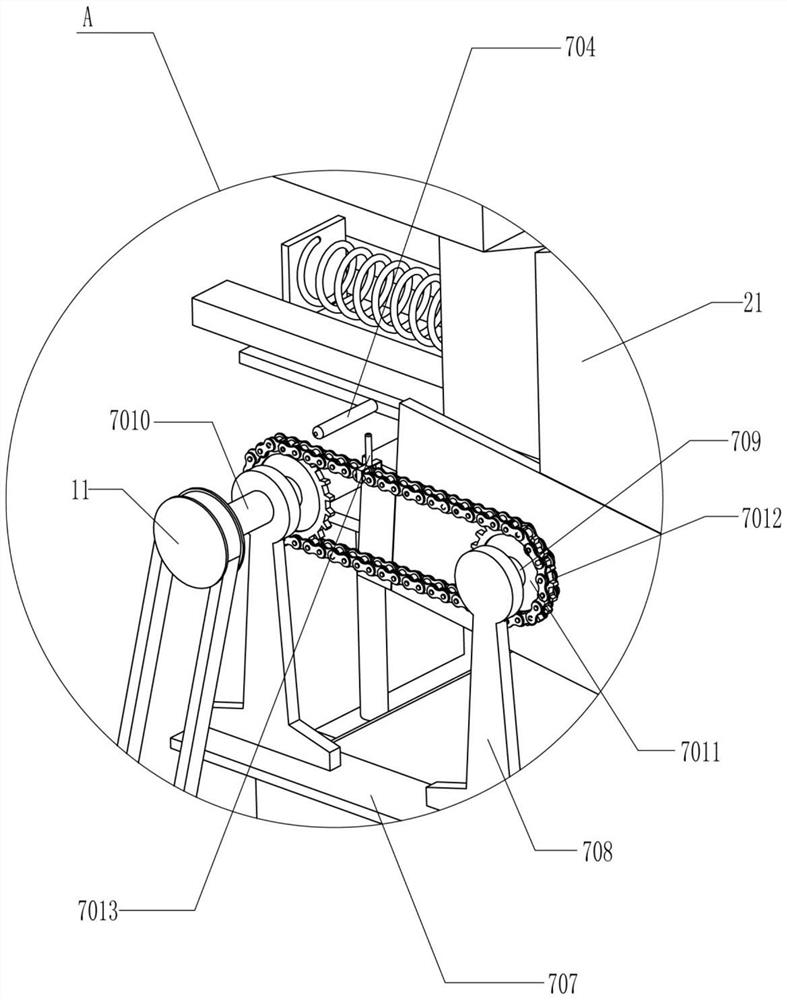

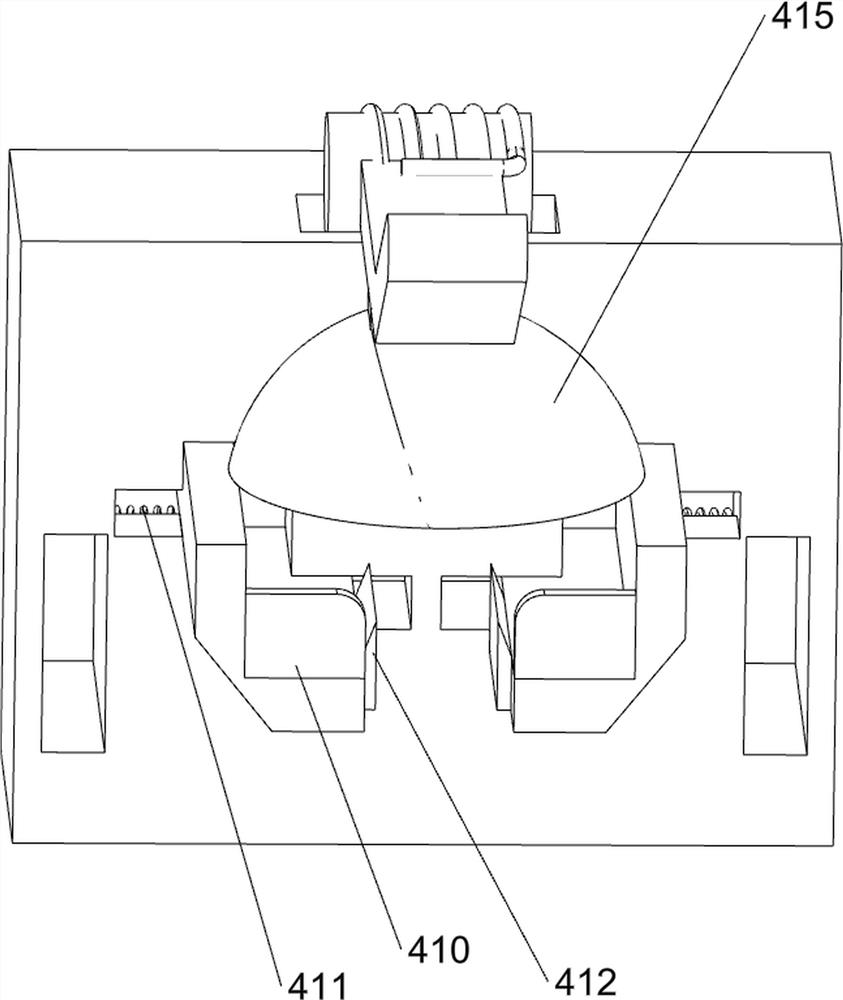

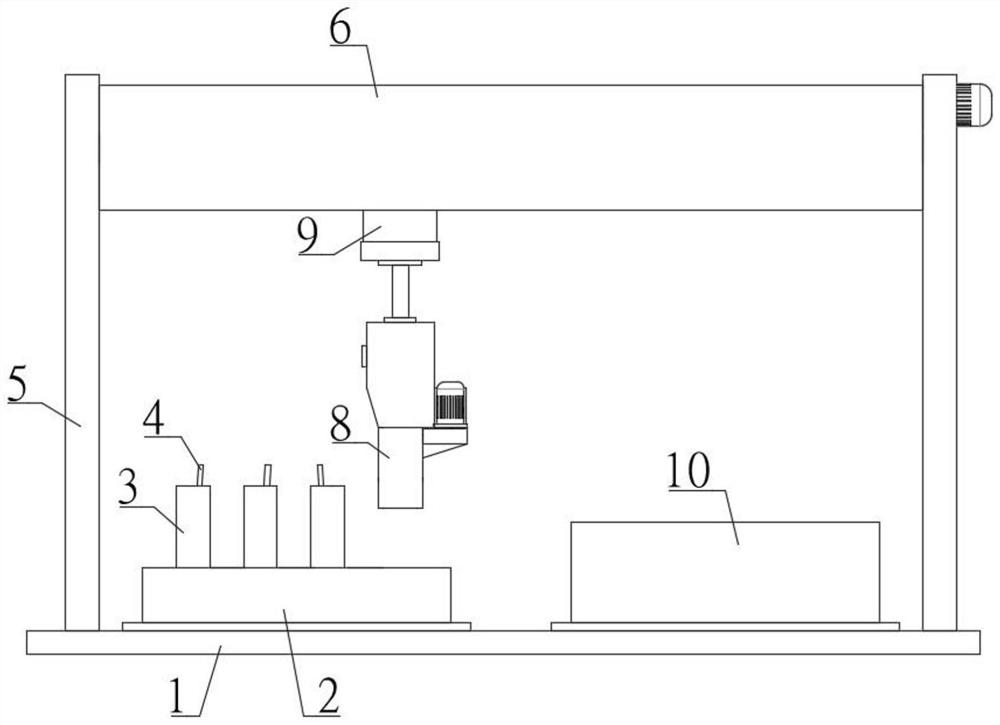

Red date separation equipment for food production

ActiveCN111672761AEasy to separateNo manual contactClimate change adaptationFood treatmentProcess engineeringIndustrial engineering

The invention discloses red date separation equipment for food production, and relates to the technical field of food production. The problems that the manual screening of red dates has personal subjective consciousness, the situation that the red dates with the same size cannot be accurately screened is caused, the manual screening often causes damage to the red dates due to the inaccurate strength, the red dates can also be polluted by impurities on the hands, the manual screening efficiency is low, and the needs of large-scale screening of the red dates for food production cannot be met aresolved. The red date separation equipment for food production comprises a bottom plate, a first bracket, a second bracket, a screening frame, collecting frames, a third bracket, a discharging frame and the like; and the first bracket is installed at one end of the bottom plate. According to the red date separation equipment, workers only need to pour the red dates into the discharging frame, a servo motor is started, the red dates in the discharging frame can intermittently and evenly fall into the screening frame, the red dates in the screening frame fall into different collecting frames according to the size, and the purpose of quickly separating the red dates with different sizes is achieved.

Owner:榆林市红满园绿色枣业开发有限公司

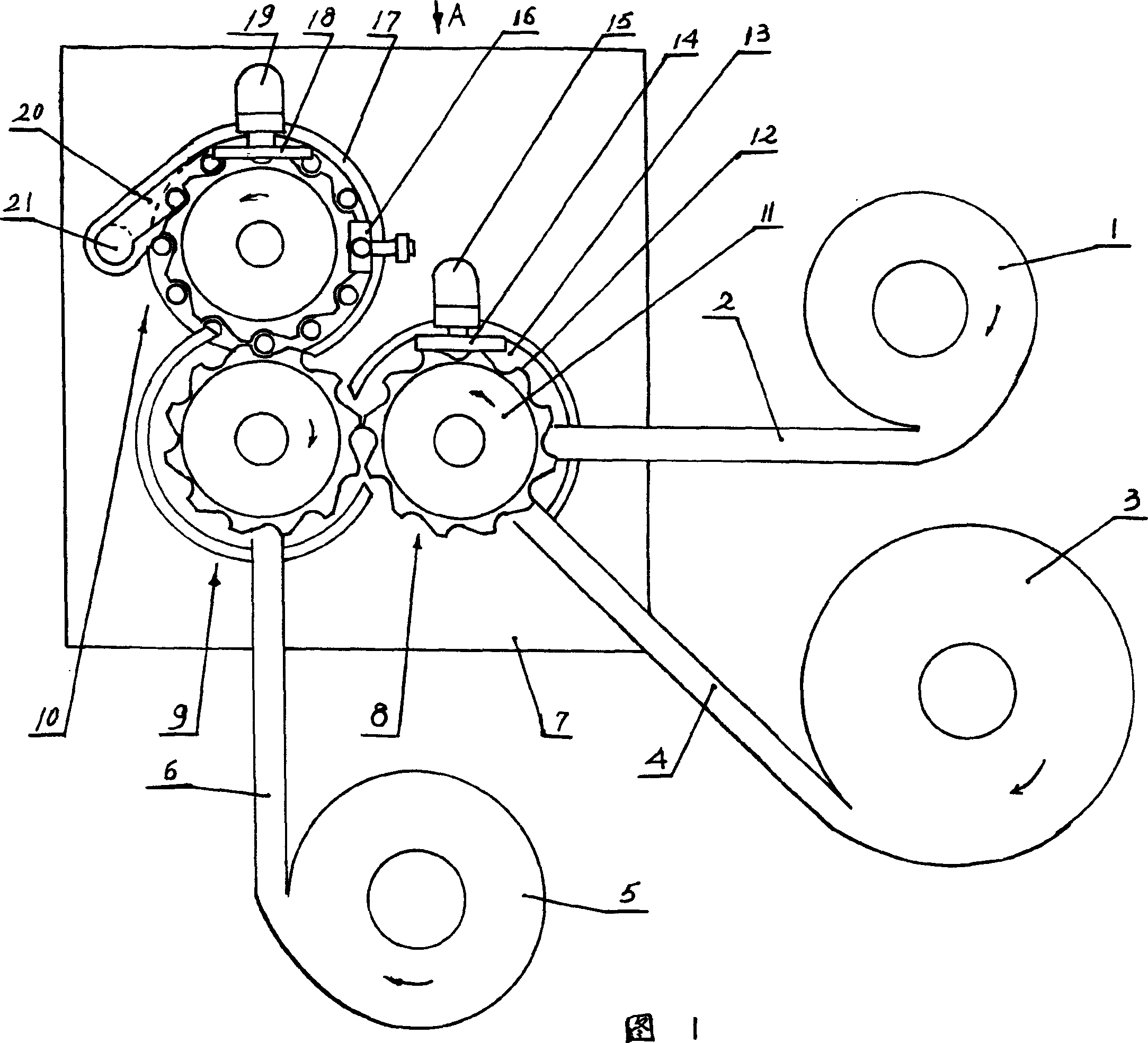

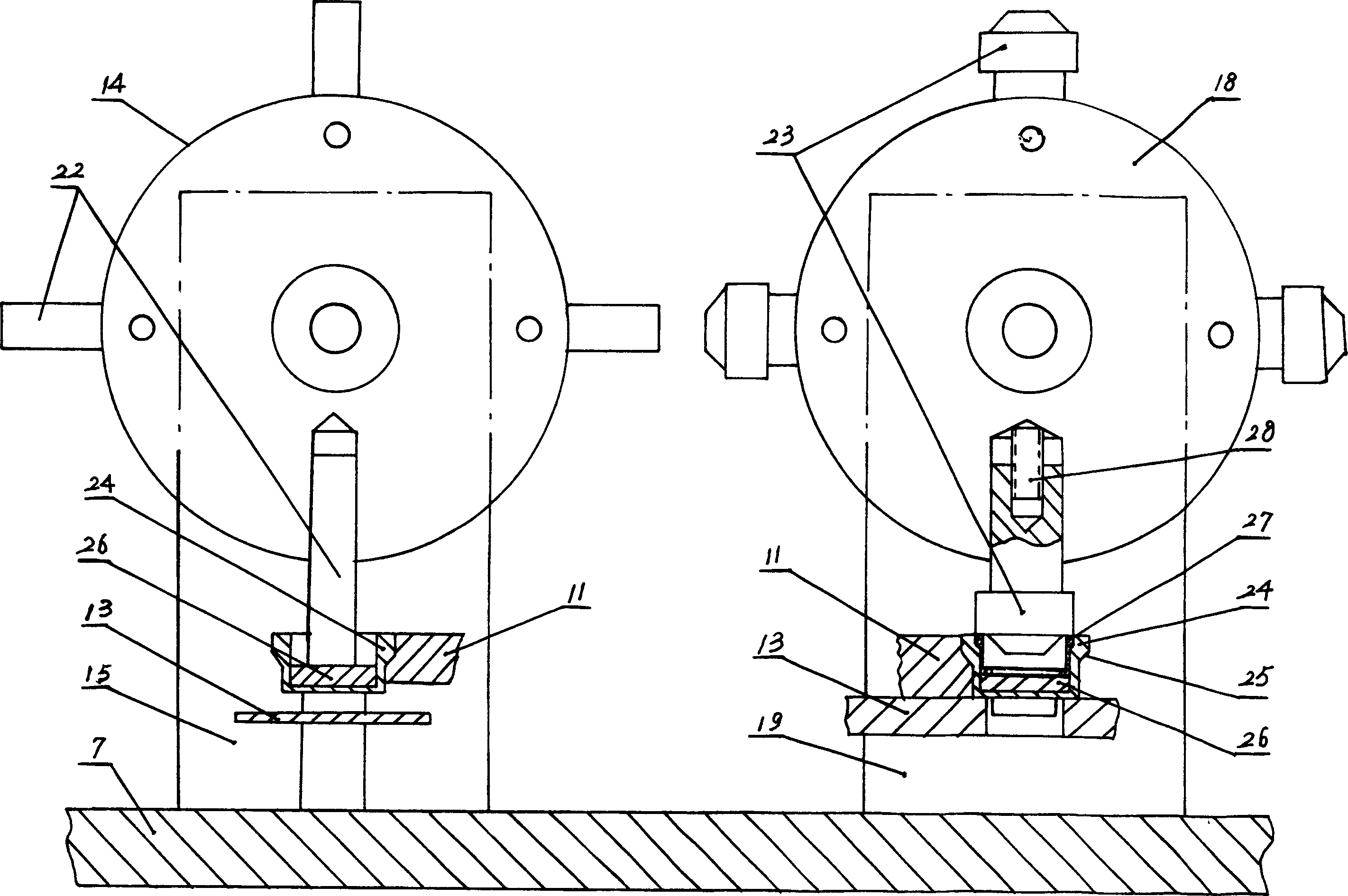

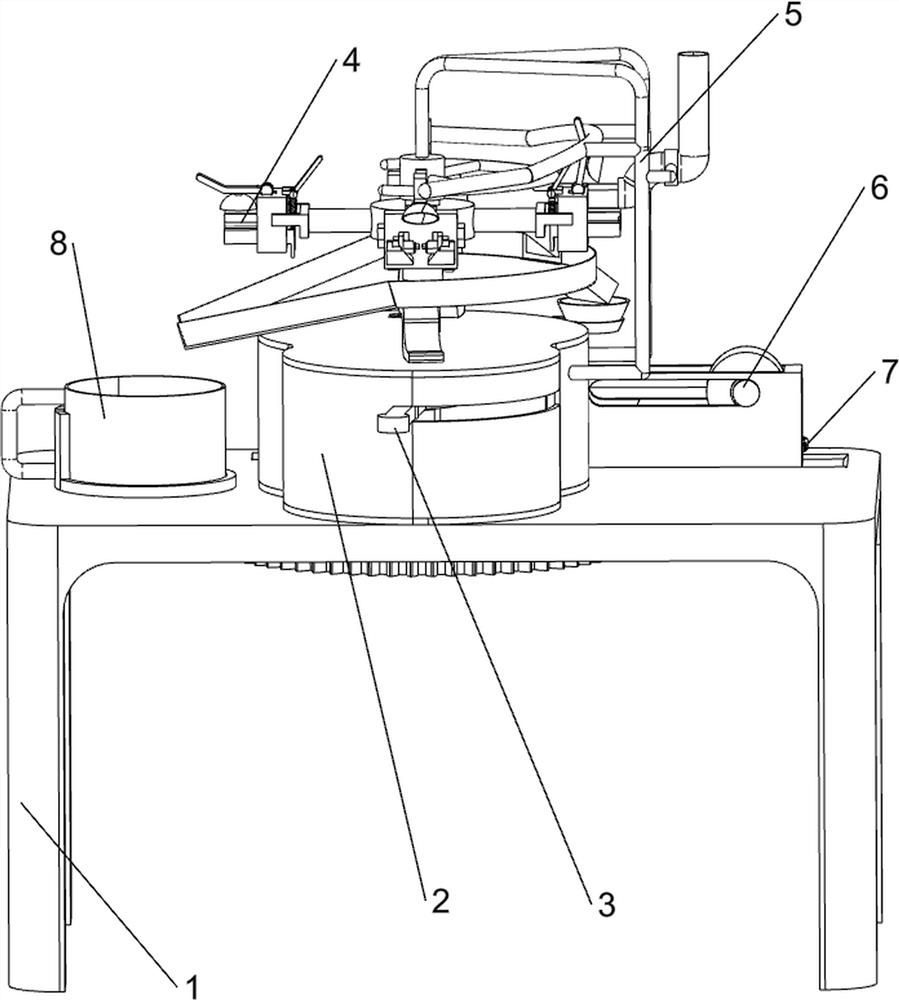

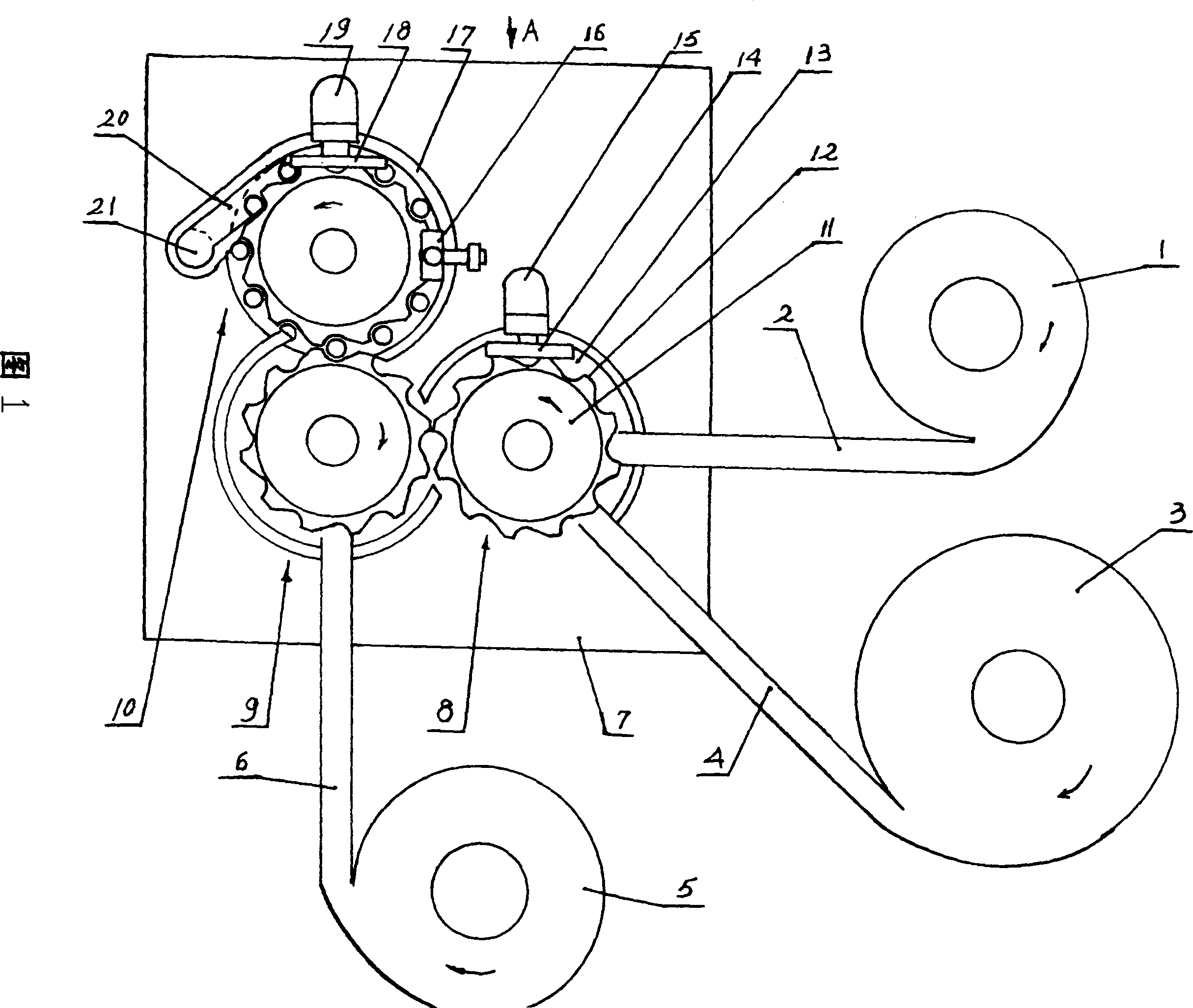

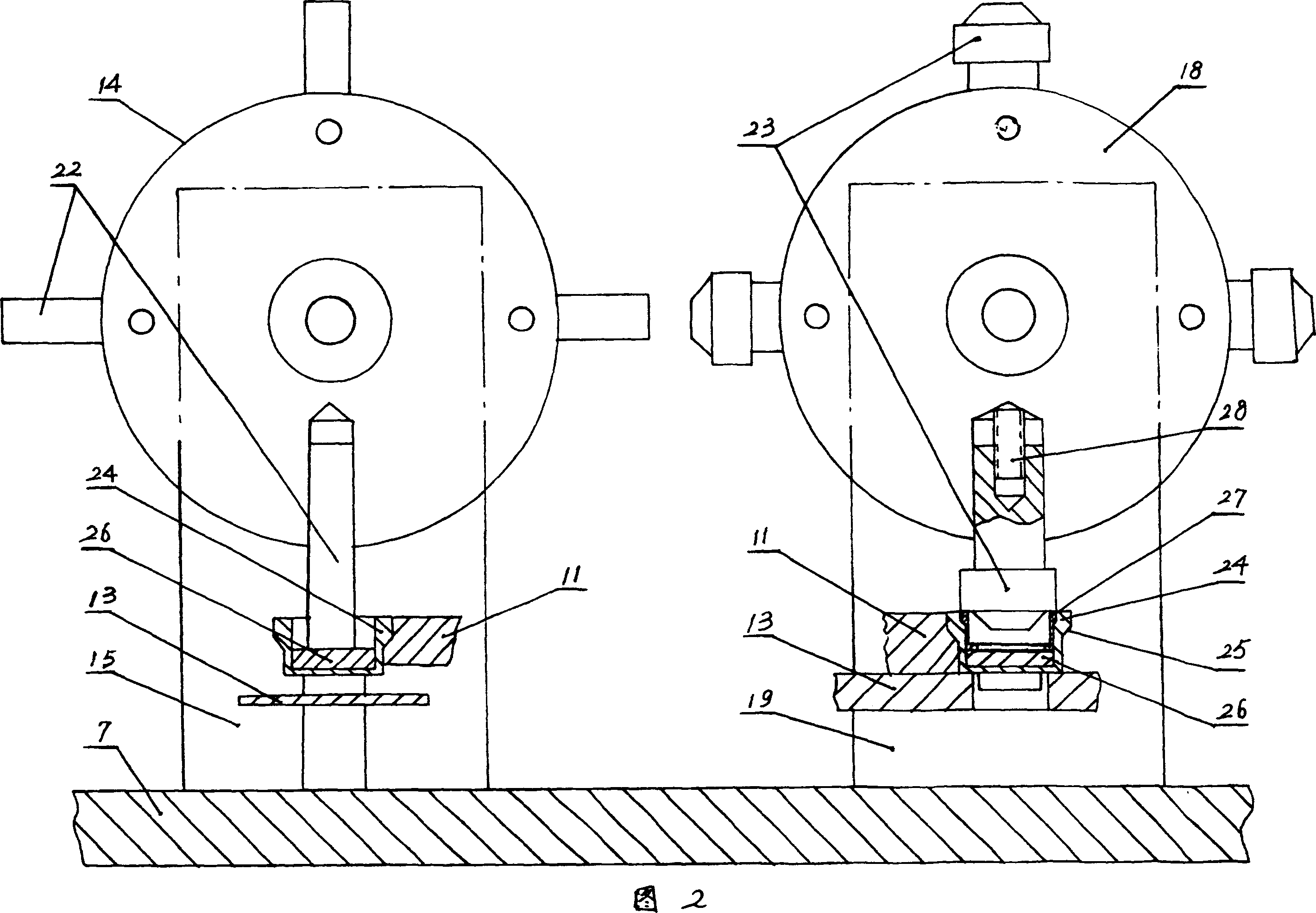

Automatic assembling machine for big fransfusion bottle cover

A full-automatic assembling machine for the big plastic perfusion bottle and its cap is composed of machine frame, a power and drive unit, a delivering unit and a pressing unit. Said delivering unit has 2 or 3 material-driving sets cooperating with each other. Each set has a disk driven by rotating axle and with push teeth on its circum ference, and a supporting plate under said disk. Said pressing unit is a pressing wheel at the side of said disk and with pressing heads installed on its periphery for contacting with workpiece. Its advantages are high effeciency and less pollution.

