Patents

Literature

33results about How to "Few measuring points" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

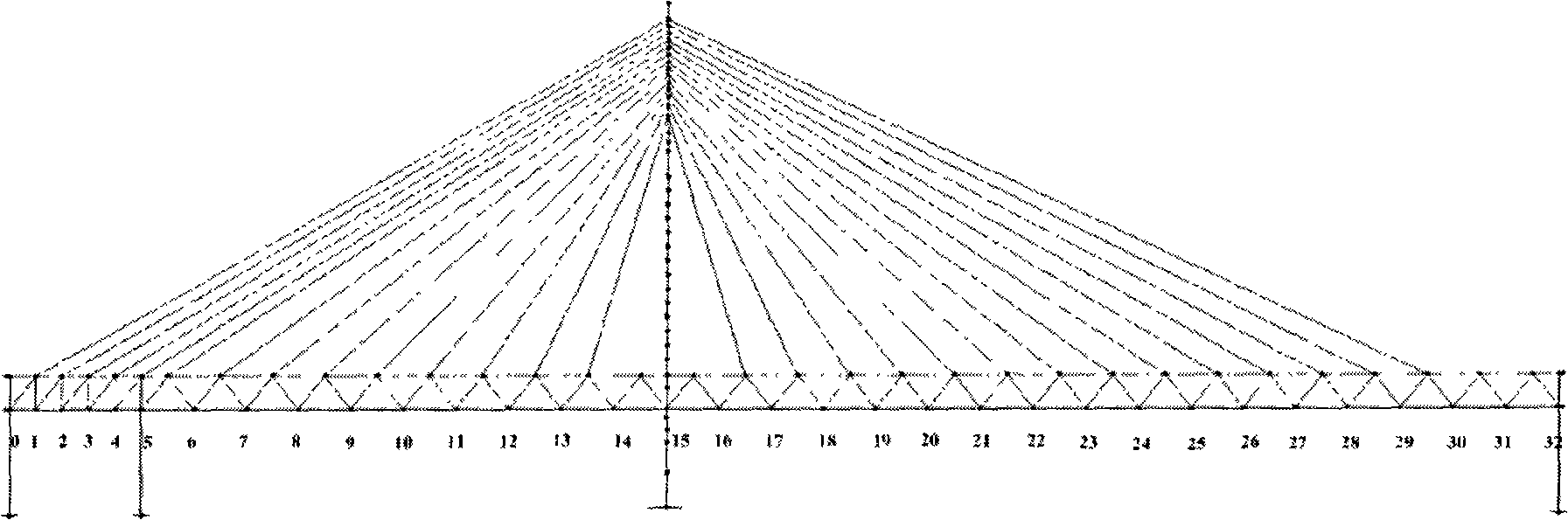

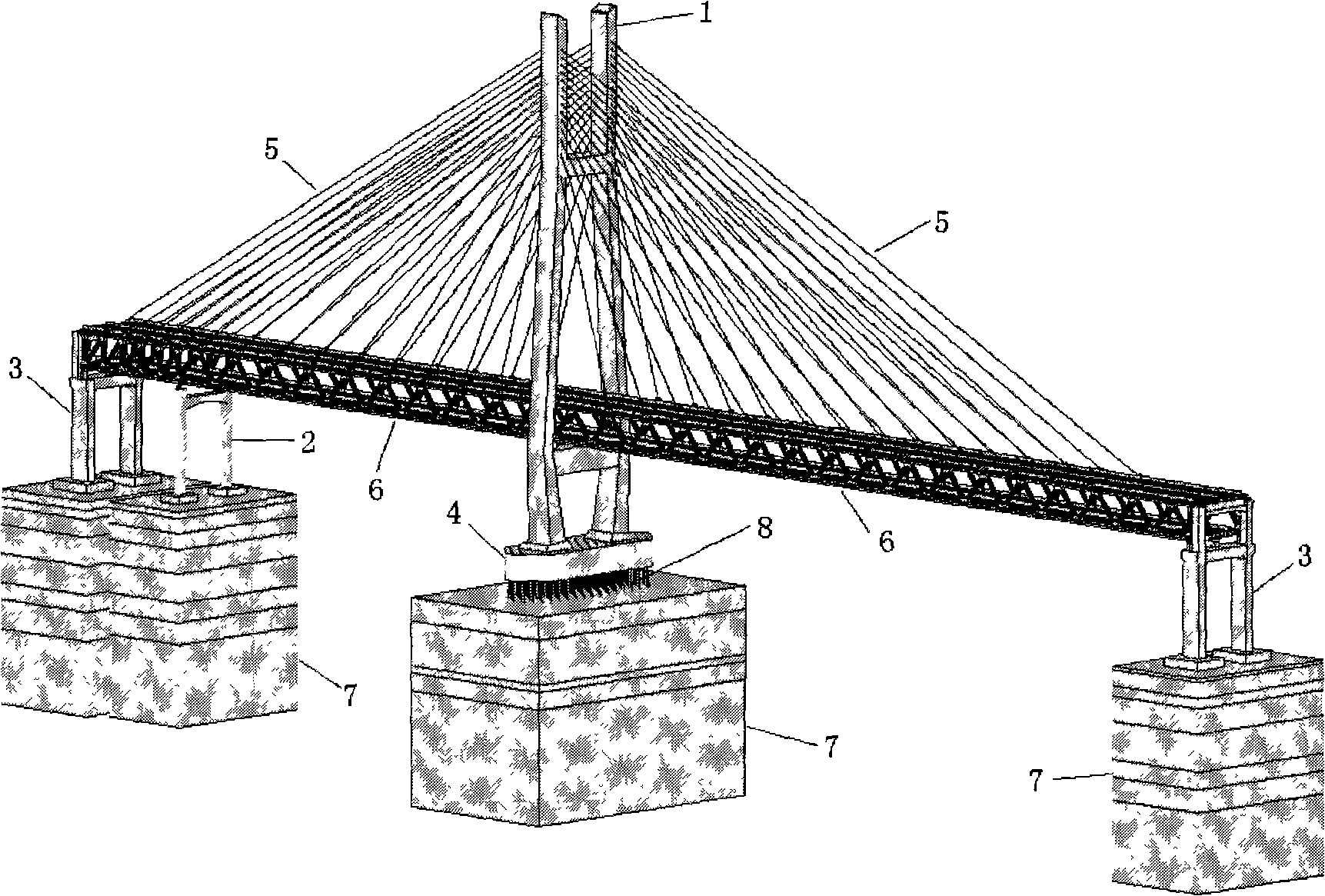

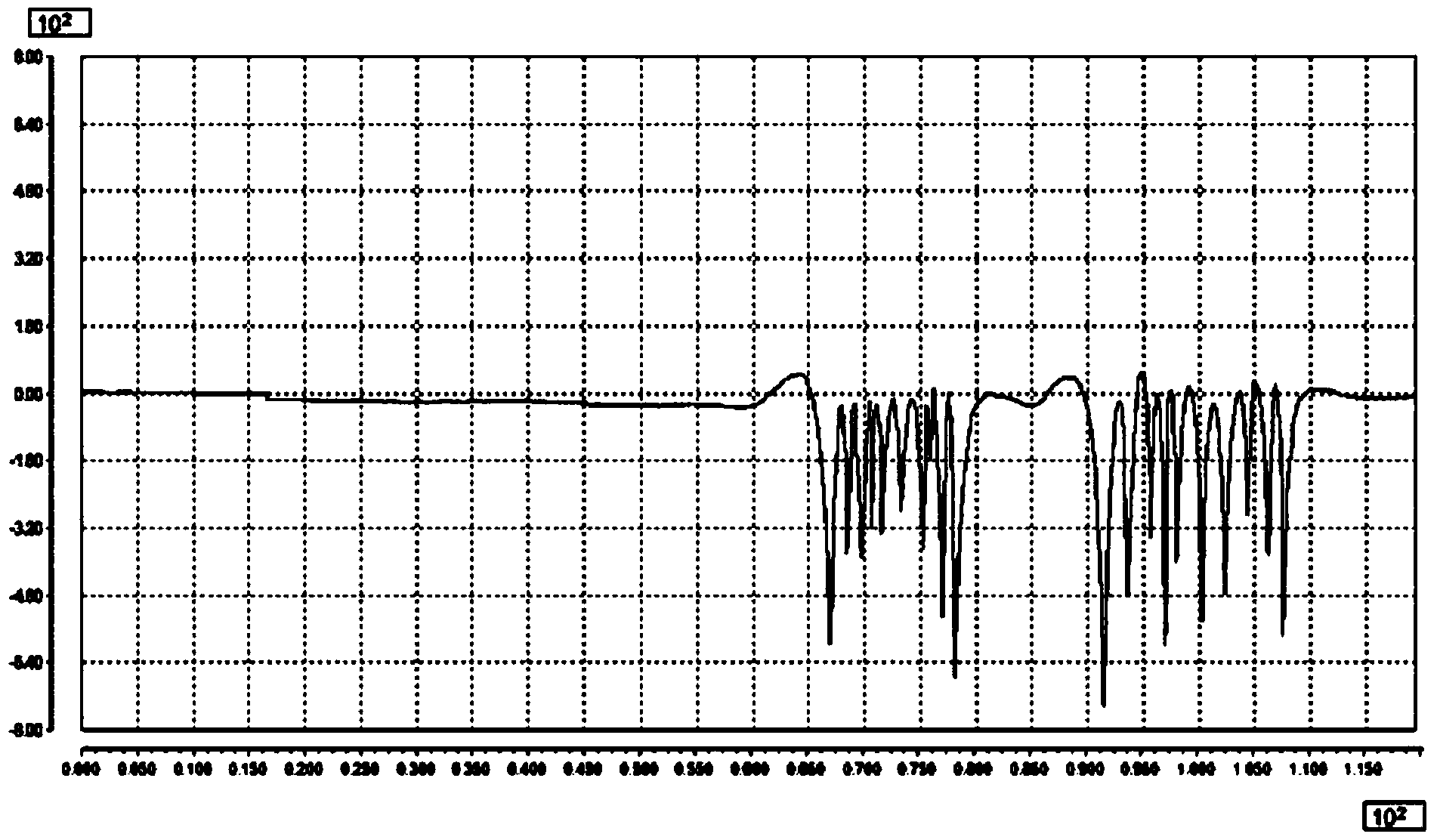

Wide span rail traffic bridge damnification recognition method

InactiveCN101281117AReduce calculation errorsImproving the accuracy of damage identificationUsing mechanical meansSpecial data processing applicationsSignal onNumerical models

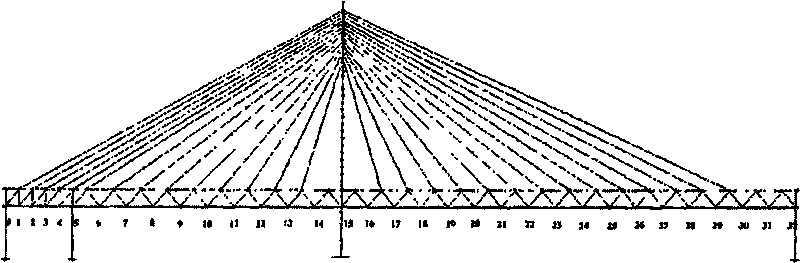

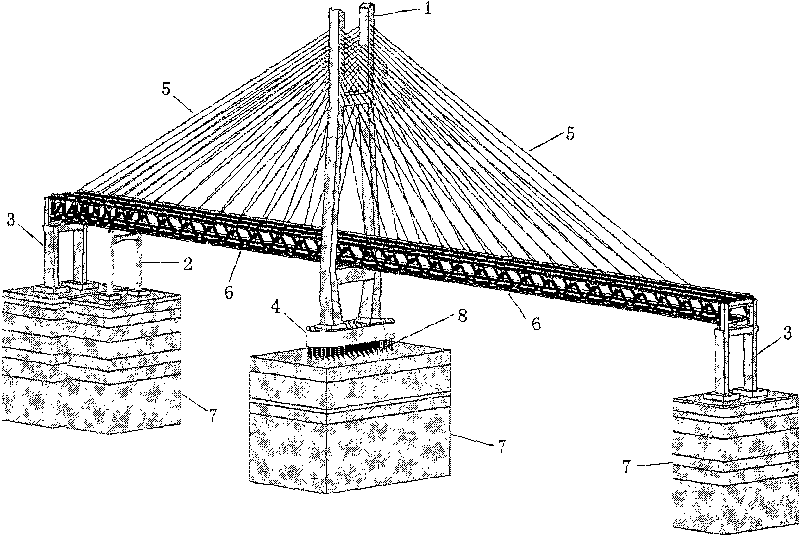

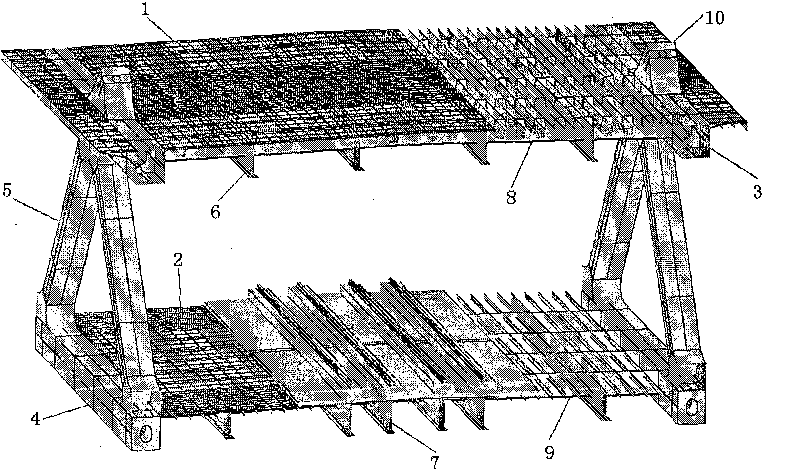

The invention relates to a large span rail traffic bridge damage recognition method, including the steps:(1) a sensor is arranged on the bridge which will be examined, the dynamic response signal of a large span rail traffic bridge is measured and is driven by that when a rail vehicle crosses the large span bridge, the signal on the sensor is red by a computer; (2) the benchmark bridge numerical model and the rail vehicle numerical model of the bridge are established; (3) a coupled mechanical analysis system comprising the benchmark bridge numerical model and the rail vehicle numerical model is initialized, an explicit integral method is used to solve the system, the simulated dynamic response signal of the benchmark bridge numerical model on a relative position is red according to the installment position of the sensor; (4) the energy spectrums of the dynamic response signal obtained by monitoring and the simulated dynamic response signal obtained by numerical simulation calculation of the bridge are solved by a multi-scale wavelet packet analysis method, and a damage recognition is carried on by recognizing index. The invention increases the precision of the bridge damage recognition, and the normal use of the bridge structure can not be affected.

