Roundness measuring frame and roundness measurement system having the same

A circular measuring frame and circular technology, applied in the field of circularity measurement, can solve the problems of large volume of circular parts, inconvenient measurement personnel, and high cost, and achieve the effects of accurate circularity calculation value, accurate measurement result, and fewer measurement points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

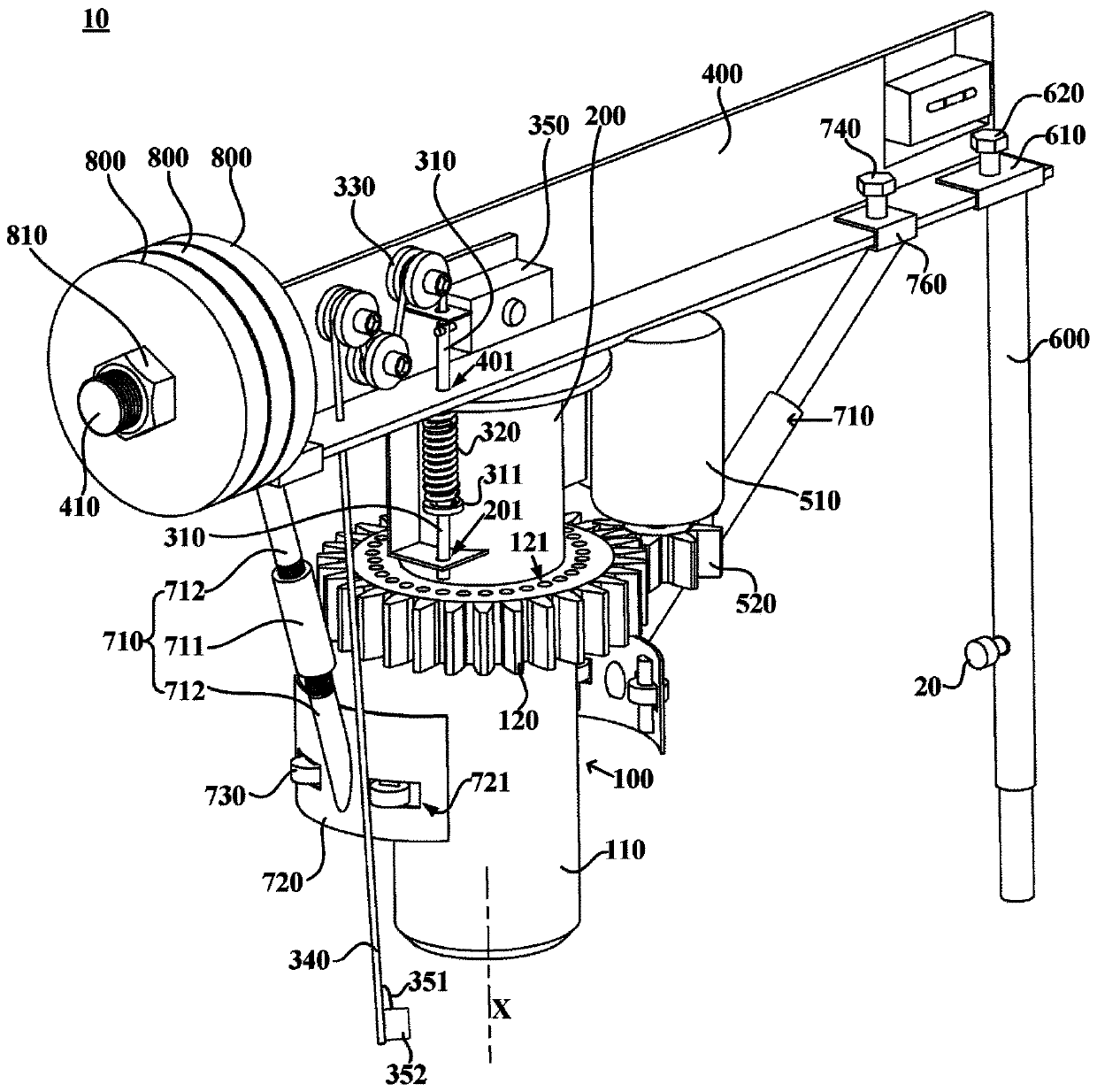

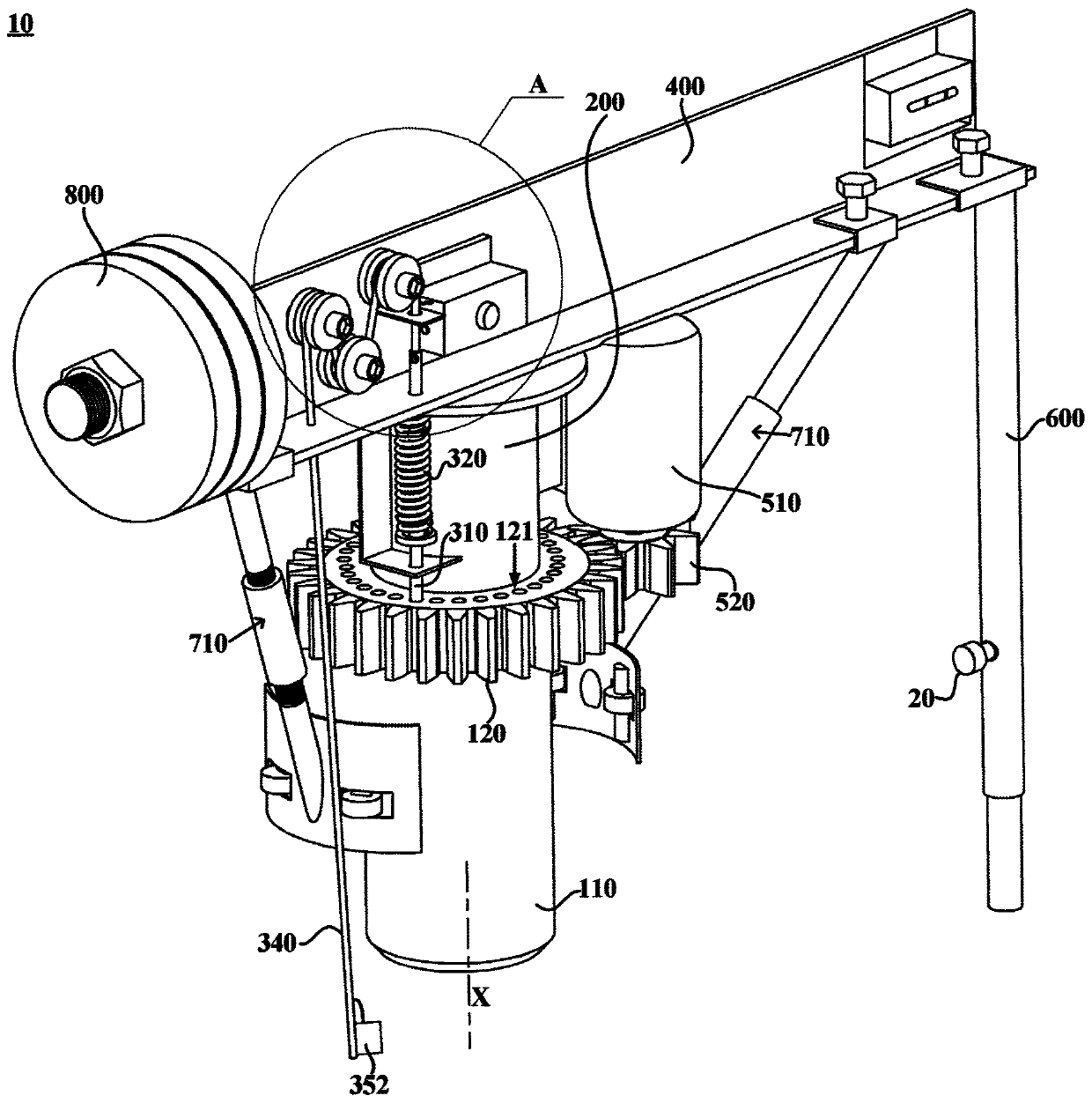

[0037] An embodiment of the present invention provides a roundness measuring system for measuring the roundness of circular components, and is especially suitable for measuring the roundness of various circular rotating shafts in hydropower equipment.