Owner:王以友 +1

Box-packed bean curd production technology

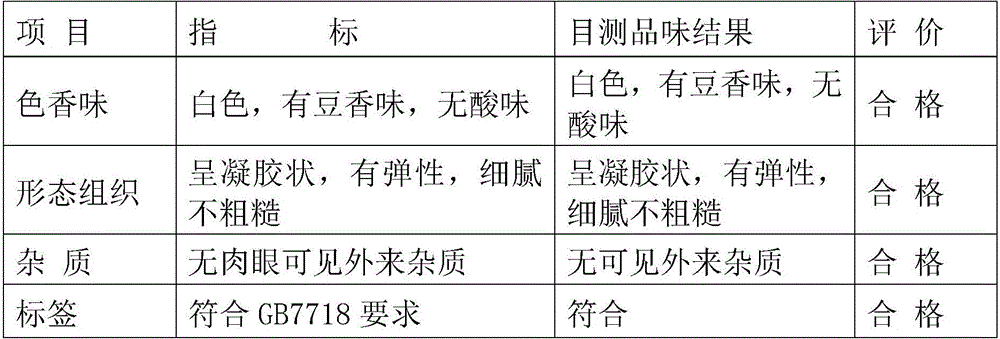

InactiveCN105746726AThe process steps are simpleStrong maneuverabilityCheese manufactureFood scienceGypsumIntegrated systems

The invention discloses a box-packed bean curd production technology.The box-packed bean curd production technology includes the steps of (1) selecting raw materials; (2), soaking; (3) grinding soybean milk; (4), filtering; (5) boiling the filtered soybean milk; (6), adding a solidifying agent into the soybean milk; (7), pouring the soybean milk into bean curd boxes.The box-packed bean curd production technology can be automatically completed through an integrated system and is simple in technological steps, highly operable and free of manual contact in the whole production process so as to guarantee product quality safety and improve the situations that traditional marinated (gypsum) bean curd, which is unpacked and sold by being freshly cut on the market, is contaminated easily and poor in sanitary conditions.Box-packed bean curd produced by the production technology has natural bean aroma, is good in water retention performance, high in stability, free of astringency, less prone to souring, tasty and refreshing, solid but elastic in nature and high in quality, and is suitable for long-distance transporting and selling.

Owner:包宇青

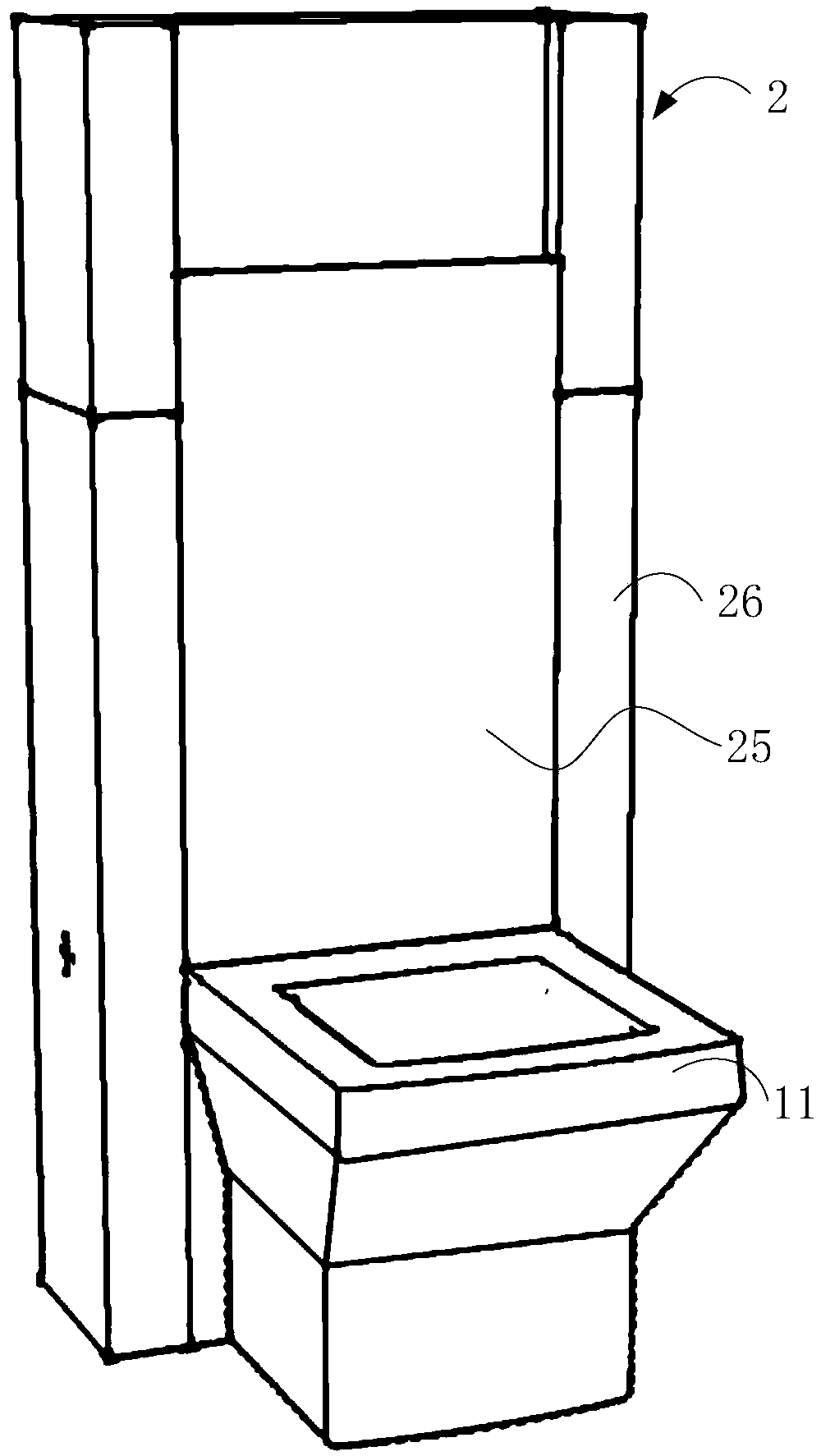

Toilet seat self-cleaning system and self-cleaning method thereof

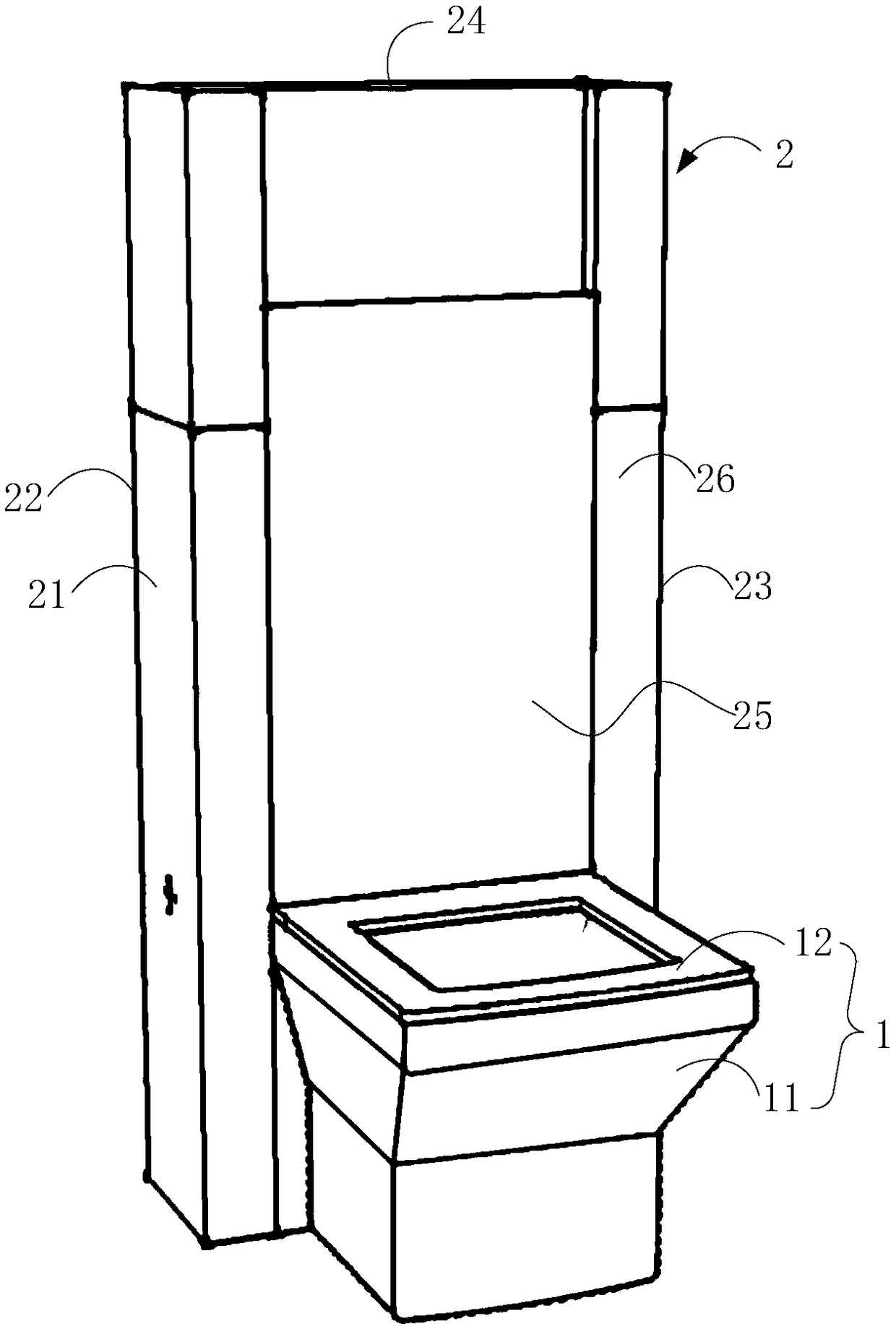

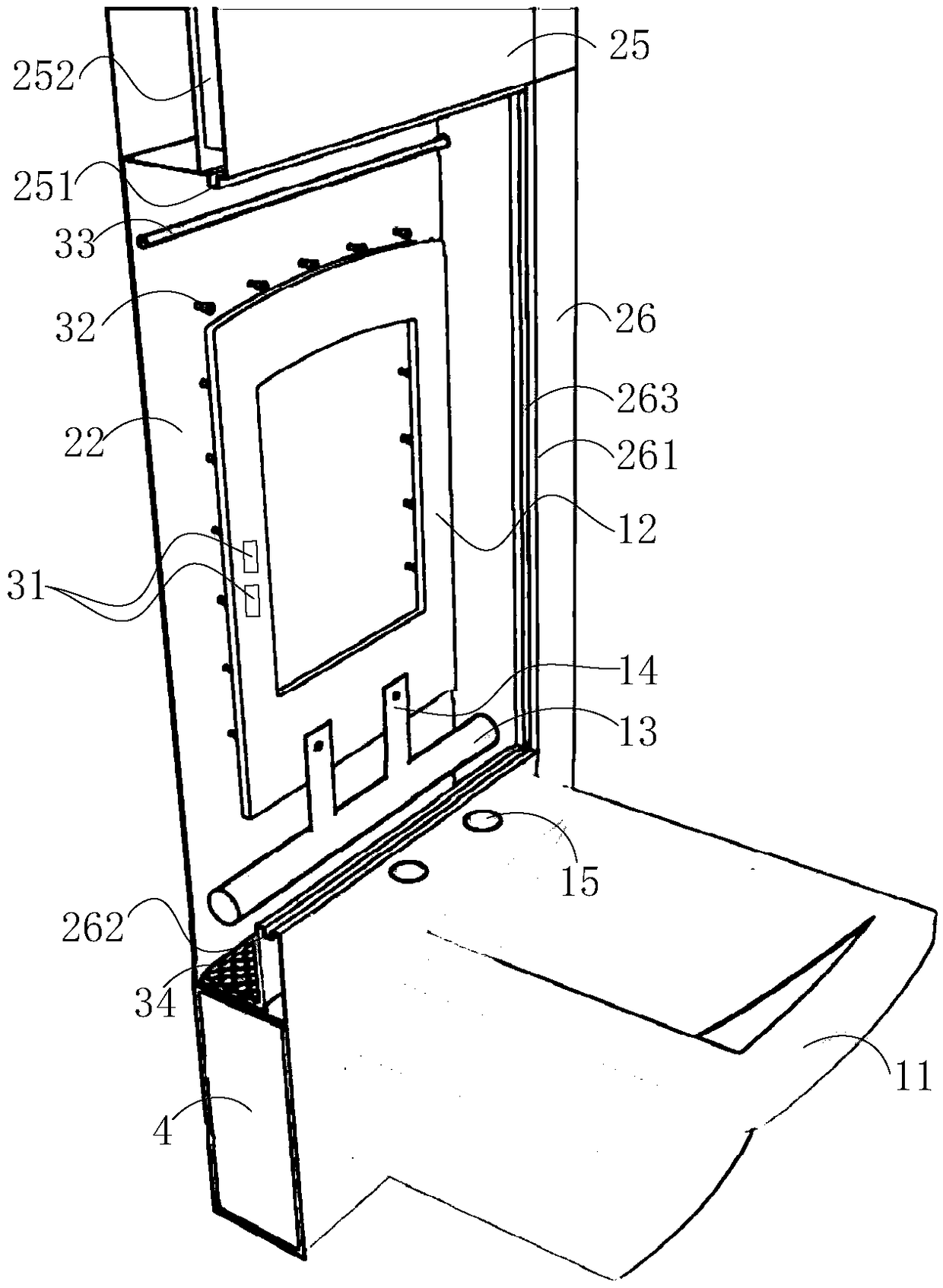

The invention relates to the technical field of sanitary ware, in particular to a toilet seat self-cleaning system and a self-cleaning method thereof. The toilet seat self-cleaning system comprises atoilet seat including a toilet seat body and a toilet seat ring rotatably connected with the toilet seat body; A wall body arranged behind the toilet bowl, wherein a receiving cavity is arranged in the wall body, and the receiving cavity is used for receiving the toilet bowl seat; a Self-cleaning assembly, including a sensing component, a control component and a shower component, wherein the sensing component is provided on the toilet seat ring and is electrically connected with the control component, the sensing component is used for sending detection information to the control component whendetecting that that toilet bowl is unused; the control components is used for controlling the automatic turning of the toilet seat into the accommodation chamber when the detection information is received and is also connected to a shower component; and the control component is further configured to control the shower component to wash the toilet seat in the accommodation chamber after the toilet seat is automatically turned into the accommodation chamber. The toilet seat self-cleaning system can realize automatic cleaning, and has the functions of washing, draining, drying and the like.

Owner:SHENZHEN MICRO SPACE CONSTR TECH CO LTD

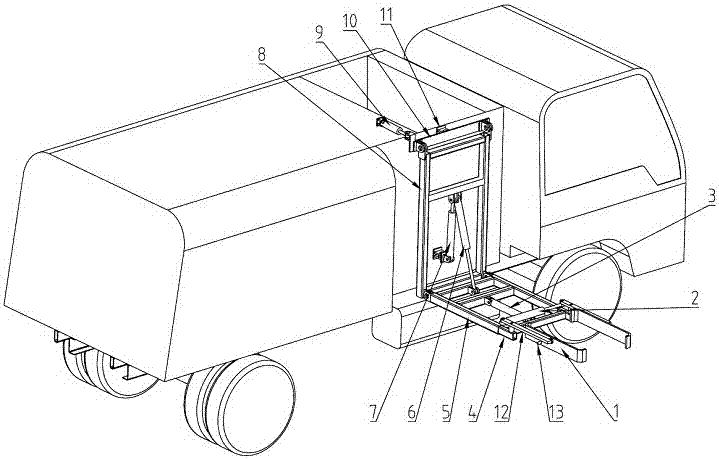

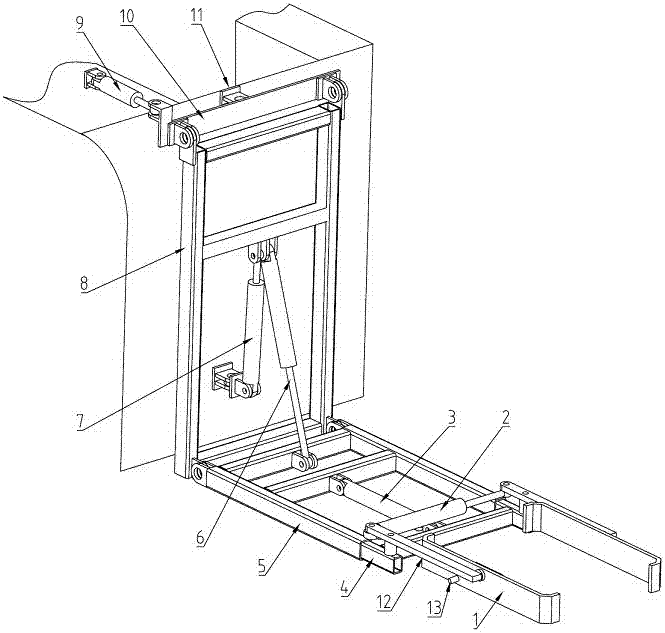

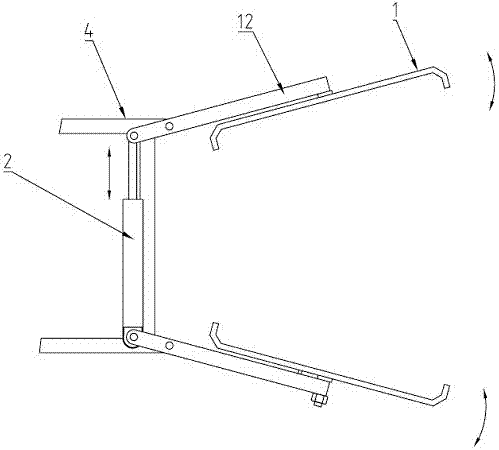

Automatic barreled garbage collecting device

PendingCN107117419AReduce labor intensitySimple designBottle emptyingLoading/unloadingTruckEngineering

The invention discloses an automatic barreled garbage collecting device. The collecting device is arranged on a garbage collecting truck. The automatic collecting device comprises a clamping mechanism and a horizontal movement, elevating and overturning mechanism. The horizontal movement, elevating and overturning mechanism is fixed to the position outside a garbage collecting truck carriage. The clamping mechanism is arranged on the horizontal movement, elevating and overturning mechanism and can clamp a garbage can. The horizontal movement, elevating and overturning mechanism drives the clamping mechanism and the garbage can to be horizontally moved, elevated and overturned. When the device is adopted for clamping the garbage can and pouring garbage, garbage can clamping and garbage pouring can be automatically completed only by controlling the action of an oil cylinder, the labor intensity is lowered, and safety and high efficiency are achieved; and the design structure is simple, and cost is low.

Owner:ZHEJIANG BAOCHENG MACHINERY TECH

Dismantling device of power battery

InactiveCN106992330AEnsure safetyReasonable structural designWaste accumulators reclaimingBattery recyclingPower batteryEngineering

The invention discloses a dismantling device for a power battery, which includes a feeding seat and a frame corresponding to the feeding seat. Mobile cutting mechanism; the side of the frame far away from the feeding seat is provided with a shell collection mechanism and a core collection mechanism; the frame is provided with a controller, and the controller is connected to the transmission mechanism, the mobile cutting mechanism, and the shell collection mechanism and core collection mechanism. The invention has a reasonable structural design, realizes continuous cutting and dismantling, and improves work efficiency. At the same time, the whole process is mechanically operated without manual contact, which ensures the safety of workers and reduces the cost of dismantling.

