Full-automatic straw production method and full-automatic production line

A production method and fully automatic technology, applied to tubular objects, other household utensils, household utensils, etc., can solve the problems of high labor cost, low degree of automation, and low sanitation conditions, and achieve low labor costs, high dimensional accuracy, Reduce the effect of the production link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

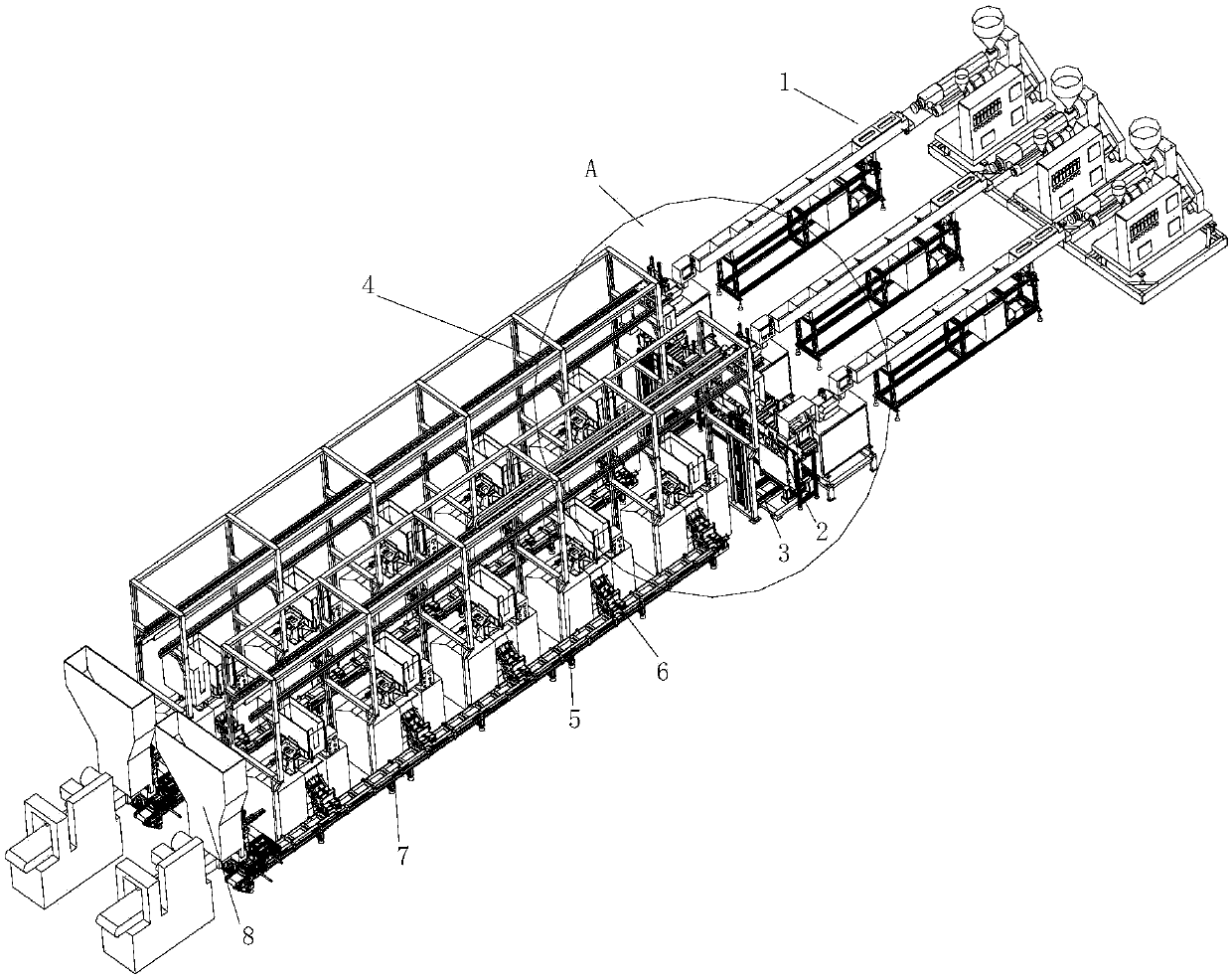

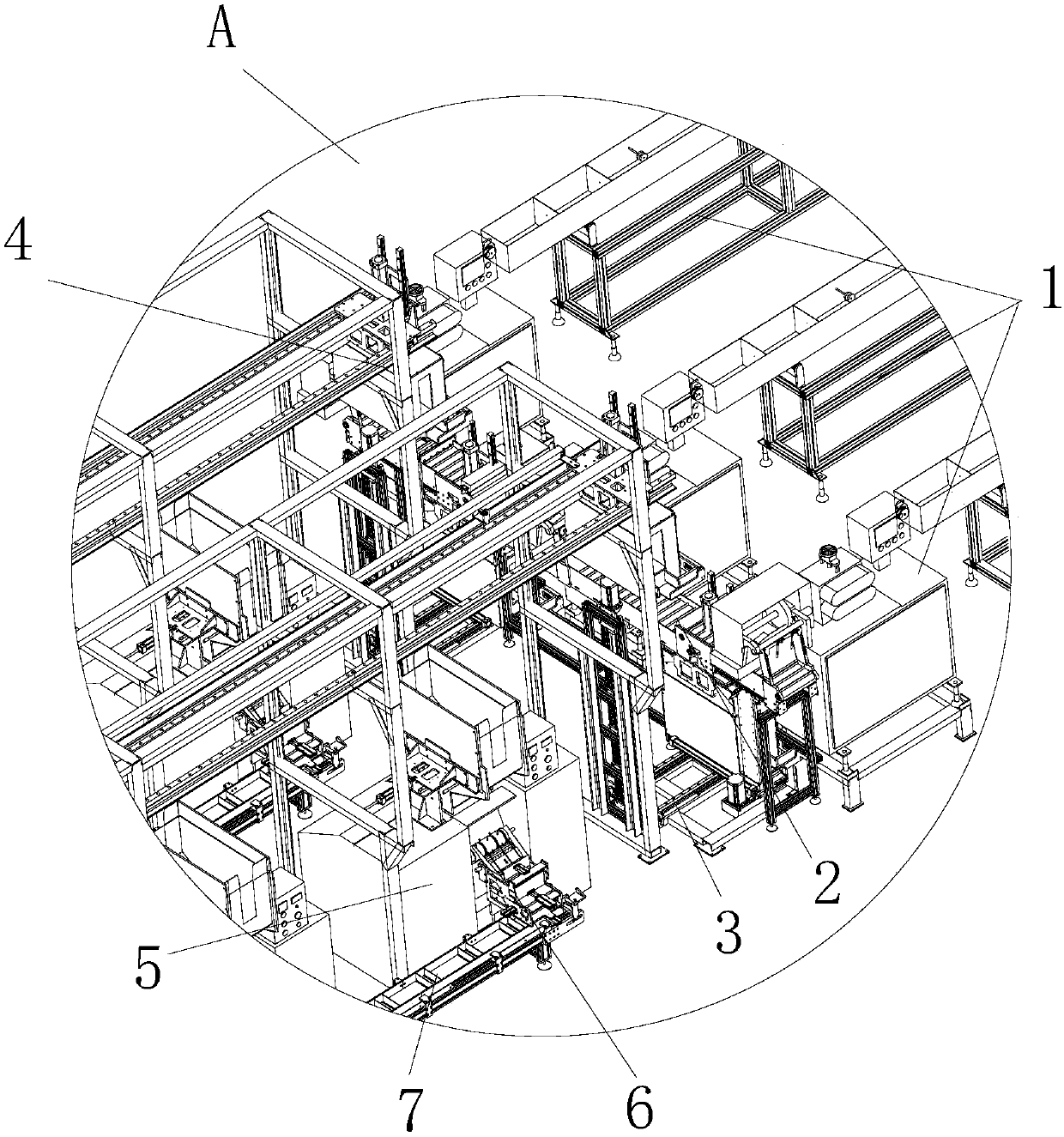

