Aging strengthening heat treatment method for nickel-based alloy GH4169

A technology of GH4169 and heat treatment method, which is applied in the field of aging strengthening heat treatment of GH4169 nickel-based alloy, can solve the problems that the heat treatment process cannot meet the requirements of special users, and achieve the effects of reducing heating defects, improving material plasticity and yield, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The aging strengthening heat treatment method of the nickel-based alloy GH4169 in this embodiment includes a full solution treatment and a two-stage aging treatment process, and the specific process steps are as follows:

[0028] (1) Full solution treatment process: Nickel-based alloy GH4169 material is kept at 1000°C for 1.5h;

[0029] (2) Two-stage aging treatment process: one-stage aging treatment, the nickel-based alloy GH4169 material is heated to 780°C at a rate of 200°C / h, and kept for 18 hours; Cool at 55°C / h to 680°C, keep warm for 25h, take out the furnace and air cool to room temperature.

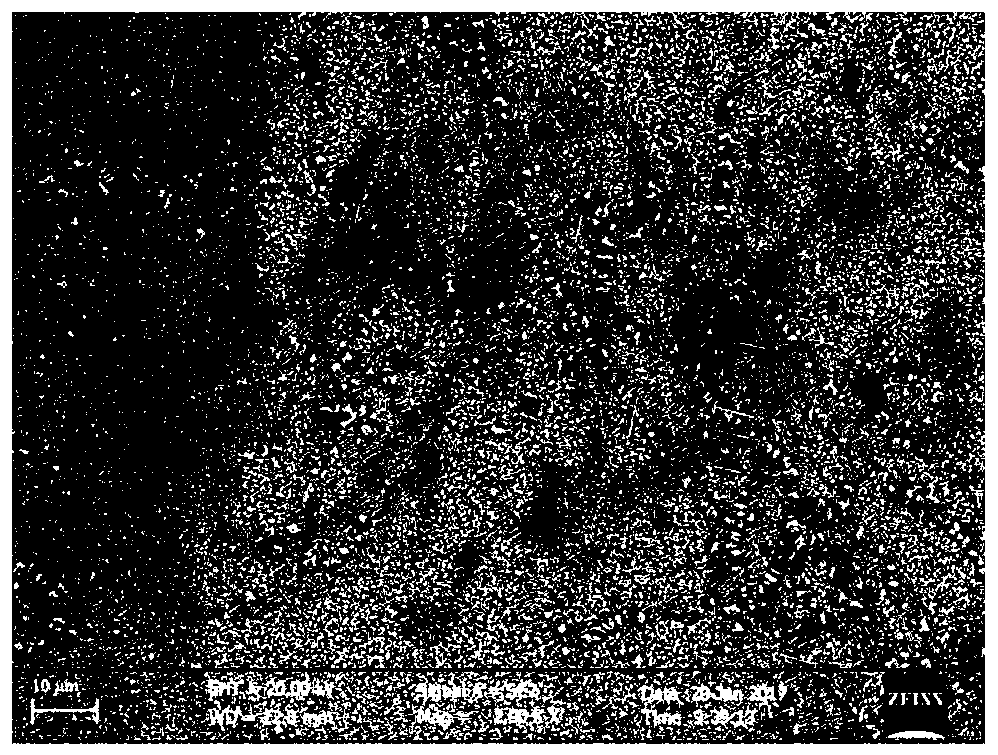

[0030] The scanning electron microscope picture of the GH4169 nickel-based alloy material after aging strengthening by the method of this embodiment is shown in figure 1 , the scanning electron microscope image of GH4169 nickel-based alloy material after standard aging strengthening treatment is shown in Figure 9 ;The figure shows, figure 1 , Figure 9 The medium γ″ p...

Embodiment 2

[0033] The aging strengthening heat treatment method of the nickel-based alloy GH4169 in this embodiment includes a full solution treatment and a two-stage aging treatment process, and the specific process steps are as follows:

[0034] (1) Full solution treatment process: Nickel-based alloy GH4169 material is kept at 1050°C for 1.2h;

[0035] (2) Two-stage aging treatment process: one-stage aging treatment, the nickel-based alloy GH4169 material is heated to 750°C at a rate of 180°C / h, and kept for 15 hours; Cool at 55°C / h to 650°C, keep warm for 20h, take out the furnace and air cool to room temperature.

