Toilet seat self-cleaning system and self-cleaning method thereof

A toilet seat and self-cleaning technology, which is applied in the field of sanitary ware, can solve the problems of poor sanitation of the toilet seat, achieve the effect of ensuring the sanitary condition, reducing the cleaning burden, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

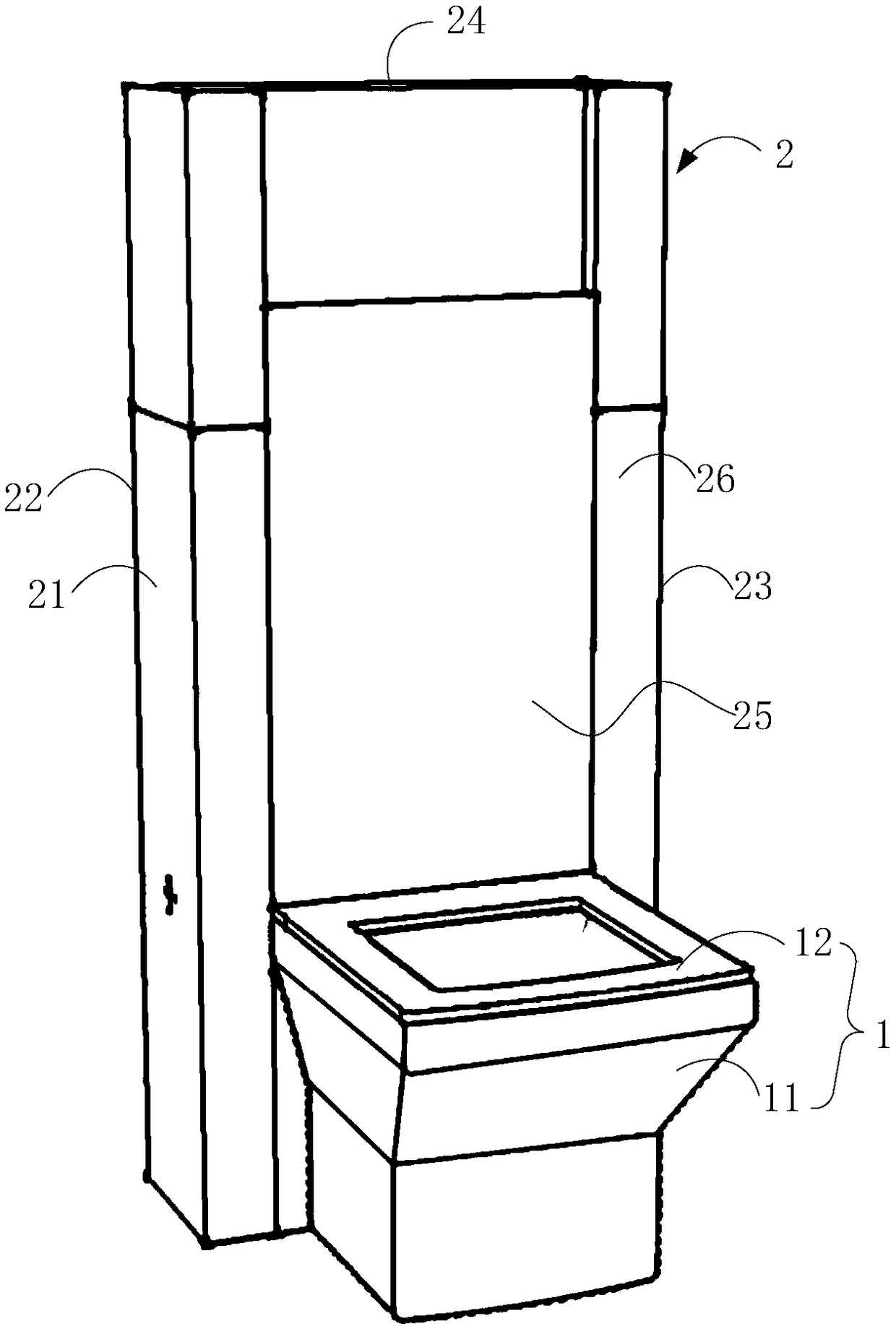

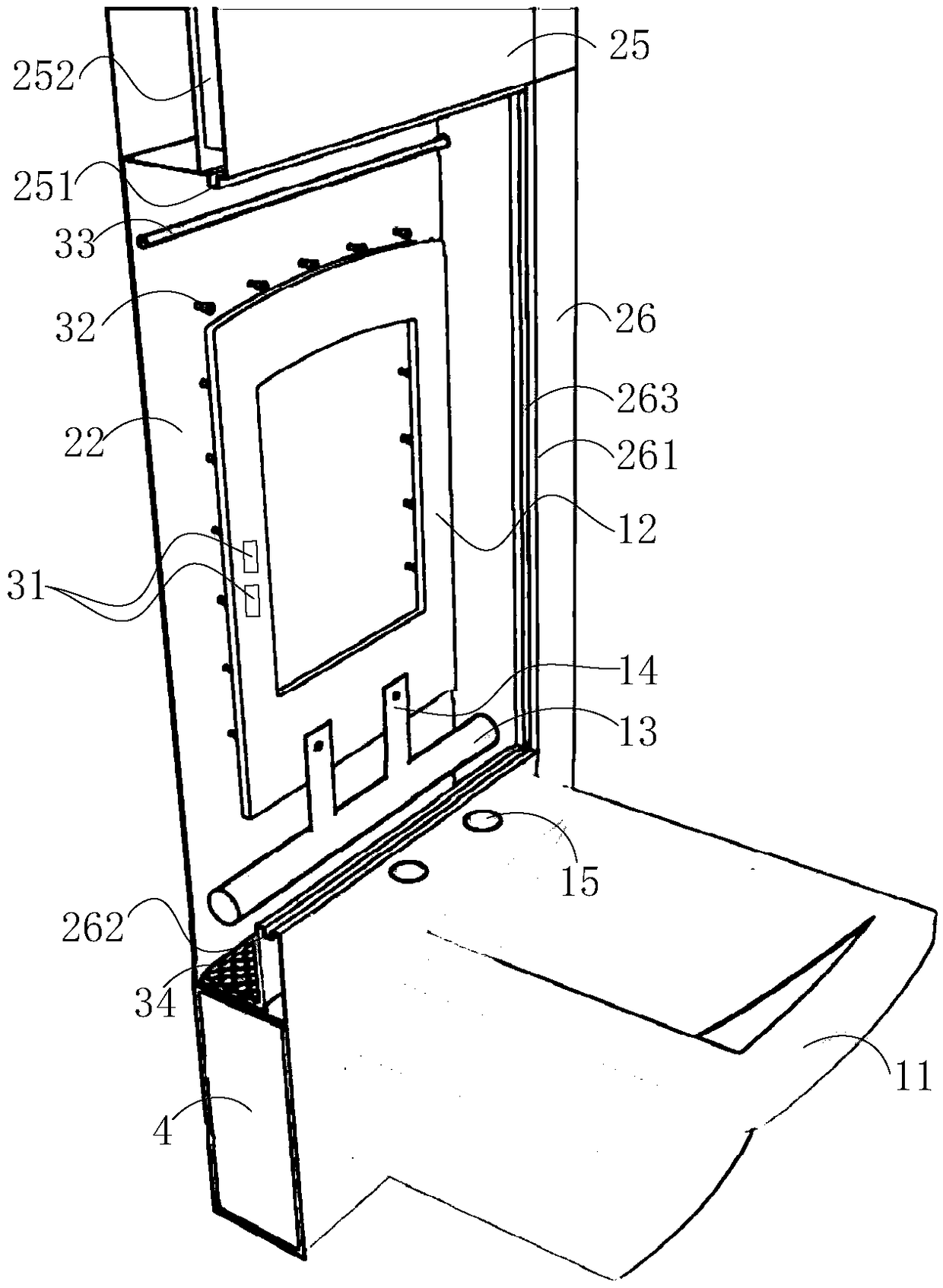

[0052] This embodiment provides a toilet seat self-cleaning system, such as Figure 1 to Figure 3 As shown, the toilet seat self-cleaning system includes: a toilet 1, a wall 2 and a self-cleaning component.

[0053] Wherein, toilet 1 comprises toilet body 11, toilet ring 12, rotating shaft 13 and connecting plate 14, and toilet body 11 is fixed on the ground (such as the ground that is covered with floor or ceramic tile, cement floor etc.), and rotating shaft 13 is located at toilet Between the body 11 and the toilet seat 12, it is used to drive the toilet seat 12 to rotate relative to the toilet body 11, the connecting plate 14 is a steel plate, one end of the connecting plate 14 is fixedly connected to the rotating shaft 13, and the other end is fixedly connected to the toilet seat 12, so that the rotation The rotation of the shaft 13 drives the toilet seat 12 to rotate upwards. At the position where the toilet body 11 is close to the joint between the toilet body 11 and th...

