Fuel conveying method and equipment of boiler for burning crop straws

A technology for fuel transportation and crops, applied in the combustion method, combustion equipment, fuel supply and other directions, can solve the problems of arched feeding device, high processing cost, poor feeding, etc., achieve stable and reliable operation, reduce processing cost, reduce Effects of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

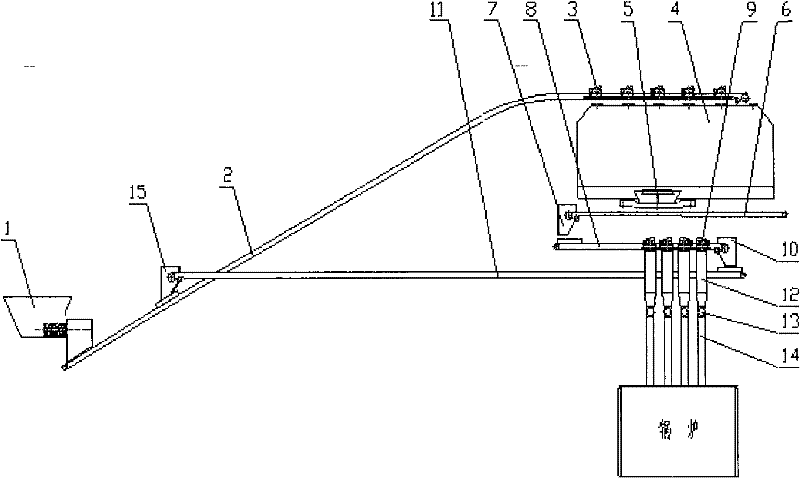

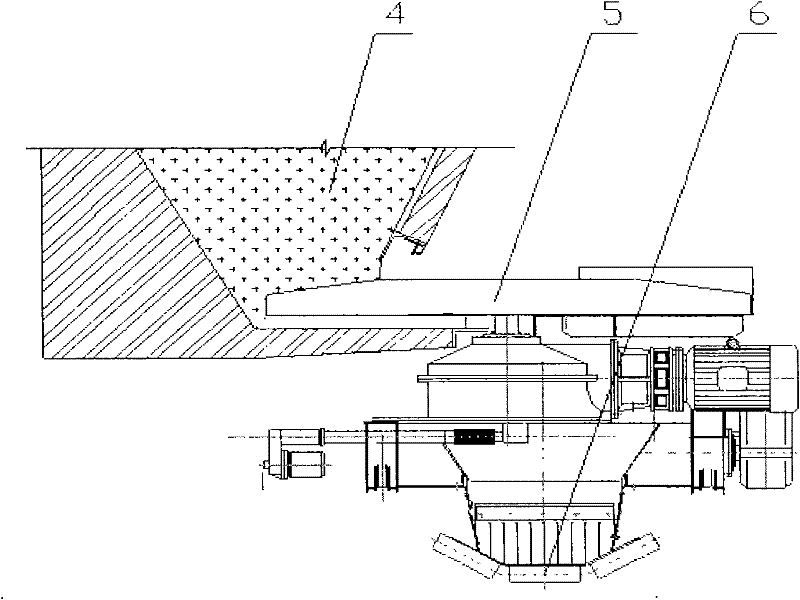

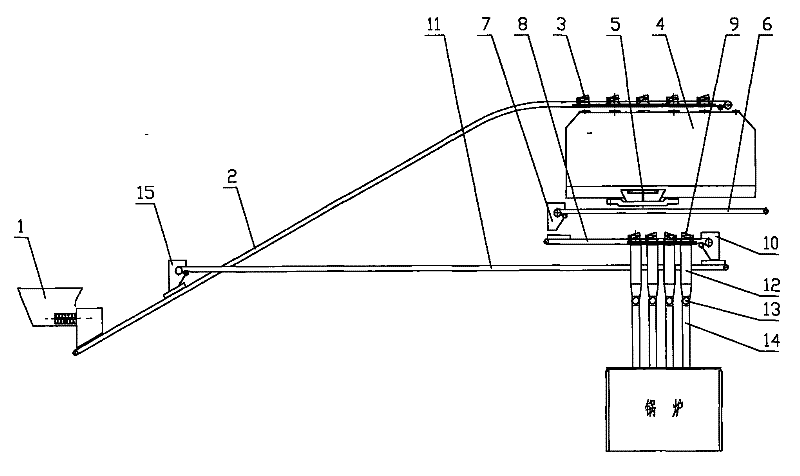

[0016] The fuel delivery method and equipment of the boiler burning crops and orange stalks of the present invention use the movable impeller feeding trolley and the drum feeder to change the feeding mode of the silo and the feeding mode of the boiler, reduce the operating cost, and realize uniform and stable feeding. and reduce equipment damage. The fuel delivery device of the present invention is mainly composed of a hopper 4, a mobile impeller feeding trolley 5, an upper-level feeding pipe 12, a drum feeder 13, and a lower-level feeding pipe 14. The crushed and pretreated crop straw fragments with a size of 5-25mm or larger are sent to the silo 4, and are fed through the movable impeller feeding trolley 5 at the bottom, and the straw fragments coming out of the movable impeller feeding trolley can be It directly falls into the upper-level feeding pipe 12, and then the crop orange stalk fuel is transported into the boiler through the lower-level feeding pipe 14 of the drum f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com