Owner:HUZHOU YOUCHUANG TECH CO LTD

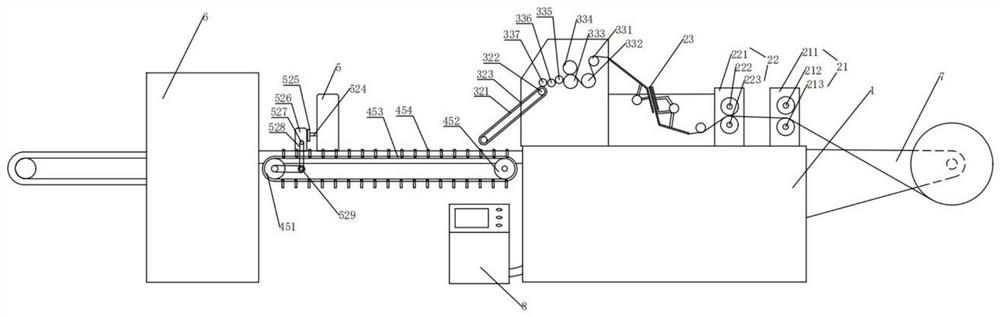

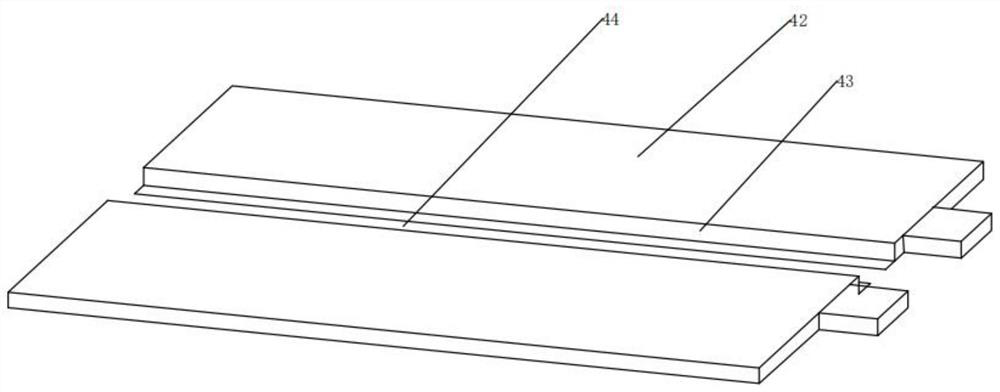

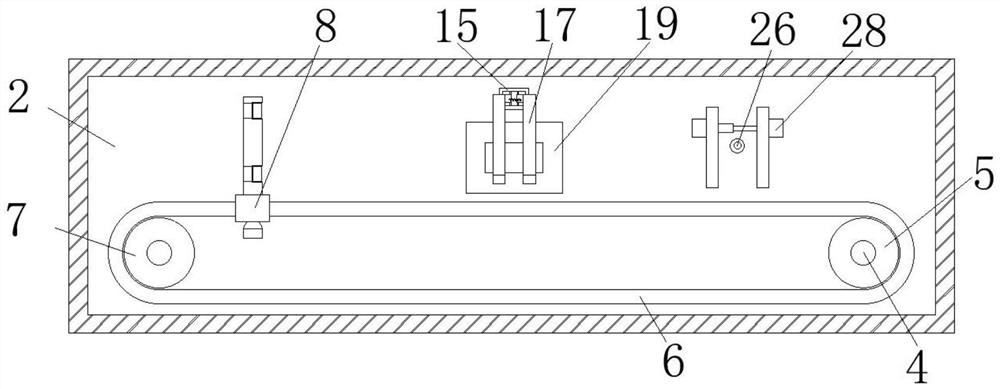

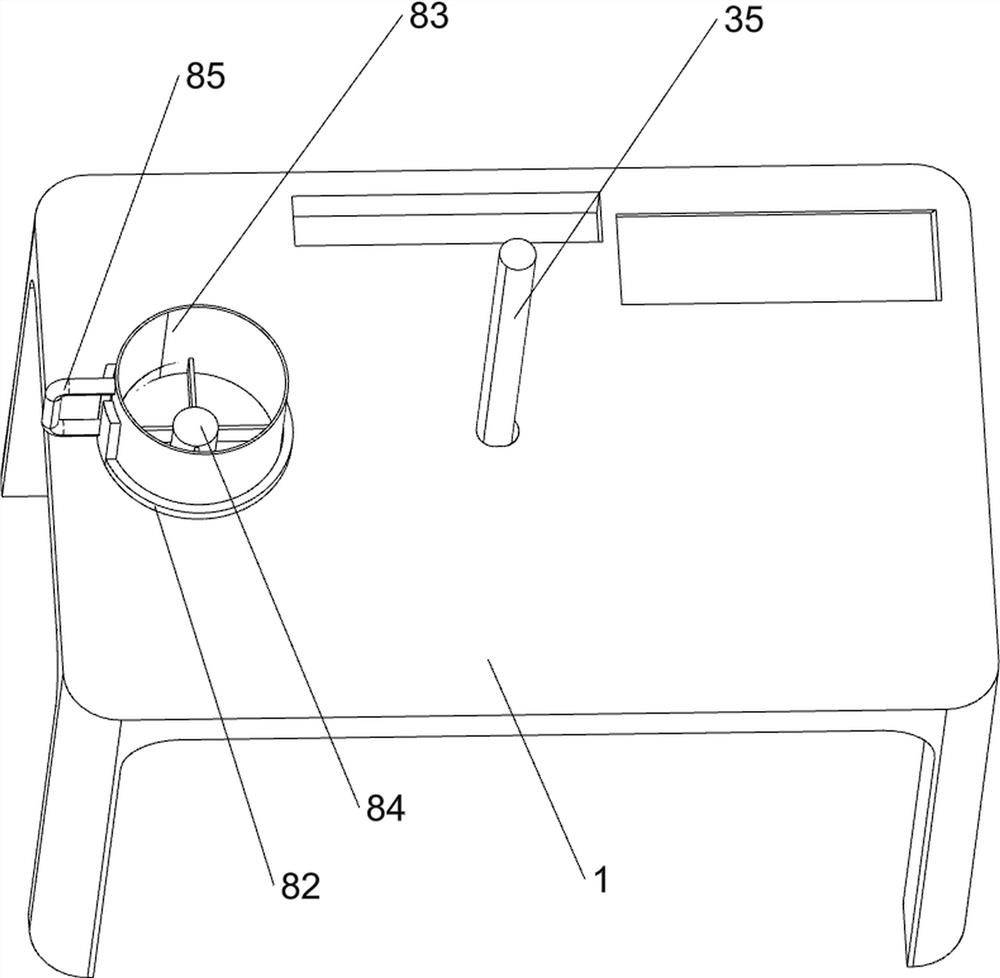

Full-automatic disposable napkin packaging production line

ActiveCN112357256AHigh degree of automationNo manual contactMechanical working/deformationFolding thin materialsRolling paperProcess engineering

The invention discloses a full-automatic disposable napkin packaging production line, and belongs to the technical field of napkin packaging. The full-automatic disposable napkin packaging productionline comprises a workbench, a napkin folding machine, a napkin cutting machine, a napkin conveying machine, a toothpick putting machine and a packaging machine. The napkin folding machine and the napkin cutting machine are fixedly arranged at the upper end of the workbench, a roll paper frame used for containing roll paper is arranged at the front end of the workbench, and the rear end of the workbench is connected with the napkin conveying machine; and the end, away from the workbench, of the napkin conveying machine is connected with the packaging machine, and the toothpick putting machine is fixedly installed at the upper end of the napkin conveying machine. The full-automatic disposable napkin packaging production line is high in automation degree, free of manual contact in the whole packaging process, clean, sanitary, and capable of reducing labor force and the production cost and improving the production efficiency.

Owner:南宁市迪雅日用纸品厂

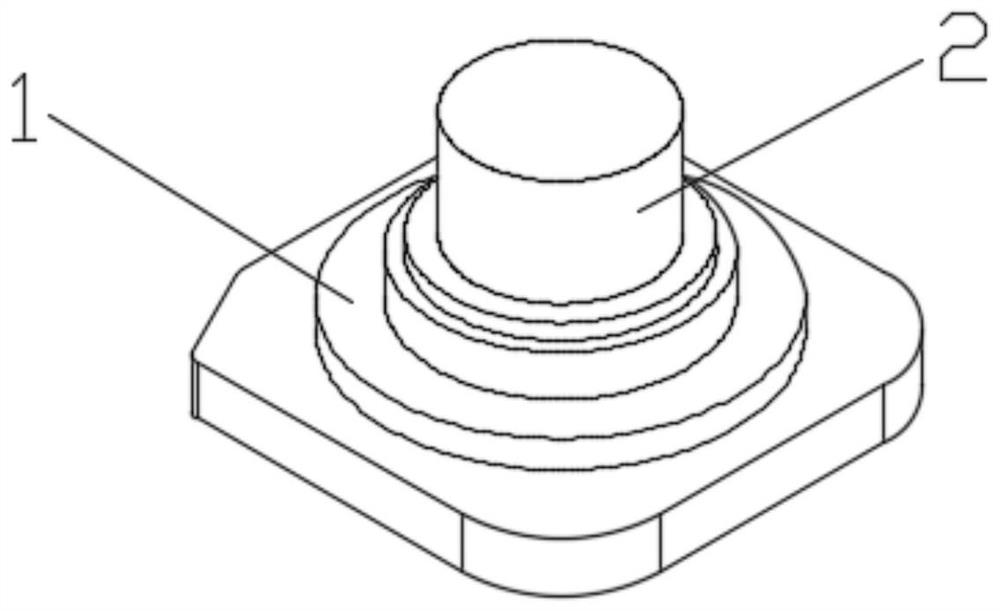

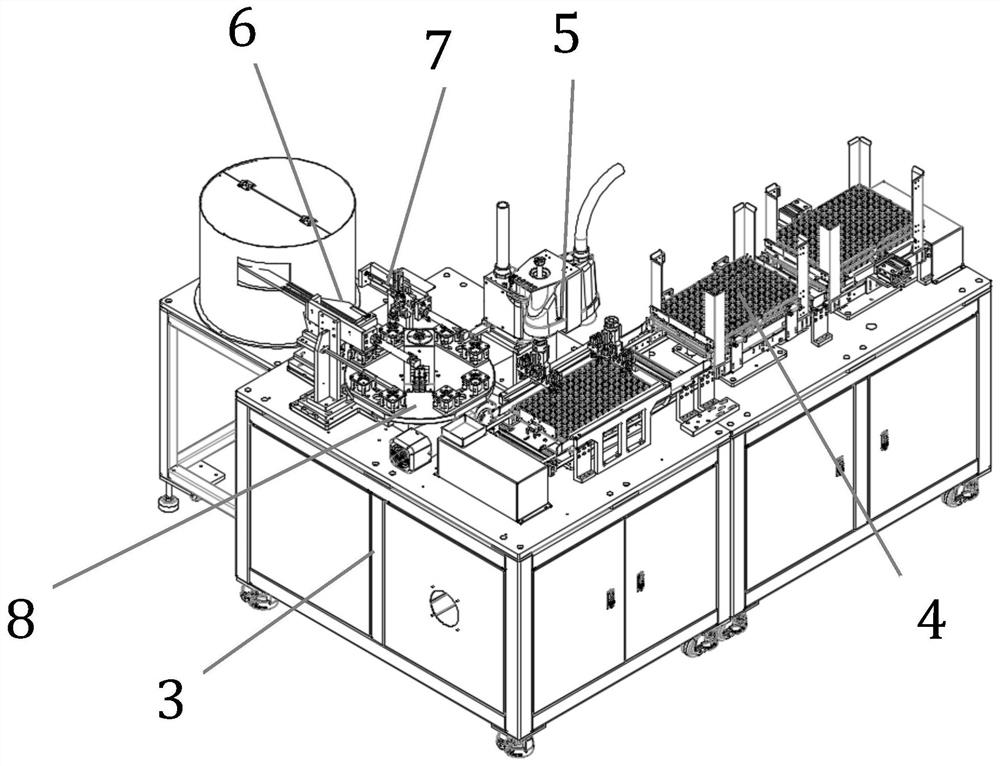

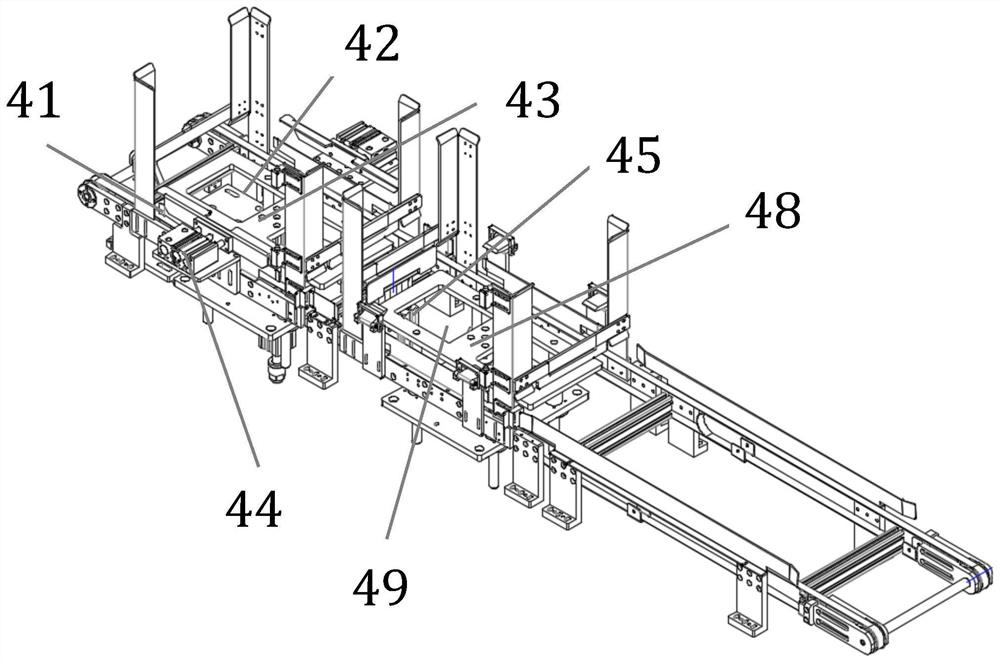

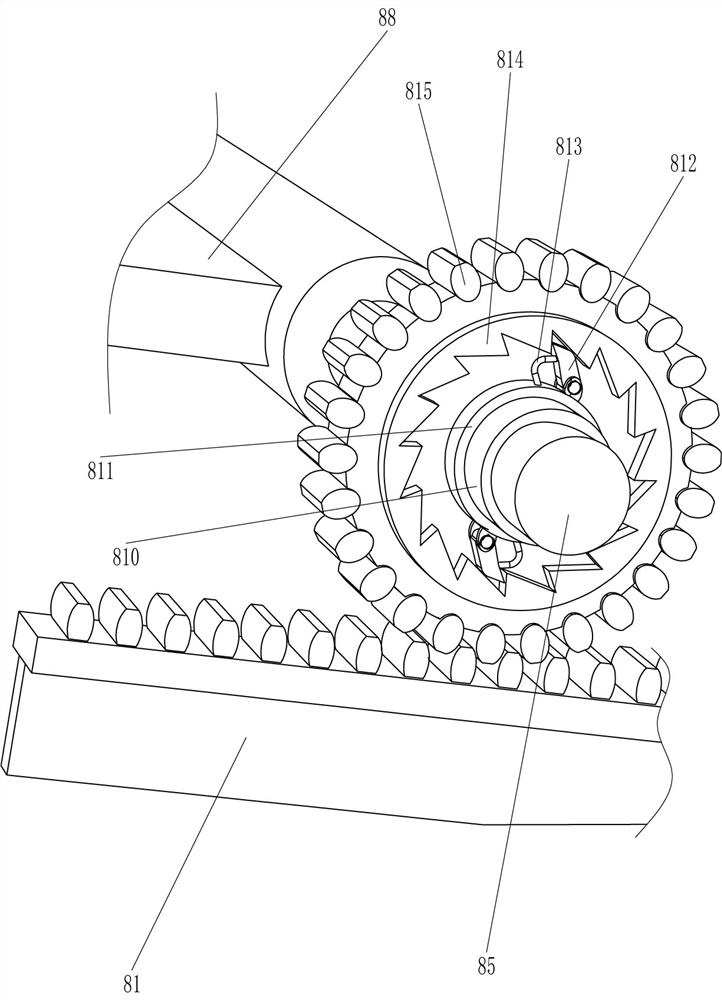

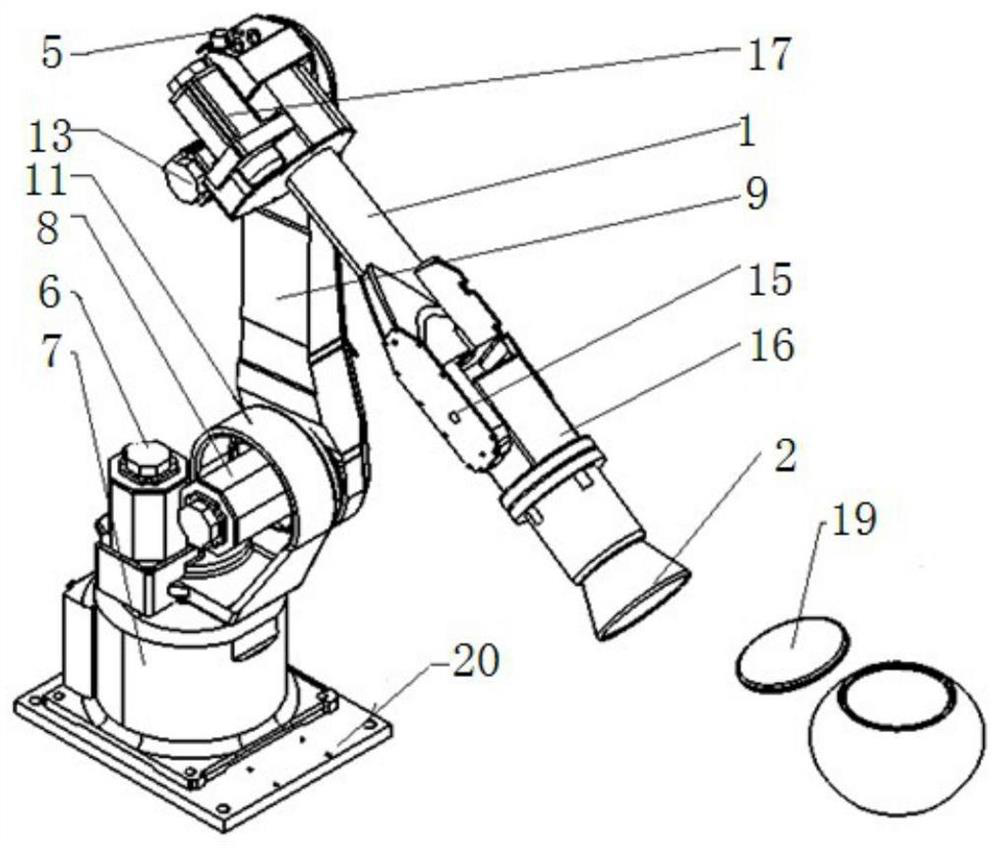

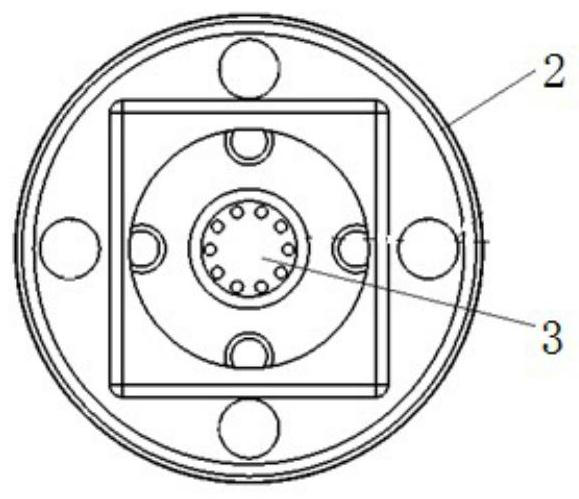

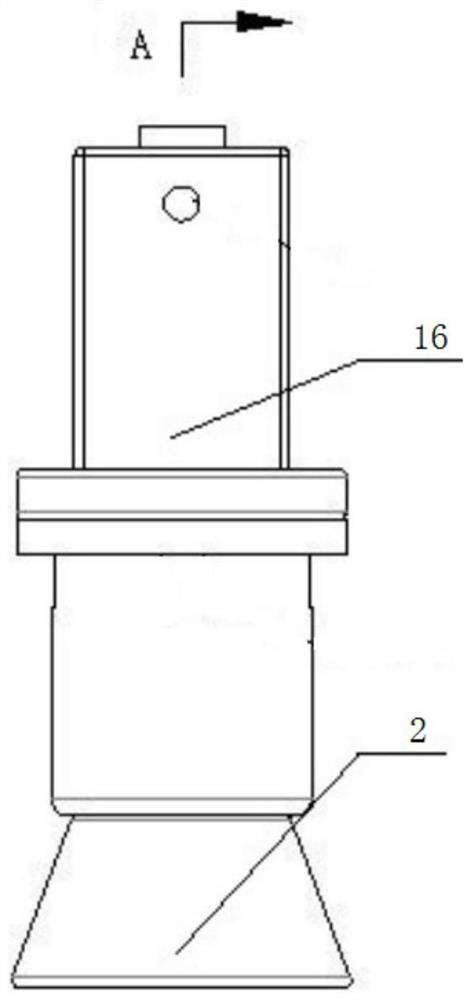

Equipment capable of automatically assembling sealing rings

PendingCN111975308AHigh degree of automationStable productionMetal working apparatusRobot handEngineering

The invention discloses equipment capable of automatically assembling sealing rings. The equipment comprises a rack, wherein the rack is provided with a pole supplying module, a manipulator pole taking and placing module, a sealing ring suppyling module, a two-axis sealing ring sucking and feeding module and a rotary disc assembly module. The equipment has the advantages that the degree of automation is high, assembly operation of the sealing rings and poles can be automatically finished, production is stable, precise and less time-consuming, and manual contact is omitted.

