Ultrahigh-strength soluble magnesium alloy as well as preparation method and application thereof

An ultra-high-strength, magnesium alloy technology, applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., can solve the problems that high-strength soluble magnesium alloys cannot meet, and achieve high tensile strength and high dissolution rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

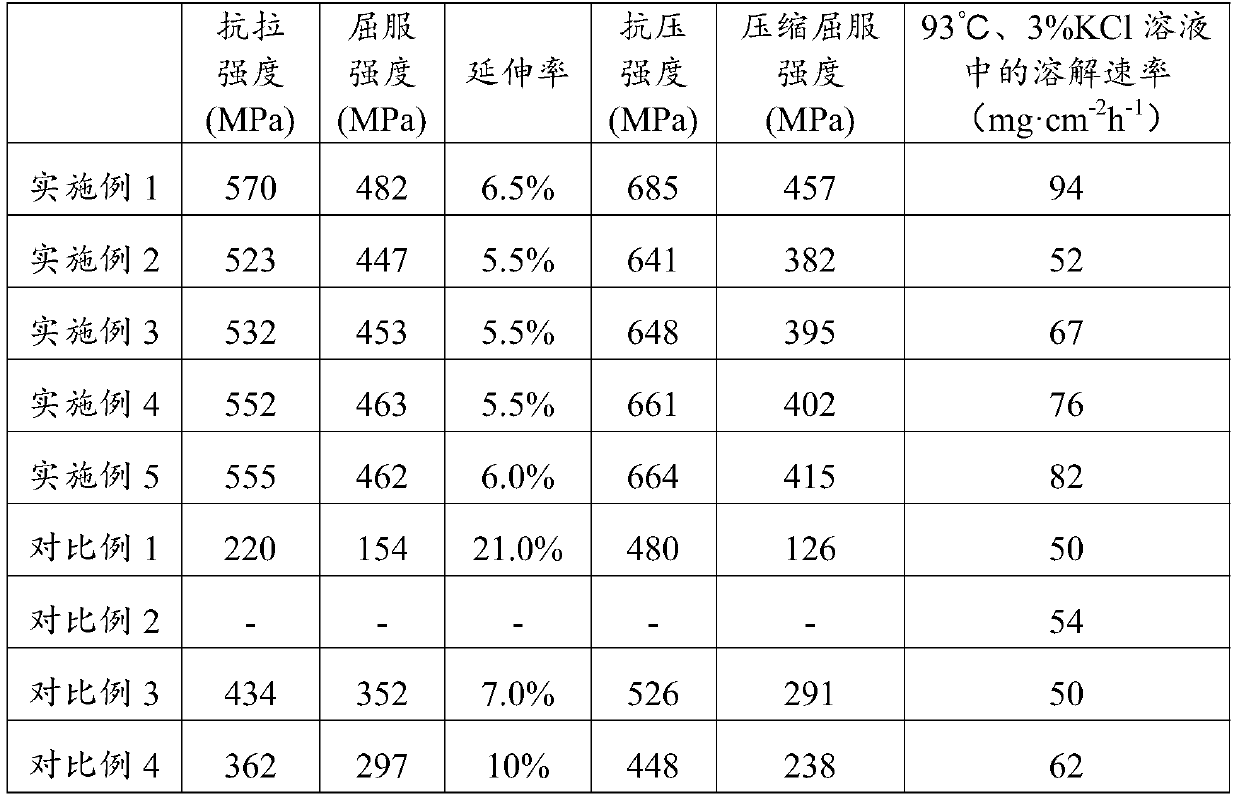

Embodiment 1

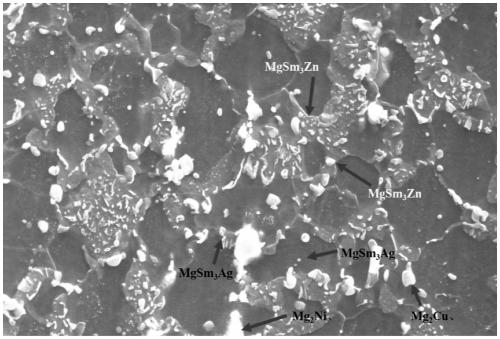

[0052] The ultra-high-strength dissolvable magnesium alloy described in this embodiment is composed of the following elements in mass percentage: Sm8.0wt%, Sc 0.1wt%, Zn 1.0wt%, Ag 0.25wt%, Cu 1.0wt%, Ni 0.5wt% %, the mass percentage of impurity elements is 0%-0.1%, and the rest is Mg.

[0053] The preparation method of the ultra-high strength dissolvable magnesium alloy described in this embodiment is as follows:

[0054] 1. Weigh the raw materials according to the ratio of the above mass percentages. The above raw materials are pure magnesium ingots, pure zinc ingots, pure silver powder, pure copper, Mg-Sm master alloys, Mg-Sc master alloys, and Mg-Ni master alloys.

[0055] 2. Under the protection of argon, melt at 720°C, melt for 40 minutes, stir for 20 minutes, and refine for 30 minutes. After refining, heat up to 760°C, stand for 40 minutes, and cast at 660°C to form a semi-continuous ingot;

[0056] 3. Take the above ingot for homogenization treatment, at 480°C, hold f...

Embodiment 2

[0061] The ultra-high-strength dissolvable magnesium alloy described in this embodiment is composed of the following elements in mass percentage: Sm10.0wt%, Sc 0.2wt%, Zn 1.4wt%, Ag 0.5wt%, Cu 2.0wt%, Ni 1.2wt% %, the mass percentage of impurity elements is 0%-0.1%, and the rest is Mg.

[0062] The preparation method of the ultra-high strength dissolvable magnesium alloy described in this embodiment is as follows:

[0063] 1. Weigh the raw materials according to the ratio of the above mass percentages. The above raw materials are pure magnesium ingots, pure zinc ingots, pure silver powder, pure copper, Mg-Sm master alloys, Mg-Sc master alloys, and Mg-Ni master alloys.

[0064] 2. Under the protection of argon, melt at 740°C, melt for 60 minutes, stir for 20 minutes, and refine for 40 minutes. After refining, heat up to 760°C, stand for 40 minutes, and cast at 680°C to form a semi-continuous ingot;

[0065] 3. Take the above ingot for homogenization treatment, at 480°C, hold f...

Embodiment 3

[0070] The ultra-high-strength dissolvable magnesium alloy described in this embodiment is composed of the following elements in mass percentage: Sm7.0wt%, Sc 0.05wt%, Zn 0.2wt%, Ag 0.25wt%, Cu 0.5wt%, Ni 0.5wt% %, the mass percentage of impurity elements is 0%-0.1%, and the rest is Mg.

[0071] The preparation method of the ultra-high strength dissolvable magnesium alloy described in this embodiment is as follows:

[0072] 1. Weigh the raw materials according to the ratio of the above mass percentages. The above raw materials are pure magnesium ingots, pure zinc ingots, pure silver powder, pure copper, Mg-Sm master alloys, Mg-Sc master alloys, and Mg-Ni master alloys.

[0073] 2. Under the protection of argon, melt at 710°C, melt for 30 minutes, stir for 10 minutes, and refine for 30 minutes. After refining, heat up to 740°C, stand for 30 minutes, and cast at 650°C to form a semi-continuous ingot;

[0074] 3. Take the above ingot for homogenization treatment, at 400°C, hold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com