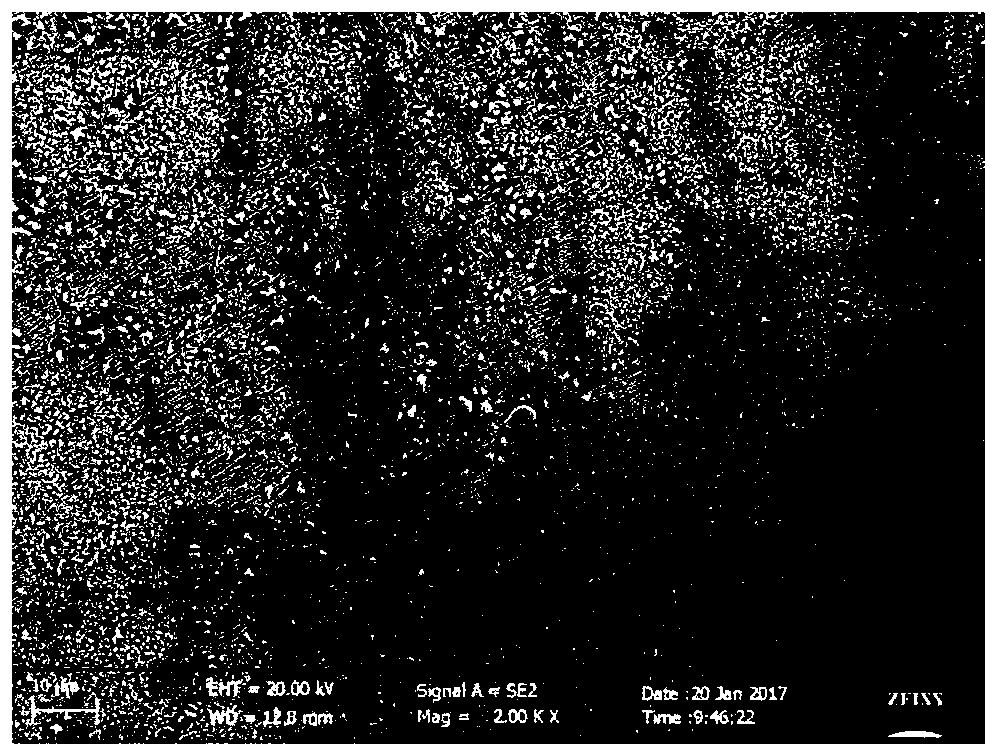

[0036] The scanning electron microscope picture of the GH4169 nickel-based alloy material after aging strengthening by the method of this embodiment is shown in figure 2 , the scanning electron microscope image of GH4169 nickel-based alloy material after standard aging strengthening treatment is shown in Figure 9 ;The figure shows, figure 2 , Figure 9 The medium γ″...

Embodiment 3

[0039] The aging strengthening heat treatment method of the nickel-based alloy GH4169 in this embodiment includes a full solution treatment and a two-stage aging treatment process, and the specific process steps are as follows:

[0040] (1) Full solution treatment process: Nickel-based alloy GH4169 material is kept at 1030°C for 1.8h;

[0041] (2) Two-stage aging treatment process: one-stage aging treatment, the nickel-based alloy GH4169 material is heated to 730°C at a rate of 150°C / h, and kept for 12 hours; the second-stage aging treatment is completed, and the nickel-based alloy GH4169 material is Cool at 55°C / h to 630°C, keep warm for 18h, take out the furnace and air cool to room temperature.

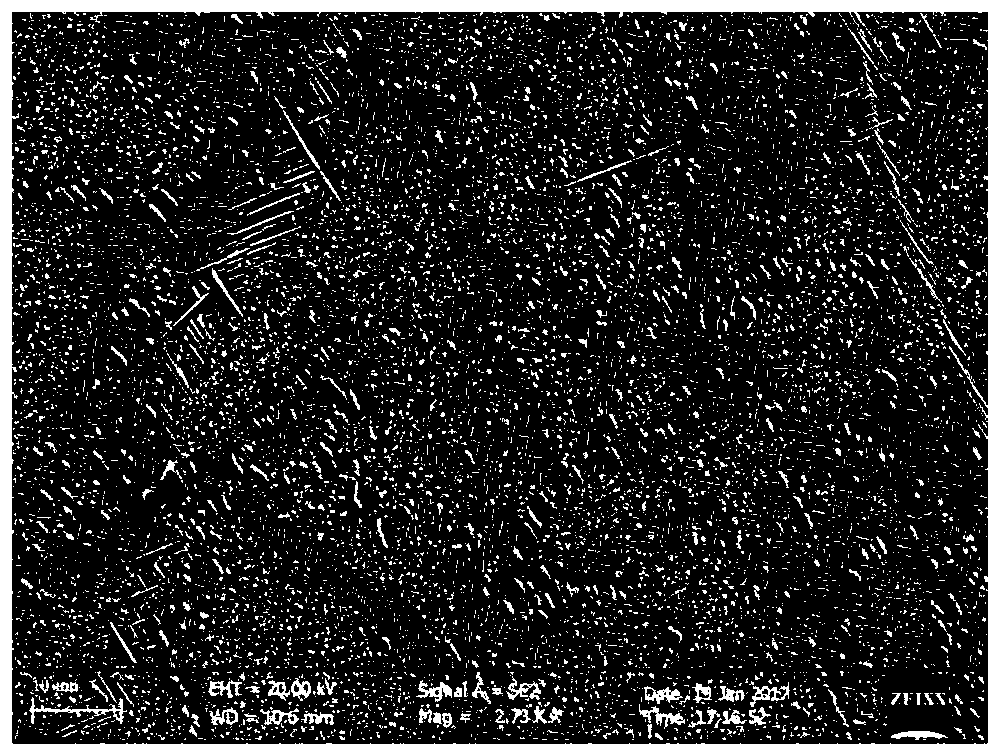

[0042] The scanning electron microscope picture of the GH4169 nickel-based alloy material after aging strengthening by the method of this embodiment is shown in image 3 , the scanning electron microscope image of GH4169 nickel-based alloy material after standard aging strengtheni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com