Box-packed bean curd production technology

A production process, tofu technology, which is applied in the field of boxed tofu production process, can solve the problems of affecting sensory quality, sour flavor, and brittleness when fired, and achieve the effect of ensuring product quality and safety, firm and elastic texture, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

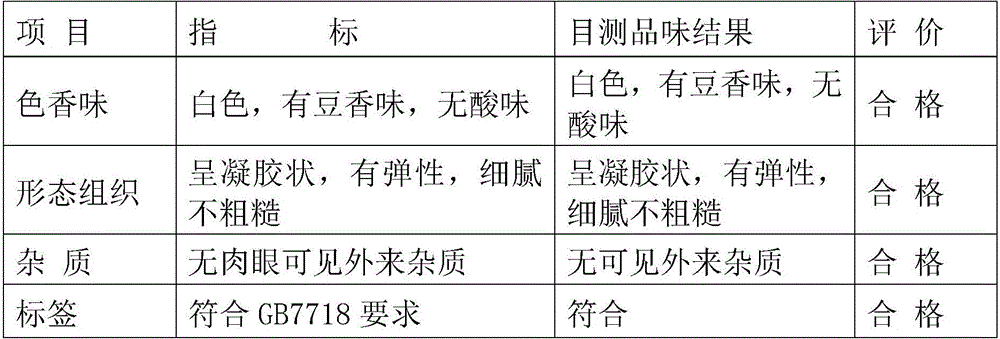

Examples

Embodiment 1

[0028] (1) Material selection: remove impurities and spoiled soybeans, and select fresh soybeans with plump and neat fruit as raw materials;

[0029] (2) Soaking: Soak the soybeans in water for 6 hours, the mass ratio of soybeans to water is 1:4, and the temperature of the water is controlled at 30°C;

[0030] (3) Refining: Refining soybeans and water according to the mass ratio of 1:3, the refining is carried out twice, the soybeans are first mixed with water and then coarsely ground to obtain a paste with a fineness of 400 μm, and then finely ground Grinding to obtain a ground paste with a fineness of 180 μm;

[0031] (4) Filtration: place the ground paste in a centrifuge for centrifugal filtration to obtain raw soybean milk, and repeat the centrifugal filtration twice;

[0032] (5) Boiling: put the raw soybean milk in a boiling tank, control the temperature at 95°C, and keep it for 10 minutes to obtain cooked soybean milk;

[0033] (6) Dipping: after the temperature of th...

Embodiment 2

[0036] (1) Material selection: remove impurities and spoiled soybeans, and select fresh soybeans with plump and neat fruit as raw materials;

[0037] (2) Soaking: Soak the soybeans in water for 12 hours, the mass ratio of soybeans to water is 1:5, and the temperature of the water is controlled at 25°C;

[0038] (3) Refining: Refining soybeans and water according to the mass ratio of 1:4, the refining is carried out twice, the soybeans are first mixed with water and then coarsely ground to obtain a paste with a fineness of 800 μm, and then finely ground Grinding to obtain a ground paste with a fineness of 190 μm;

[0039] (4) Filtration: place the ground paste in a centrifuge for centrifugal filtration to obtain raw soybean milk, and repeat the centrifugal filtration twice;

[0040] (5) Boiling: put raw soybean milk in a boiling tank, control the temperature at 98°C, and keep it for 7 minutes to obtain cooked soybean milk;

[0041] (6) Dipping: After the temperature of the co...

Embodiment 3

[0044](1) Material selection: remove impurities and spoiled soybeans, and select fresh soybeans with plump and neat fruit as raw materials;

[0045] (2) Soaking: Soak the soybeans in water for 18 hours, the mass ratio of soybeans to water is 1:6, and the temperature of the water is controlled at 20°C;

[0046] (3) Refining: Refining soybeans and water at a mass ratio of 1:5, the refining is divided into two times, firstly mixing soybeans with water and then coarsely grinding to obtain a paste with a fineness of 1000 μm, and then finely grinding Grinding to obtain a ground paste with a fineness of 200 μm;

[0047] (4) Filtration: the ground paste is placed in a centrifuge for centrifugal filtration to obtain raw soybean milk, and the centrifugal filtration is repeated 3 times;

[0048] (5) Boiling: put raw soybean milk in a boiling tank, control the temperature at 100°C, and keep it for 5 minutes to obtain cooked soybean milk;

[0049] (6) Order pulp: After the temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com