High-efficiency persimmon peeling machine

A high-efficiency, peeling machine technology, applied in the fields of vegetable or fruit peeling, food science, application, etc., can solve the problems of time-consuming and labor-consuming, hidden sanitation, low efficiency, etc., and achieve the goal of expanding the grasping range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

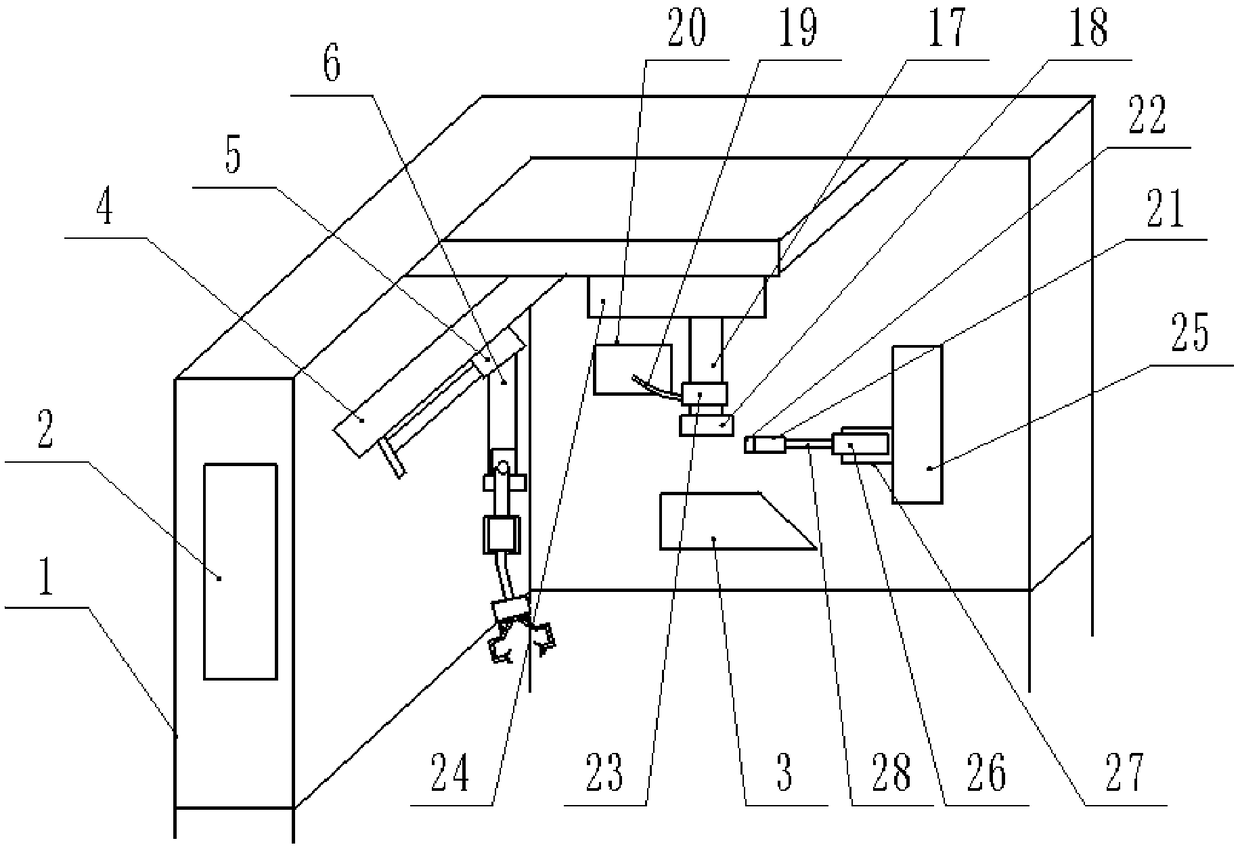

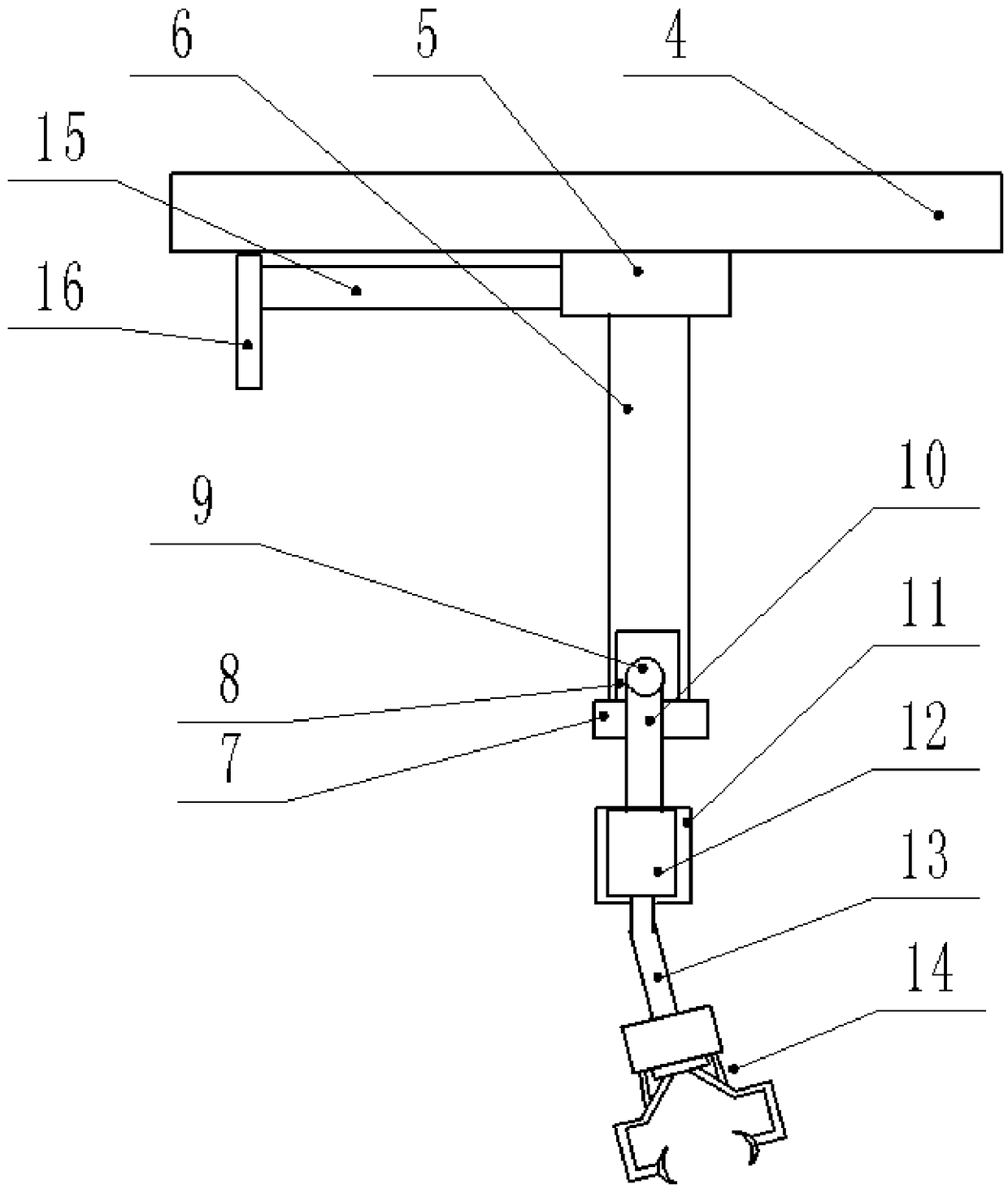

[0033] See figure 1 and figure 2 , a high-efficiency persimmon peeling machine, comprising a frame 1, the frame 1 is provided with a controller 2, an automatic grabbing device, an automatic peeling device and a collecting hopper 3, the automatic grabbing device and the automatic The peeling device is matched and connected, and the collecting hopper 3 is movably arranged on the frame 1 and is located below the suction cup 18 in the automatic peeling device. Preferably, the persimmon peeling machine also includes a second linear motor (not shown) arranged in the frame 1, the second linear motor is connected to the controller, and the collecting hopper 3 is connected to the controller. The second linear motor is connected through a connecting rod so as to drive the collecting hopper 3 to perform reciprocating linear motion through the second linear motor. When the peeler was peeling, the collecting hopper 3 was positioned at the bottom right of the suction cup 18, and when the...

Embodiment 2

[0042] In this embodiment, except that the parts by weight of the constituents of the materials used to make the ceramic knife and the average particle size of each material are different, everything else is the same as in Example 1.