Owner:SHANGHAI JIAO TONG UNIV

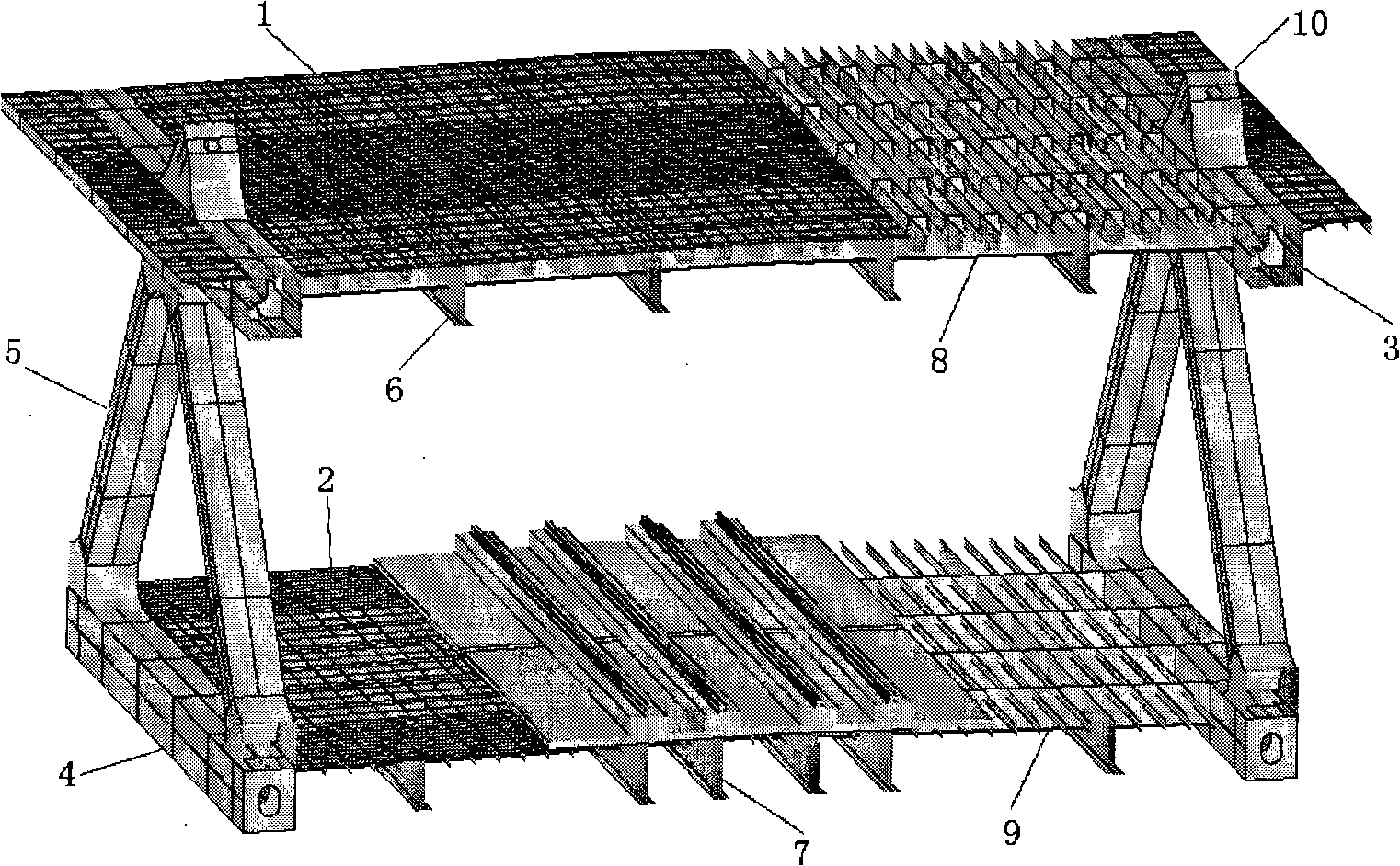

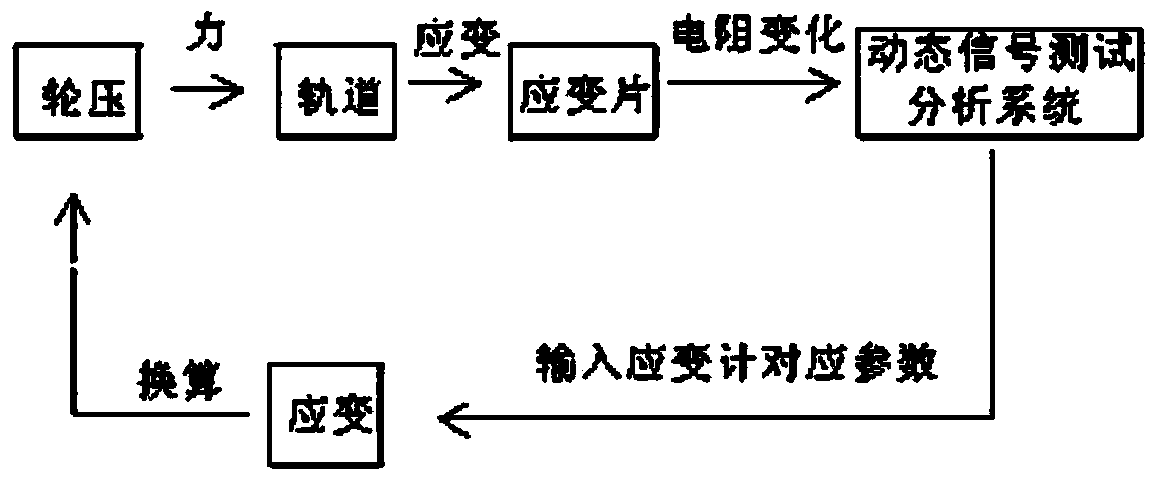

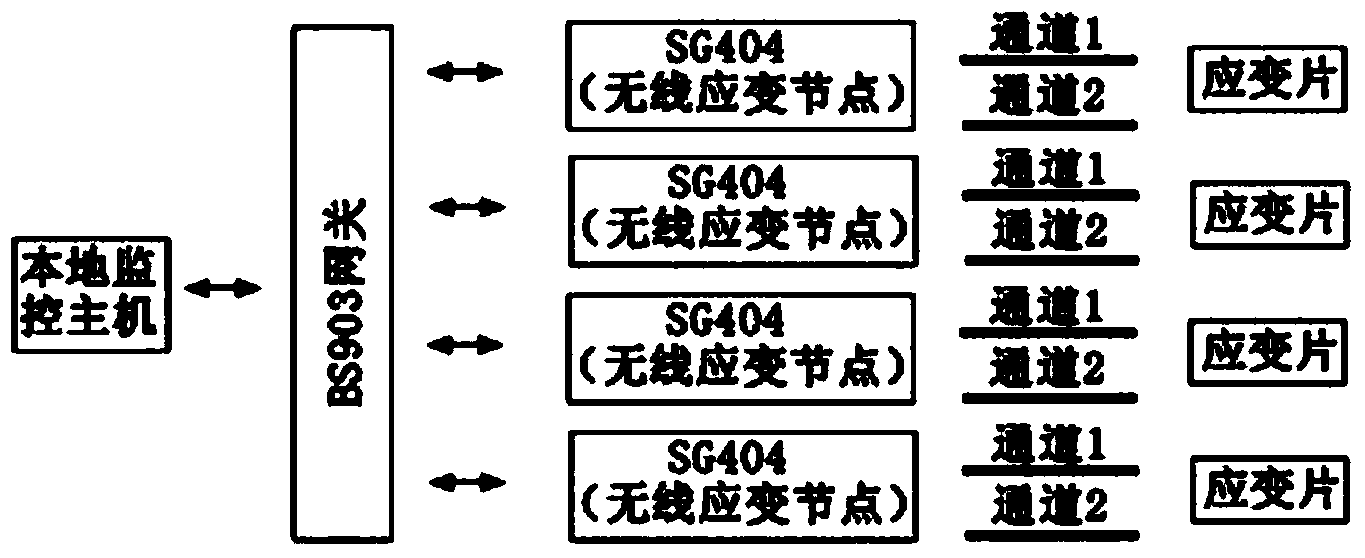

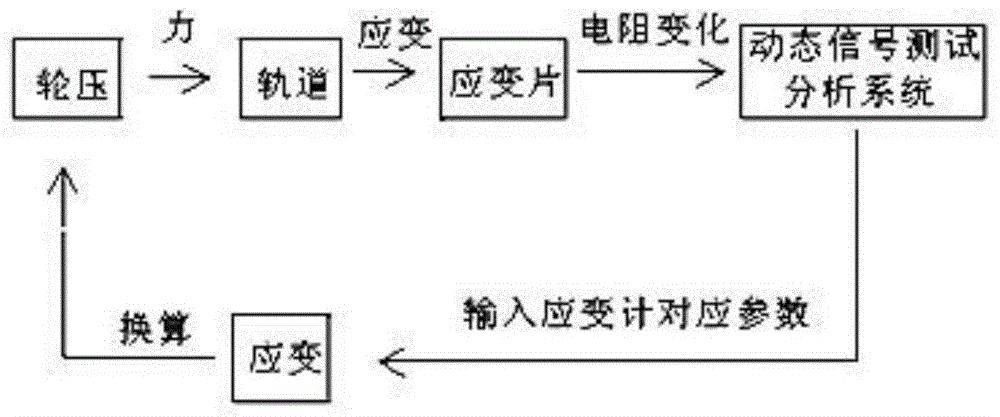

Measuring method for crane cart wheel pressure

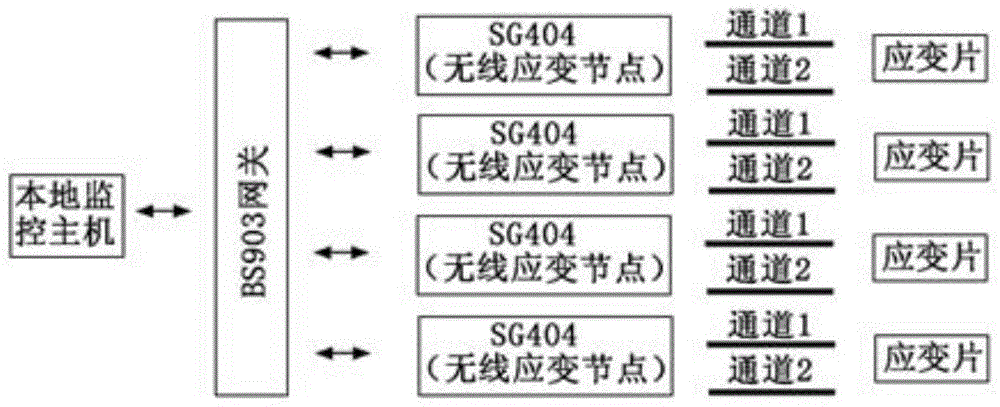

ActiveCN104034469ALoose arrangementOptimize layoutApparatus for force/torque/work measurementLifting capacityEngineering

The invention discloses a measuring method for a crane cart wheel pressure. The measuring method for the crane cart wheel pressure includes steps that (1) distributing foils, to be specific, pasting strain foils at the lateral surface of a cart track; (2) building a wheel pressure monitoring system, to be specific, connecting the strain foils and wireless strain nodes with a monitoring host; (3) calibrating, to be specific, enabling a crane to locate in a no-load state, enabling a crane dolly to locate at a proper position, enabling the cart to pass the cart track in a constant speed, and using the wheel pressure monitoring system to record a strain-time curve so as to obtain a wheel pressure and strain calibrating coefficient (shown in the description); (4) measuring the cart wheel pressure on site, to be specific, when the dolly is located at a set position according to a set lifting capacity, gathering the corresponding strain value, and converting the strain value into the corresponding wheel pressure (shown in the description). The measuring method for the crane cart wheel pressure is easy and practical, is capable of precisely measuring the actual value of each wheel pressure, is more direct and reliable than a calculation method, is capable of directly reflecting the wheel pressure non-uniformity of the crane under different working conditions and provides essential data for optimizing, using and maintaining the crane wheels and saving civil engineering cost.

Owner:NANTONG BRANCH OF SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

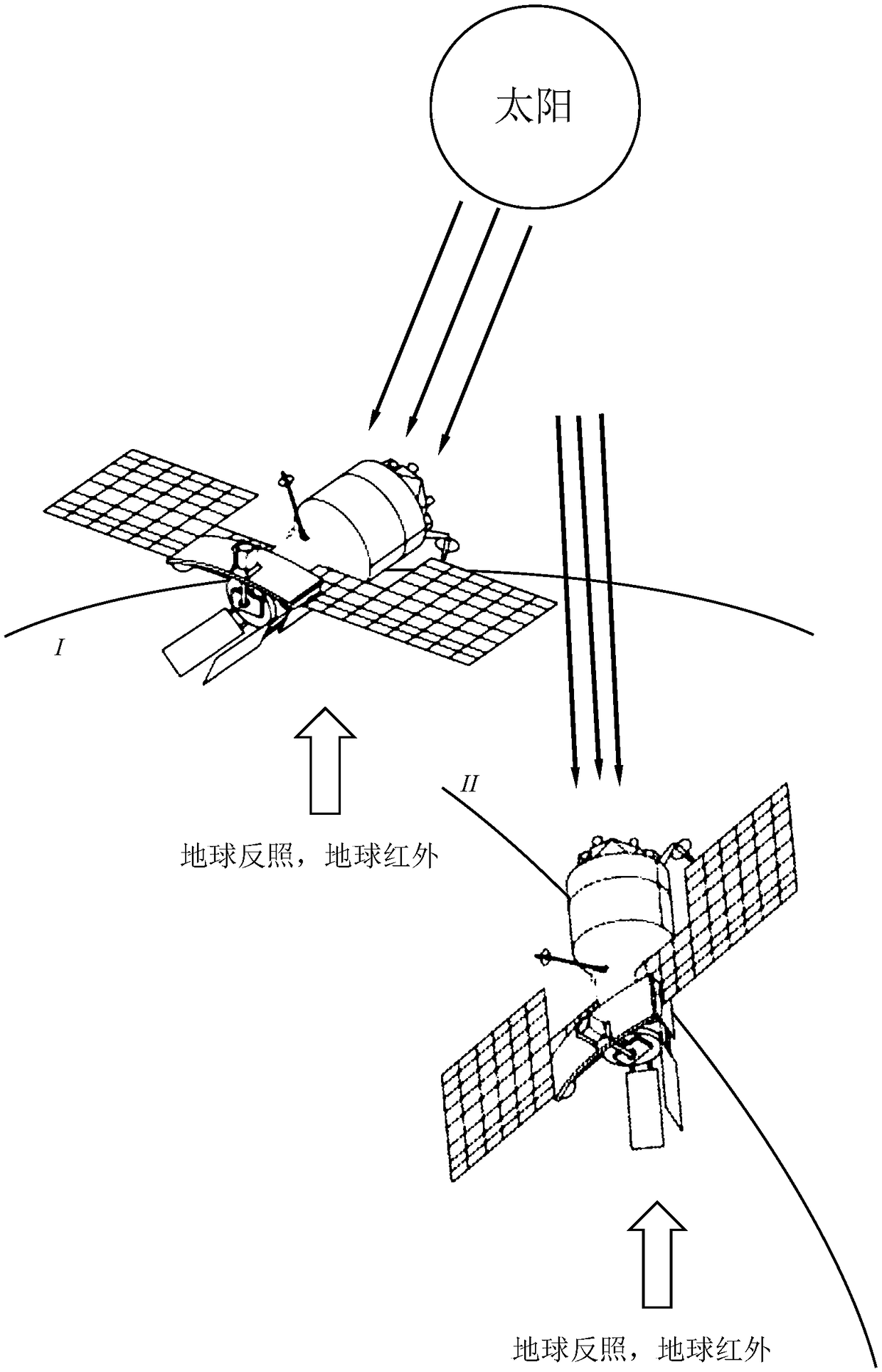

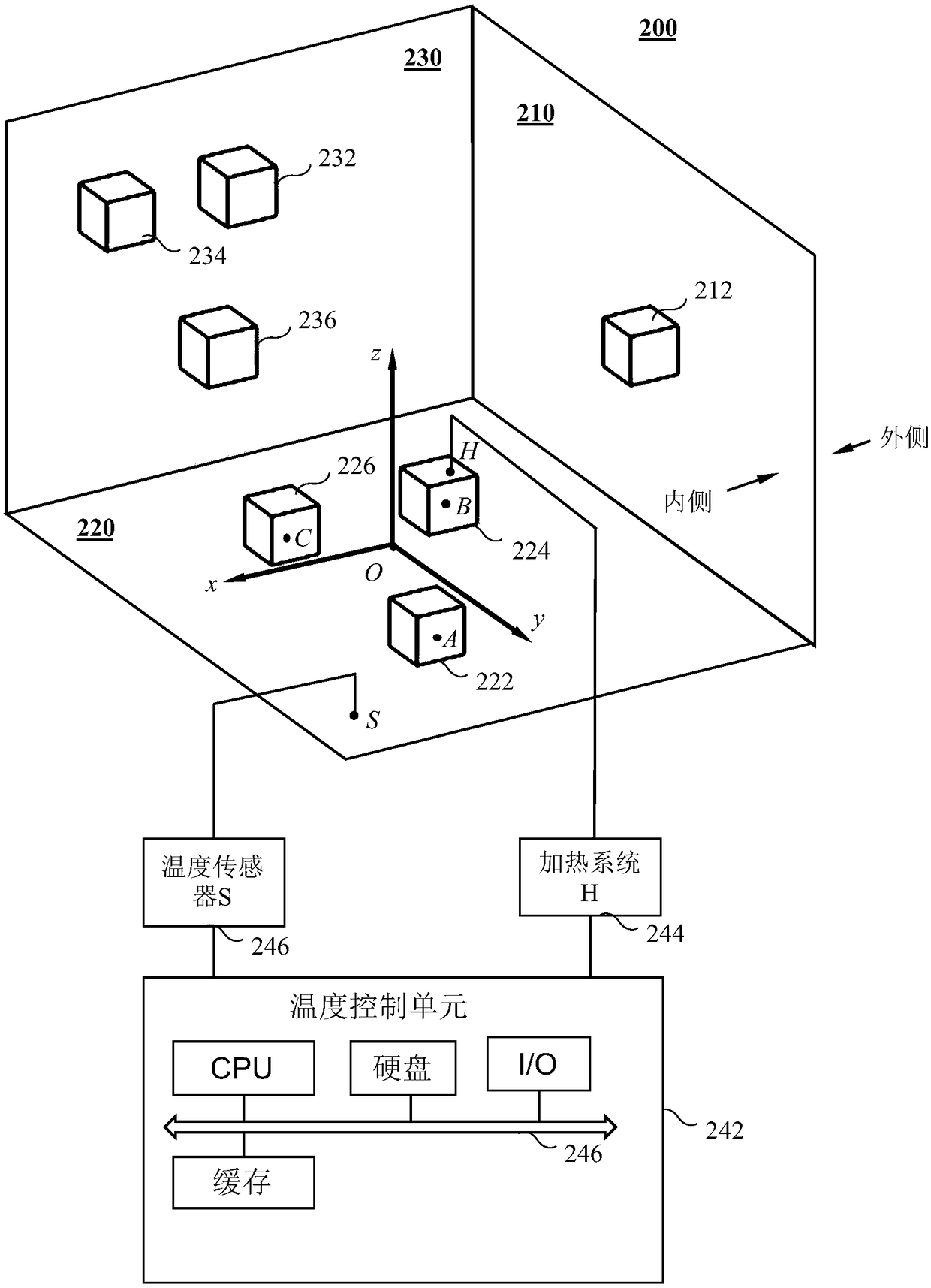

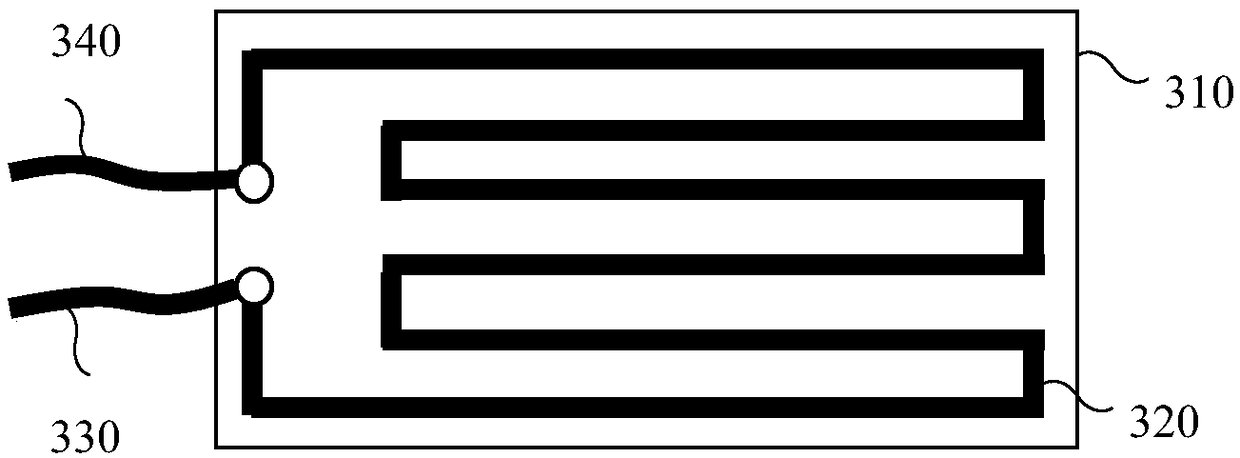

Temperature control system, spacecraft and temperature control method of spacecraft

InactiveCN109324648ASimplify thermal control systemFew measuring pointsTemperatue controlTemperature controlControl system

The invention provides a spacecraft. The spacecraft comprises a temperature control system. The temperature control system comprises at least one temperature sensor, a heating system and a temperaturecontrol unit, wherein each temperature sensor in the at least one temperature sensor is installed on one temperature measuring point of measured equipment for measuring the temperature data of the temperature measuring point, and the measured equipment comprises a plurality of target temperature control points located at other positions; the heating system is used for generating an additional temperature field for the measured equipment in a power-on state; and the temperature control unit is used for receiving the temperature data of the at least one temperature measuring point measured by the at least one temperature sensor in the working state of the measured equipment, judging the temperatures of the plurality of target temperature control points in other positions according to a pre-stored temperature field model in the preset working state of the measured equipment, and controlling the heating system to heat the measured equipment and regulating and controlling the temperaturesof the target temperature control points.

