Oxidative calcining device for processing of ammonium paratungstate

A calcining device, the technology of ammonium paratungstate, applied in tungsten compounds, packaging, inorganic chemistry, etc., can solve the problems of troublesome operation, contamination of fine ammonium paratungstate powder, physical injury of operators, etc., so as to reduce the trouble of cleaning packaging bags and improve operation safety. , Reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

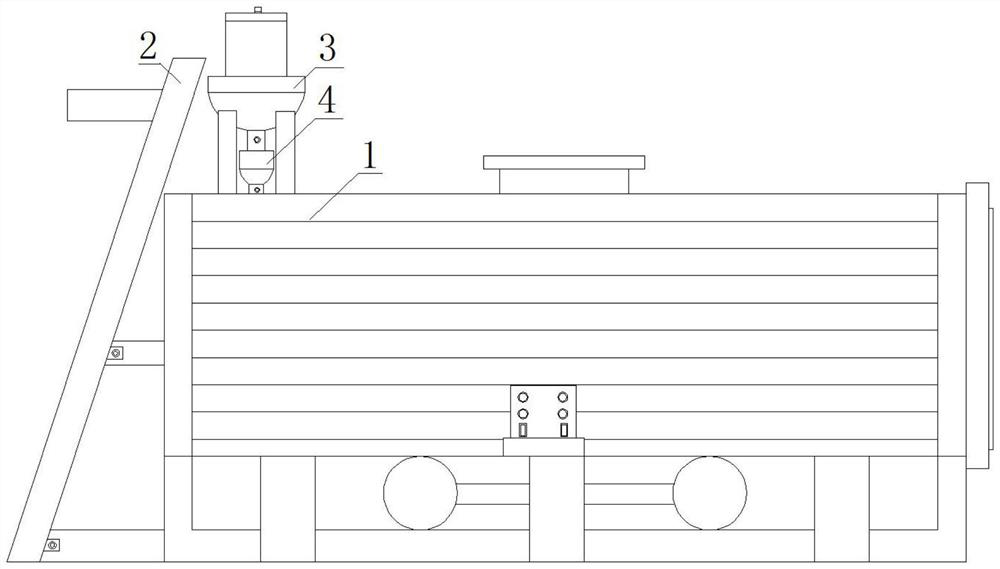

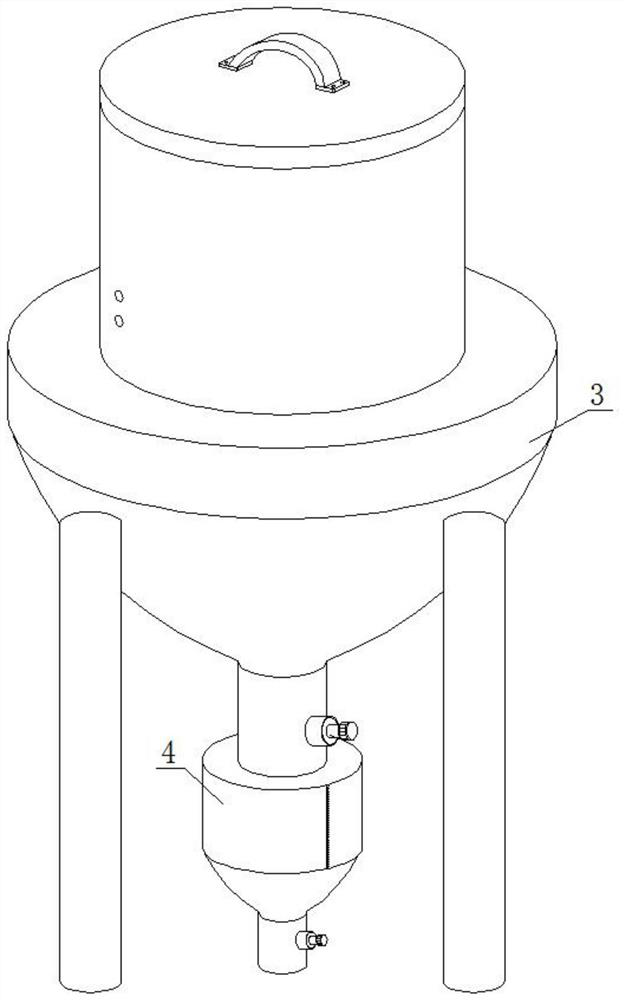

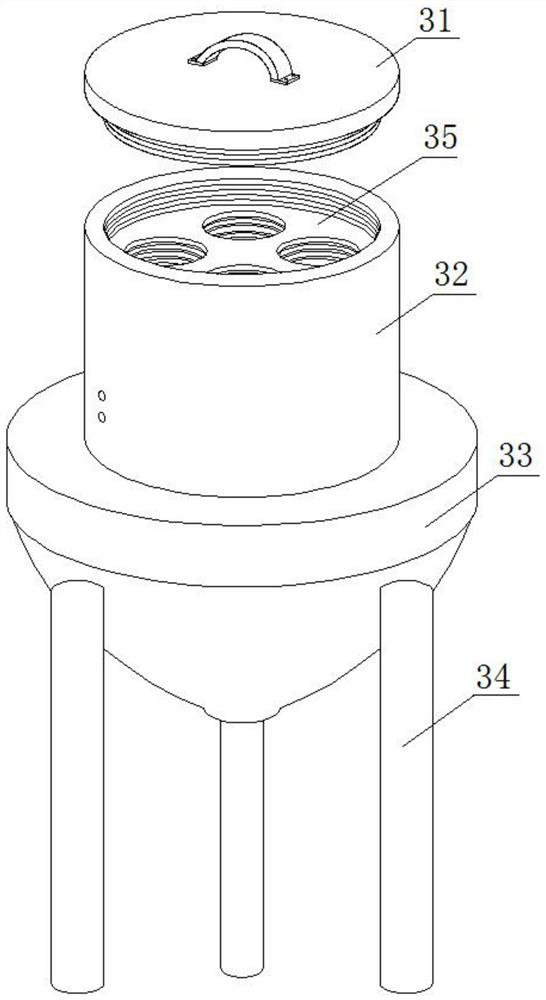

[0034] see Figure 1-3, an oxidation calcination device for ammonium paratungstate processing, comprising an oxidation calcination main machine 1, a ladder 2, a feeding mechanism 3 and a discharge mechanism 4, the ladder 2 is arranged at one end of the oxidation calcination main machine 1, and the upper end of the ladder 2 is connected to the feeding mechanism 3 The level of the middle part is the same, the feeding mechanism 3 is set on the upper end side of the oxidation calcining host 1, the upper end of the discharge mechanism 4 is connected to the lower end of the feeding mechanism 3, and the lower end of the discharge mechanism 4 is connected to the material inlet of the oxidation calcining host 1 Connected, the feeding mechanism 3 includes a sealing cover 31, a discharge mechanism 32, a storage tank 33 and a support column 34, the lower end of the sealing cover 31 is threadedly connected with the upper end of the discharge mechanism 32, and the discharge mechanism 32 is a...

Embodiment 2

[0040] see Figure 1-3 , an oxidation calcination device for ammonium paratungstate processing, comprising an oxidation calcination main machine 1, a ladder 2, a feeding mechanism 3 and a discharge mechanism 4, the ladder 2 is arranged at one end of the oxidation calcination main machine 1, and the upper end of the ladder 2 is connected to the feeding mechanism 3 The level of the middle part is the same, the feeding mechanism 3 is set on the upper end side of the oxidation calcining host 1, the upper end of the discharge mechanism 4 is connected to the lower end of the feeding mechanism 3, and the lower end of the discharge mechanism 4 is connected to the material inlet of the oxidation calcining host 1 Connected, the feeding mechanism 3 includes a sealing cover 31, a discharge mechanism 32, a storage tank 33 and a support column 34, the lower end of the sealing cover 31 is threadedly connected with the upper end of the discharge mechanism 32, and the discharge mechanism 32 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com