Owner:苏州明益信智能设备有限公司

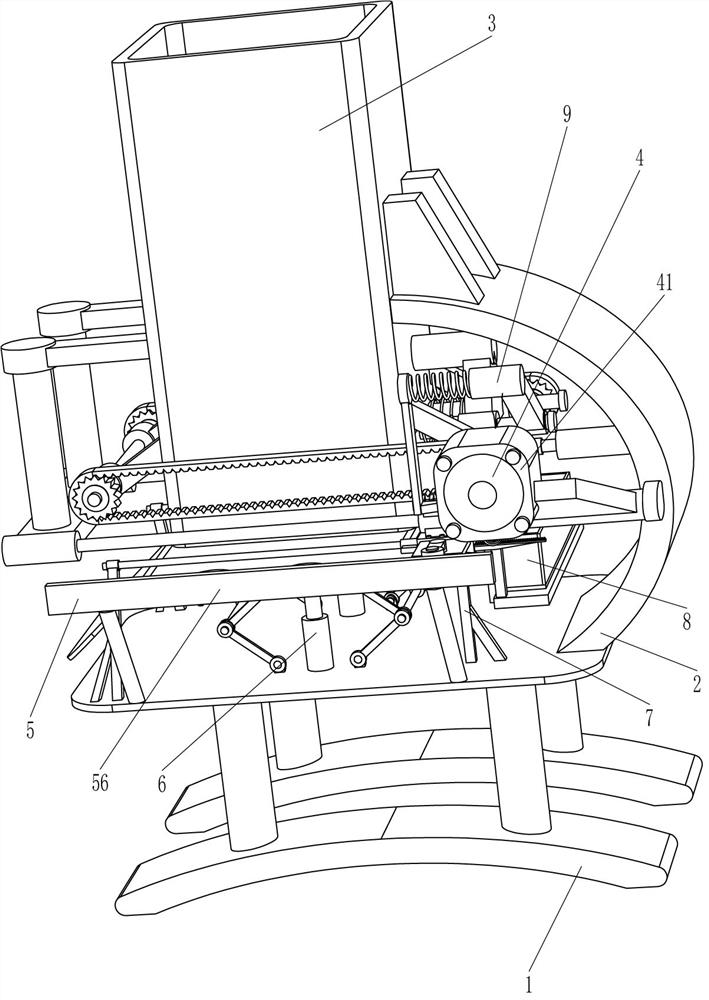

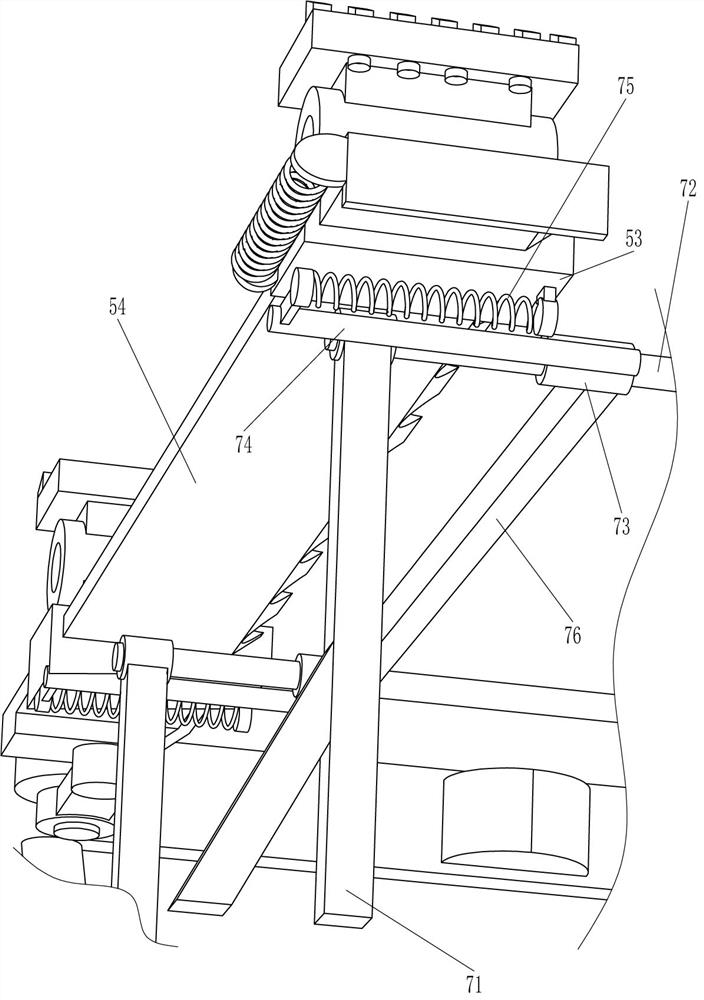

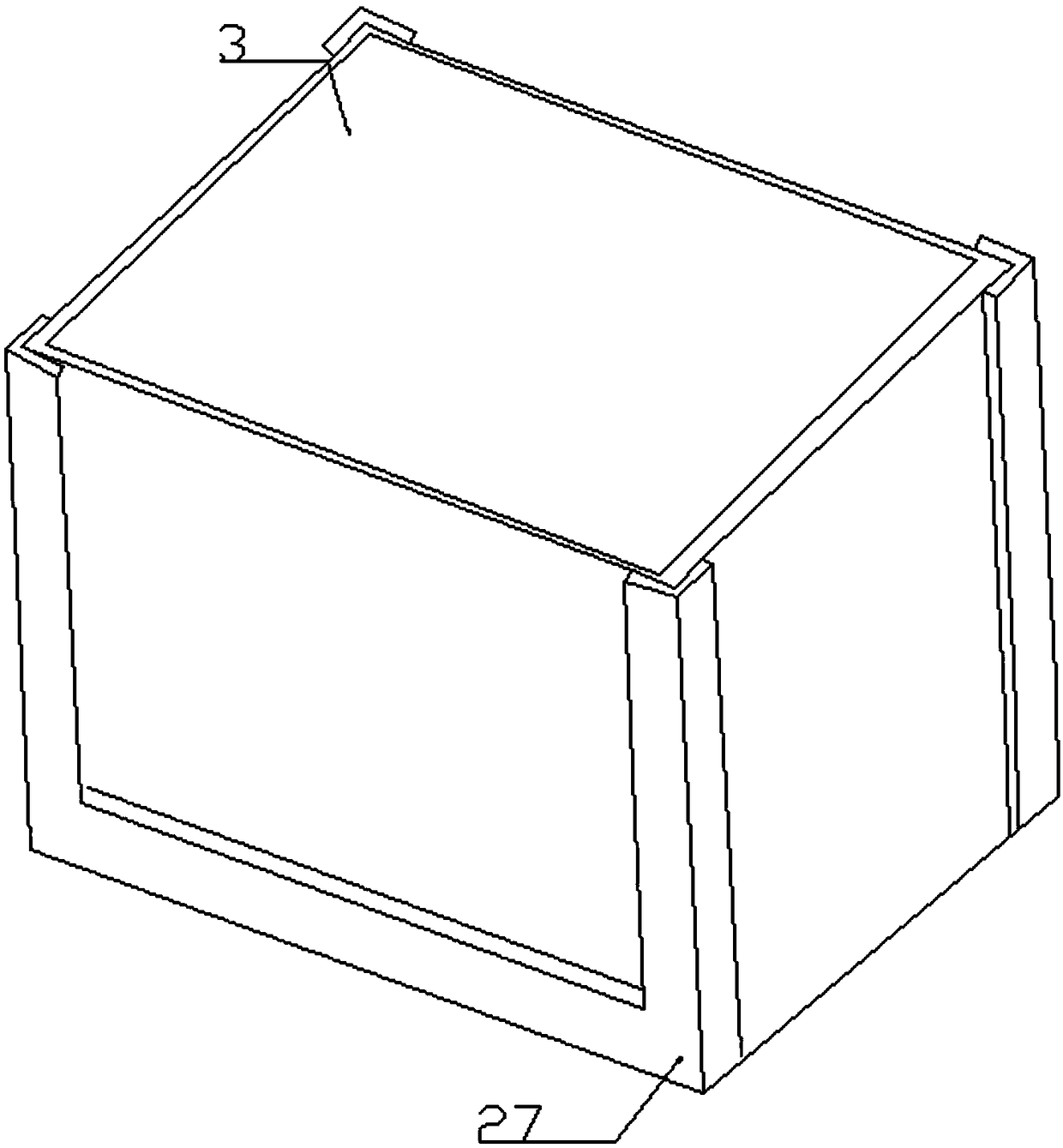

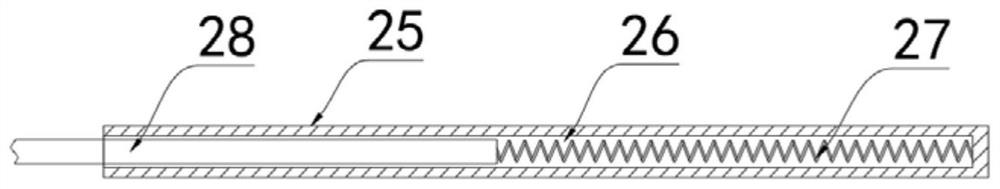

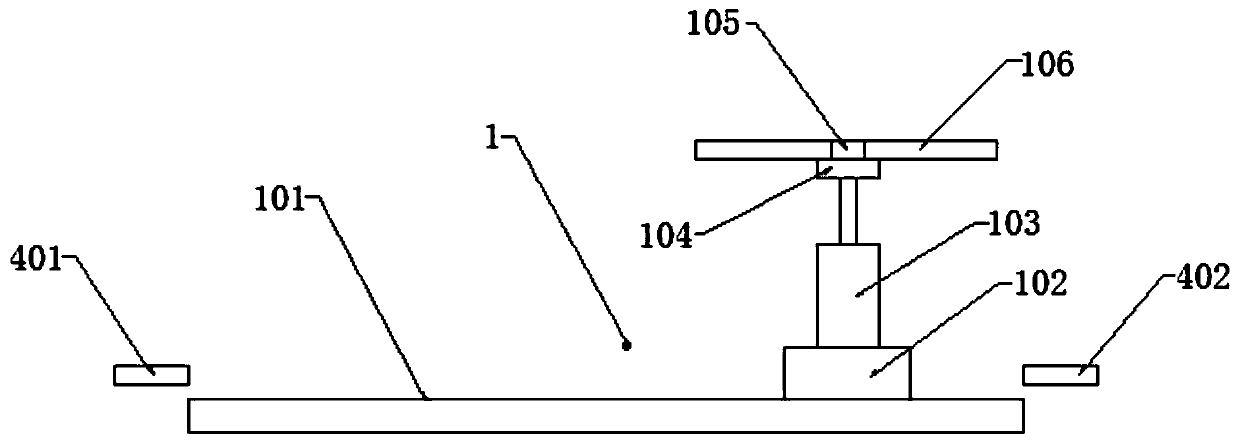

Quantitative cutting machine for rough blank in model clay production

ActiveCN112792966AReduce laborNo manual contactCeramic shaping apparatusCeramic materials productionPush outStructural engineering

The invention relates to a quantitative cutting machine, in particular to a quantitative cutting machine for a coarse blank in model clay production. According to the technical scheme, the quantitative cutting machine for the coarse blank in model clay production is capable of realizing quantitative cutting, and the operation is simple. The quantitative cutting machine for the coarse blank in model clay production comprises a base, a mounting frame connected to one side of the top of the base, a feeding pipe connected with the side part of the mounting frame, a driving mechanism connected to the feeding pipe, and a cutting mechanism connected between the base and the feeding pipe and connected with the driving mechanism. Through cooperation of the driving mechanism, the cutting mechanism, a thickness adjusting mechanism and a discharging mechanism, the thickness of clay to be cut by people can be adjusted, the clay is automatically pushed out after being cut, manual contact is not needed, and the labor amount of people can be reduced.

Owner:卢美

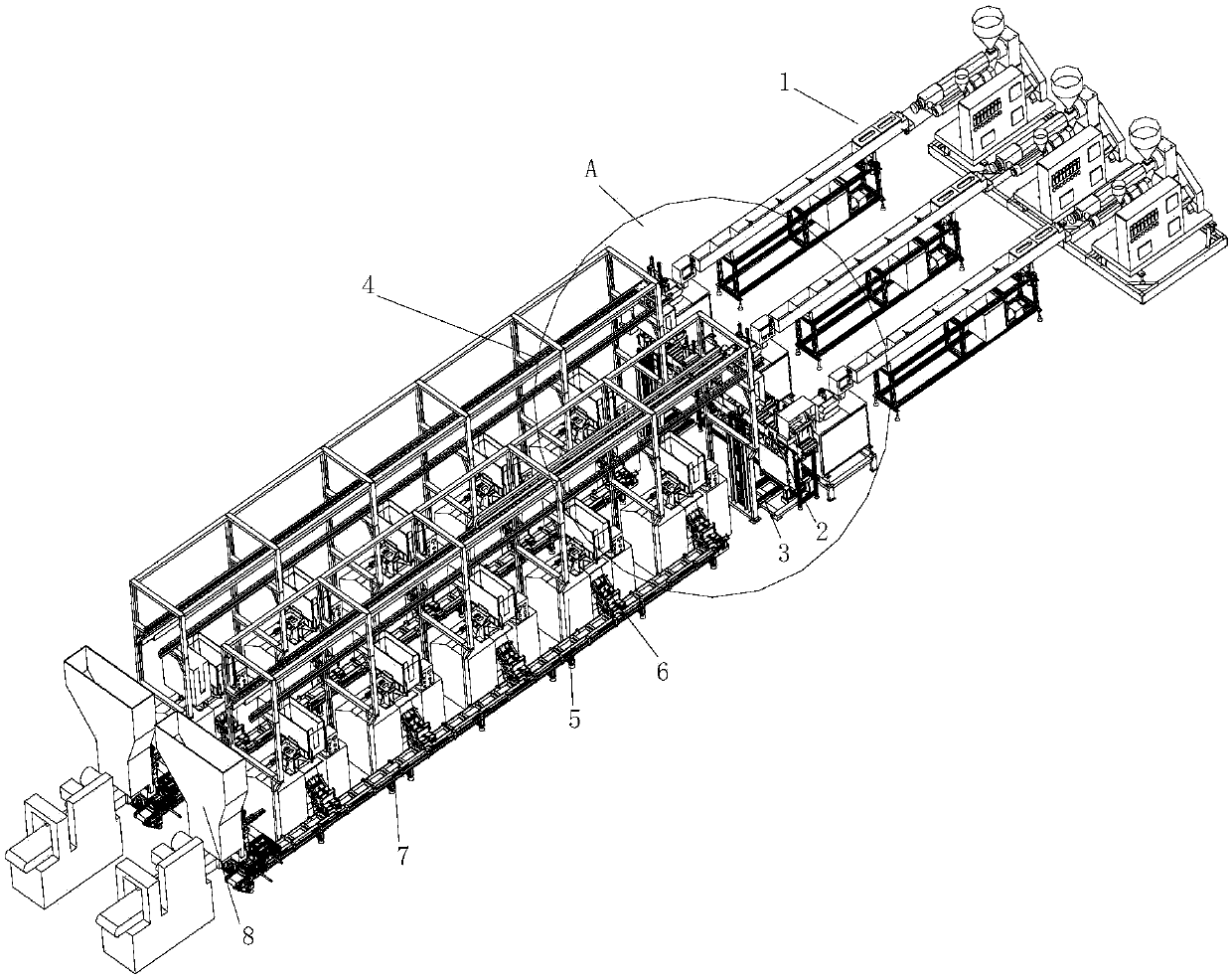

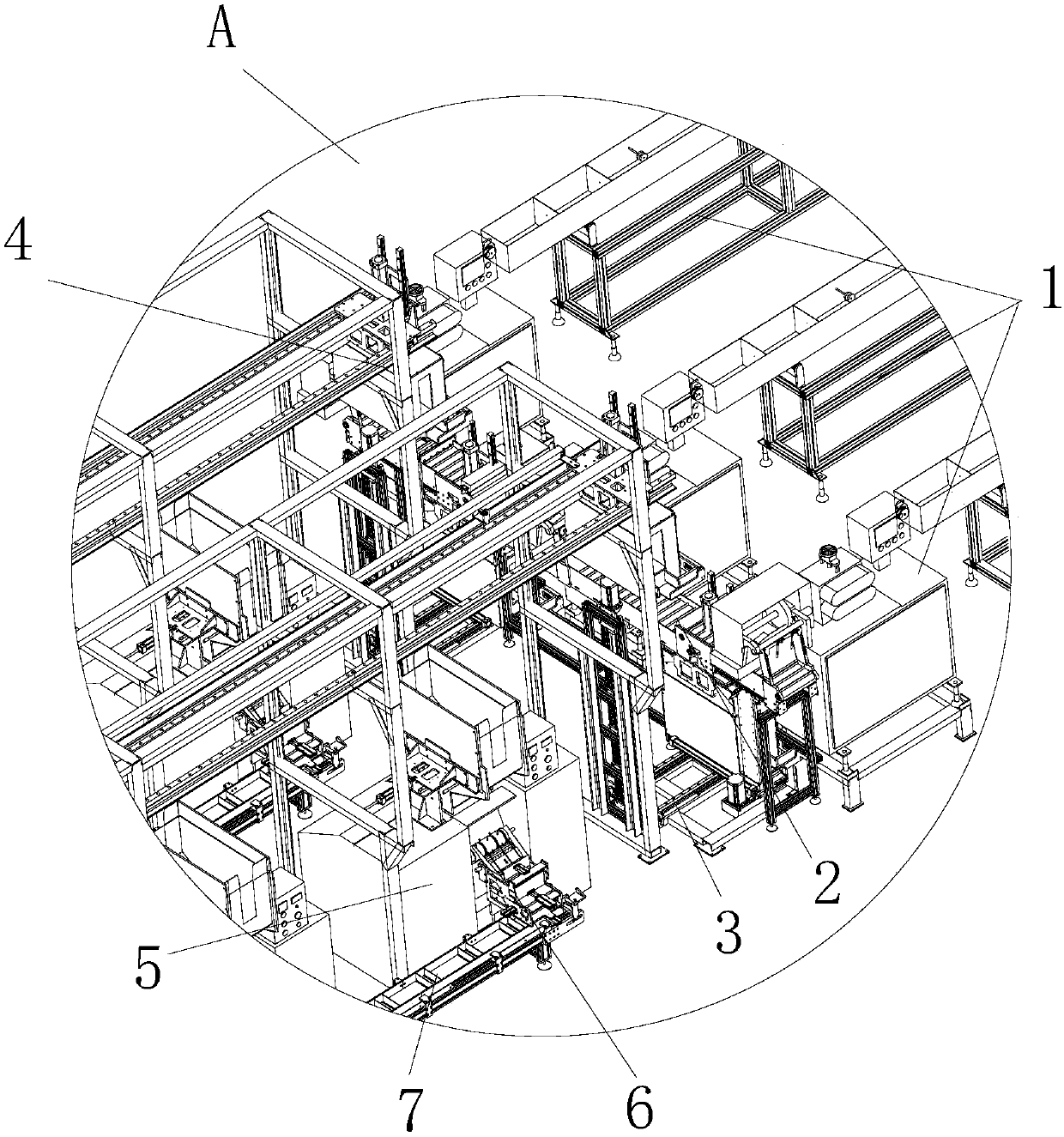

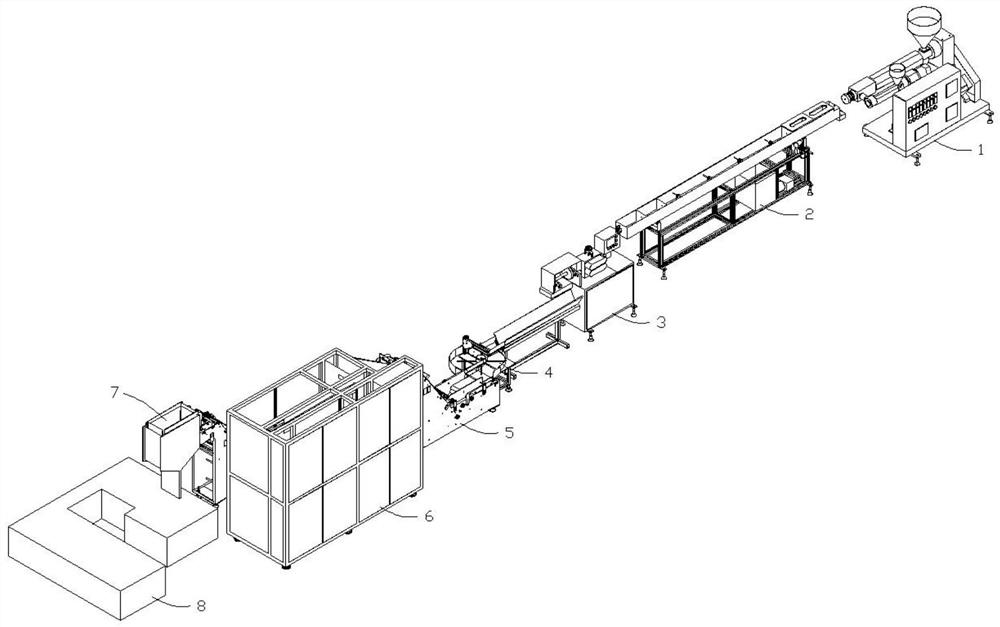

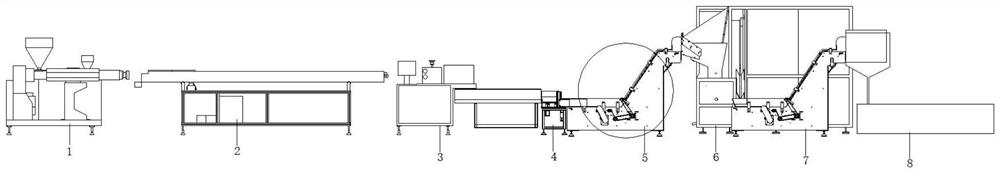

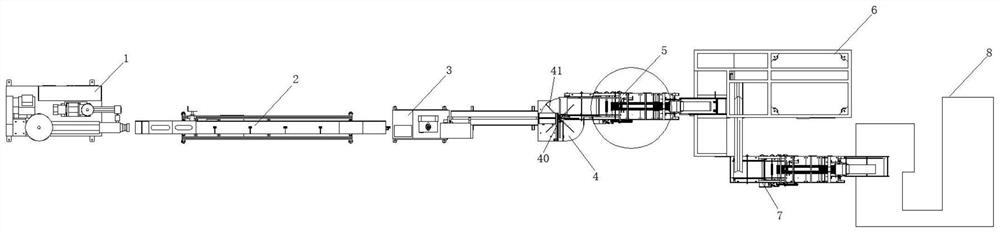

Full-automatic straw production method and full-automatic production line

PendingCN109986814ARealize fully automatic flow productionNo manual contactTubular articlesProduction lineStraight tube

The invention discloses a full-automatic straw production method which comprises the following steps: (1) extrusion molding: feeding materials into a feeding part of an extrusion production line, enabling heating parts of extrusion production to start to work at the same time, debugging an extruder of the extrusion production line, performing extrusion molding after debugging is finished, and cutting to form a straight pipe; (2) pipe mixing: conveying the formed straight pipe to a pipe mixing device through a first conveying line, and the pipe mixing device uniformly mixes colors of the straight pipe; (3) straight pipe conveying; (4) bent pipe forming: enabling the formed bent pipe to fall into a calculation separation temporary storage device, and carrying out calculation, separation andtemporary storage; (5) bent pipe conveying: placing the bent pipe on a bent pipe conveying device when the calculation separation temporary storage device receives a discharging signal; (6) packaging:conveying the formed bent pipe to packaging equipment for packaging through the bent pipe conveying device; finishing automated production of straws. The invention further discloses a full-automaticstraw production line for implementing the method.

