Acid etching liquid regenerative cycle method and system

An acidic etching solution and acidic technology, which is applied in the direction of photographic process, instrument, photographic auxiliary process, etc., can solve the problems of inability to recycle etching liquid, low efficiency of copper sheet recovery, and low efficiency of electrolytic copper extraction, so as to save oxidant and hydrochloric acid The use, simple structure, and the effect of reducing the generation of harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: A method for regenerating and circulating acidic etching solution.

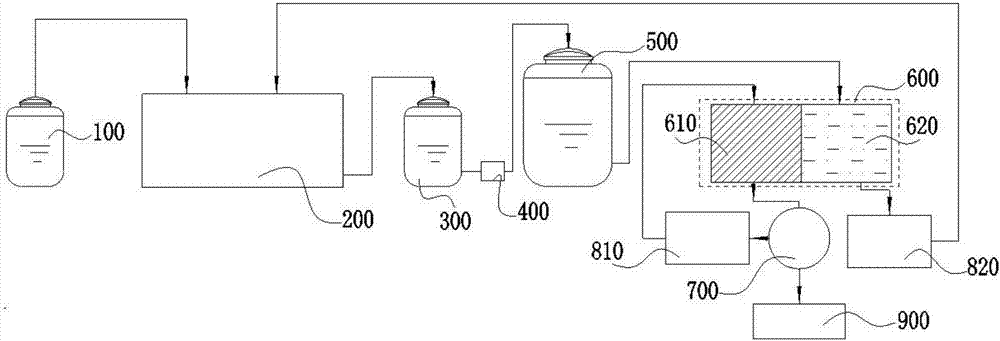

[0029] refer to figure 1 Shown, a kind of acidic etchant regeneration cycle method specifically comprises the following steps:

[0030] S1, the collection of acid etching solution, the acid etching solution produced on the PCB acid etching production line is collected to the waste liquid tank through pipelines;

[0031] S2. Filtration and deployment of acid etching solution. The acid etching solution after precipitation and stabilization in the waste liquid tank is filtered through a filter and then transported into the electrolyte preparation tank for deployment. Clear water is added to the electrolyte preparation tank to remove copper in the acid etching electrolyte. The ion concentration is adjusted to 40 g / L;

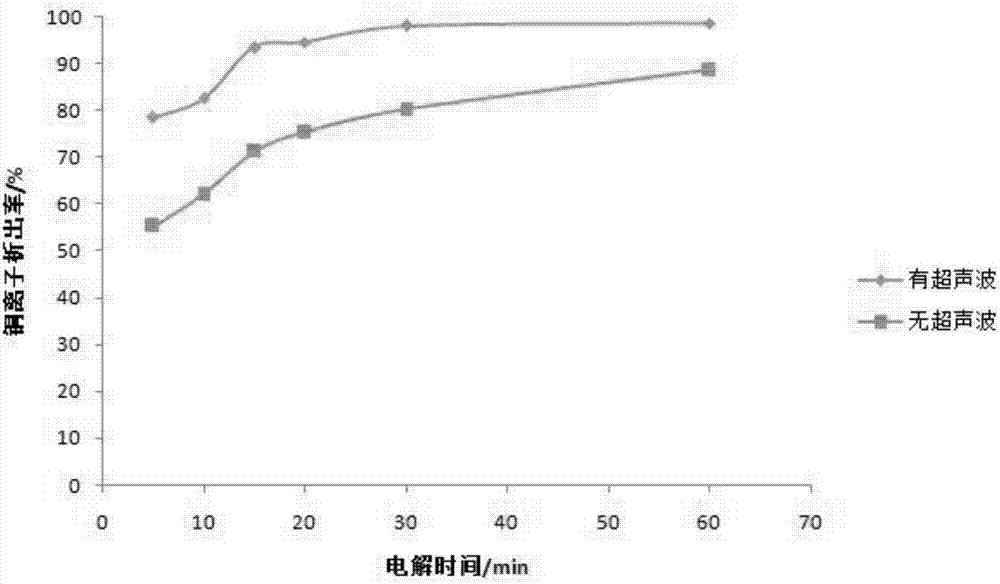

[0032] S3. Ultrasonic assisted electrolysis. The prepared acidic etching electrolyte is transported to the electrolytic cell, and an ultrasonic generator is installed in the ...

Embodiment 2

[0039] Embodiment 2: A kind of acidic etchant regeneration circulation system.

[0040] refer to figure 1 As shown, a kind of acidic etching solution regeneration circulation system comprises: hydrochloric acid storage tank 100, the hydrochloric acid that provides PCB acidic etching is stored in described hydrochloric acid storage tank 100; PCB acidic etching production line 200, described PCB acidic etching production line 200 For etching PCB board; waste liquid tank 300, described waste liquid tank 300 and PCB acid etching production line 200 are connected by pipeline, and described waste liquid tank 300 is used for collecting the acid etching liquid that PCB acid etching production line 200 produces; Electrolysis Liquid preparation tank 500, the electrolyte preparation tank 500 is connected to the waste liquid tank 300 through pipelines, and the electrolyte preparation tank 500 is used to prepare the concentration of acidic etching electrolyte; filter 400, the filter 400 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com