Method for expelling carbonate in production of aluminum oxide

A kind of alumina and carbonate technology, applied in the direction of alumina/hydroxide, etc., can solve the problems of difficult production control and poor salt discharge effect, and achieve convenient and accurate lye deployment operation, speed up the precipitation speed, and simplify the process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

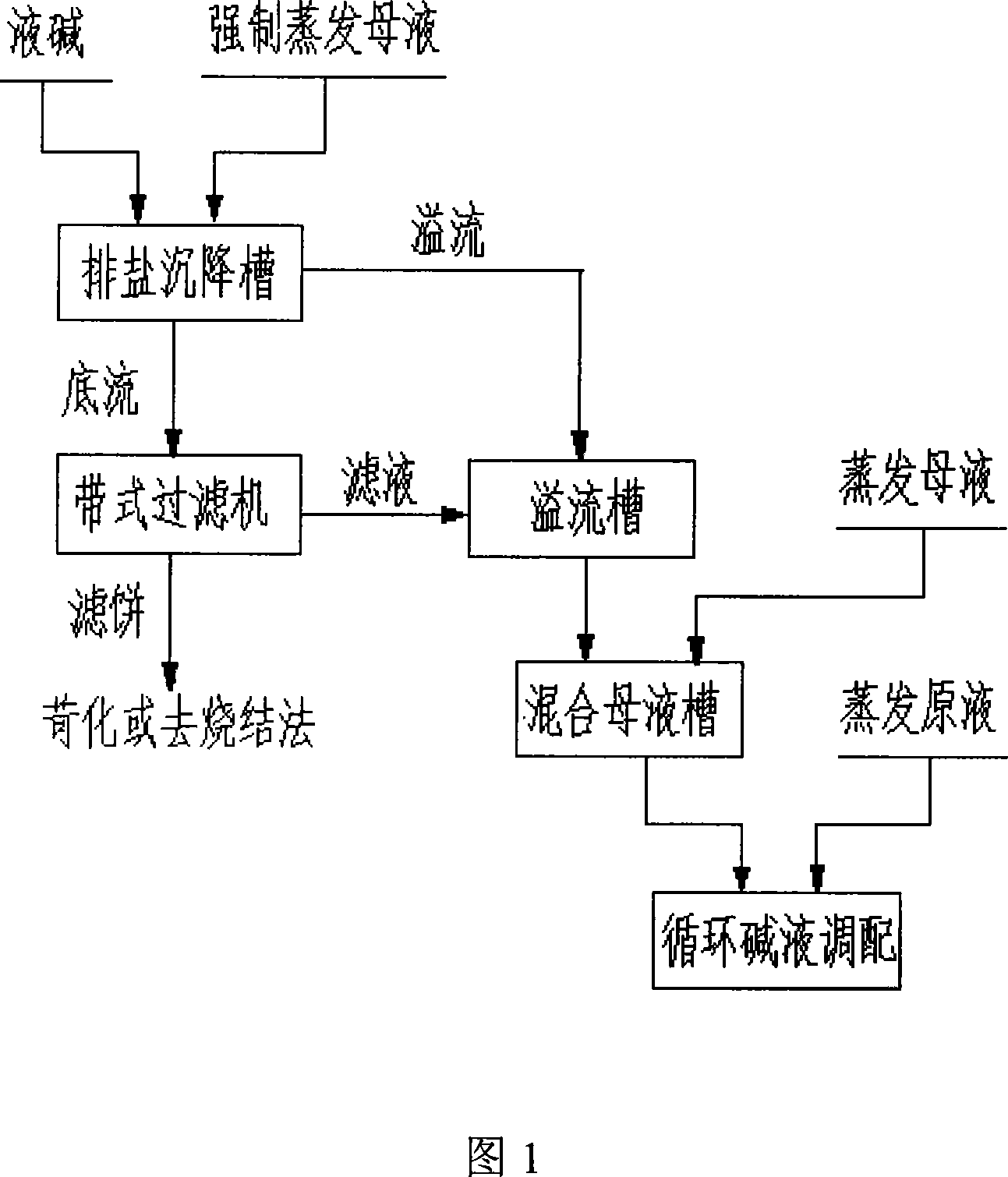

[0013] A method for removing carbonates in alumina production. The process is to pump the liquid caustic to supplement the Bayer process system and the mother liquor through the forced circulation evaporator to the salt discharge sedimentation tank, and the bottom flow of the sedimentation tank adopts a belt type The filter performs liquid-solid separation, and the filtrate and the overflow of the settling tank enter the overflow tank together, and the mixed mother liquor and evaporation stock liquid after the liquid caustic soda, the settling tank overflow, and the evaporation mother liquor are mixed in proportion to the circulating alkali liquor; the filter filters The cake is causticized or returned to the sintering method to produce alumina. Because the normal temperature and high concentration of liquid caustic soda is added to the salt discharge sedimentation tank, the temperature of the sedimentation tank can be reduced and the caustic concentration of the solution can be i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com