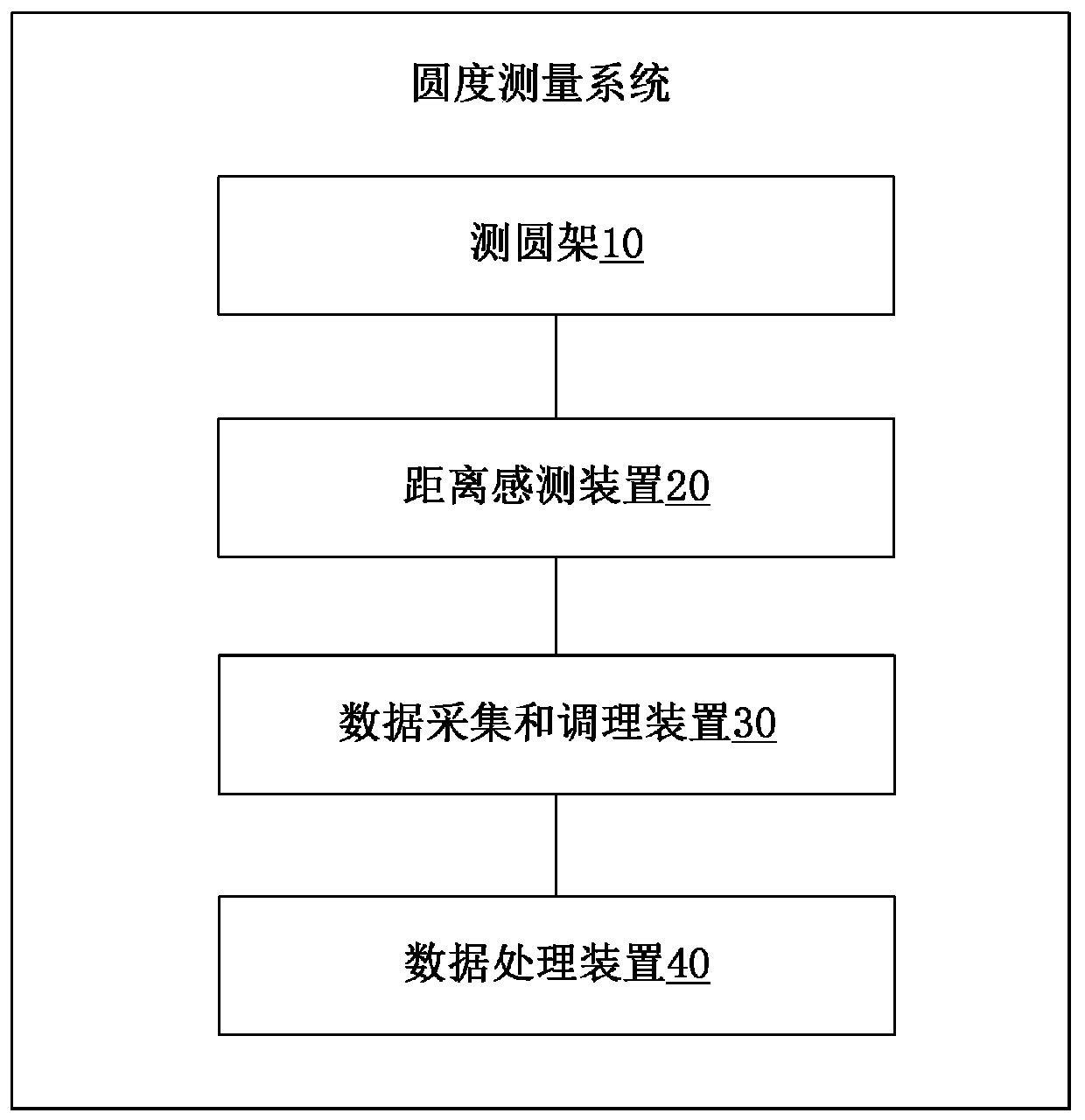

[0038] figure 1 is a schematic block diagram of a roundness measuring system according to an embodiment of the present invention. Such as figure 1 As shown, the roundness measurement system may generally include a circular measuring frame 10 , a distance sensing device 20 , a data acquisition and conditioning device 30 and a data processing device 40 .

[0039] Wherein, the circular measuring frame 10 is used for installing the distance sensing device 20 , and can drive the distance sensing device 20 to rotate around the measured circular part through manual operation or driven by the motor 510 .

[0040] There is a gap between the distance sensing device 20 and the circumferential surface of the measured circular part. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com