Owner:银河航天(北京)通信技术有限公司

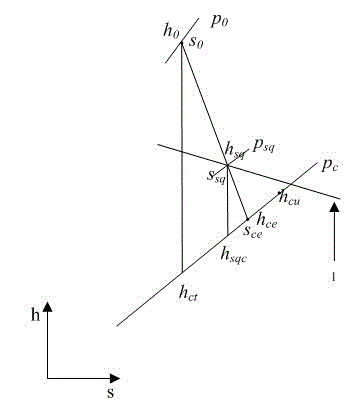

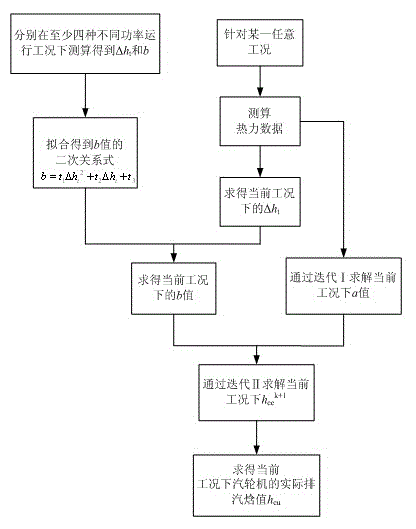

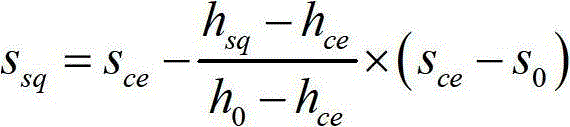

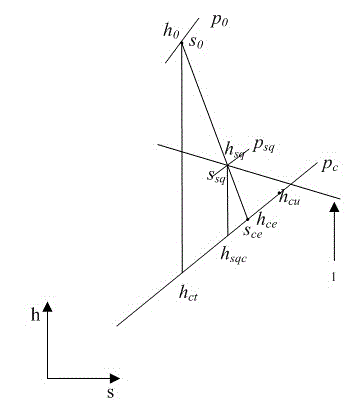

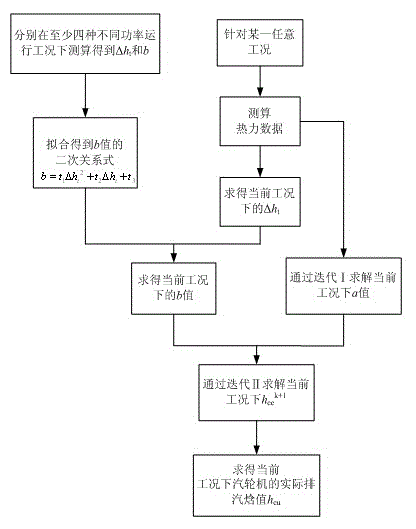

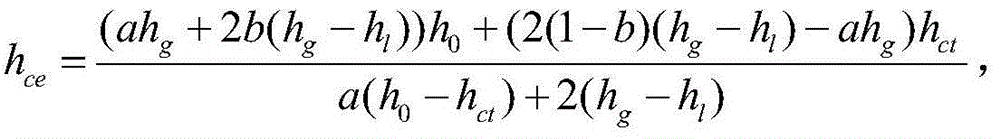

Method for detecting exhaust enthalpy of turbine

InactiveCN102749156AThe calculation process is simple and clearNo need to know structure parametersCalorimeterObservational errorMeasuring instrument

The invention discloses a method for detecting exhaust enthalpy of a turbine. The method includes the following steps of measuring and calculating a change rule of a specific parameter when a working condition changes according to designed data or test measured data, calculating to obtain a numerical value of the specific parameter under one certain working condition, acquiring partial heating power data of a low pressure cylinder under the certain working condition by the aid of a measuring instrument, reasonably assuming on the basis of a stage loss theory to obtain a numerical model for calculating the exhaust enthalpy of the turbine, substituting the numerical value of the specific parameter and the partial heating power data into the numerical model for calculating the exhaust enthalpy of the turbine to calculate the value of exhaust enthalpy of the turbine under the certain working condition. On the basis of stage loss theory, stage losses of the turbine are sorted into exhaust steam loss relating to volume flow, moisture loss relating to moisture and other losses relating to ideal enthalpy drop, and the calculation is simple, clear and highly precise. Detailed structural parameter of the low pressure cylinder is not needed, so measure points are reduced, and influence on calculated result caused by measuring error is small.

Owner:SOUTHEAST UNIV

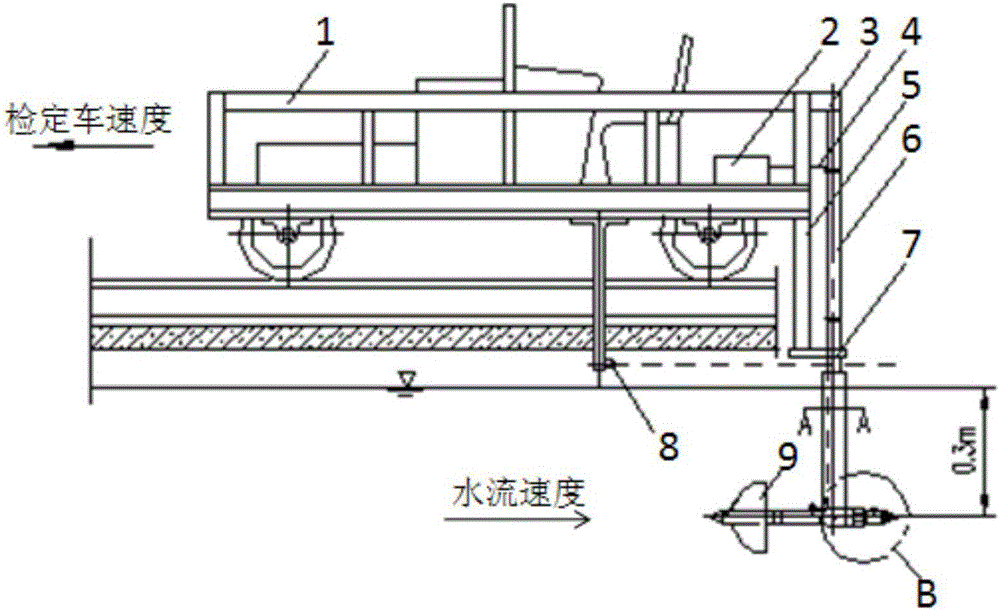

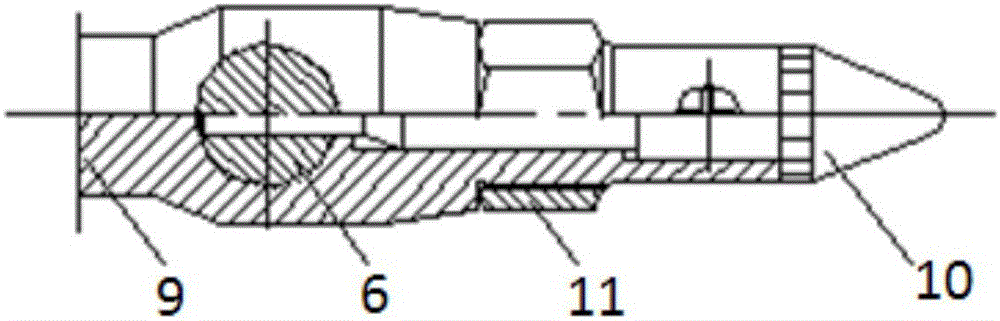

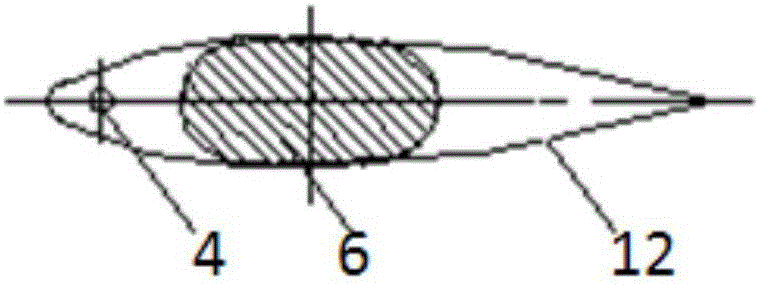

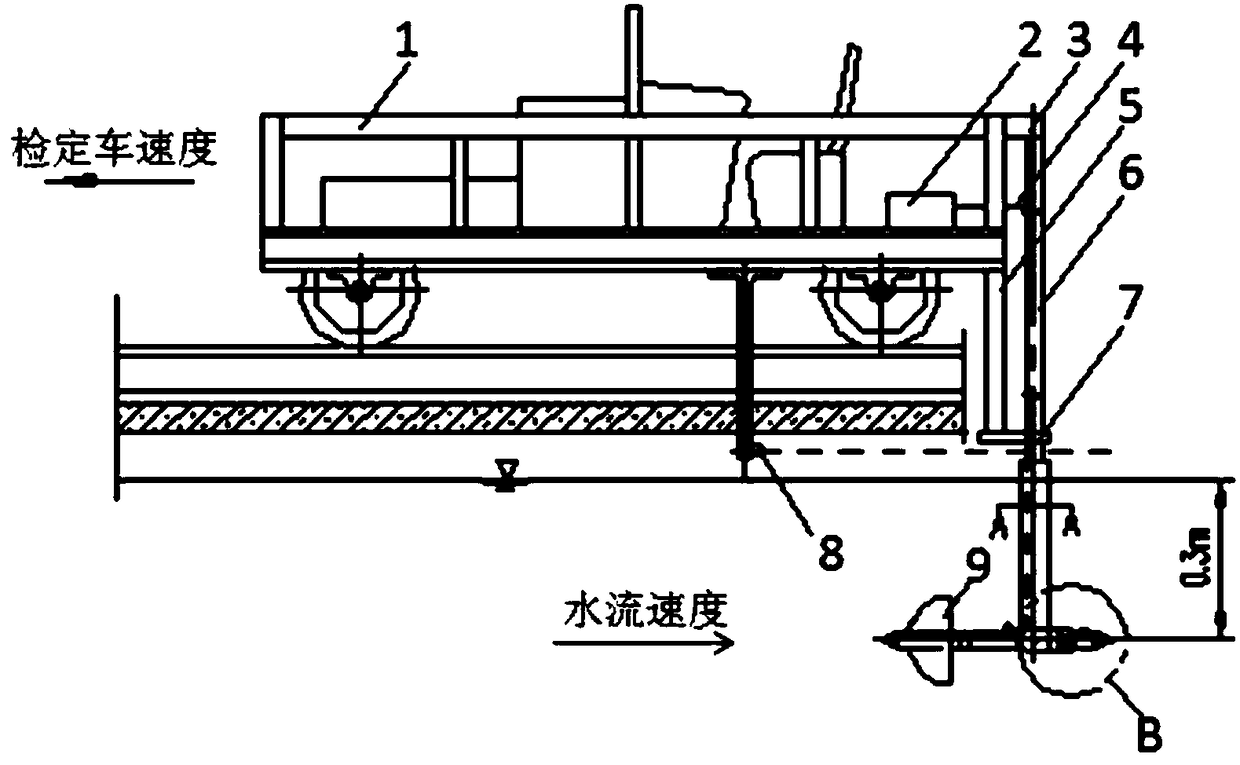

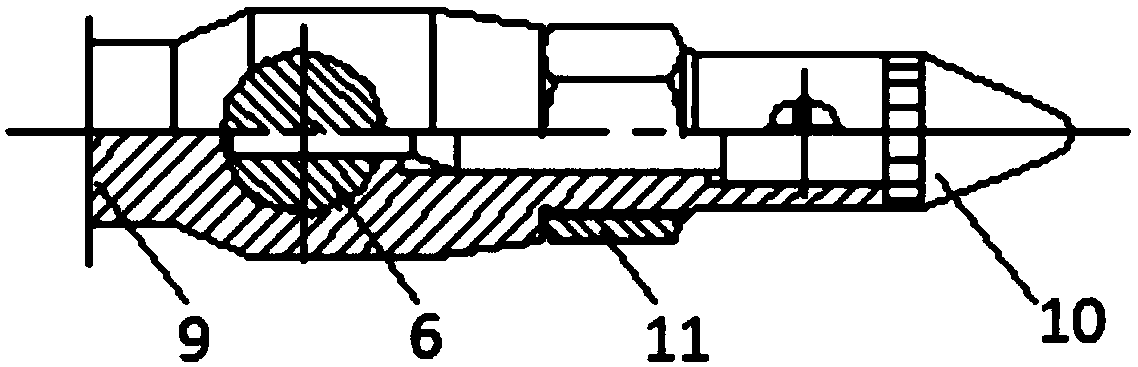

Current meter high-speed linear formula integration detection method and detection device

ActiveCN105954543AImprove test accuracyReliable referenceTesting/calibration of speed/acceleration/shock measurement devicesCurrent meterBall bearing

The invention discloses a current meter high-speed linear formula integration detection method and a detection device. The method comprises the following steps: cleaning a ball bearing; detecting average frictional resistance moment M of the ball bearing; detecting a propeller current meter rotating speed V0 and an instrument rotation bearing internal frictional resistance moment M, and confirming that a standard is reached; fixedly installing three detected current meters at the lower end of a measuring rod and placing them into water of a detection water tank; adjusting an axial directions of the current meters; tranquilizing a water body in the tank; starting a motor, a detection vehicle running from a lowest speed and gradually increasing its speed, and detecting instrument output signals and data; and according to a GB / T21699 detection method of rotor type current meter in linear open channel, by use of a least square method, calculating values of a and b of a detection formula and a middle and high-speed whole-line average mean square deviation sigma. According to the invention, the program and steps of a conventional detection method in the prior art are substantially simplified, the precision of detection results of the current meters can be ensured, at the same time, the production efficiency is improved, the working conditions are improved, the management rules are simplified, manpower and material resources are reduced, and the production operation cost is decreased.