Owner:义乌市双童日用品有限公司

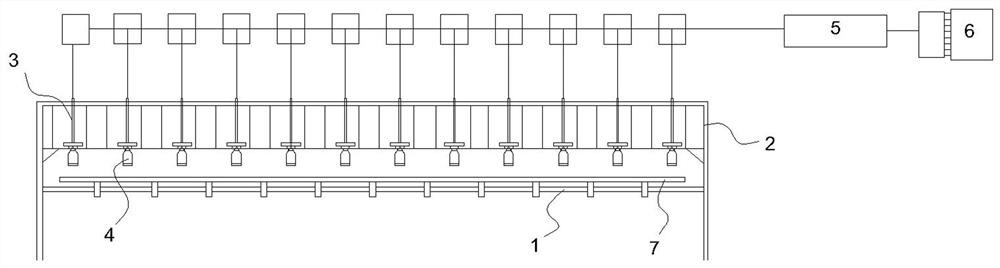

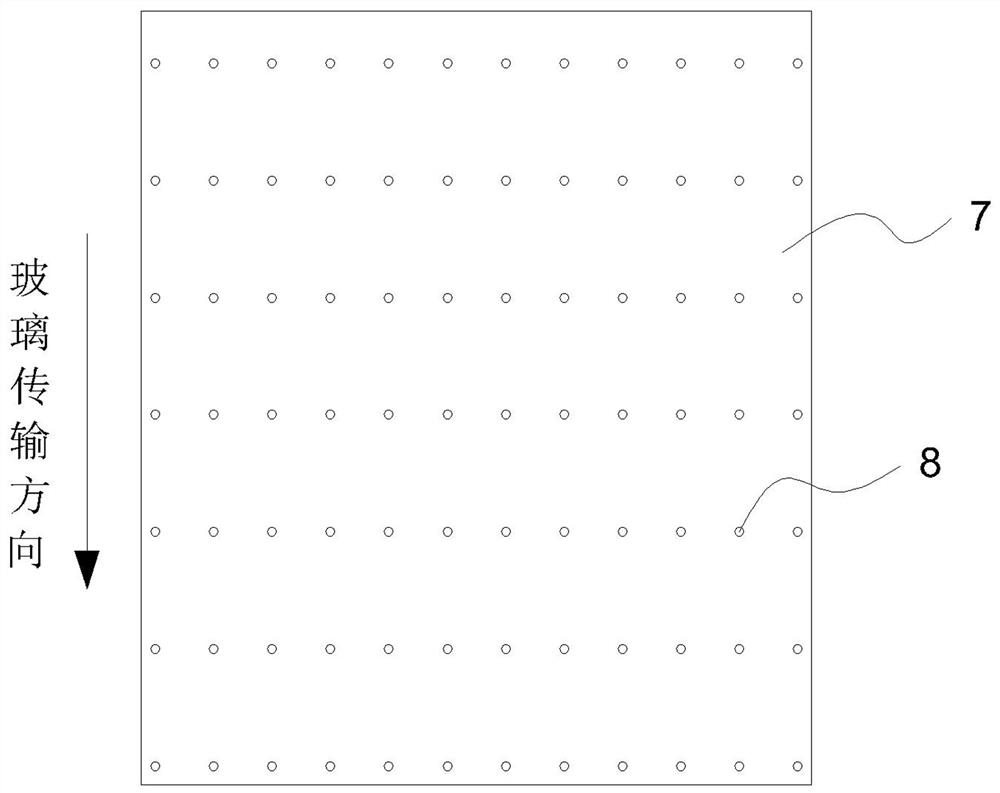

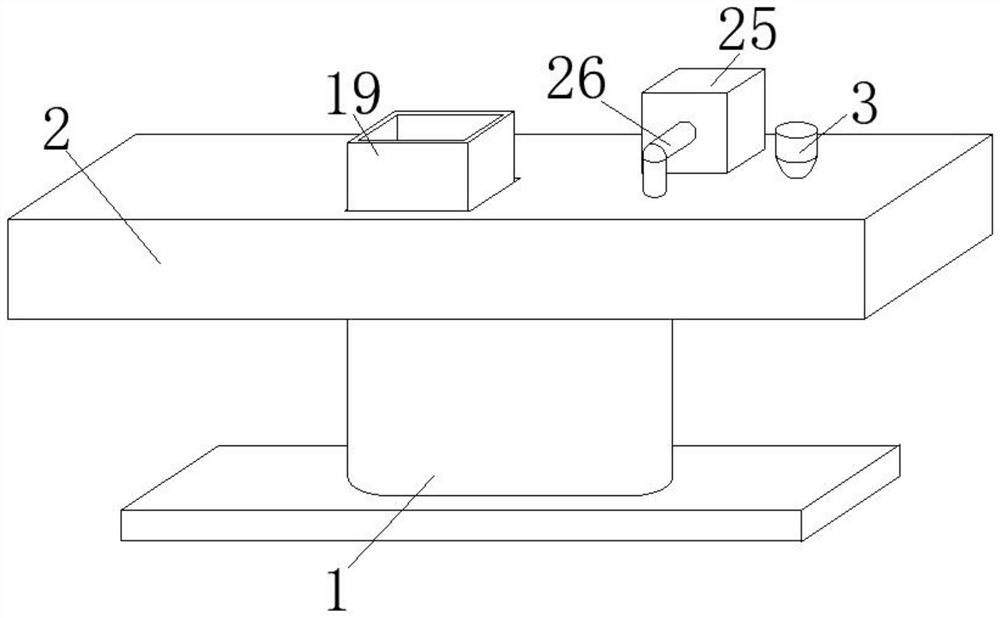

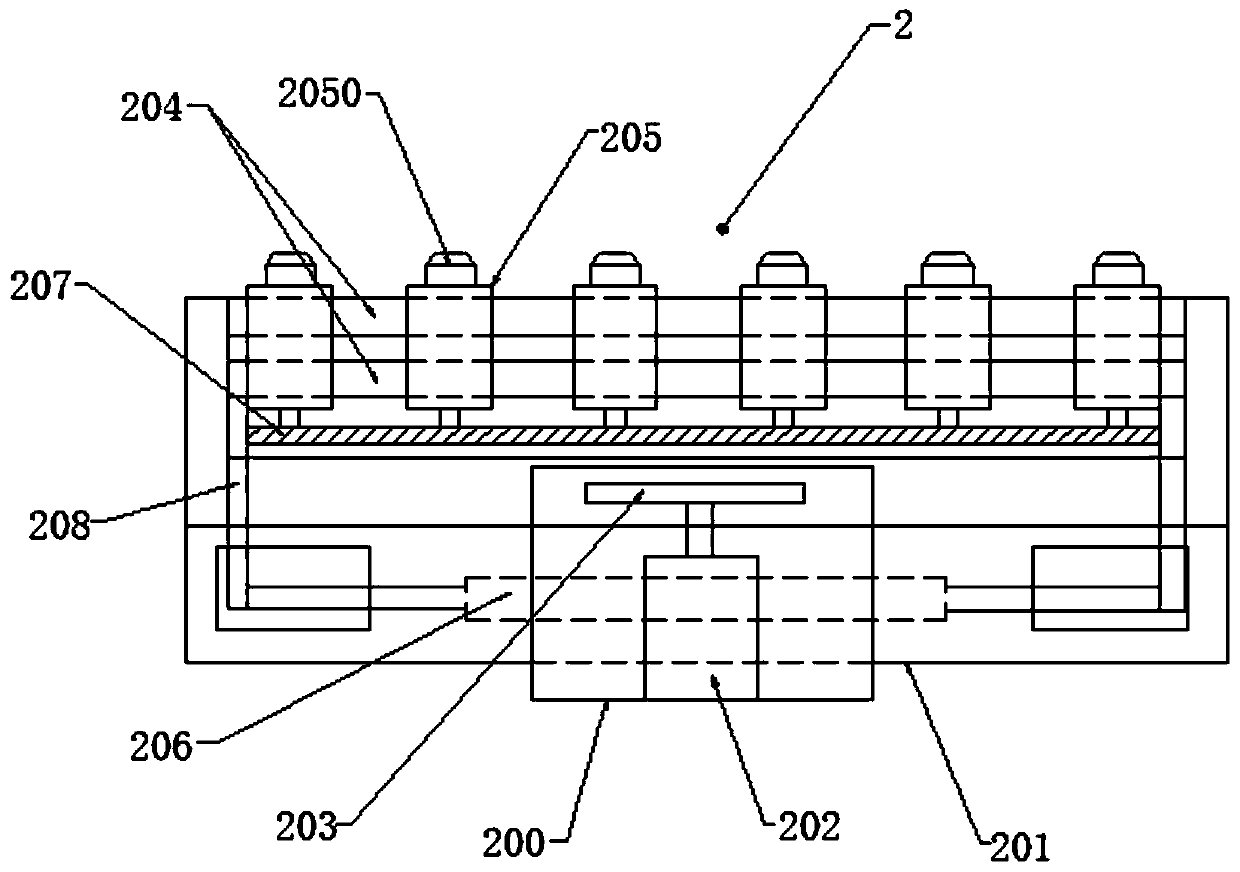

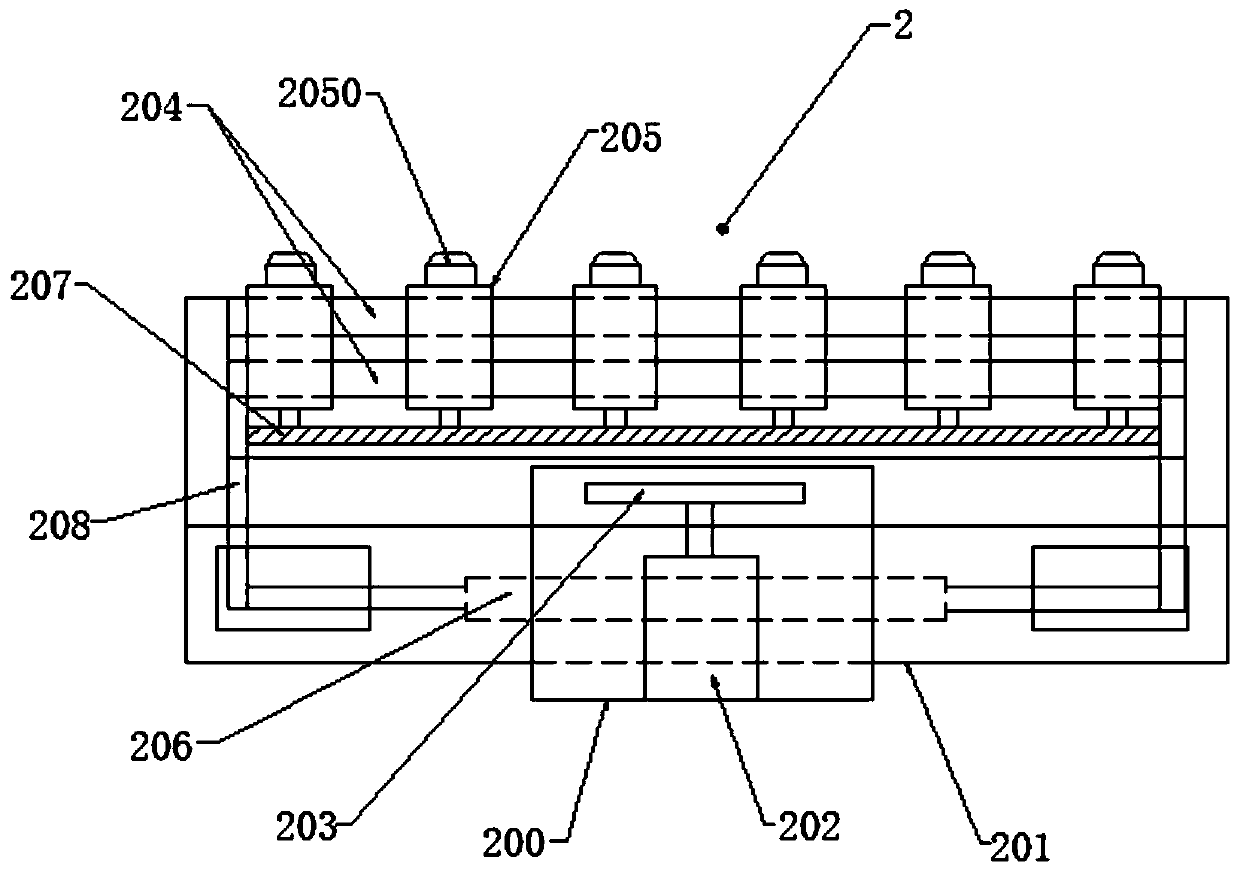

On-line nondestructive thickness measuring device for advanced-generation substrate glass

InactiveCN112229337ANo manual contactQuality is not affectedUsing optical meansMeasuring instrumentControl cell

The invention discloses an on-line nondestructive thickness measuring device for advanced-generation substrate glass, which comprises a mounting bracket arranged above a glass transmission roller, themounting bracket is vertical to the transmission direction of a glass plate, a group of laser thickness measuring instruments are arranged at intervals along the mounting bracket, and probes of the laser thickness measuring instruments are vertically arranged downwards; the measuring device further comprises a laser thickness measuring control unit and an upper computer which are in communicationconnection with each other. Each laser thickness measuring instrument is connected with the laser thickness measuring control unit. When the glass plate is conveyed by the glass conveying roller, thelaser thickness measuring instrument detects the thickness of the glass plate in real time and feeds back a detection result to the upper computer; the device can measure the glass thickness of the glass plate on line before and after surface grinding, does not affect the surface quality of the glass, and improves the detection efficiency.

Owner:BENGBU CHINA OPTOELECTRONIC TECH CO LTD

Automatic vacuum packaging equipment for vacuum packaging of snacks and working method of automatic vacuum packaging equipment

InactiveCN111977060AReduce labor costsReduce production error ratePackaging by pressurising/gasifyingWrapper twisting/gatheringFood safetySnack food

The invention discloses automatic vacuum packaging equipment for vacuum packaging of snacks and a working method of the automatic vacuum packaging equipment. The automatic vacuum packaging equipment comprises a base, a workbench is fixedly connected with the top end of the base, a first cavity is formed in the workbench, and a first motor is installed on the top face of the workbench. According tothe automatic vacuum packaging equipment, automatic transportation, automatic bagging and automatic vacuumizing and sealing can be achieved, so that workers are liberated, the labor cost is reduced,and meanwhile the production error rate is reduced, so that the packaging quality is guaranteed; meanwhile, automatic bag expanding can be achieved, manual bag expanding is not needed, time and laborare saved, delayed manual operation is avoided, so that waste is not prone to happening during food bagging, and consumption of raw material cost is reduced; and meanwhile, manual contact is not needed, the probability that food is polluted by external bacteria is reduced, the food safety coefficient is increased, the food packaging amount can be accurately controlled, the packaging amount of eachbag is equal, uneven packaging amount is avoided, the packaging quality is uniform, and the automatic packaging quality is improved.

Owner:ANHUI HEXIAN SUN ISLAND FOOD

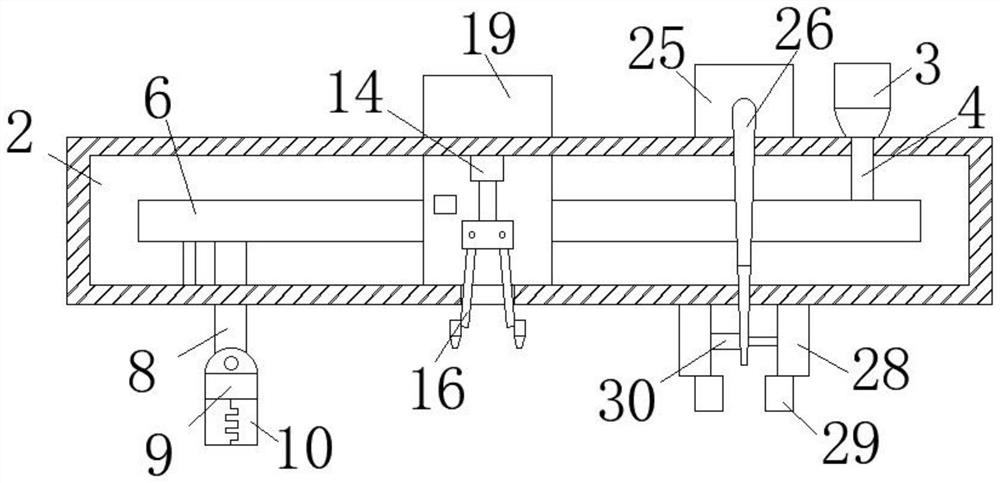

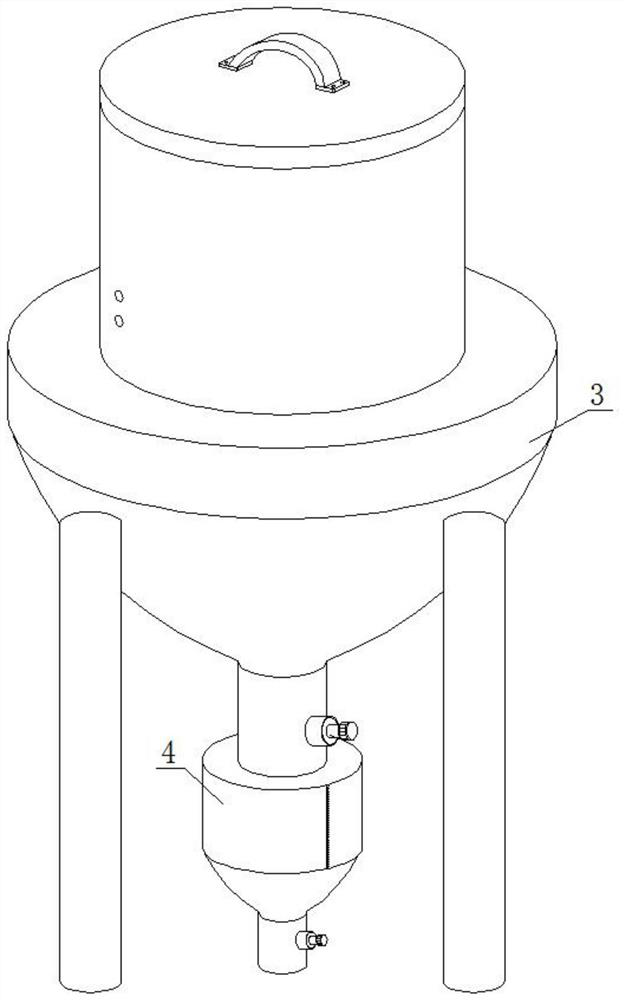

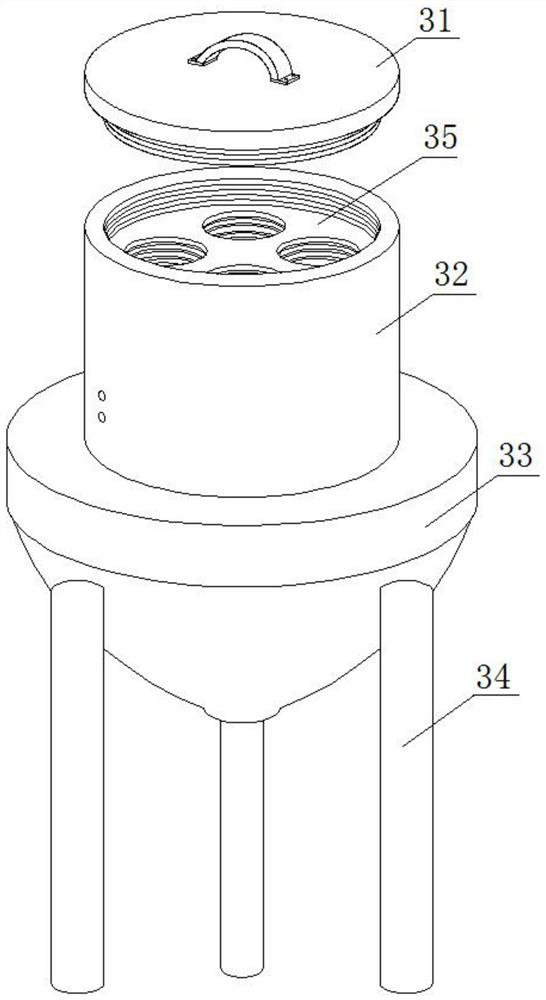

Purification equipment for intelligently treating chemical tail gas

InactiveCN112076576AAvoid damageEasy to take outCombination devicesTreatment involving filtrationActivated carbonHazardous substance

The invention relates to the technical field of environment-friendly purification, and discloses purification equipment for intelligently treating chemical tail gas. The equipment comprises an adsorption barrel, a conical hopper fixedly communicates with the bottom end of the adsorption barrel, a corrugated pipe is fixedly connected to the top end of the adsorption barrel, a gas purification innerbarrel is connected to the top end of the adsorption barrel in a penetrating mode, and one end of the gas purification inner barrel extends to the inside of the adsorption barrel and is fixedly provided with a spiral guide vane. According to the invention, a dissolving solution is sprayed out to be dissolved with chemical tail gas, purified gas is introduced through the bottom end of the gas purification inner barrel, the purified gas passes through a fixed filter screen during exhausting, harmful substances are absorbed through activated carbon, wastewater flows into a sewage collection boxfrom a sewage outlet in the bottom end of the adsorption barrel, sewage flows into a sedimentation barrel from the sewage collection box, and after sedimentation is completed, a shielding cover is pushed to stretch a filter plate, so that the filter plate drives the solid sediments to float upwards, the solid sediments can be taken out conveniently, manual contact with a dissolved solution is notneeded, and operators are prevented from being injured.

Owner:潘彬夫

Medical trash incineration device

The invention provides a medical trash incineration device, and belongs to the field of environment-friendly devices. The medical trash incineration device comprises a feeding furnace and an incineration furnace. A feeding port is formed in the upper portion of the left side of the feeding furnace. A material storage box is arranged at the bottom end of the inner portion of the feeding furnace. Afirst conveyor belt is arranged at the bottom of the feeding furnace. First electric rolling wheels are arranged at the two ends of the first conveyor belt. An extrusion device is arranged at the topend of the inner portion of the feeding furnace. A feeding furnace automatic lifting door is arranged on the lower right portion of the feeding furnace. An incineration furnace automatic lifting dooris arranged on the lower left portion of the incineration furnace. A second conveyor belt is arranged at the bottom of the incineration furnace. Second electric rolling wheels are arranged at the twoends of the second conveyor belt. An air blower is arranged on the lower right portion of the incineration furnace. The medical trash incineration device is simple in structure and flexible and convenient to use, trash which is put in can be extruded and smashed, the size is reduced, subsequent incineration can also be more thorough, the trash can automatically enter the incineration furnace afterbeing put in, manual contact is not needed, spreading of viruses and bacteria is reduced, and the whole trash conveying process is in a closed space all the time so that spreading of the viruses andthe bacteria can be prevented.

Owner:六安市智奇工业设计有限公司

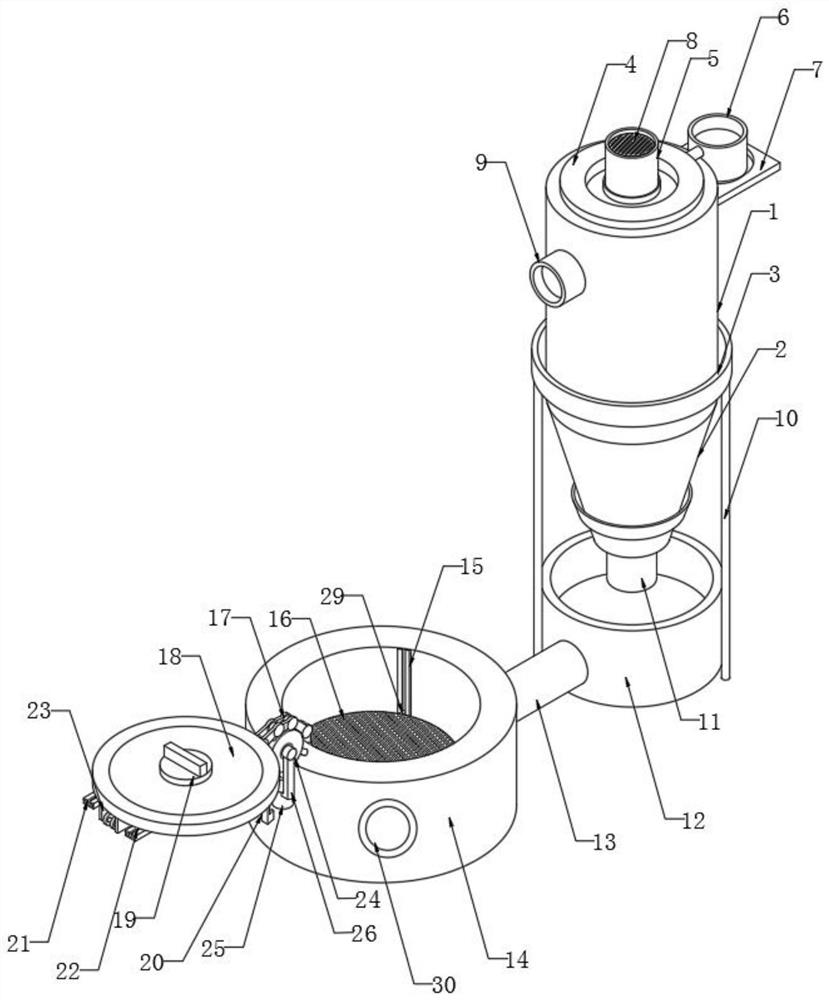

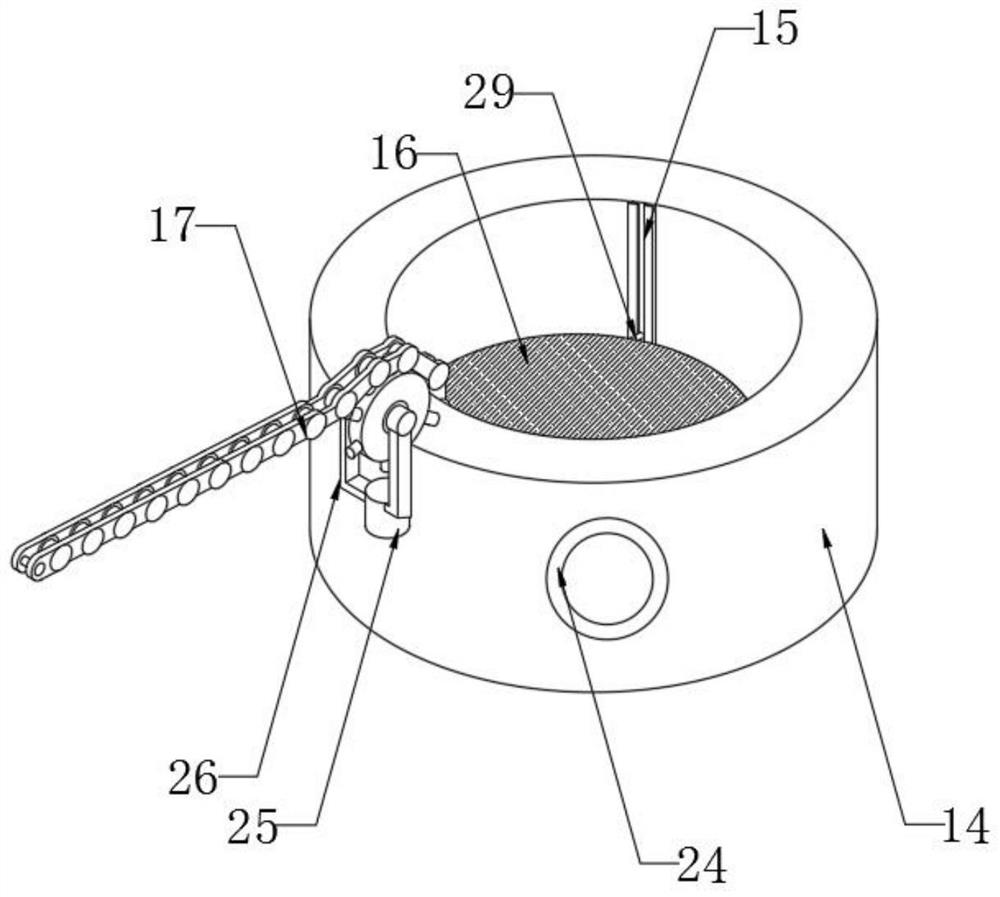

Small environment-friendly multifunctional egg shelling machine

InactiveCN112401694ARealize automatic peelingNo manual contactKitchen equipmentEggshellProcess engineering

The invention relates to an egg shelling machine, in particular to a small environment-friendly multifunctional egg shelling machine. The technical problem to be solved is to provide the small environment-friendly multifunctional egg shelling machine capable of automatically shelling eggs, separating egg white from eggshells and automatically stirring the egg white. The small environment-friendlymultifunctional egg shelling machine comprises a supporting frame and a supporting cylinder, wherein the top of the supporting frame is connected with the supporting cylinder; a power mechanism whichis connected into the supporting cylinder; a power mechanism which is connected with the husking mechanism; and a supporting cylinder which is connected with the discharging mechanism. Through cooperation of the power mechanism, the husking mechanism and the discharging mechanism, automatic husking of eggs can be achieved, egg white and eggshells are separated, manual contact is not needed, and sanitation and convenience are achieved.