Embodiment 2

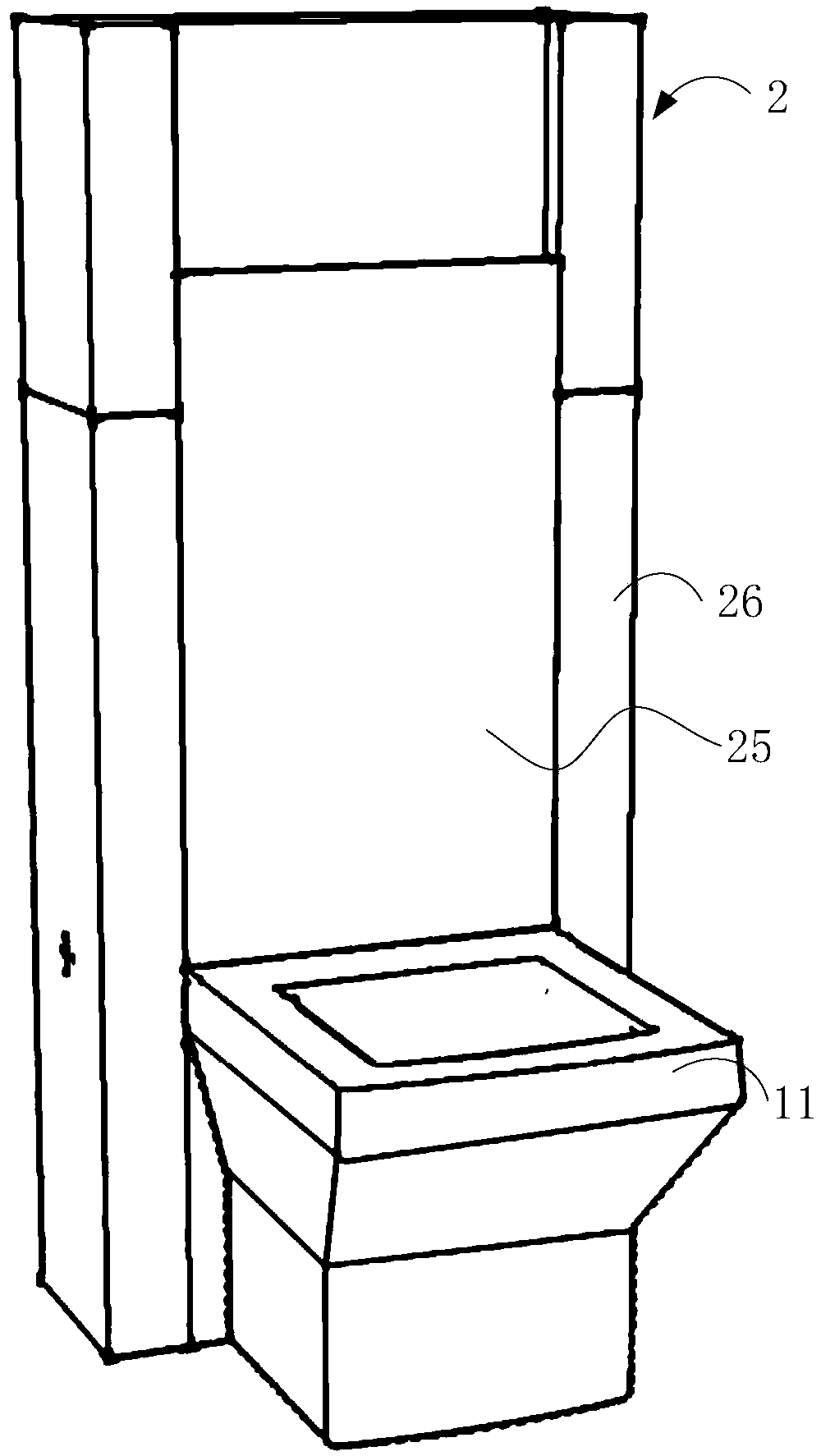

[0071] This embodiment provides a toilet seat self-cleaning system, such as Figure 4 to Figure 6 As shown, the toilet seat self-cleaning system includes: a toilet 1, a wall 2 and a self-cleaning assembly.

[0072] Wherein, toilet 1 comprises toilet body 11, toilet ring 12, rotating shaft 13 and connecting plate 14, and toilet body 11 is fixed on the ground (such as the ground that is covered with floor or ceramic tile, cement floor etc.), and rotating shaft 13 is located at toilet Between the body 11 and the toilet seat 12, it is used to drive the toilet seat 12 to rotate relative to the toilet body 11, the connecting plate 14 is a steel plate, one end of the connecting plate 14 is fixedly connected to the rotating shaft 13, and the other end is fixedly connected to the toilet seat 12, so that the rotation The rotation of the shaft 13 drives the toilet seat 12 to rotate upwards. At the position where the toilet body 11 is close to the joint between the toilet body 11 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com