Owner:JIANGSU NANSHUI WATER AFFAIRS TECH CO LTD +1

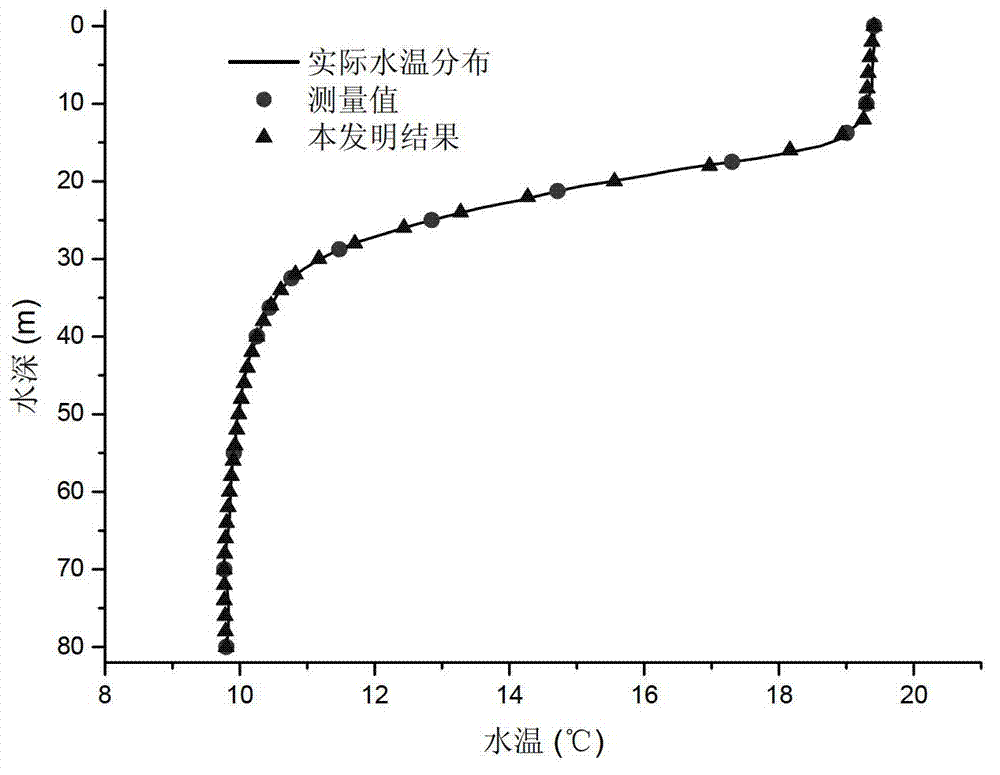

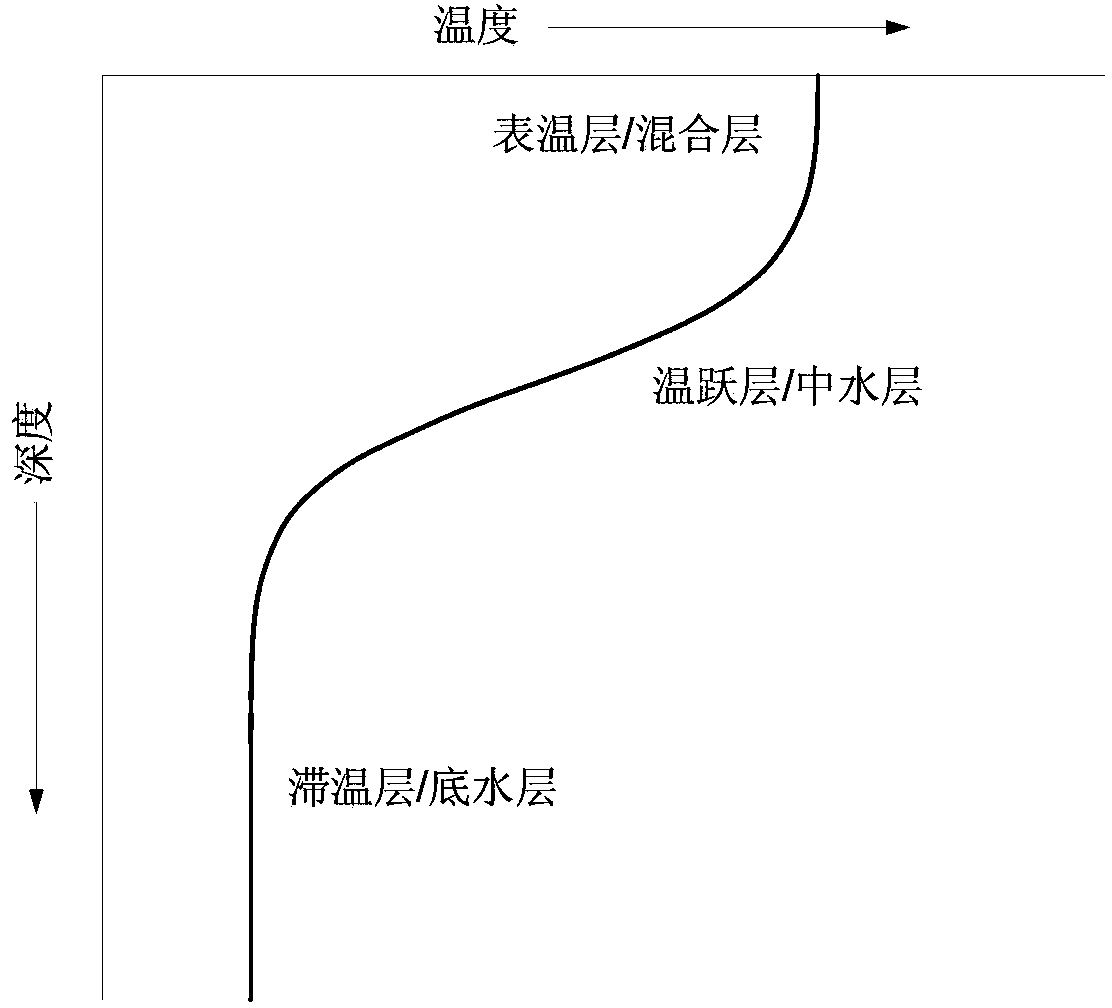

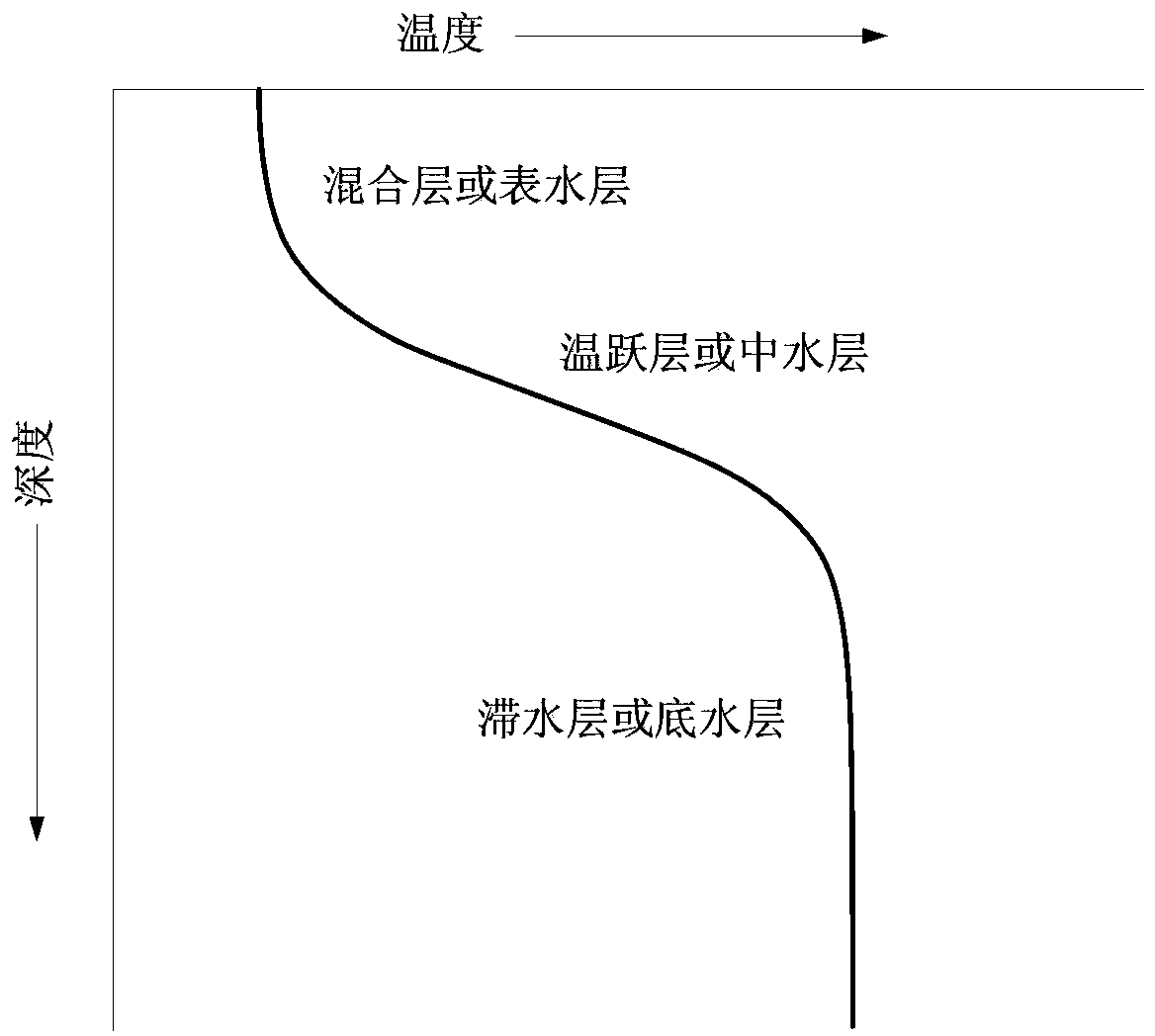

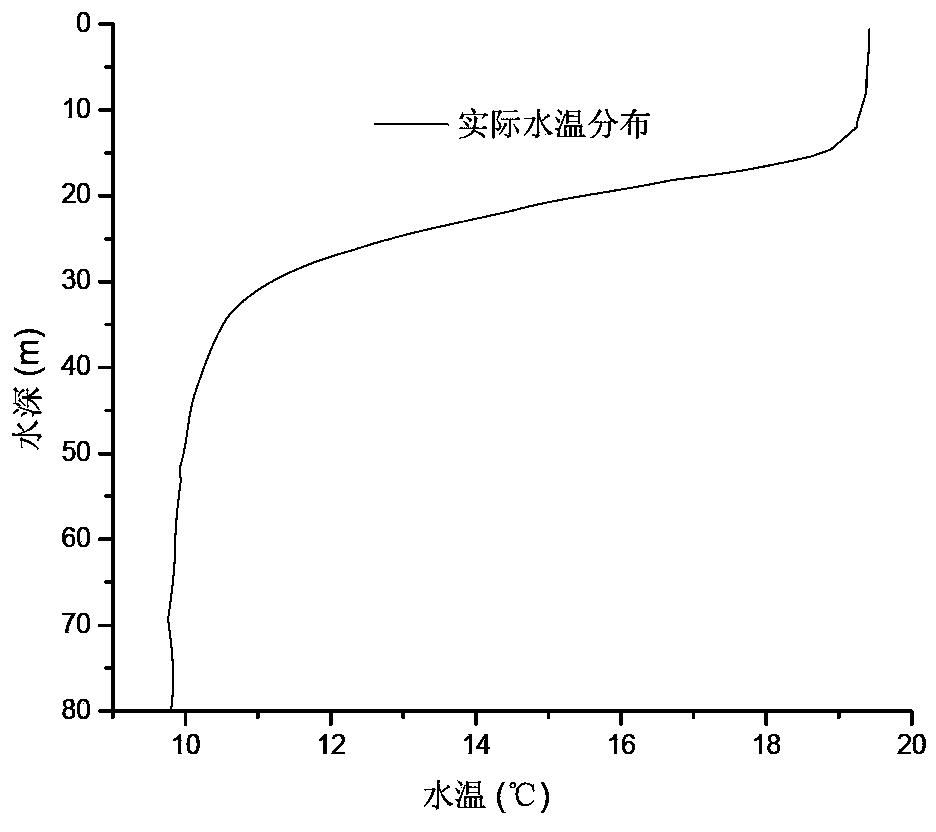

Measuring method of deepwater reservoir vertical direction water temperature distribution

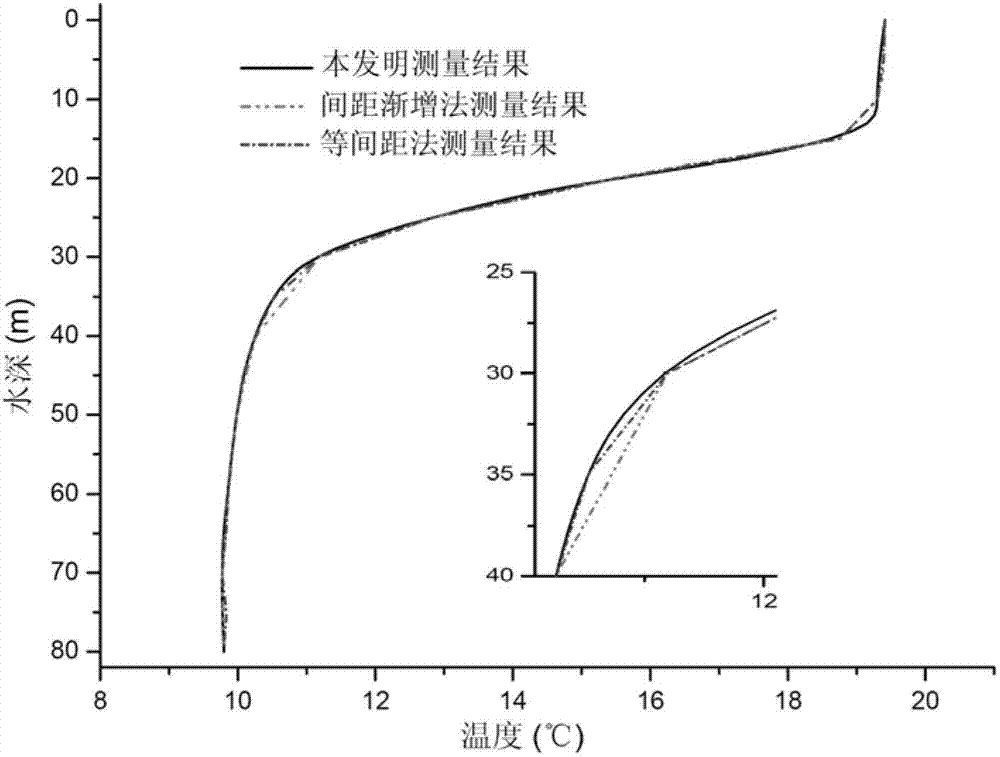

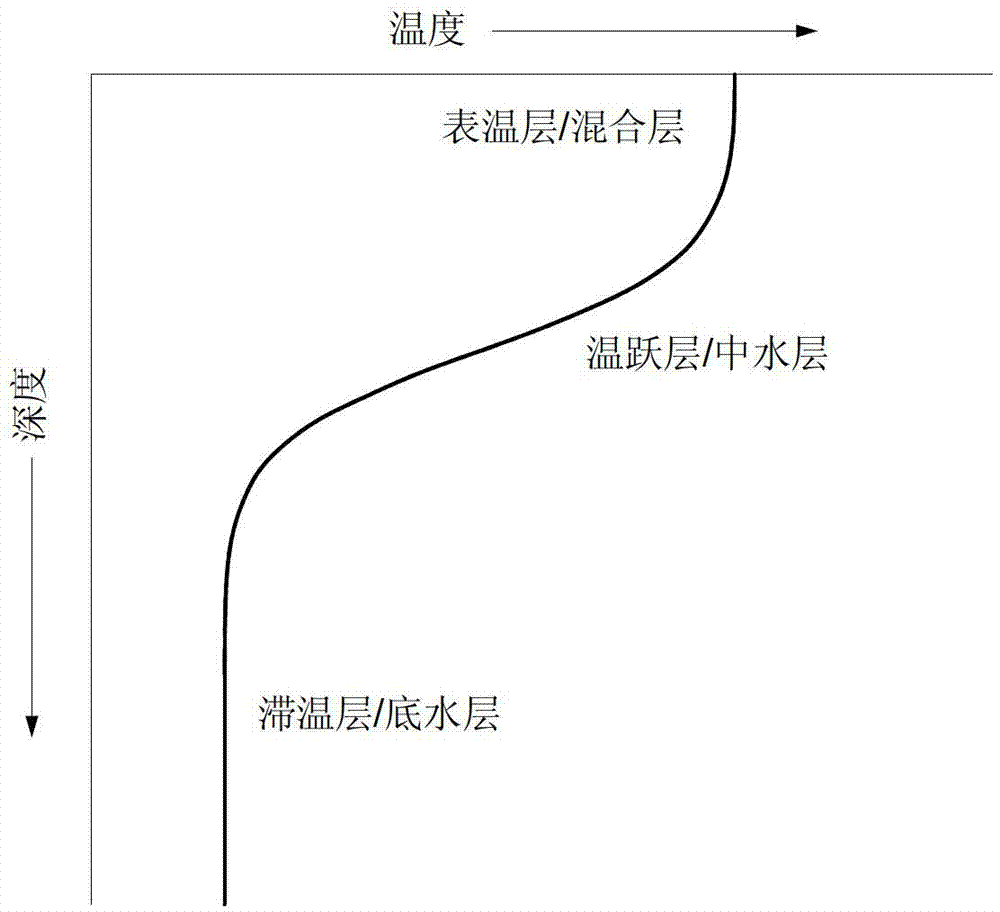

ActiveCN103162869AAvoid missingExcellent measurement methodTemperature measurement of flowing materialsMeasurement pointWater temperature

The invention discloses a measuring method of deepwater reservoir vertical direction water temperature distribution. Control spacing of measuring points is obtained according to measuring accuracy of an instrument, from the water depth of 10 meters to 15 meters to the bottom of a reservoir, the points are measured in every 10 meters to 15 meters, temperature gradients of the points are calculated by a method of back inserting, if the temperature gradient of a certain point is larger than 0.05 DEG C / m, the ratio of the absolute value of the difference of the temperature gradient of the certain point and that of an adjacent point to the temperature gradient of the certain point is calculated, if the ratio is larger than 15%, measuring water temperature is increased to a middle point of the certain point and the adjacent point so as to enable the water temperature of all points to satisfy the condition that the absolute value of the temperature gradient of water temperature is not more than 0.05 DEG C / m or the ratio of the absolute value of the difference of the temperature gradient of the certain point and that of the adjacent point to the temperature gradient of the certain point is not more than 15% or the spacing of the measuring points is not more than two times of the control spacing. The temperatures of all points are sequenced according to the water depth, and then the deepwater reservoir vertical direction water temperature distribution can be obtained through spline interpolation.

Owner:CHINA THREE GORGES CORPORATION

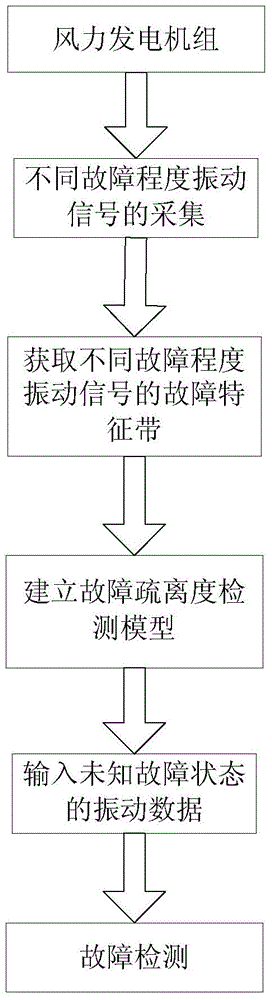

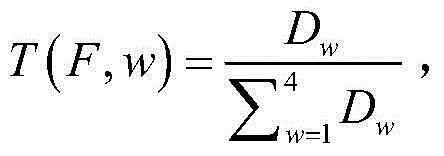

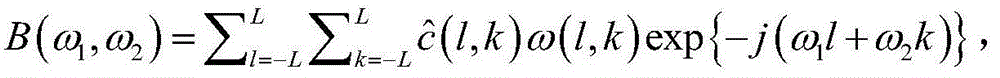

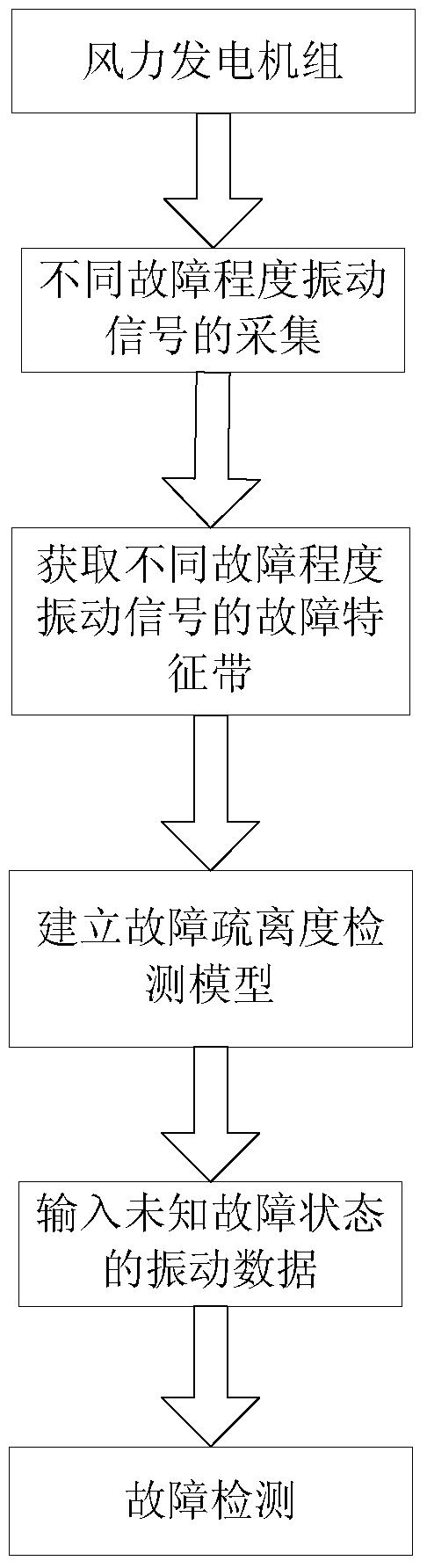

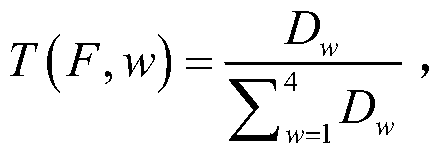

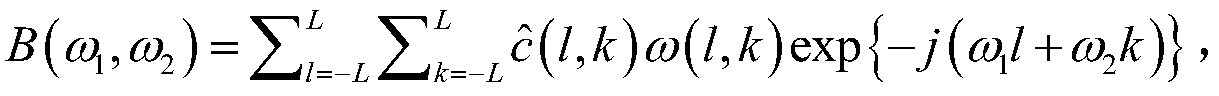

Wind turbine generating set fault diagnosis method based on bispectral entropy

ActiveCN104897277AReduce distractionsEasy extractionSubsonic/sonic/ultrasonic wave measurementElectricityDiagnosis methods

The invention relates to a wind turbine generating set fault diagnosis method based on bispectral entropy. The method includes the steps: collecting vibration signals of a wind turbine generating set in a normal running state, a minor faulty state, a medium faulty state and a severe faulty state; calculating fault characteristic bands of all the vibration signals; establishing a fault deviation degree detection model; collecting vibration signals of a to-be-detected wind turbine generating set, carrying out fault characteristic band calculation on the to-be-detected vibration signals, obtained fault characteristics are input to the fault deviation degree detection model, calculating the fault deviation degree between the faulty state and the above four faulty states, and finally obtaining the minimal deviation degree which is the faulty state of the wind turbine generating set. The fault characteristics of non-stationary signals can be effectively extracted, fault diagnosis for the wind turbine generating set can be carried out, and the fault diagnosis precision can be improved. The method can be widely applied to fault diagnosis for wind turbine generating set equipment.