Owner:唐召志

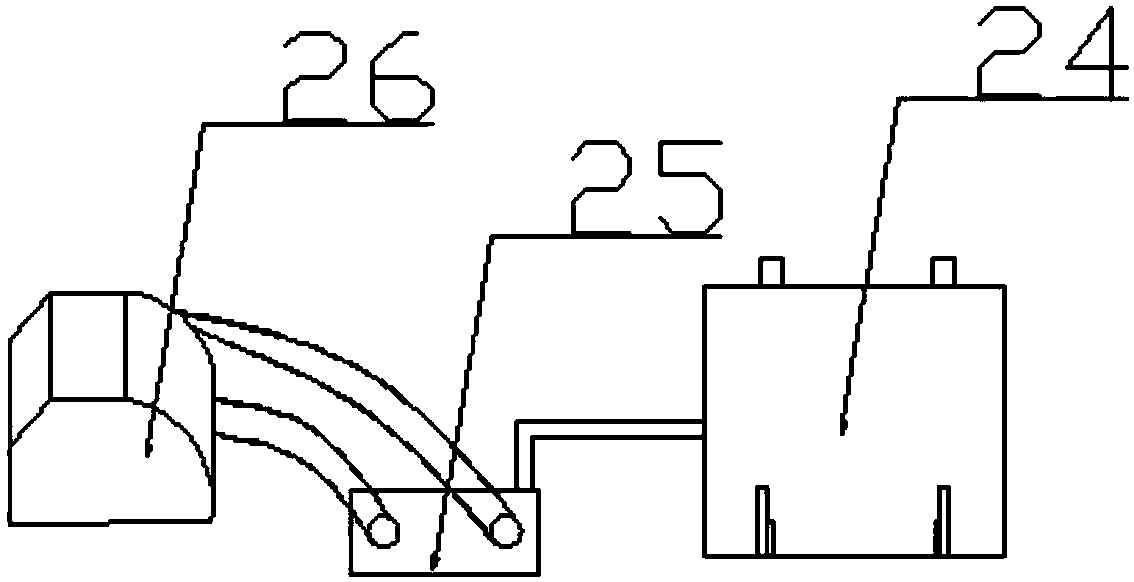

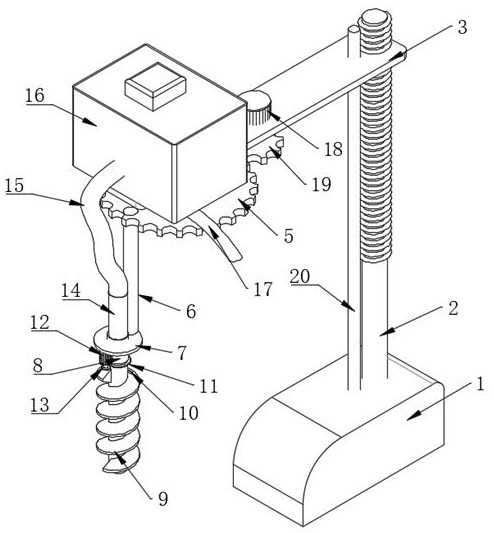

Oxidative calcining device for processing of ammonium paratungstate

PendingCN112849610AAvoid harmImprove operational safetyArticle unpackingLoading/unloadingManual handlingAmmonium paratungstate

The invention discloses an oxidative calcining device for processing of ammonium paratungstate. The oxidative calcining device comprises an oxidative calcining main machine, a ladder, a charging mechanism and a discharging mechanism, wherein the ladder is arranged at one end of the oxidative calcining main machine; the charging mechanism is arranged on one side of the upper end of the oxidative calcining main machine; the upper end of the discharging mechanism is connected with the lower end of the charging mechanism; and the lower end of the discharging mechanism is connected with a charging hole of the oxidative calcining main machine. The oxidative calcining device disclosed by the invention has the beneficial effects that automatic bag opening operation can be realized, the operation safety is improved, and the ammonium paratungstate conveniently, quickly and cleanly flows out of the bag, so that the trouble of manually clearing a packaging bag at the second time is reduced, the automatic bag breaking and charging effects are improved, automatic dropping of the ammonium paratungstate is conveniently realized, the packaging bag stays in a discharging tank or hanged on a drill bit, so that convenience is provided for manually clearing, fixed-material conveying for oxidative calcination of the ammonium paratungstate is realized, and the calcination quantity is convenient to control; and in the nearly-enclosed charging whole process, manual contact is not needed, the manual operation comfort level is high, and the operation is safe and reliable.

Owner:李金珠

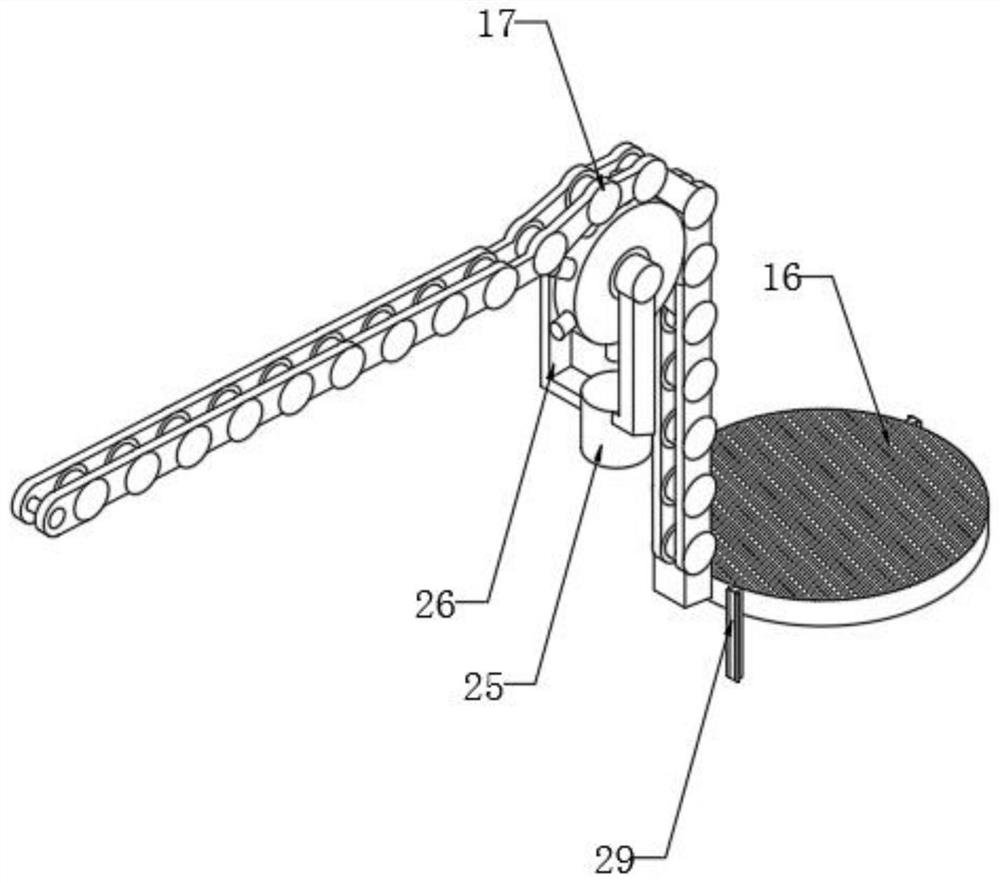

Product performance detection device for integrally molded inductor production and detection method thereof

PendingCN113866512ARealize dust removalRealize automatic feeding processResistance/reactance/impedenceMeasurement instrument housingInductorMechanical engineering

The invention discloses a product performance detection device for integrally molded inductor production and a detection method thereof. The product performance detection device comprises a base, an L-shaped plate is fixedly connected to the upper end of the base, a detection driving mechanism is installed on the L-shaped plate, a guide groove is formed in the upper end of the base, and a sliding groove opposite to the bottom of the guide groove is formed in the bottom of the base; the sliding groove communicates with the guide groove through a discharging groove and a moving groove, and four supporting rods are fixedly connected to the base. The invention further discloses a detection method of the product performance detection device for production of the integrally-molded inductors, and the method comprises the following steps: S1, placing the integrally-molded inductors in a material frame in a stacked manner, and then starting an electric telescopic rod. According to the invention, the electric telescopic rod works, automatic feeding can be conducted on inductors, meanwhile, automatic taking can be achieved, manual participation is not needed, the labor amount of workers is greatly reduced, meanwhile, manual contact is not needed, and pollution to the inductors is reduced.

Owner:浙江富尔科技有限公司

Clean wine jar capping device

InactiveCN112158370ANo pollutionAchieve compactionPackagingConveyor partsProcess engineeringCap device

The invention discloses a clean wine jar capping device. The clean wine jar capping device comprises a telescopic rod. The fixed end of the telescopic rod is connected with a driving device used for driving the telescopic rod to rotate, the telescopic rod is connected with a suction nozzle through a first connecting piece, the end, away from the suction nozzle, of the first connecting piece is closed, and the movable end of the telescopic rod penetrates through the first connecting piece to extend into the suction nozzle. A pressure sensor is arranged at the movable end of the telescopic rod.The clean wine jar capping device further comprises an air pipe which penetrates through the telescopic rod and the first connecting piece to be communicated with the suction nozzle. The driving device controls the telescopic rod to drive the suction nozzle, so as to convey a jar cap to a wine jar automatically without the touch of people, so that the wine jar may not be contaminated. An air pressure adsorption structure is formed by an air guide pipe hole, the air pipe and the suction nozzle, so that the wine jar cap is grabbed. The air pressure sensor controls an electric push rod to extendso as to press the jar cap, so that the situation that the uniformity of a sealing cap cannot meet the sealing requirement due to manual pressing is avoided.

Owner:XI'AN POLYTECHNIC UNIVERSITY +1

Straw full-automatic production line and production method

PendingCN114379049AReduce production linksHigh dimensional accuracyPackagingTubular articlesProcess engineeringManufacturing line

Owner:义乌市双童日用品有限公司

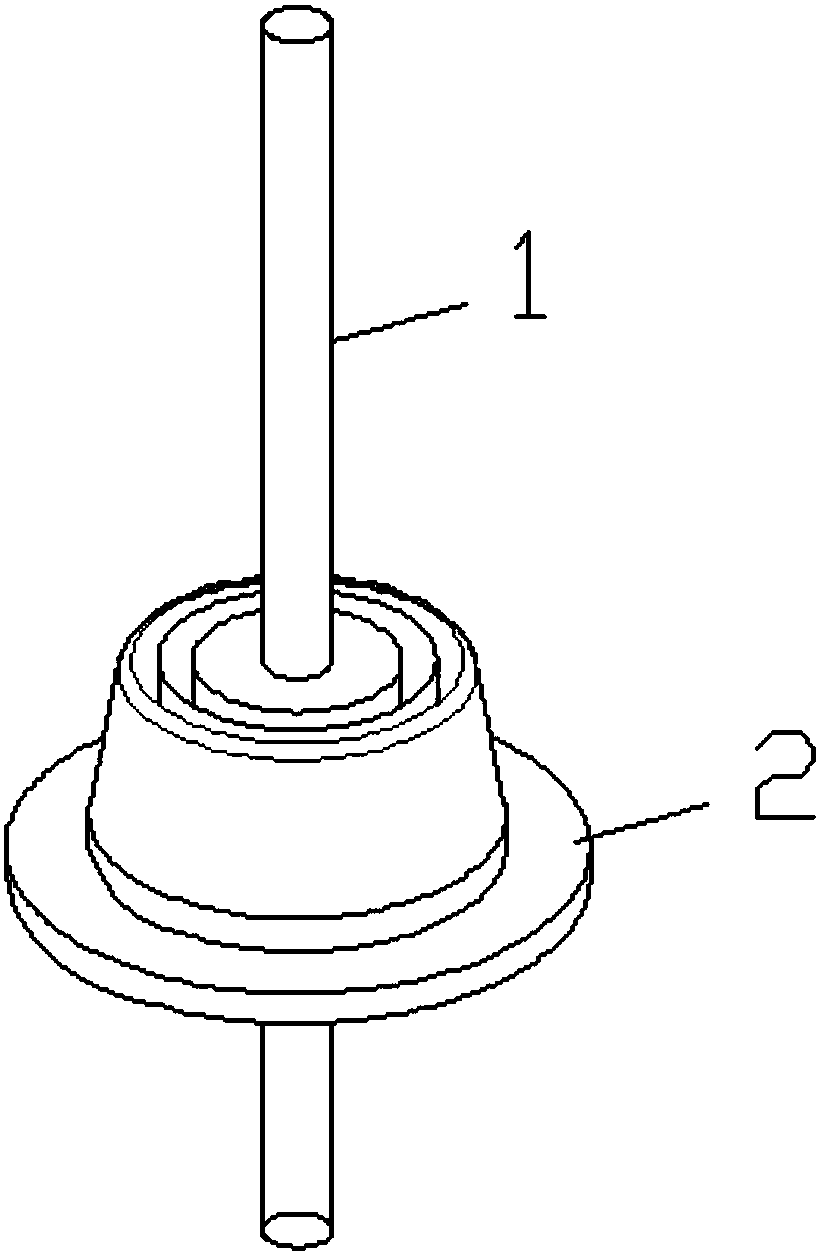

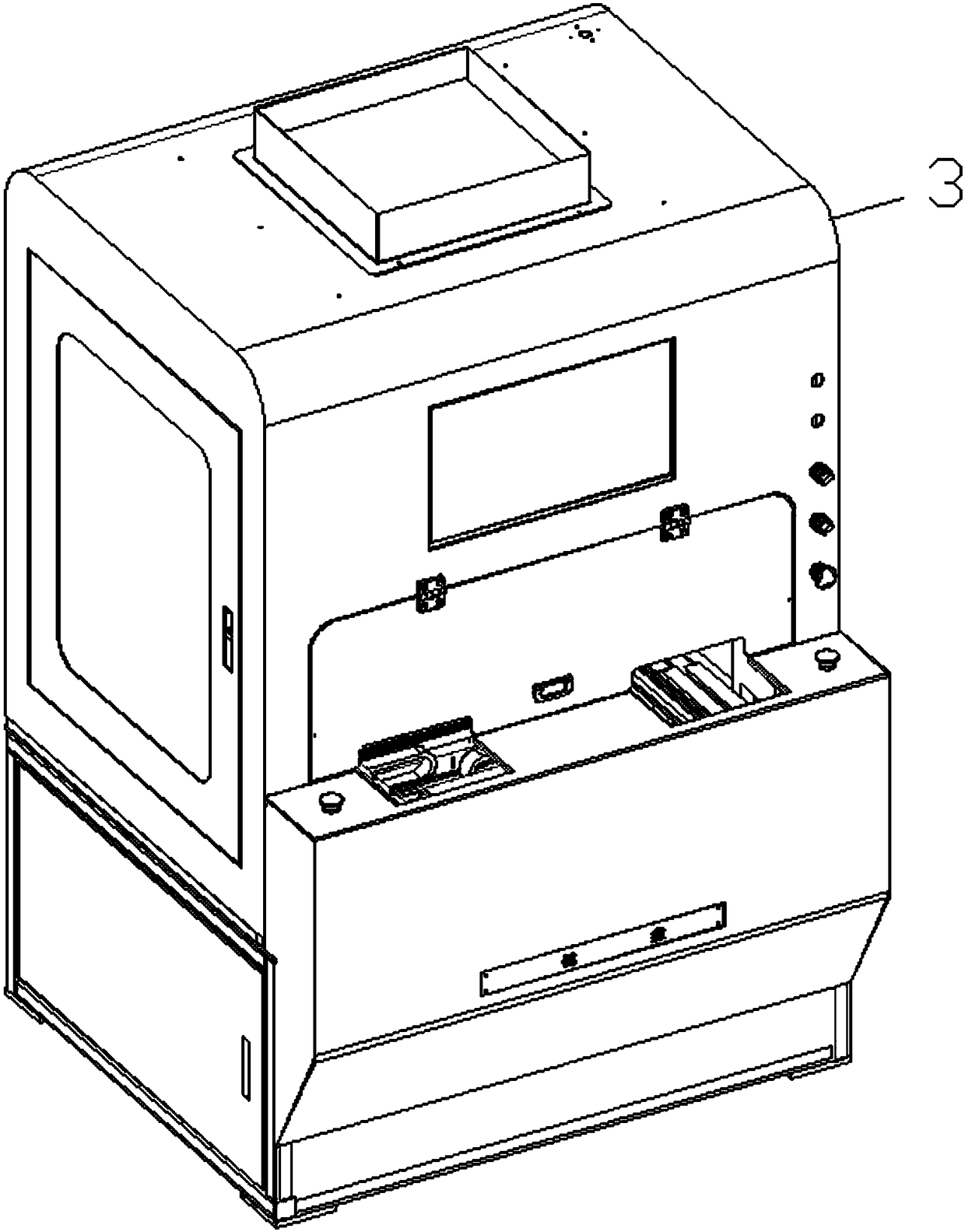

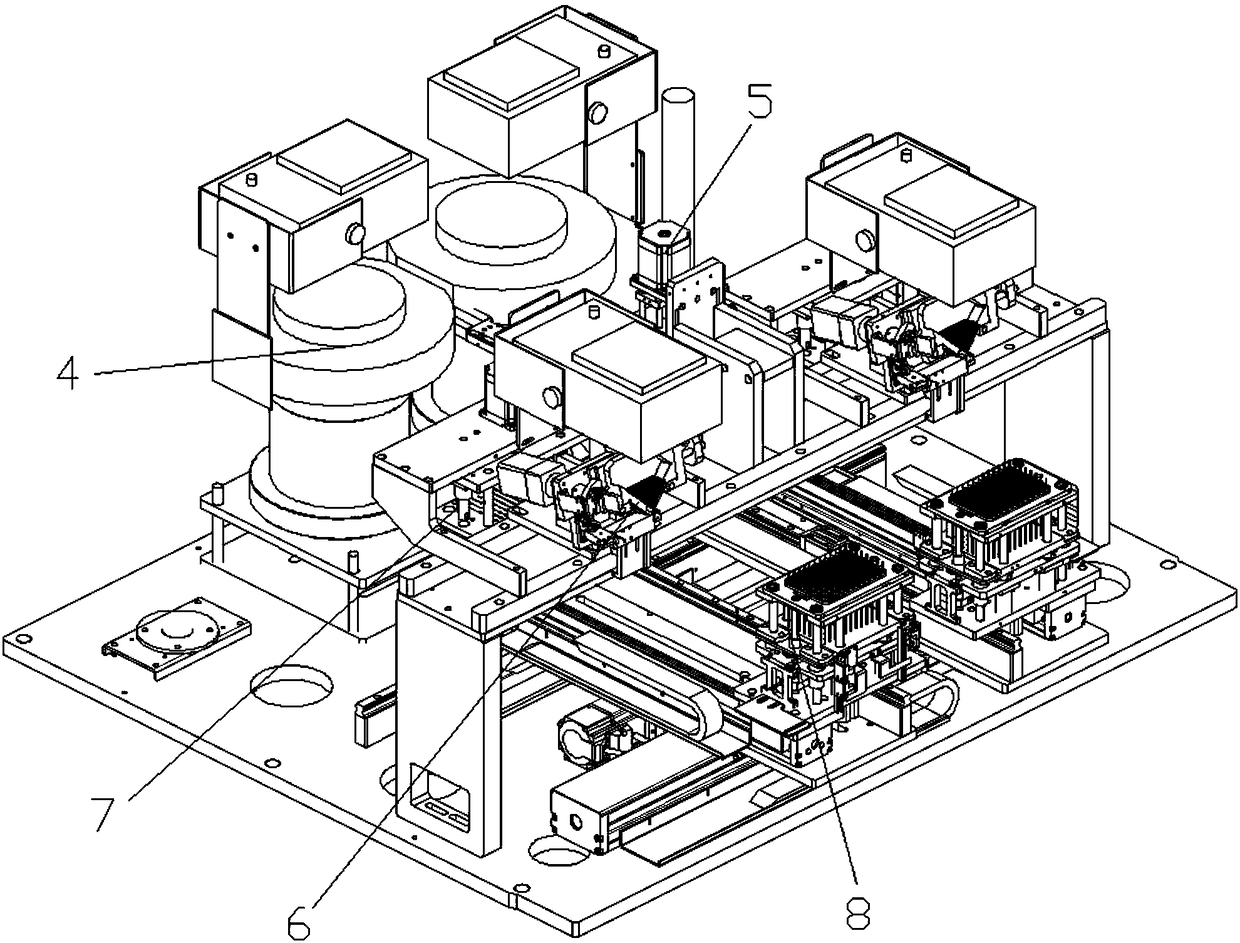

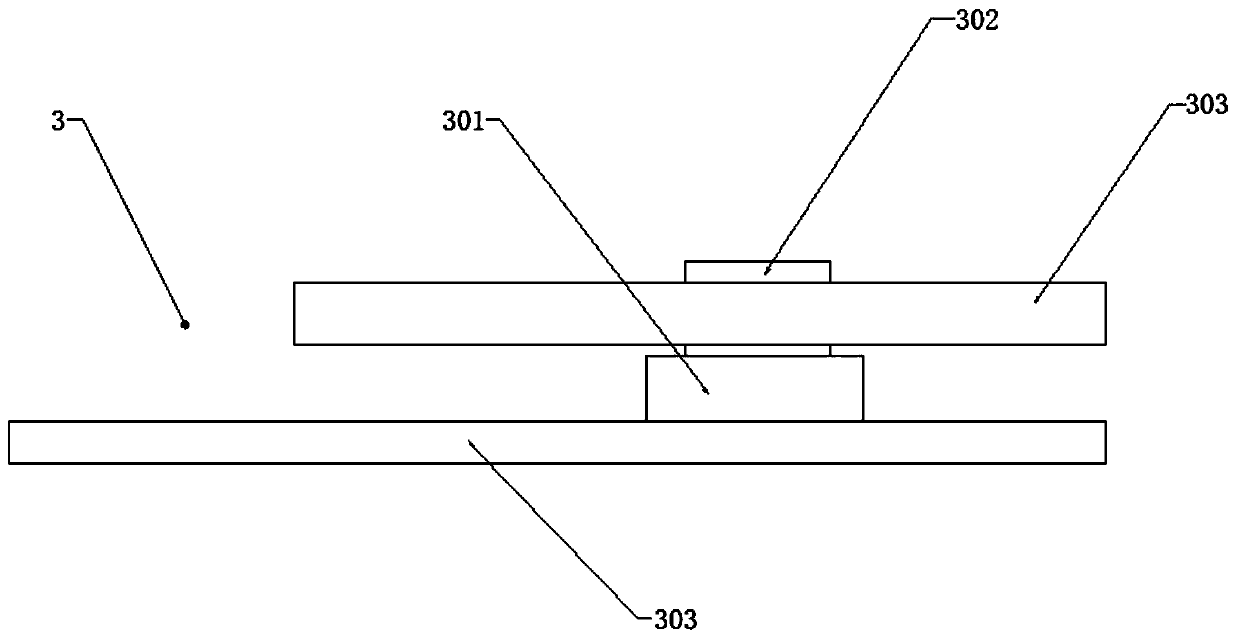

Automatic needle assembling device

PendingCN108581416ASolve the problem of compression fractureControl assembly accuracyMetal working apparatusEngineeringWell control

The invention discloses an automatic needle assembling device which comprises a rack. Assembling modules on the rack are used for assembling glass needles and rubber sleeves by utilizing the cooperation of sleeves and ejector pins; rubber sleeve feeding modules are used for providing the rubber sleeves to be assembled; rubber sleeve picking and press-fitting modules are used for sucking the rubbersleeves provided by the rubber sleeve feeding modules, and press-fitting the rubber sleeves onto the sleeves in a one-to-one correspondence way; glass needle feeding modules are used for providing the glass needles to be assembled, and enabling the glass needles to fall into the sleeves in a one-to-one correspondence way; and pressing modules are used for press-fitting with assembling jigs and fixing the positions of the rubber sleeves on pick-and-place plates. The automatic needle assembling device provided by the invention is high in automation degree and capable of automatically accomplishing assembling operation of the glass needles and the rubber sleeves, and has the advantages of stability and accuracy in production; without manual touch, the pollution caused on the reaction surfaces of the glass needles due to manual touch is avoided; by applying the sleeves, the problem that the glass needles are pressed so as to be fractured during the assembling process is solved; and by applying the ejector pins, the assembling accuracy of the lengths of one ends, exposed out of the rubber sleeves, of the glass needles can be well controlled.

