Centrifugal type wind-blowing-off and pressing-ring tearing-off method of fresh corn husk

A fresh corn, centrifugal technology, applied in threshing equipment, applications, agricultural machinery and tools, etc., can solve the problems of easy scratches on the surface of corn, low corn peeling efficiency, unsatisfactory peeling rate and seed breaking rate, etc. Achieve the effect of thorough peeling and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

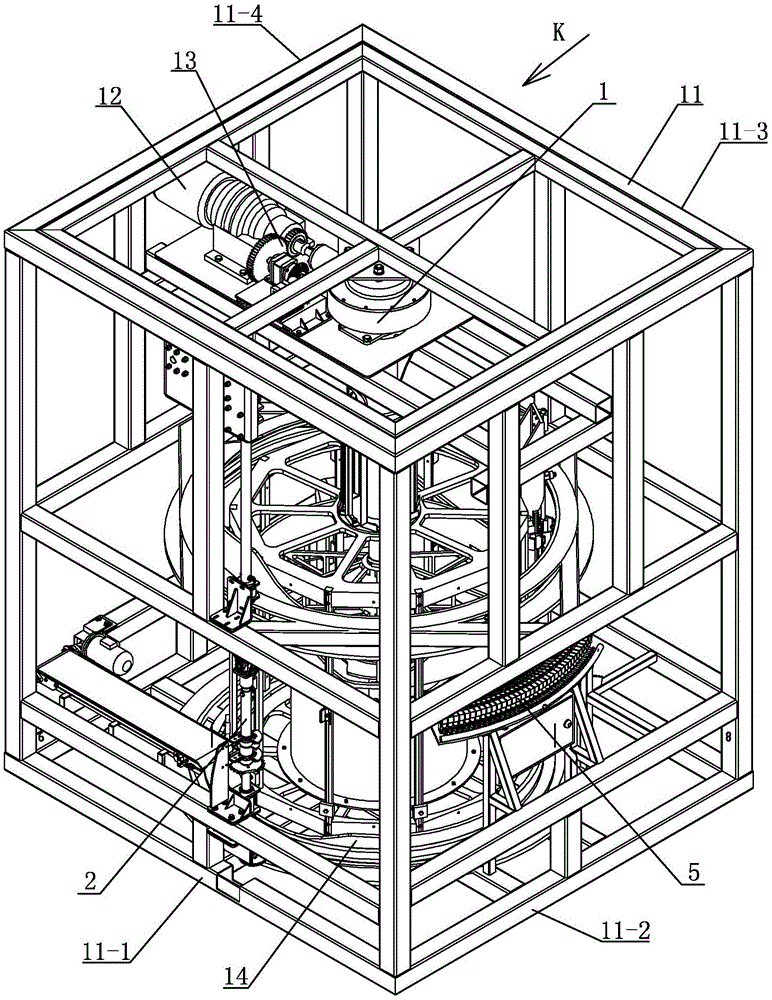

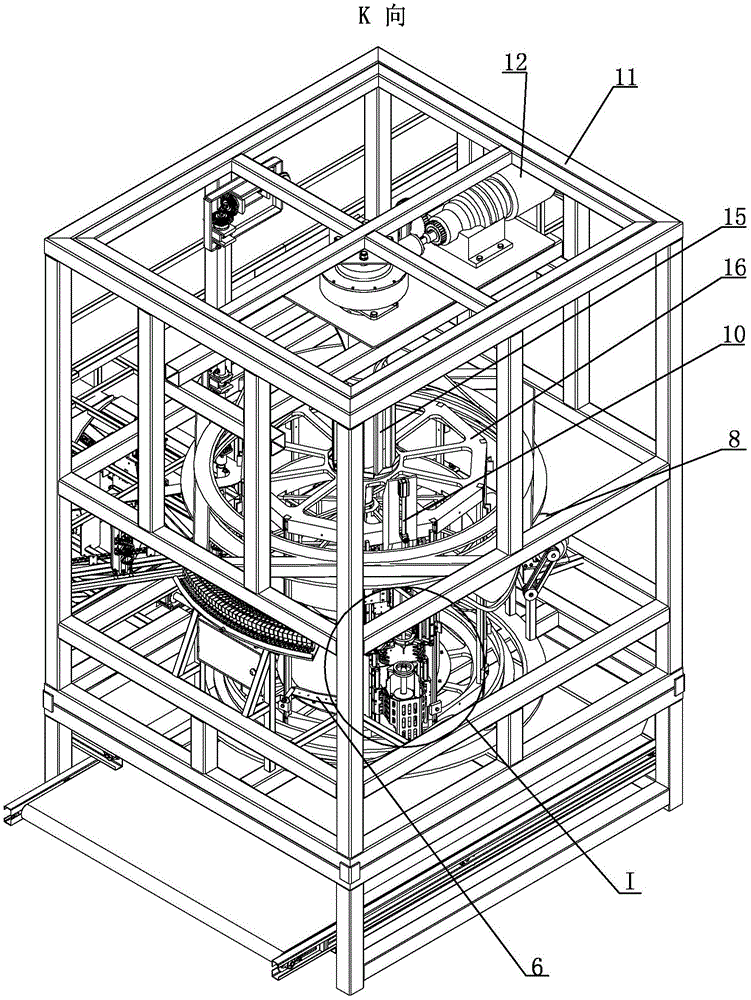

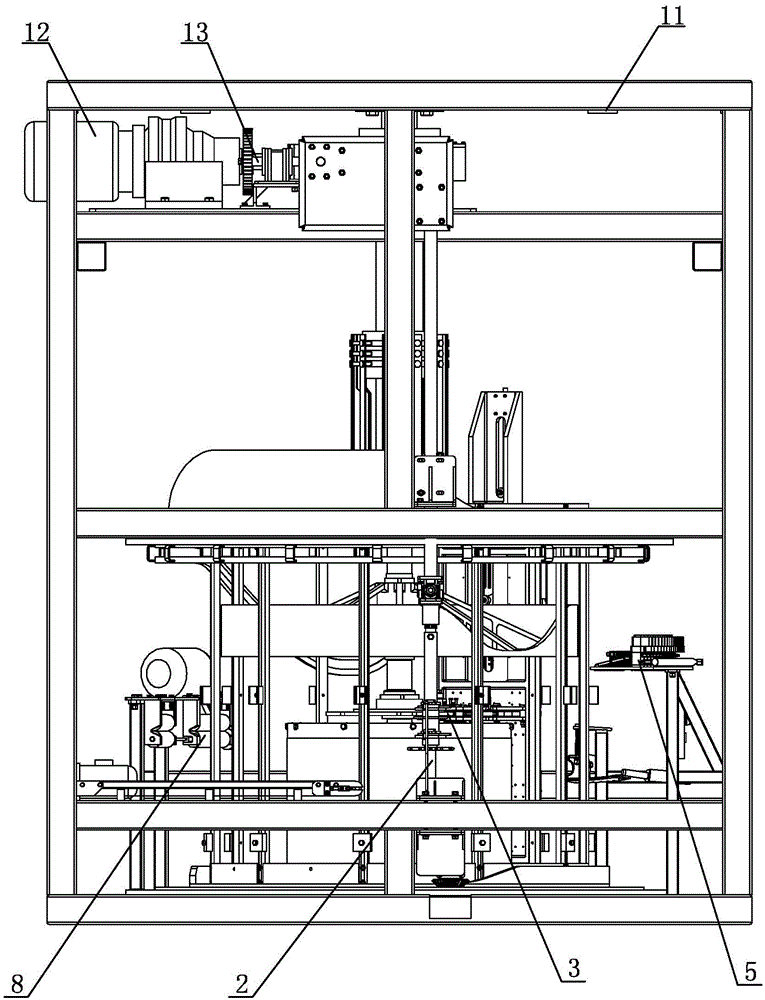

[0028] Specific implementation mode one: combine Figure 1 to Figure 16 Describe this implementation mode, this implementation mode is realized through the following steps:

[0029] Step 1. Install corn: the corn 17 is transported to the rotary knife 2 on the host system 1 by a transport trolley, the corn clamping robot 3 clamps the corn 17 to the rotary knife 2, and the tip of the rotary knife 2 is inserted into the root of the corn , at the same time, the thimble 9-1 on the limit mechanism 9 at the top of the corn is inserted into the top of the corn;

[0030] Step 2. Centrifugally rotate the corn 17: The corn 17 starts to rotate under the drive of the rotary knife 2. The rotating speed of the rotary knife 2 is 200 rpm to 2000 rpm. Due to the centrifugal force, the corn husk 17-1 spreads outwards In an open state, the open state is that the angle α between the corn husk 17-1 and the bottom horizontal plane of the corn 17 is 11°-100°;

[0031] Step 3. Blowing off the corn h...

specific Embodiment approach 2

[0039] Specific implementation mode two: combination figure 1 with image 3 To describe this embodiment, the rotation speed of the rotary knife 2 in the step 2 of this embodiment is 1000 rpm. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0040] Specific implementation mode three: combination Figure 12 To illustrate this embodiment, when the corn husk 17-1 is in an open state in Step 2 of this embodiment, the angle α between the corn husk 17-1 and the bottom horizontal plane of the corn 17 is 50°. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com