Owner:BEIJING INFORMATION SCI & TECH UNIV

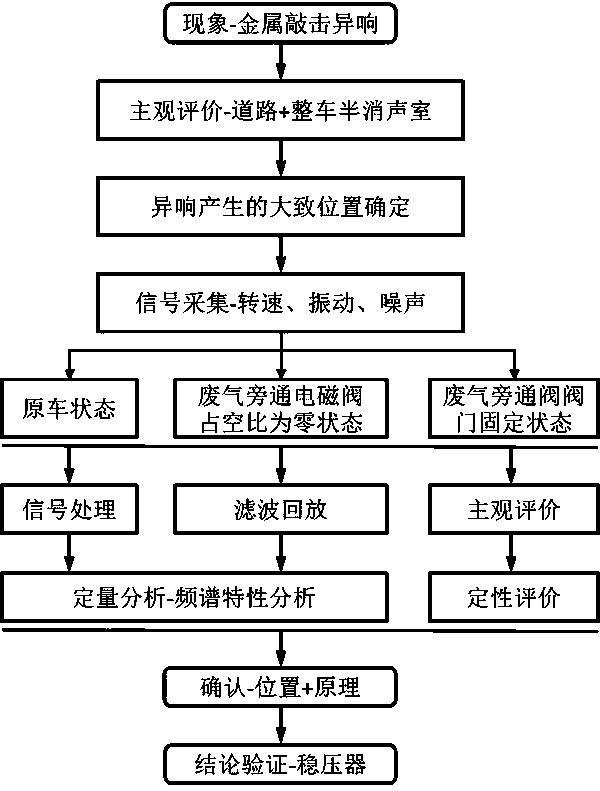

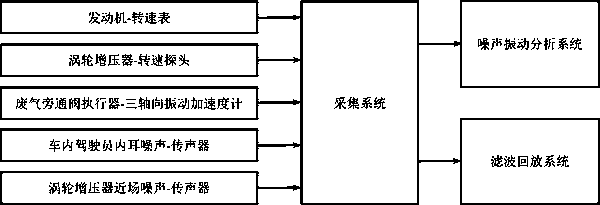

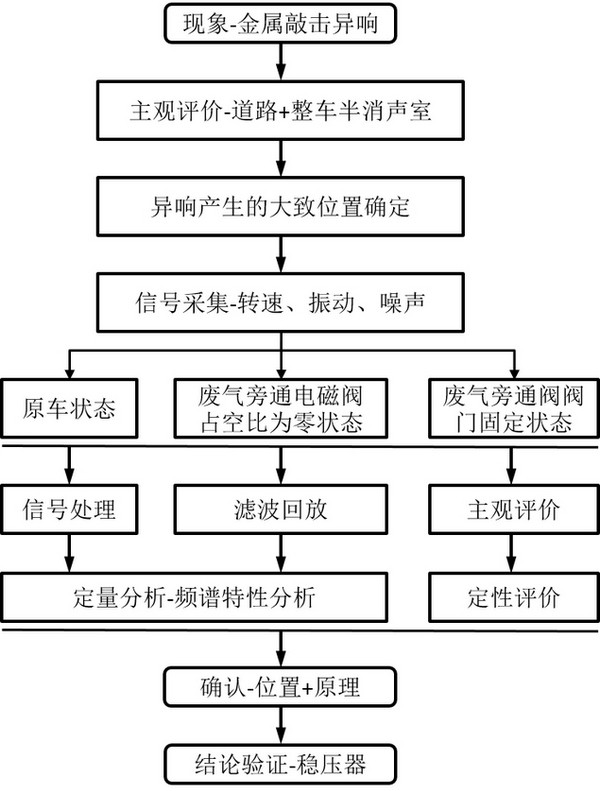

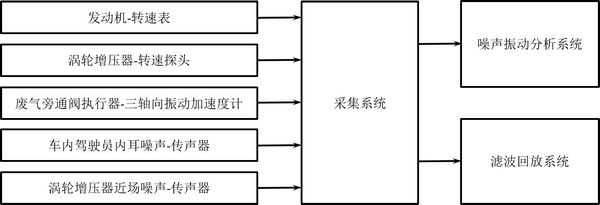

Turbocharger abnormal sound diagnosis method

ActiveCN111366347AEfficient and clear diagnosis methodQuick searchMachine part testingSound sourcesTurbocharger

The invention relates to a turbocharger abnormal sound diagnosis method. The method comprises steps of 1) noise vibration analysis; 2) filtering playback, the engine crankshaft rotating speed and theturbocharger rotor rotating speed corresponding to the frequency when abnormal sound occurs in the noise in a vehicle and the turbocharger near-field noise are filtered and separated; 3) excitation source control, the opening and closing time proportion of a turbocharger waste gas bypass valve is controlled by adjusting the duty ratio; 4) subjective evaluation, subjective evaluation is performed on in-vehicle abnormal sounds and turbocharger near-field noise in three states of an original vehicle state, adjustment of the duty ratio of a waste gas bypass valve controller to be zero and fixationof a waste gas bypass valve; 5) confirmation of the source of abnormal noise; and 6) conclusion verification, a pressure stabilizer is arranged at an air outlet of an air compressor of the turbocharger, and the conclusion is verified through objective improvement of abnormal sound quantification. The method is advantaged in that the abnormal sound source is quickly found by controlling possible excitation source state change, and the test period is short.

Owner:XIANGYANG DAAN AUTOMOBILE TEST CENT

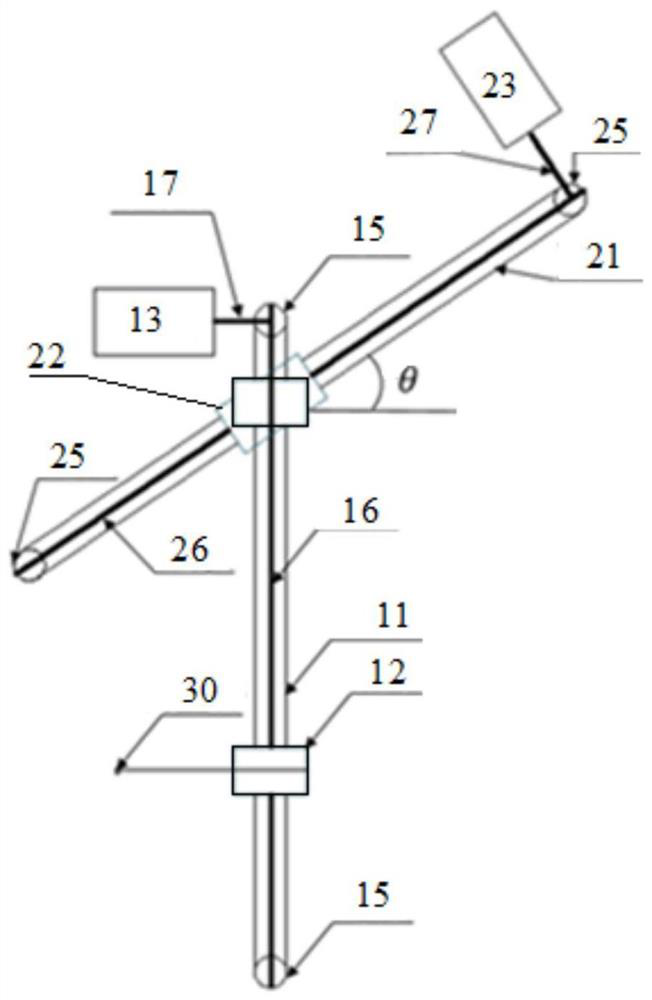

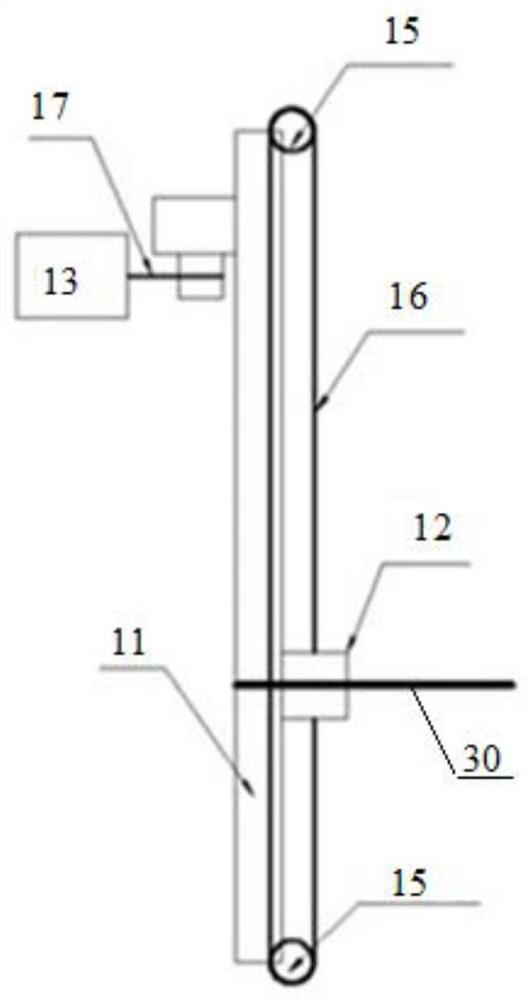

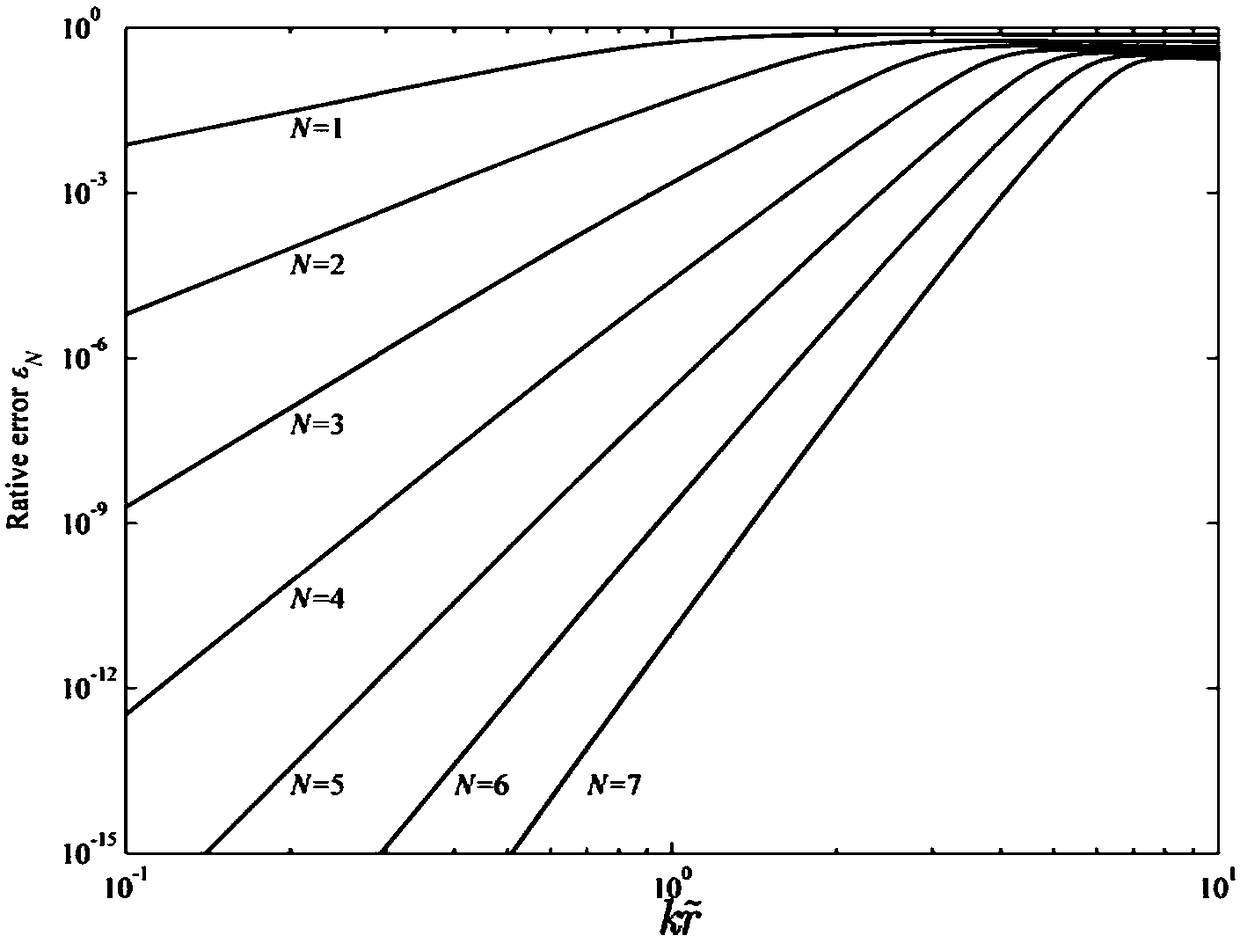

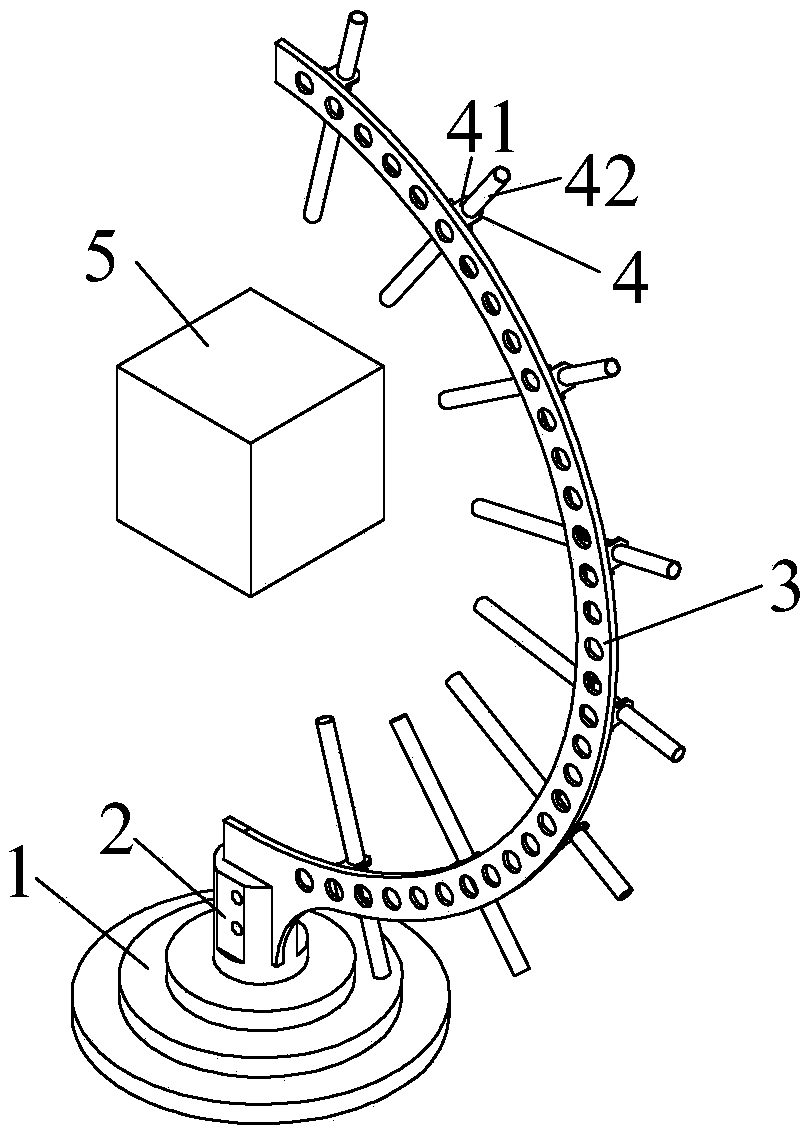

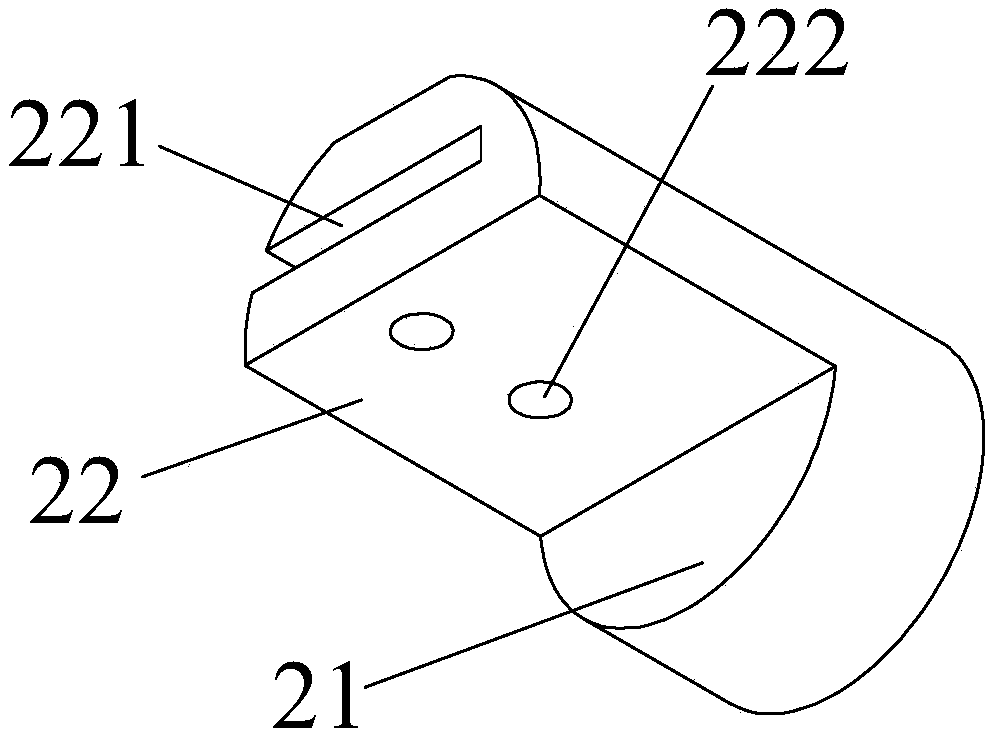

Near-field acoustic holography test method based on spherical function basic solution and near-field acoustic holography test device thereof