Owner:苏州明益信智能设备有限公司

Material taking equipment convenient for calcining traditional Chinese medicine decoction pieces and use method of material taking equipment

PendingCN114751197AImprove work efficiencyAvoid damage to healthBulk conveyorsLoading/unloadingElectric machineryProcess engineering

The invention discloses material taking equipment convenient for calcining traditional Chinese medicine decoction pieces and a use method thereof, relates to the technical field of traditional Chinese medicines, and aims to solve the problems that minerals such as shells and fossils are stacked together after being crushed and calcined, so that the heat dissipation effect is poor, at present, the minerals need to be manually taken after the temperature is reduced, the manual material taking speed is low, the consumed time is long, and the working efficiency is high. In order to solve the problems that in the prior art, in the prior art, manual material taking is slow, a trace amount of materials can be sucked into the respiratory tract, infection is caused, and body health is affected, the following scheme is provided: the device comprises a base, a motor cavity is formed in the base, the top of the motor cavity is rotatably connected with a screw rod, and the screw rod is sleeved with a moving plate in a threaded manner; and a rotating mechanism is rotationally connected to the interior of the moving plate. According to the material taking device, materials can be mechanically taken without waiting for temperature reduction, the materials are rapidly cooled while being taken, the material taking efficiency is improved, manual direct contact is not needed during mechanical material taking, and the condition of health damage is avoided.

Owner:安徽淮草堂中药饮片有限公司

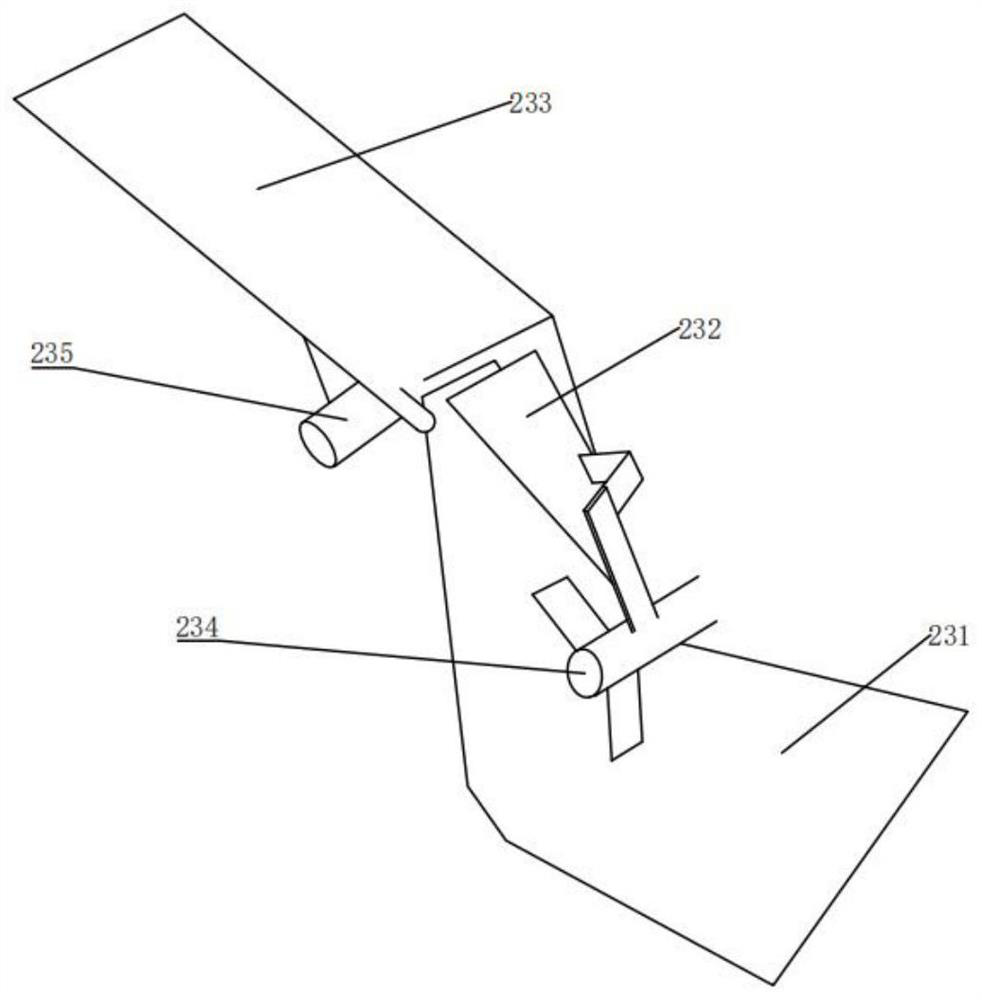

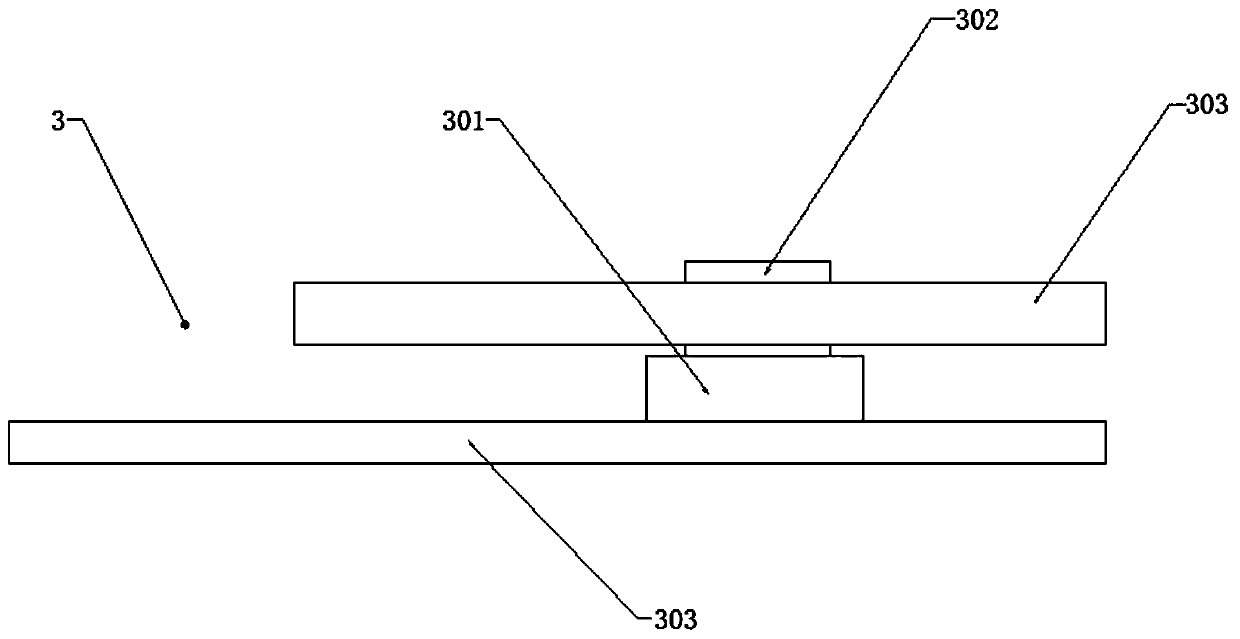

Conveying mechanism and conveying method of molding device for injection molding liquid plastic bottle

ActiveCN108162253BIncrease productivityImprove the level of civilized productionDomestic articlesProcess engineeringMechanical engineering

The invention relates to a conveying mechanism of a forming device of injection molding liquid plastic bottles. The conveying mechanism is characterized by comprising a rack, and a first clamping conveying assembly, a linking conveying assembly and a second clamping conveying assembly are sequentially arranged on the rack according to the conveying flow. The conveying mechanism has the beneficialeffects that manual conveying and feeding are replaced, labor force of manual work can be replaced, production efficiency is improved, manual contact is not needed in products, potential safety hazards are removed, manual pollutions are eradiated, product quality is ensured, and the civilized production degree is improved also.

Owner:ZHEJIANG DUBANG PHARMA

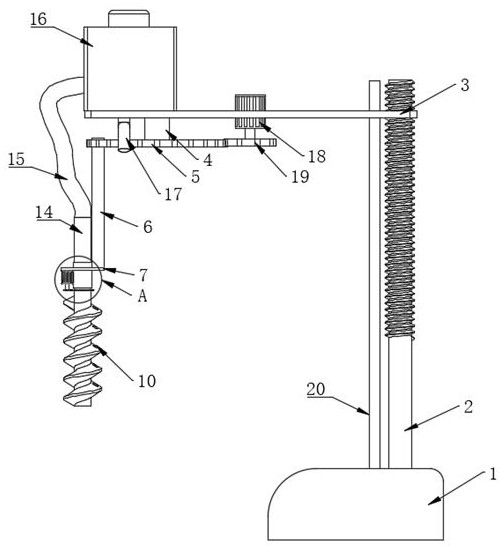

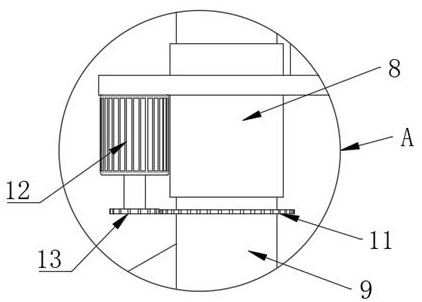

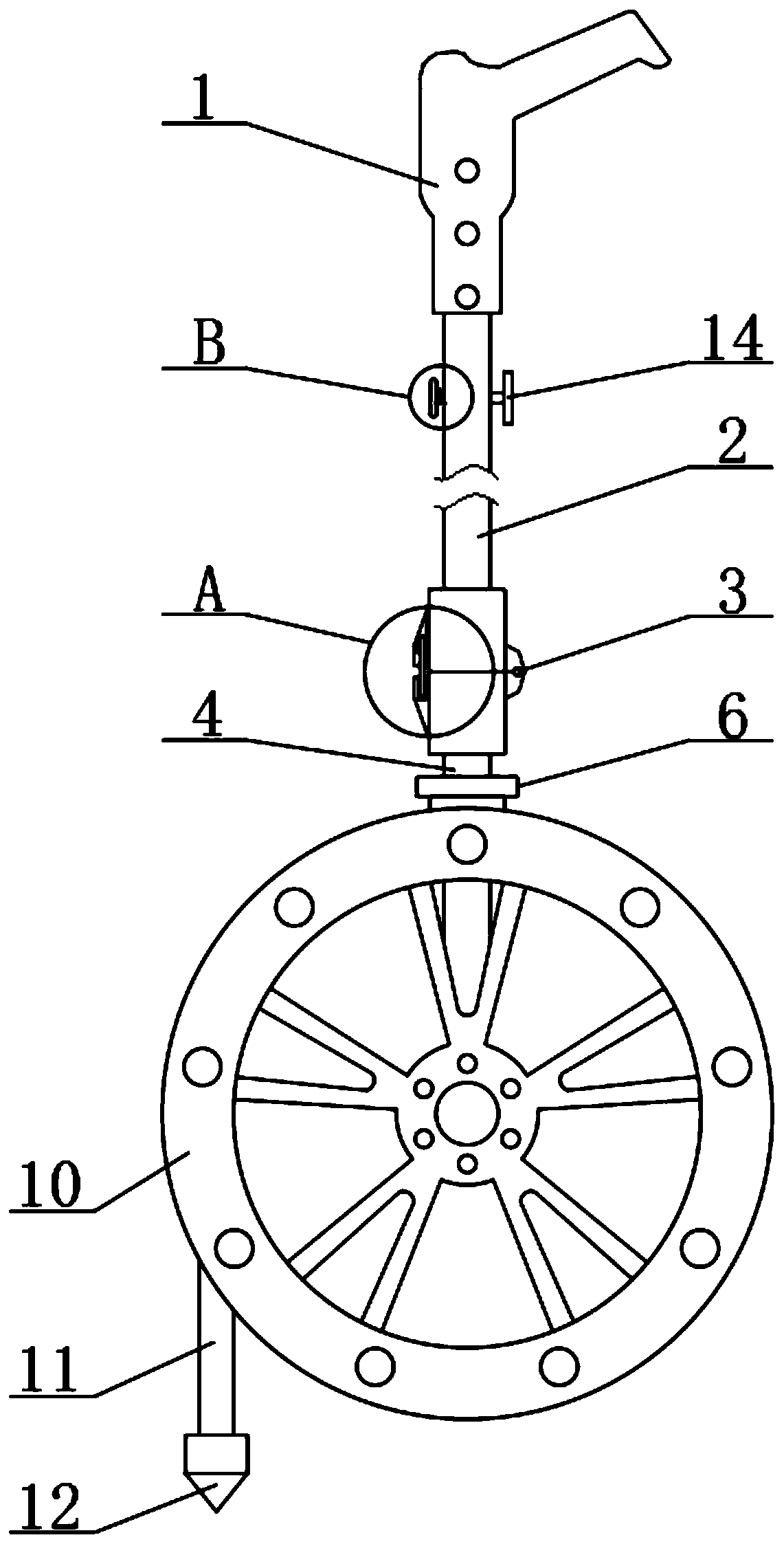

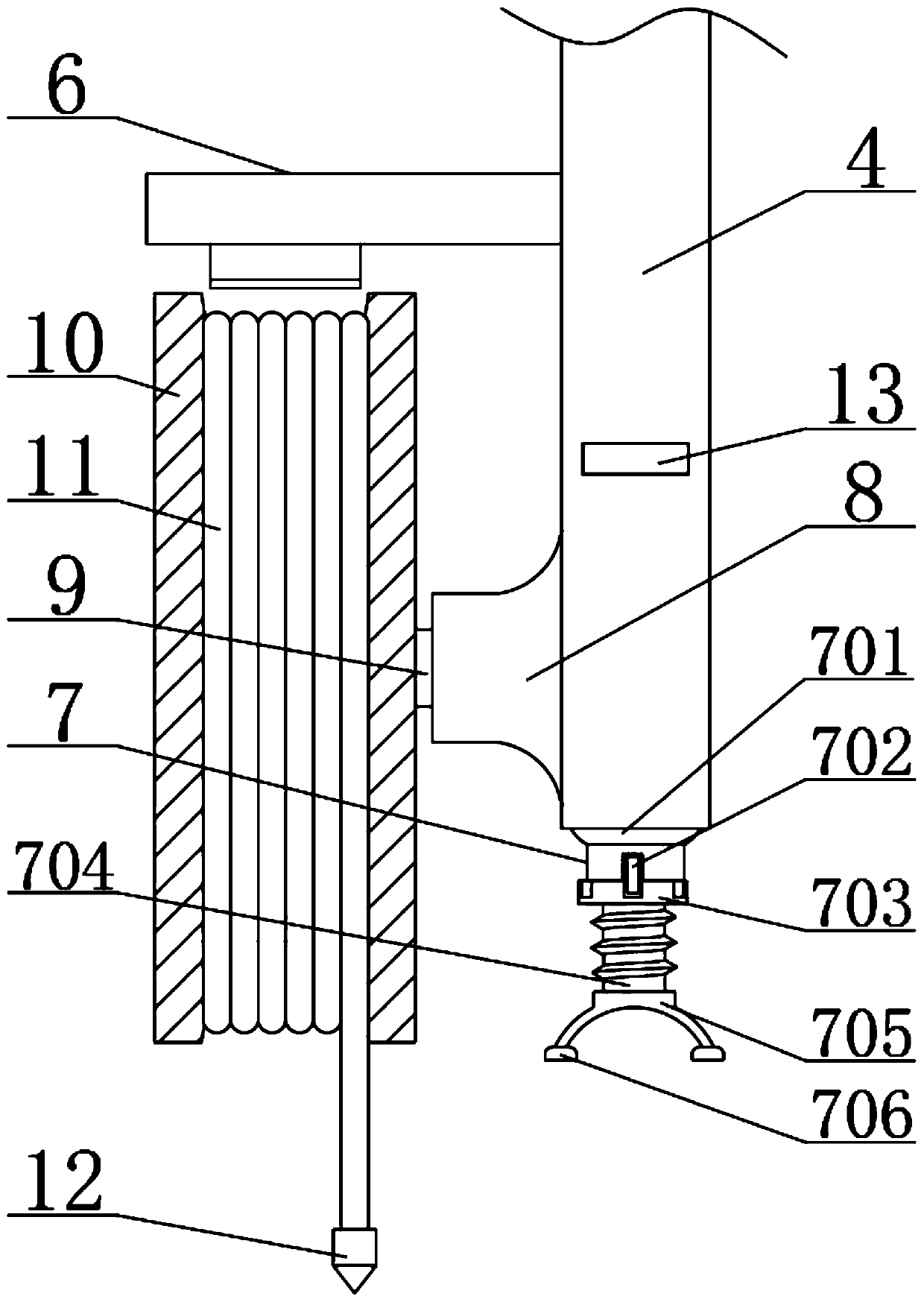

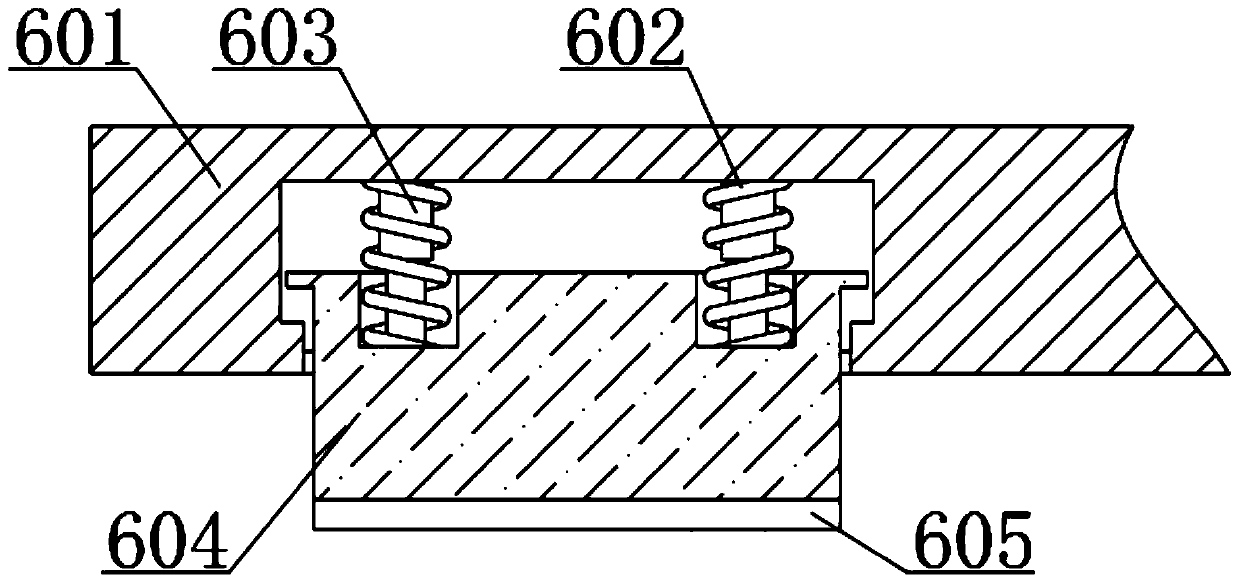

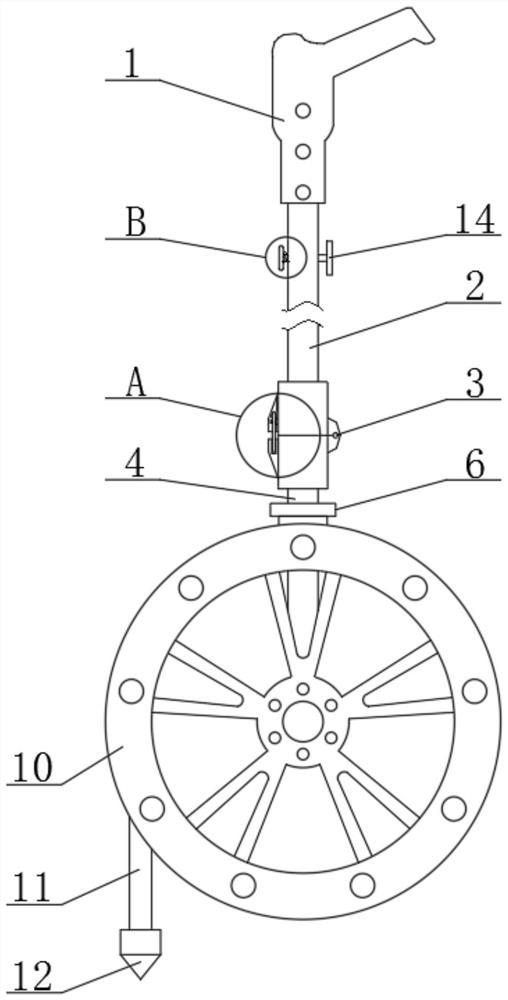

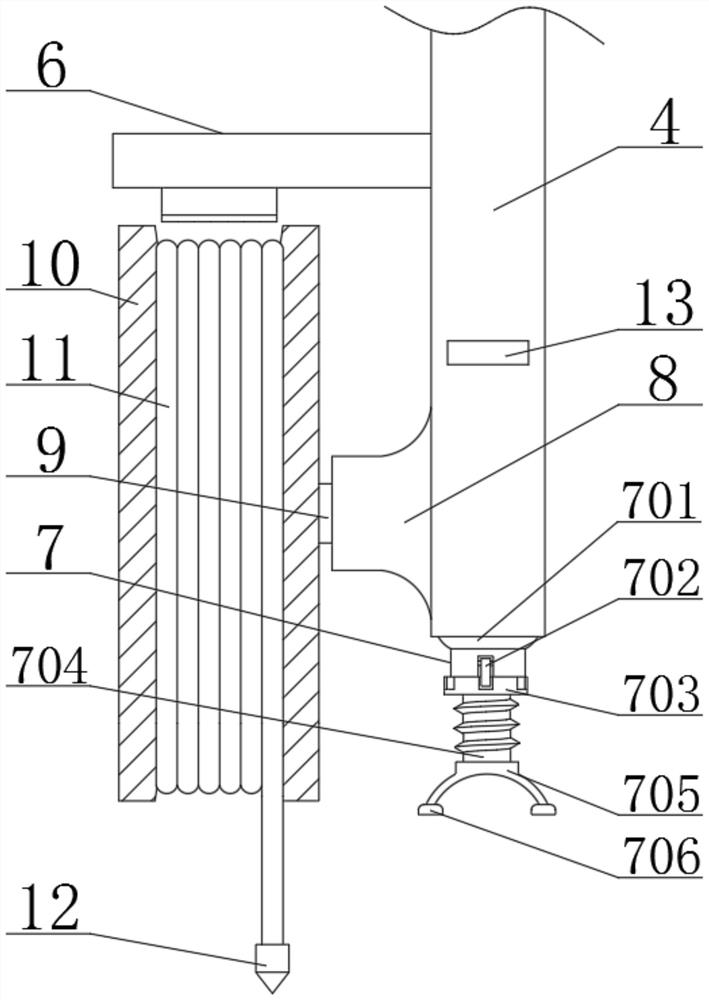

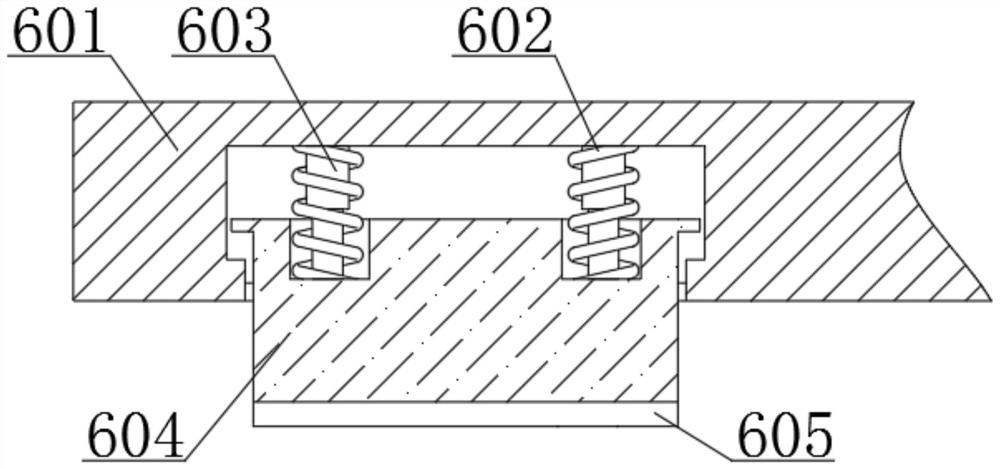

Electric portable coal bunker depth detector

ActiveCN110671995AImprove work efficiencyEasy to operateMechanical depth measurementsElectrical and Electronics engineeringMechanical engineering