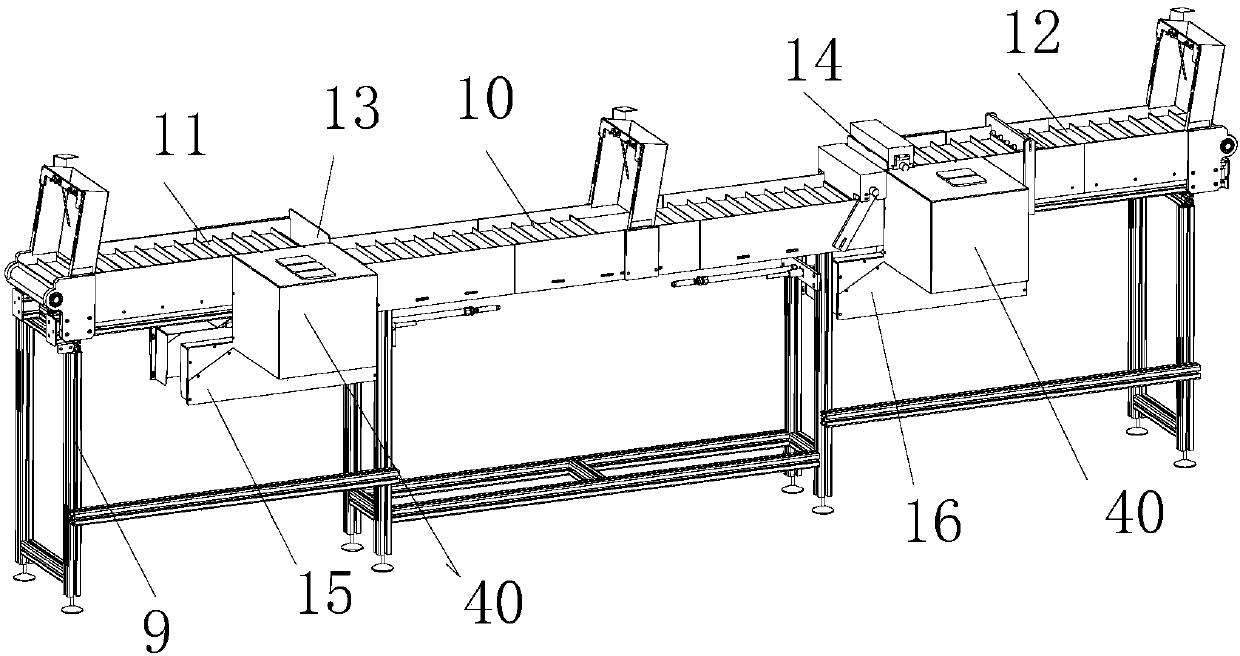

[0045] Example: see Figure 1 to Figure 7 , the present embodiment provides a fully automatic production method for straws, which includes the following steps:

[0046] (1) Extrusion molding: three extrusion production lines 1 are set, and the extrusion production line 1 includes a feeding section, a heating section, an extrusion section, a cutting section and a first conveying line; feeding to the feeding section of the extrusion production line 1, The heating part of the extrusion production line 1 starts to work at the same time, and the extruder of the extrusion production line 1 is debugged. After the debugging is completed, the extruder is extruded and cut to form a straight tube;

[0047] When debugging the extruder, the extruder in the middle should be debugged first, and then the extruders on both sides should be debugged.

[0048] (2) pipe mixing: a pipe mixing device 2 is set, and the pipe mixing device 2 is connected with the first conveying line; Tube device 2 u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com