ActiveCN106124037AScientific and effective selectionConvenient sound pressure measurementSubsonic/sonic/ultrasonic wave measurementPosition fixationMeasurement pointSound pressure

The invention provides a near-field acoustic holography test method based on a spherical function basic solution and a near-field acoustic holography test device thereof. The test method comprises the steps that the order N of the used spherical function basic solution and the number and the position of microphones on a spherical holographic measuring surface are determined, sound pressure measurement is performed on the determined measurement points and the acoustic physical quantity of the surface of a vibration structure is reversely reconstructed by using the acquired measurement result. The device comprises a base (1), a rotating shaft (2), a semicircular support (3) and a test mechanism (4). The semicircular support (3) can circumferentially rotate along with the rotating shaft (2). The test mechanism (4) is fixedly installed on the semicircular support (3) and can measure acoustic pressure information of the spherical holographic measuring surface surrounding the vibration structure (5).

Owner:SHANGHAI JIAO TONG UNIV

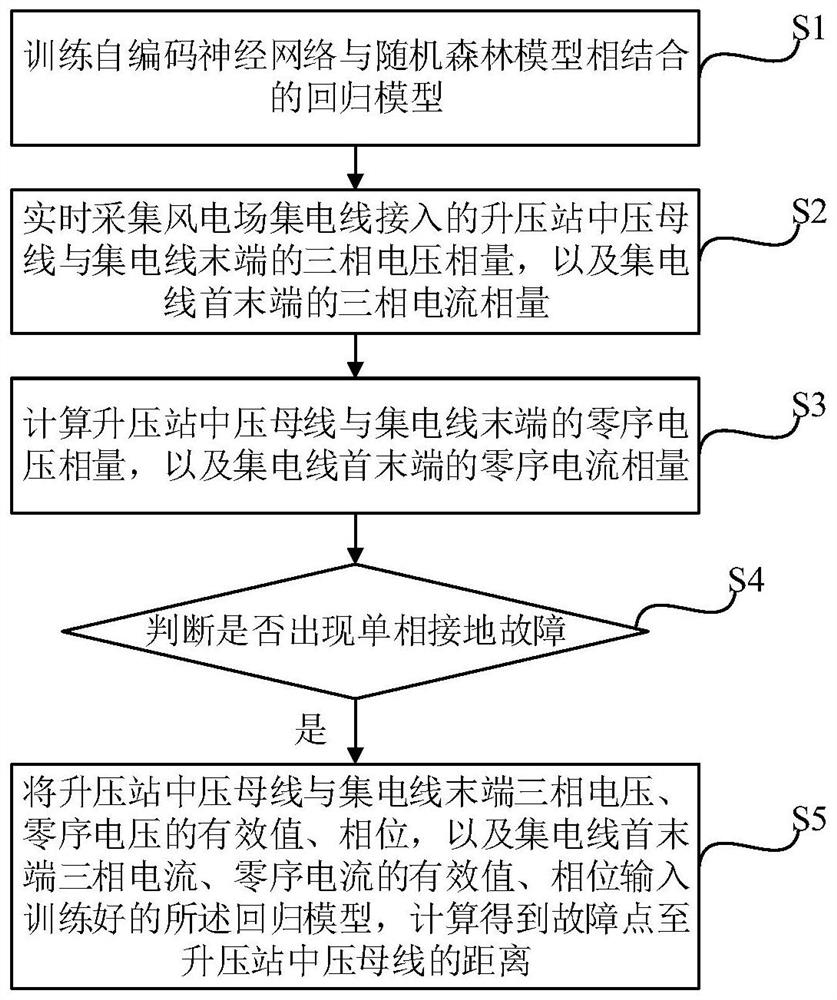

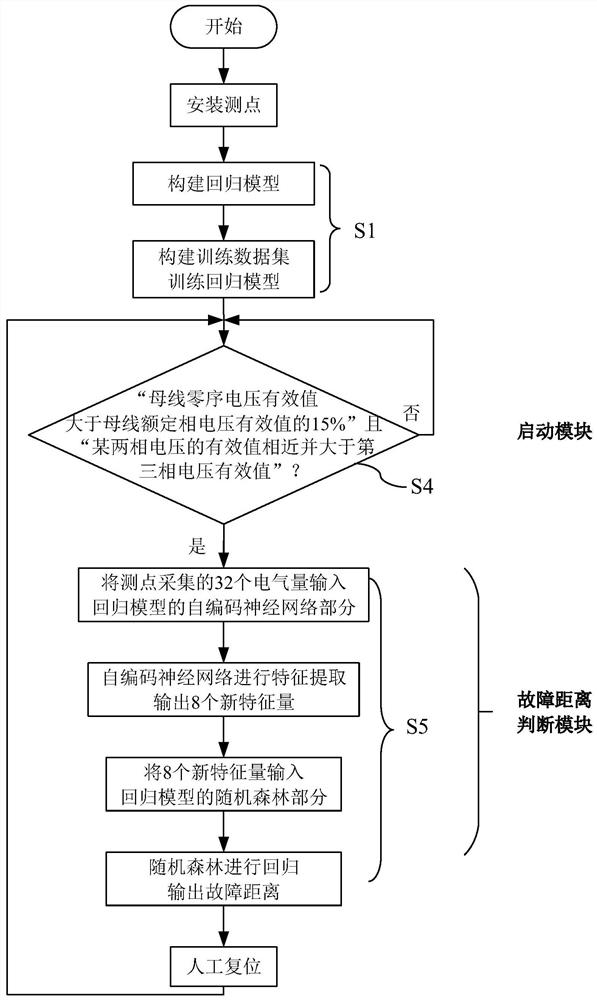

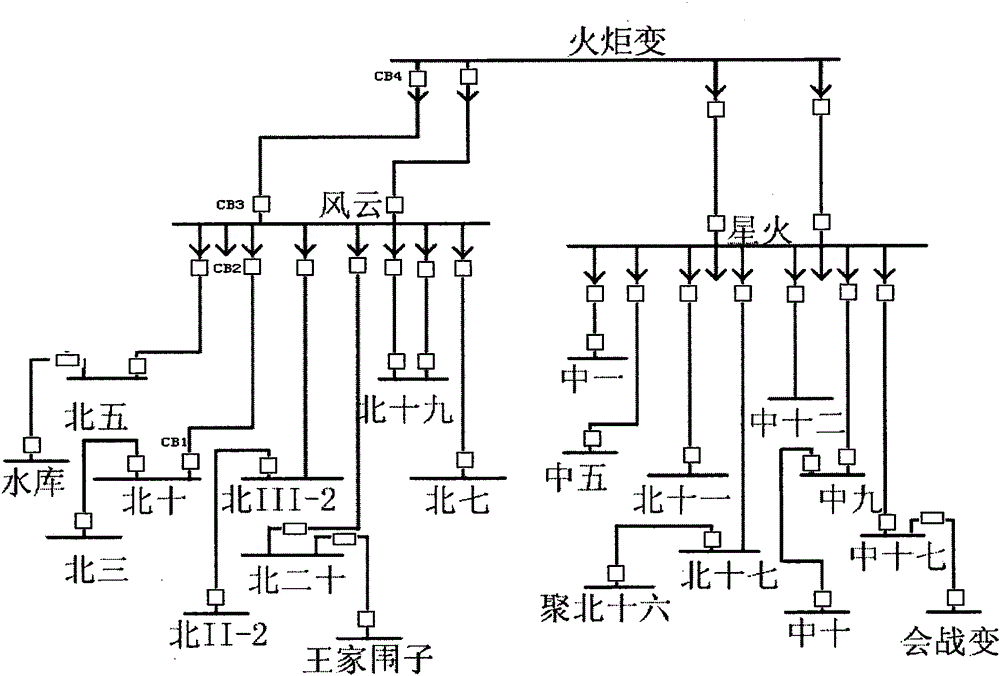

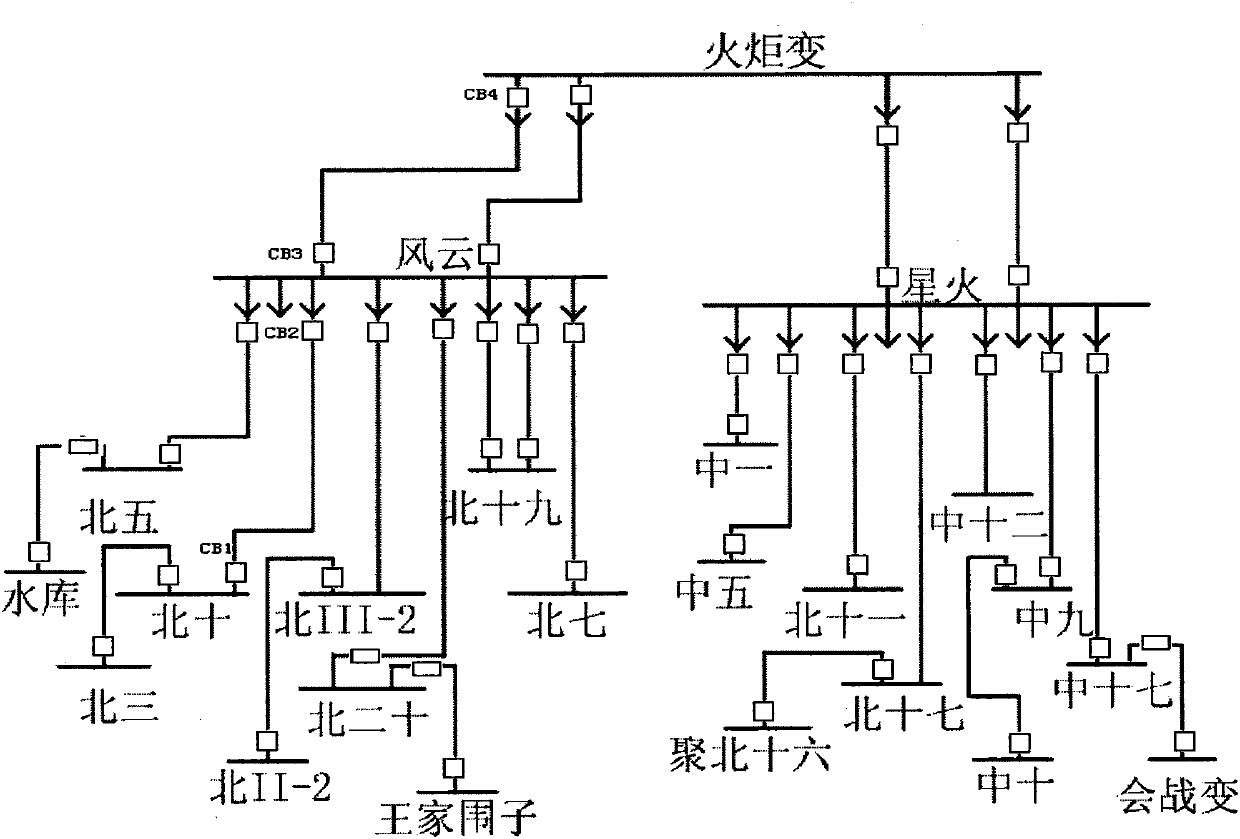

Wind power plant current collection line single-phase earth fault positioning method

ActiveCN112816831AAccurately determine the location of the fault pointLess investmentFault location by conductor typesShort-circuit testingPhase currentsControl engineering

The invention provides a wind power plant current collection line single-phase earth fault positioning method. The method comprises the following steps: training a regression model combining a self-encoding neural network and a random forest model; collecting three-phase voltage phasors of a booster station medium-voltage bus connected to a wind power plant current collection line and the tail end of the current collection line in real time, and three-phase current phasors of the head end and the tail end of the current collection line; calculating zero-sequence voltage phasors of a medium-voltage bus and the tail end of a current collection wire in the booster station and zero-sequence current phasors of the head end and the tail end of the current collection wire; judging whether a single-phase earth fault occurs or not; and if YES, inputting the effective values and phases of the three-phase voltage and the zero-sequence voltage of the booster station medium-voltage bus and the tail end of the current collection line and the effective values and phases of the three-phase current and the zero-sequence current of the head end and the tail end of the current collection line into the trained regression model, and calculating the distance from the fault point to the booster station medium-voltage bus. According to the invention, the problems of inaccurate single-phase earth fault positioning and multiple measuring points of the current collection line in the prior art can be solved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