The invention relates to the technical field of coal bunker depth measurement, in particular to an electric portable coal bunker depth detector. The electric portable coal bunker depth detector comprises a handle, an upper unit fixing rod, a rotating shaft and a lower unit fixing rod, the front end face of the handle is fixedly connected with buttons which are distributed in an upper-middle-lowermode. The lower end face of the handle is fixedly connected with the upper unit fixing rod. The rotating shaft is fixedly connected to the right side of the lower end face of the upper unit fixing rod, the upper unit fixing rod is rotationally connected with the lower unit fixing rod through the rotating shaft, a limiting device is slidably connected to the front end face of the lower unit fixingrod, and connecting devices are fixedly connected to the left end face of the upper unit fixing rod and the left end face of the lower unit fixing rod respectively. According to the device, through the arrangement of a take-up wheel, a measuring rope and a gravity cone, the take-up wheel is driven to rotate through rotation of a rotating motor, the rope unwinding and winding speed can be increased, manual hand-held pay-off and take-up are not needed, the working efficiency is greatly improved, operation is easy, labor is saved, manual contact is not needed, cleanness and sanitation are achieved, and good practical value is achieved.

Owner:SHAANXI ZHENGTONG COAL IND CO LTD

The conveying mechanism of the molding device for injection molding liquid plastic bottles

ActiveCN108177275BEliminate potential safety hazardsIncrease productivityDomestic articlesProcess engineeringMechanical engineering

The invention relates to a conveying mechanism of a molding device for injection molding liquid plastic bottles. The conveying mechanism is characterized by comprising a frame; and a first clamping and conveying module, a joining and conveying module and a second clamping and conveying module are arranged on the frame in sequence according to a conveying flow. The conveying mechanism replaces manual conveying and loading, cancels labors, improves the production efficiency, prevents manual contact of products, eliminates potential safety hazards, prevents manual pollution, guarantees the product quality, and improves the civilized production degree.

Owner:ZHEJIANG DUBANG PHARMA

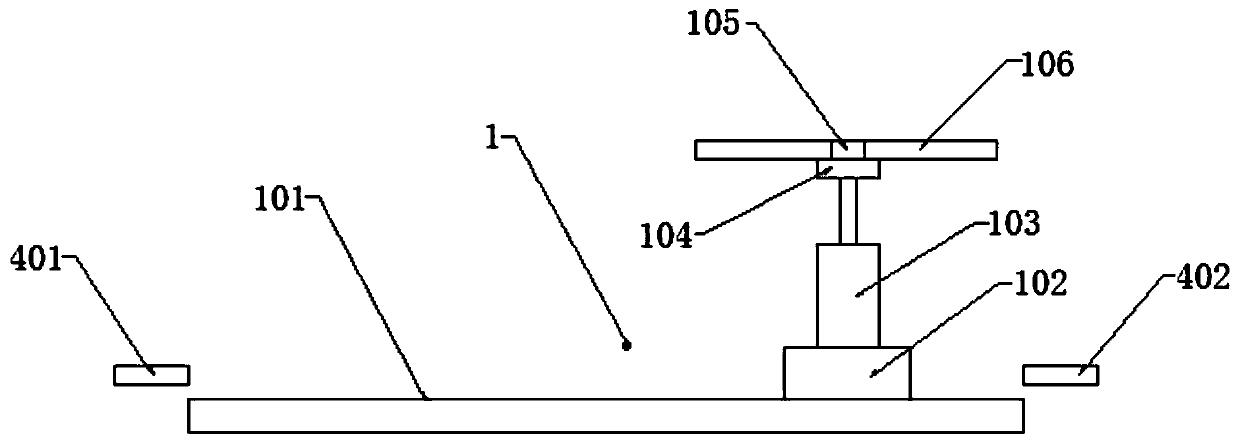

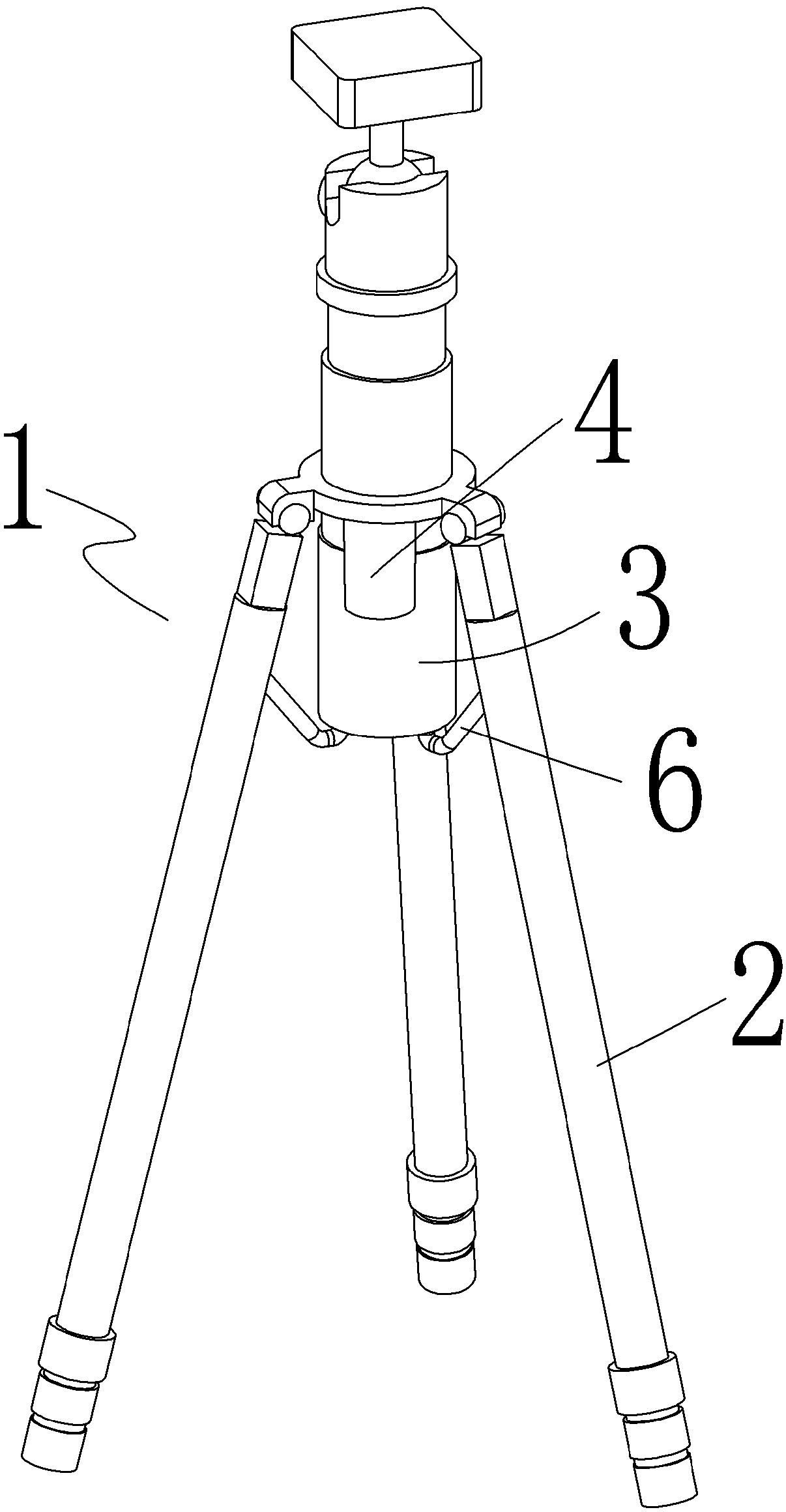

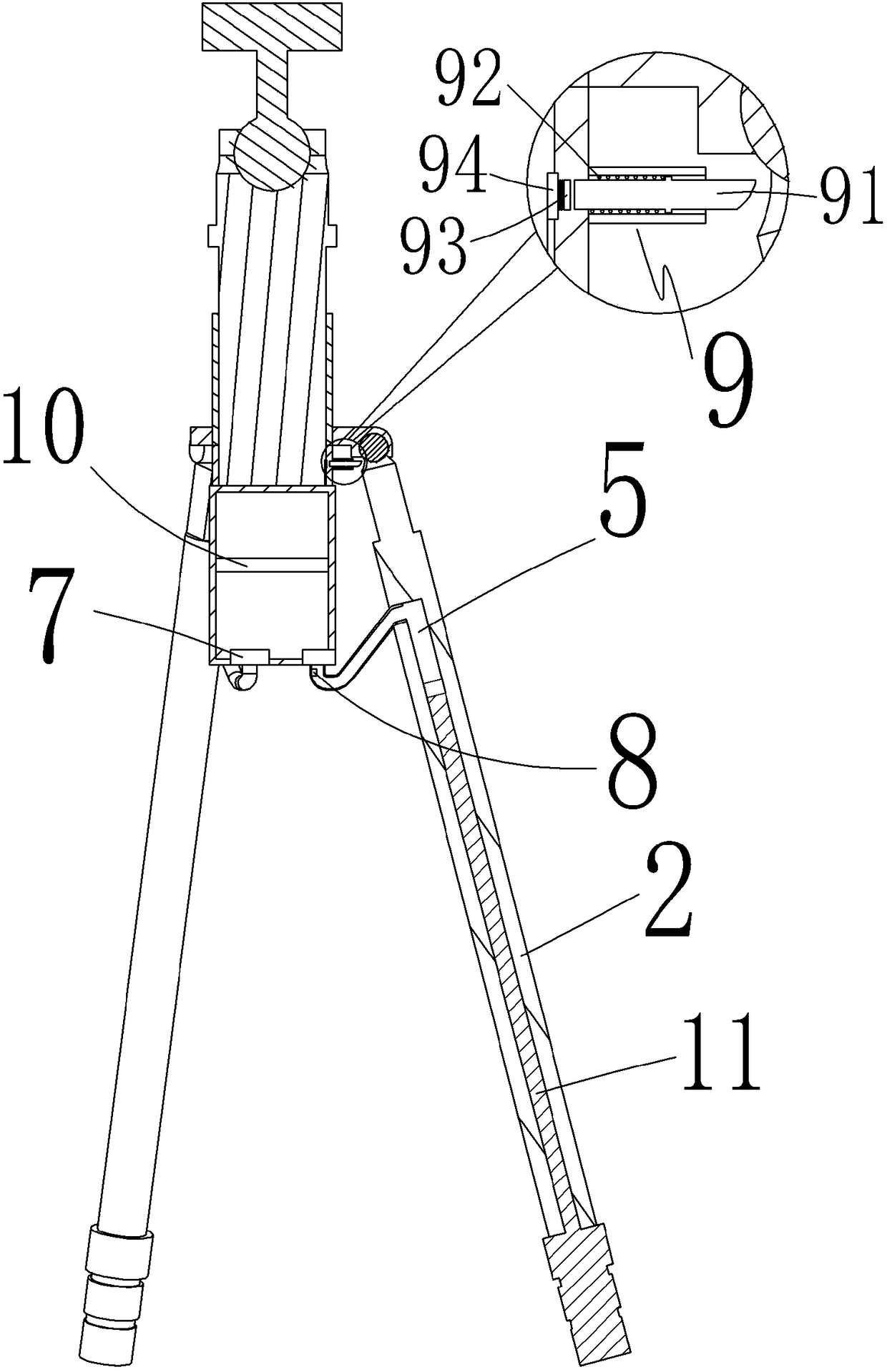

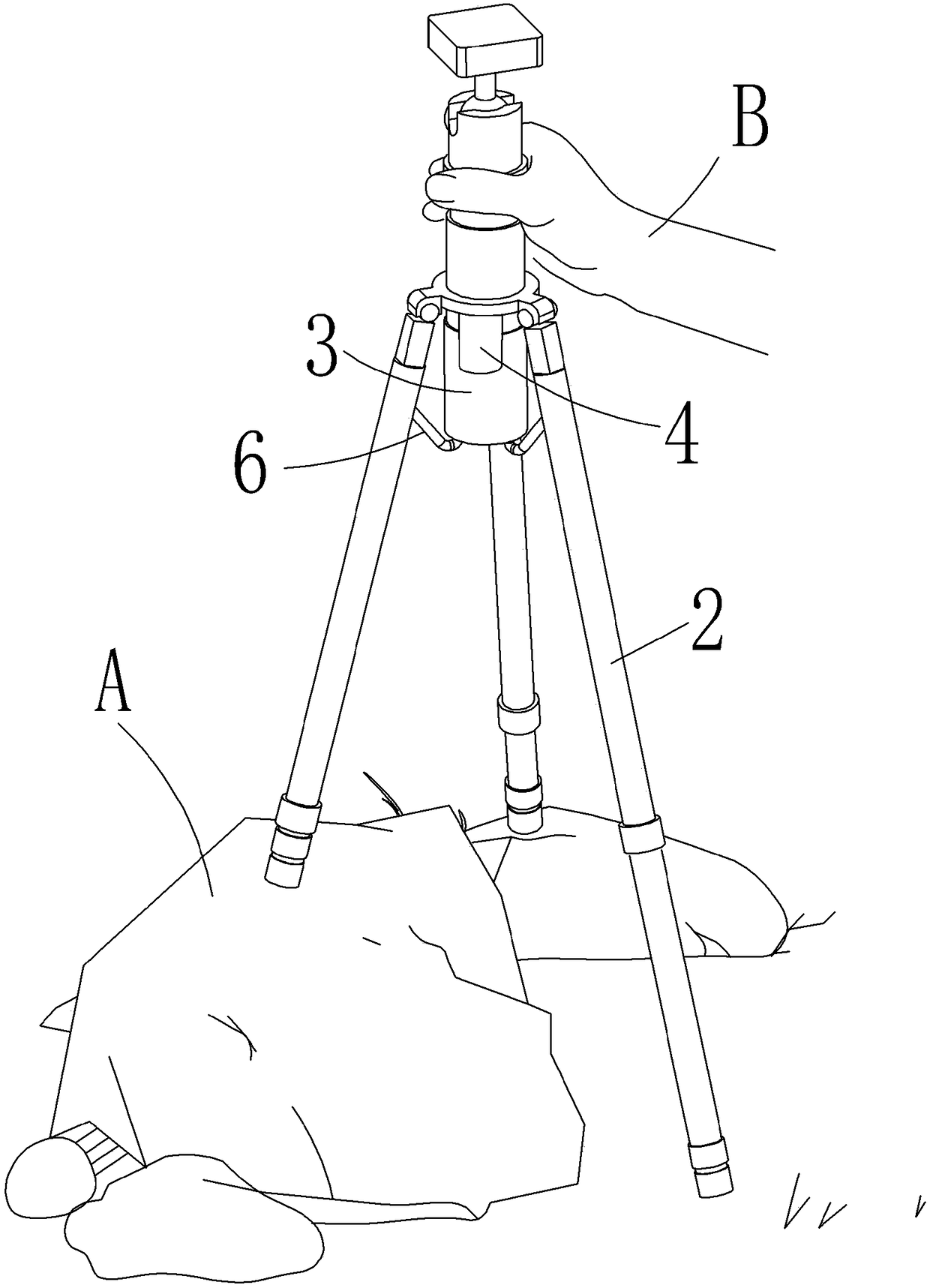

Camera support pressurization system

PendingCN108361523ANo manual contactEasy to useStands/trestlesCamera body detailsEngineeringAtmospheric pressure

The invention discloses a camera support pressurization system. The camera support pressurization system comprises a support body, wherein a plurality of telescopic supporting legs are arranged on thesupport body; the camera support pressurization system is characterized in that a pressurization cavity is arranged at the lower part of the support, one side of the pressurization cavity is providedwith a pneumatic pump, and the pneumatic pump is connected to the upper part of the pressurization cavity; the pressurization cavity comprises a plurality of connecting pipes which are arranged at the bottom and are connected to an inner pipe cavity of the supporting legs, a magnetic control valve is arranged on the openings of the connecting pipes, and one side of the magnetic control valve is further provided with a pressure sensor; and a main switch of the pneumatic pump, the magnetic control valve and the pressure sensor is arranged at the hinged position of the supporting legs, the mainswitch is turned on when the supporting legs are unfolded towards the periphery, and the main switch is turned off when the supporting legs are folded towards the center. According to the camera support pressurization system, the supporting legs are pressurized and stretched through the pneumatic pump, when the supporting legs meet resistance in the stretching process, the pressure sensor measuresthe pressure change, the magnetic control valve is directly or indirectly controlled to cut off the air pressure from the pressurization cavity, so that the supporting legs can be stretched and keptin an stretched state; and the supporting legs do not need to be touched manually, and are automatically adjusted according to the contact surface, so that time and labor are saved, and use is convenient and fast.

Owner:章伟松

An electric portable coal bunker depth detector

InactiveCN110671995BIncrease the speed of the ropeImprove work efficiencyMechanical depth measurementsElectric machineBunker

The invention relates to the technical field of coal bunker depth measurement, in particular to an electric portable coal bunker depth detector, which includes a handle, an upper unit fixing rod, a rotating shaft and a lower unit fixing rod, and the front end of the handle is fixedly connected with the upper, middle and lower distribution button, the lower end of the handle is fixedly connected with an upper unit fixing rod, the right side of the lower end of the upper unit fixing rod is fixedly connected with a rotating shaft, and the upper unit fixing rod is connected with a lower unit fixing rod through the rotation of the rotating shaft, and the lower unit fixing rod The front end of the unit fixed rod is slidingly connected with the limit device, and the left end face of the upper unit fixed rod and the left end face of the lower unit fixed rod are fixedly connected with a connecting device; By rotating the motor to drive the take-up wheel to rotate, the speed of releasing and receiving the rope can be increased, and there is no need for manual hand-held take-up and take-up, greatly improving work efficiency, easy operation, labor-saving, no manual contact, clean and hygienic, and has good practical value .

Owner:SHAANXI ZHENGTONG COAL IND CO LTD

Corrugated board forming automatic production line

ActiveCN104607551BLoad accuratelyConsistent moldingShaping toolsMetal-working feeding devicesProduction lineEngineering

A full-automatic production line for forming corrugated boards comprises a forming press and a board conveying device. The forming press comprises an n-shaped support. Two upper mold guide seats are arranged on two transverse side stand columns of the n-shpaed support respectively, an upper mold is installed between the two upper mold guide seats, an upper mold installation plate is arranged on the upper mold, the upper mold is in sliding fit with the upper mold guide seats through the upper mold installation plate, a press forming oil cylinder is arranged on the upper portion of the n-shaped support, a piston rod of the press forming oil cylinder is connected with the upper mold installation plate, a lower mold fixing plate is arranged on the lower portion of the n-shaped support, a lower mold is arranged on the lower mold fixing plate, the upper mold and the lower mold vertically correspond to each other, and a rack is arranged on the feeding side of the n-shaped support. The board conveying device comprises two lifting frames, an upper pressing roller and a lower pressing roller are installed between the two lifting frames, the two ends of the upper pressing roller are movably connected with lifting components of the two lifting frames respectively, and one end of the upper pressing roller is connected with a driving device. The full-automatic production line has the advantages of being simple in structure, low in manufacturing cost and convenient to use.

Owner:SHANDONG SHUIBO WELDING & CUTTING EQUIP MFG CO LTD

Rapid gynecological disease detection device

PendingCN114544969ANo pollution in the processNo manual contactSurgeryVaccination/ovulation diagnosticsEngineeringGynecological disease

The invention discloses a rapid gynecological disease detection device, and relates to the technical field of gynecological disease detection devices.The rapid gynecological disease detection device comprises a bottom plate used for containing a reagent containing box and a waste collecting box and further comprises a displacement adjusting assembly, a detection assembly and a control assembly, the displacement adjusting assembly is installed on the bottom plate through a support, and the displacement adjusting assembly is provided with a displacement end; the lifting adjusting assembly is installed at the displacement end of the displacement adjusting assembly, and the lifting adjusting assembly is provided with a lifting end; the non-contact mixing assembly is mounted at the lifting end of the lifting adjusting assembly, and the non-contact mixing assembly is not in direct contact with the diluent in the reagent tube for liquid mixing. Through cooperation of the displacement adjusting assembly and the lifting adjusting assembly, the non-contact mixing assembly can move to a designated position and conduct non-contact mixing treatment on reagent tubes, manual contact is not needed in the process, and safety and no pollution are achieved.

Owner:安徽深蓝医疗科技股份有限公司

Automatic assembling machine for big fransfusion bottle cover

A full-automatic assembling machine for the big plastic perfusion bottle and its cap is composed of machine frame, a power and drive unit, a delivering unit and a pressing unit. Said delivering unit has 2 or 3 material-driving sets cooperating with each other. Each set has a disk driven by rotating axle and with push teeth on its circum ference, and a supporting plate under said disk. Said pressing unit is a pressing wheel at the side of said disk and with pressing heads installed on its periphery for contacting with workpiece. Its advantages are high effeciency and less pollution.

Owner:王以友 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com