[0043] In this embodiment, the manufacturing materials of the ceramic knife all include the following components by weight: 3 parts of graphene, 3 parts of magnesium oxide, 5 parts of yttrium oxide, 3 parts of aluminum oxide, 15 parts of silicon nitride, 1.5 parts of titanium carbide and 1.5 parts of titanium nitride. Wherein, the average thickness of the graphene is 20 nm, and the average longest diameter of the graphene is 5 μm. The average particle size of the magnesium oxide is 1 μm; the average particle size of the yttrium oxide and the aluminum oxide is 1 μm; the average particle size of the silicon nitride is 0.5 μm. The average particle size of the titanium carbide is 2 μm. The average particle size of the titanium nitride is 0.75 μm. ...

Embodiment 3

[0045] In this embodiment, except that the parts by weight of the constituents of the materials used to make the ceramic knife and the average particle size of each material are different, everything else is the same as in Example 1.

[0046] In this embodiment, the manufacturing materials of the ceramic knife all include the following components by weight: 5 parts of graphene, 5 parts of magnesium oxide, 7 parts of yttrium oxide, 5 parts of aluminum oxide, 25 parts of silicon nitride, 2 parts of titanium carbide and 2 parts of titanium nitride. Wherein, the average thickness of the graphene is 30 nm, and the average longest diameter of the graphene is 8 μm. The average particle size of the magnesium oxide is 1.5 μm; the average particle size of the yttrium oxide and the aluminum oxide is 1.5 μm; the average particle size of the silicon nitride is 0.9 μm. The average particle size of the titanium carbide is 3 μm. The average particle size of the titanium nitride is 1 μm.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com