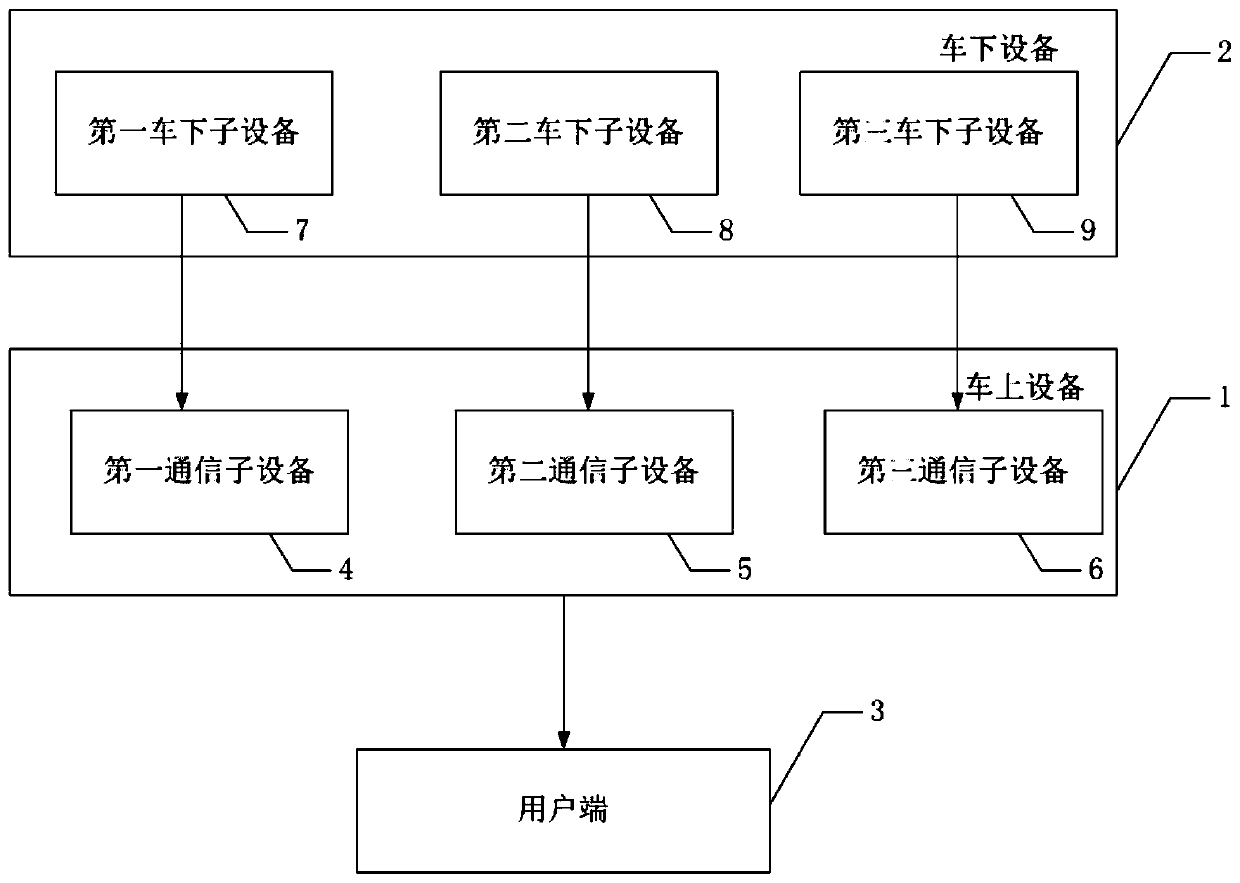

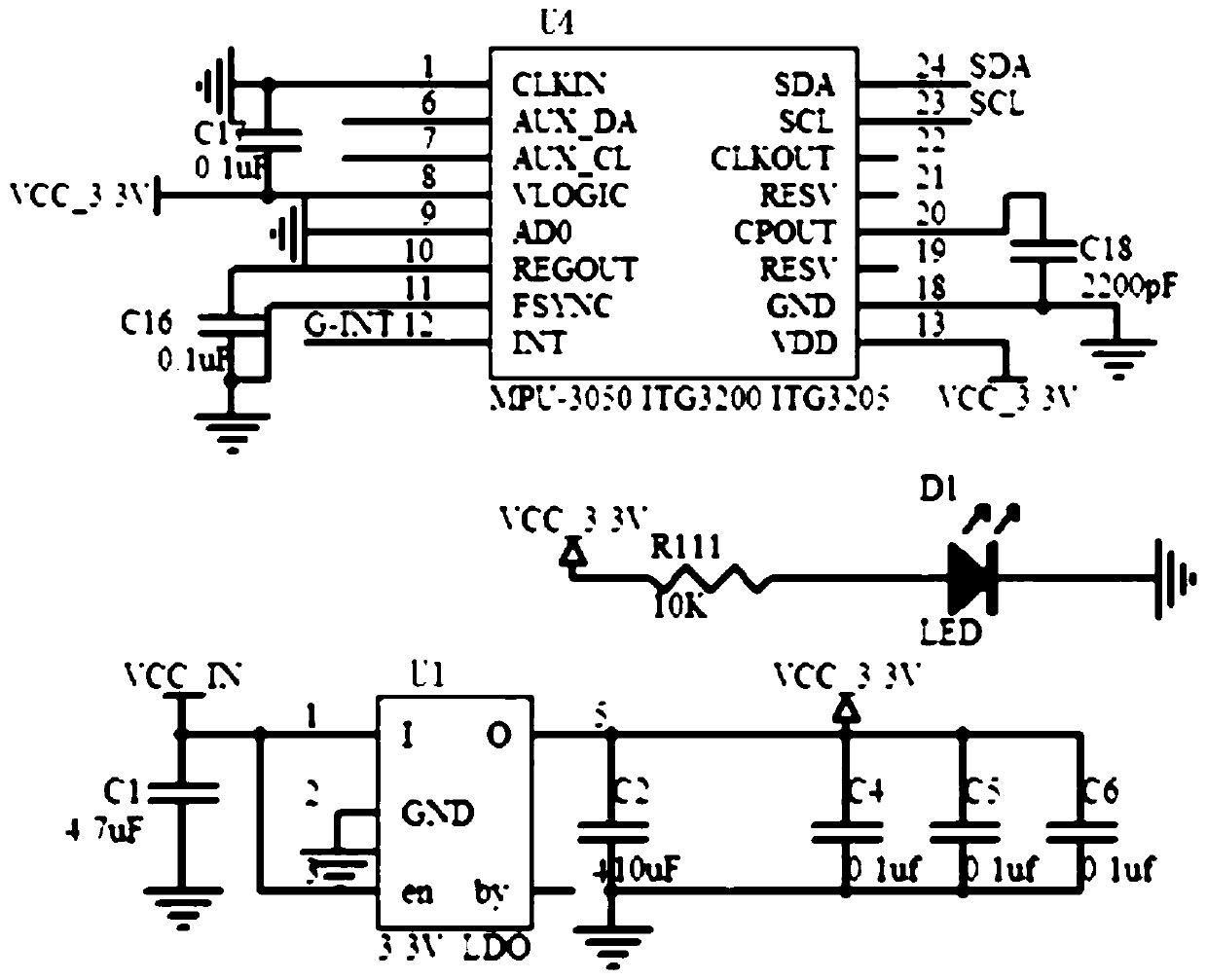

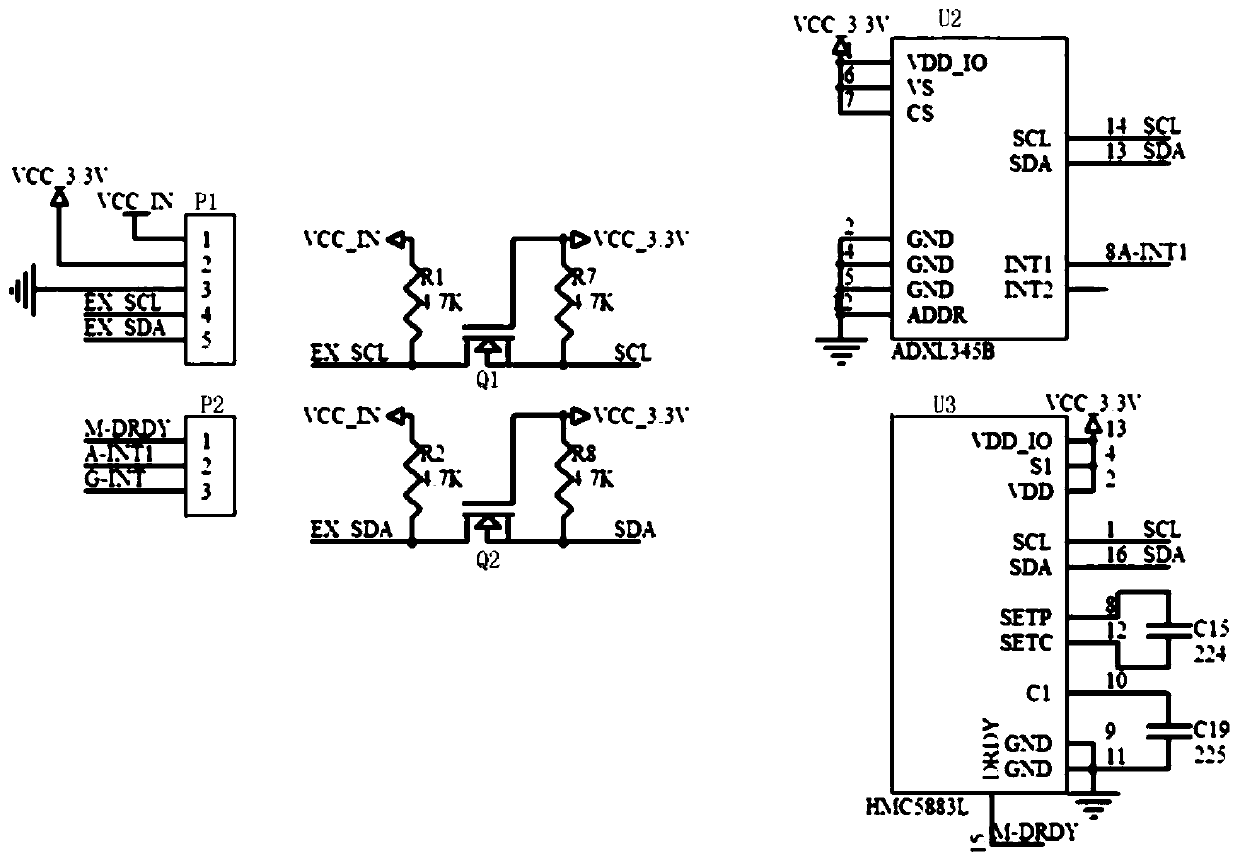

Railway vehicle body vibration fatigue monitoring system and method

PendingCN111122186AFew measuring pointsSimple compositionRailway vehicle testingMonitoring systemBody vibration

The invention discloses a rail vehicle body vibration fatigue monitoring system and a method. The rail vehicle body vibration fatigue monitoring system comprises on-vehicle equipment, off-vehicle equipment and a user terminal. The on-vehicle device is in communication connection with the off-vehicle device and the user terminal. The system provided by the invention needs few sensor measuring points, and is simple in equipment hardware composition, small in size and convenient to carry. And the system can also feed back the real-time situation to the user, so that the user is guided to focus ondesign and maintenance. According to the method, the power spectral density is adopted as calculation input, the calculation speed is high, and the collection period of the under-vehicle equipment can be greatly shortened. Meanwhile, the fatigue weak part of the vehicle body provided by the method can provide an important basis for vehicle body structure design, so that workers are guided to payattention to a vehicle body maintenance area during maintenance; the sensitive frequency provided by the method can guide the design of a vehicle suspension system; and the real-time change of the fatigue damage value of the vehicle body is also one of guidance bases for workers to perform line maintenance and vehicle body maintenance period adjustment.

Owner:SOUTHWEST JIAOTONG UNIV

Determination method of wheel pressure of crane

ActiveCN104034469BLoose arrangementOptimize layoutApparatus for force/torque/work measurementLifting capacityEngineering

The invention discloses a measuring method for a crane cart wheel pressure. The measuring method for the crane cart wheel pressure includes steps that (1) distributing foils, to be specific, pasting strain foils at the lateral surface of a cart track; (2) building a wheel pressure monitoring system, to be specific, connecting the strain foils and wireless strain nodes with a monitoring host; (3) calibrating, to be specific, enabling a crane to locate in a no-load state, enabling a crane dolly to locate at a proper position, enabling the cart to pass the cart track in a constant speed, and using the wheel pressure monitoring system to record a strain-time curve so as to obtain a wheel pressure and strain calibrating coefficient (shown in the description); (4) measuring the cart wheel pressure on site, to be specific, when the dolly is located at a set position according to a set lifting capacity, gathering the corresponding strain value, and converting the strain value into the corresponding wheel pressure (shown in the description). The measuring method for the crane cart wheel pressure is easy and practical, is capable of precisely measuring the actual value of each wheel pressure, is more direct and reliable than a calculation method, is capable of directly reflecting the wheel pressure non-uniformity of the crane under different working conditions and provides essential data for optimizing, using and maintaining the crane wheels and saving civil engineering cost.

Owner:NANTONG BRANCH OF SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

Wide span rail traffic bridge damnification recognition method

InactiveCN101281117BIn line with the actual situationReduce calculation errorsUsing mechanical meansSpecial data processing applicationsSignal onNumerical models

The invention relates to a large span rail traffic bridge damage recognition method, including the steps:(1) a sensor is arranged on the bridge which will be examined, the dynamic response signal of alarge span rail traffic bridge is measured and is driven by that when a rail vehicle crosses the large span bridge, the signal on the sensor is red by a computer; (2) the benchmark bridge numerical model and the rail vehicle numerical model of the bridge are established; (3) a coupled mechanical analysis system comprising the benchmark bridge numerical model and the rail vehicle numerical model is initialized, an explicit integral method is used to solve the system, the simulated dynamic response signal of the benchmark bridge numerical model on a relative position is red according to the installment position of the sensor; (4) the energy spectrums of the dynamic response signal obtained by monitoring and the simulated dynamic response signal obtained by numerical simulation calculation of the bridge are solved by a multi-scale wavelet packet analysis method, and a damage recognition is carried on by recognizing index. The invention increases the precision of the bridge damage recognition, and the normal use of the bridge structure can not be affected.

Owner:SHANGHAI JIAO TONG UNIV

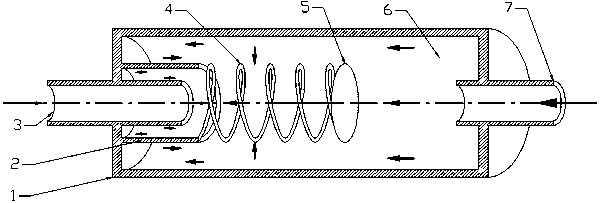

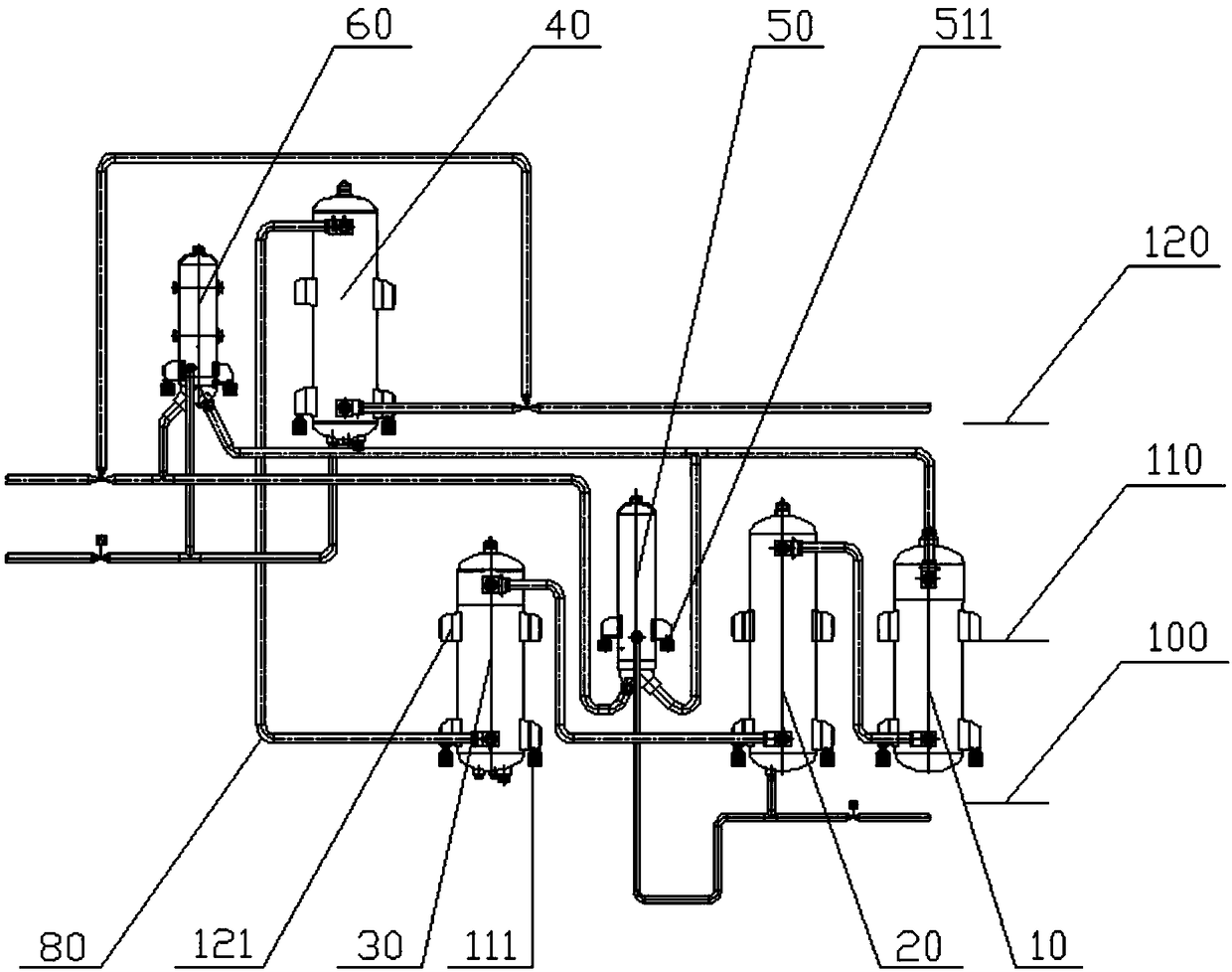

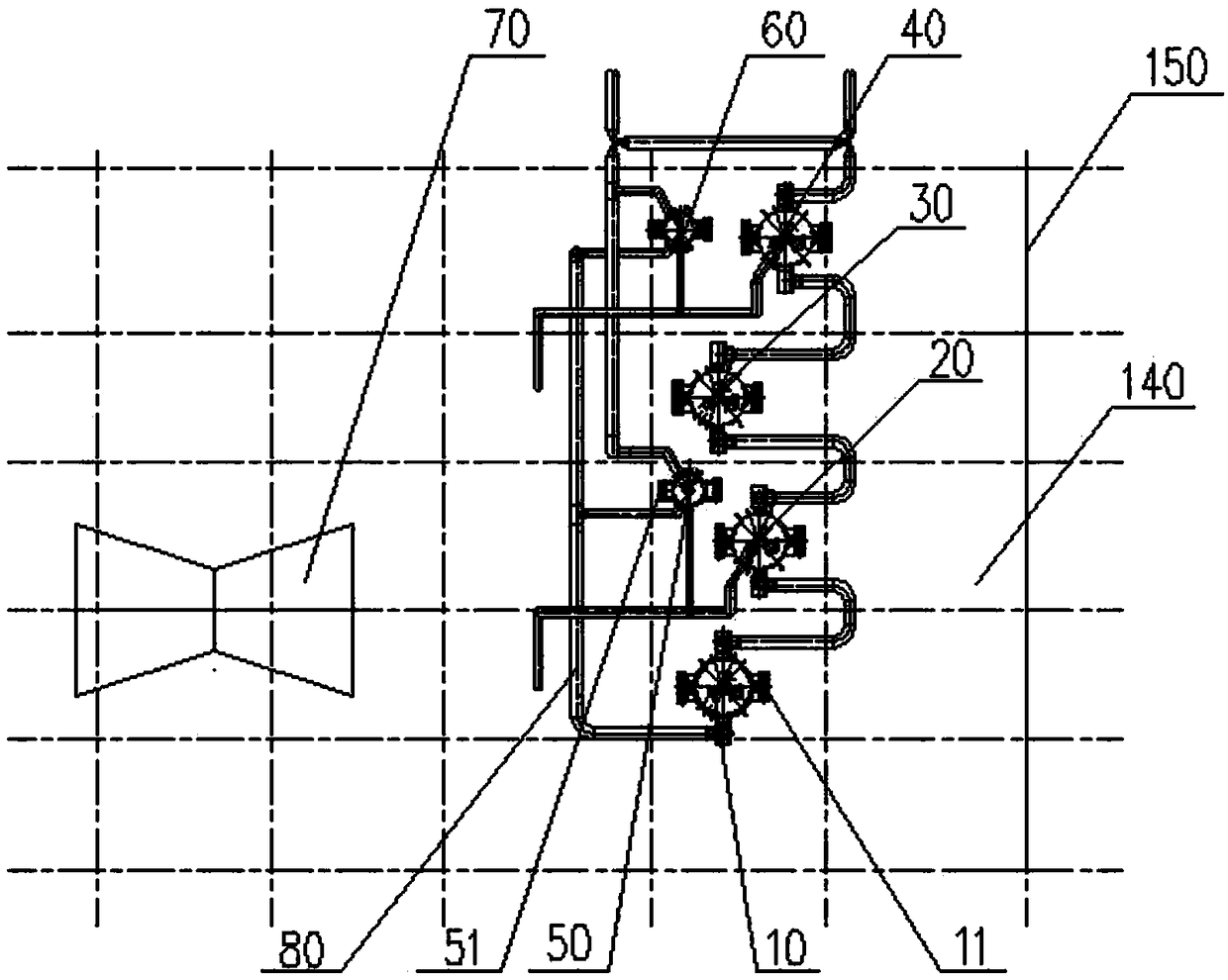

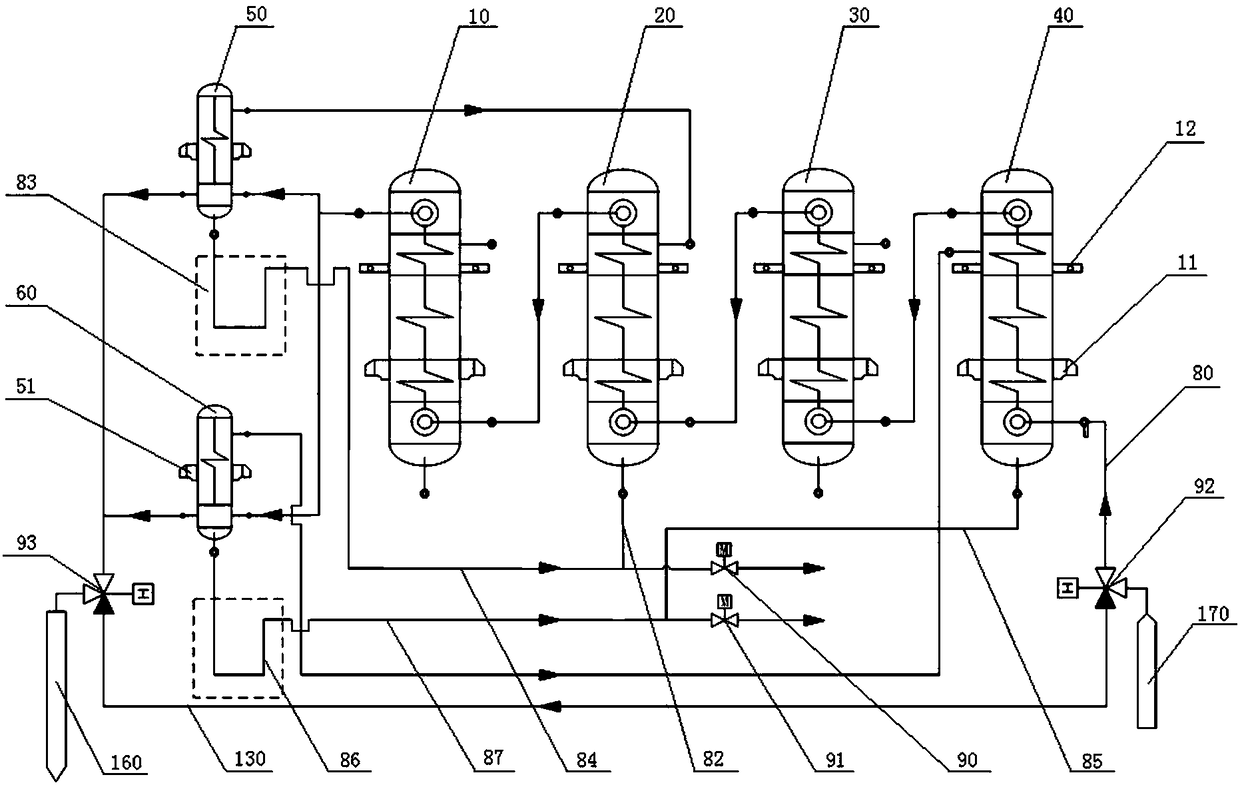

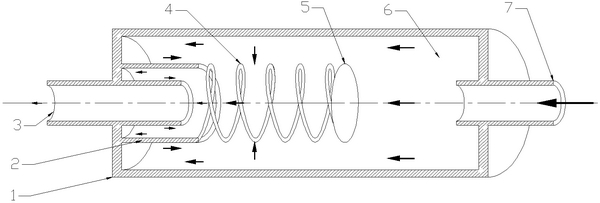

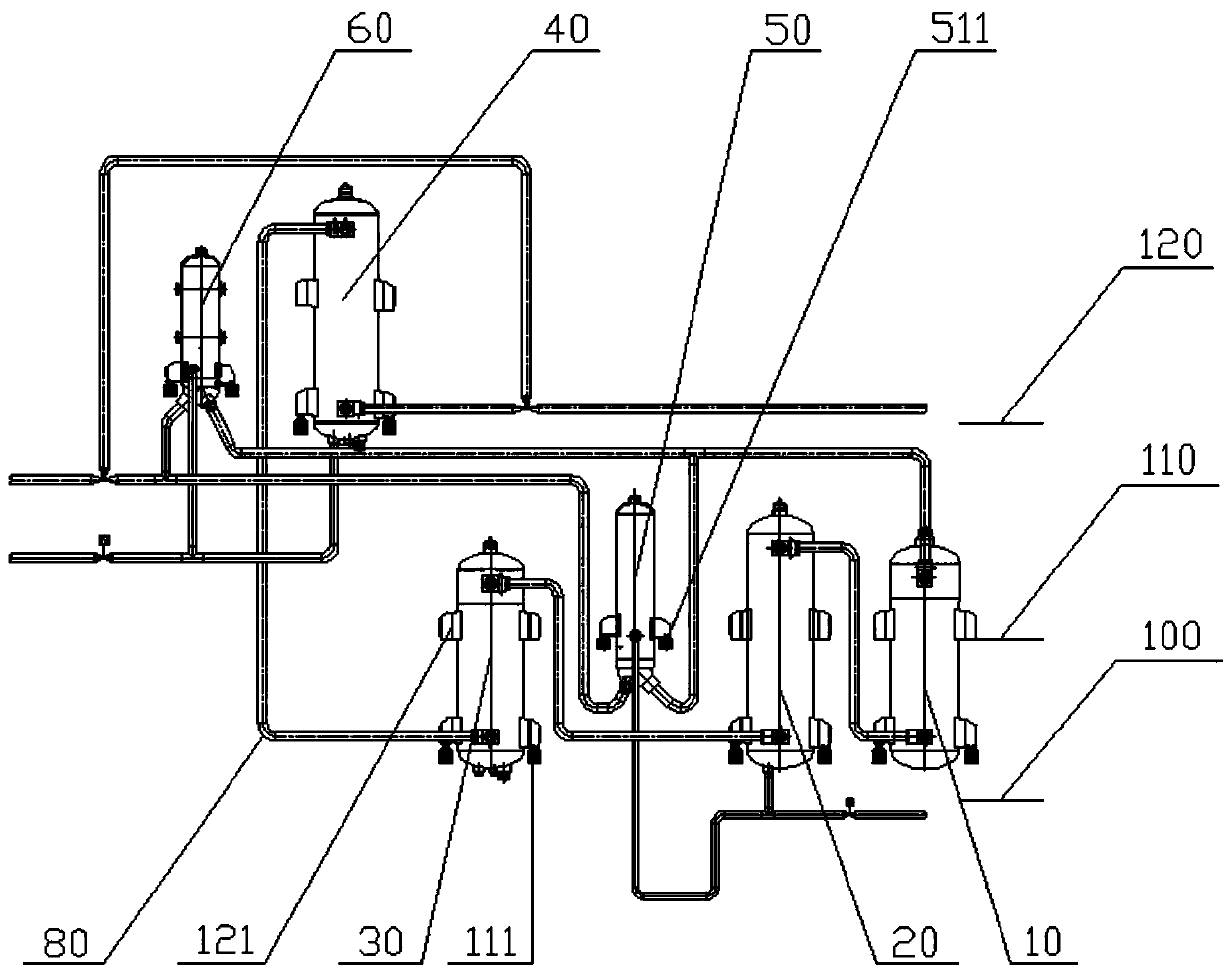

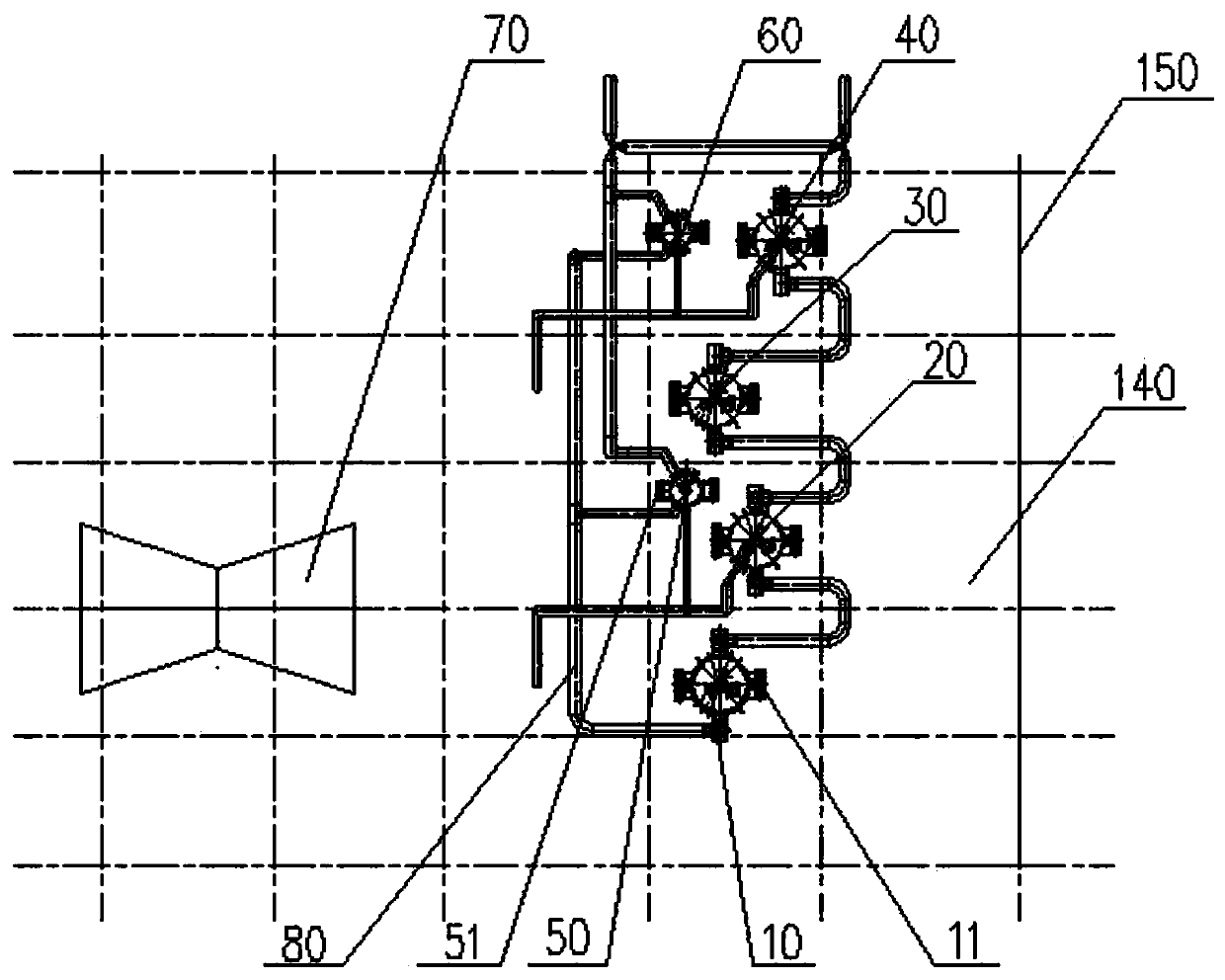

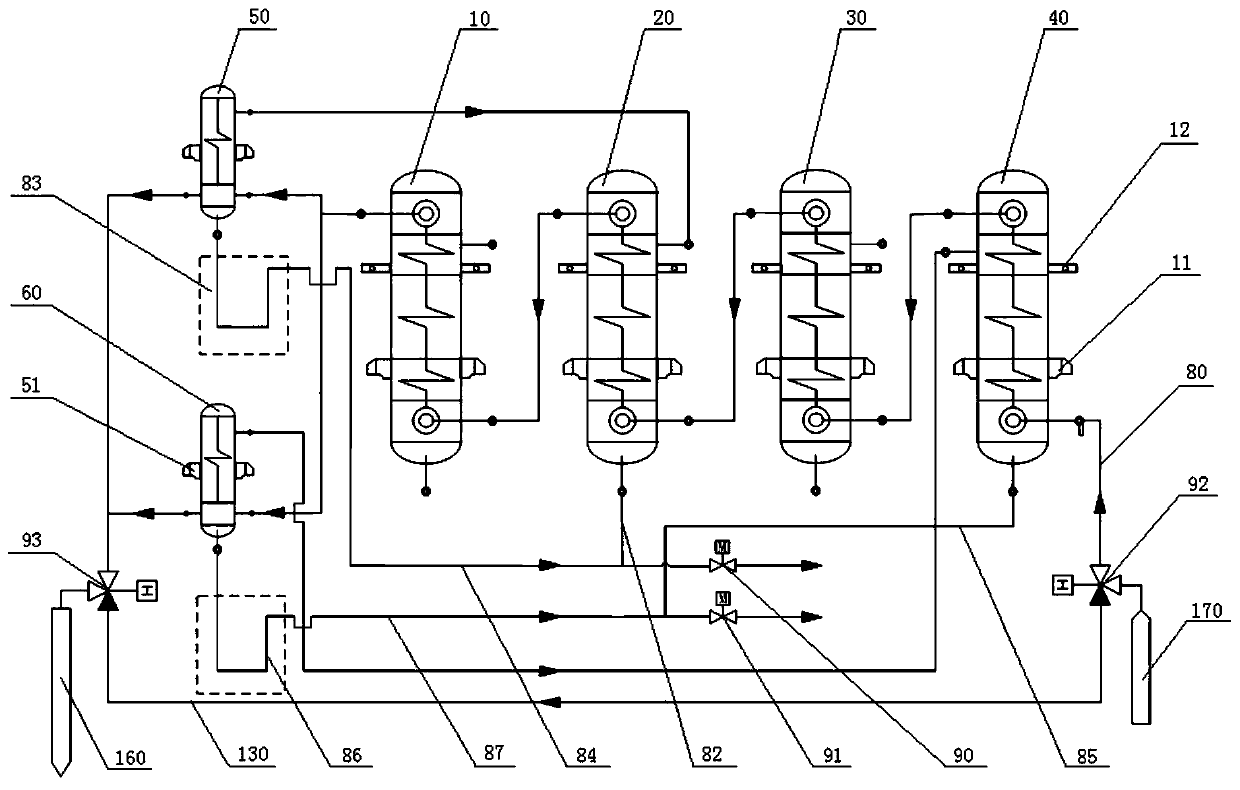

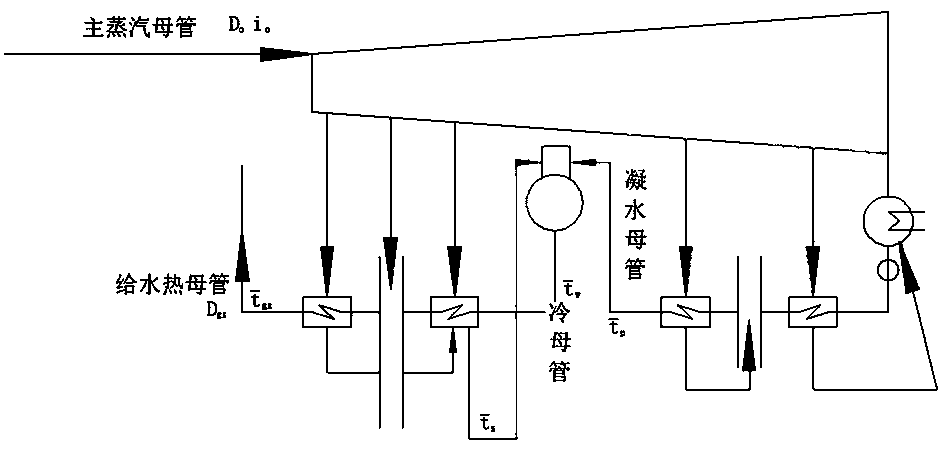

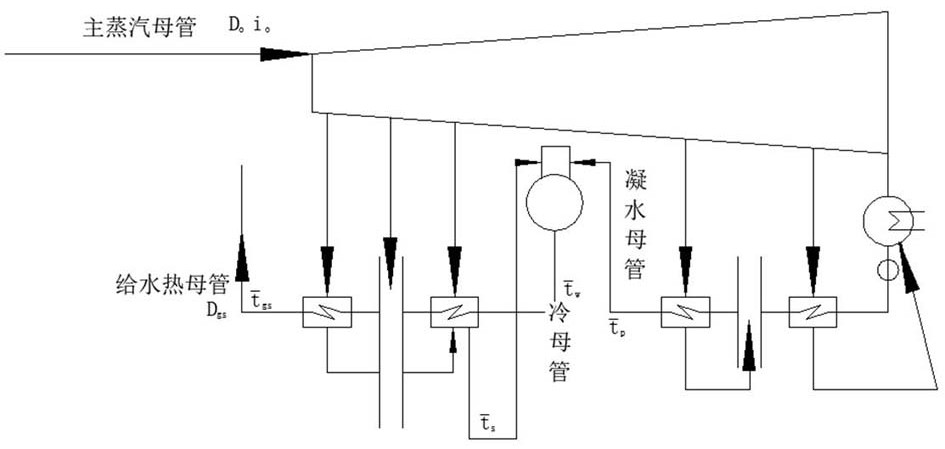

Secondary reheating million unit high-pressure heater system structure and application method thereof

The invention discloses a secondary reheating million unit high-pressure heater system structure. The structure comprises a steam turbine, a high-pressure heater set and an external steam cooler set;the high-pressure heater set comprises a first high-pressure heater, a second high-pressure heater, a third high-pressure heater and a fourth high-pressure heater; single-row coiler vertical high-pressure heaters are adopted; the first high-pressure heater, the second high-pressure heater and the third high-pressure heater are arranged in a zero-meter layer of a steam machine room; the fourth high-pressure heater is arranged in an operation layer of a deaeration room; the external steam cooler set comprises a second external steam cooler and a fourth external steam cooler; U-shaped tube vertical heaters are adopted; the second external steam cooler is arranged in a middle layer of the steam machine room; and the fourth external steam cooler is arranged in the operation layer of the deaeration room. Meanwhile, the invention discloses an application method of the secondary reheating million unit high-pressure heater system structure. The structure has the characteristics of capability ofreducing the manufacturing cost of the steam machine room, simplification of the system, reduction of the engineering quantity, improvement of the unit economy, acceleration of the unit start time and the like.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST +1

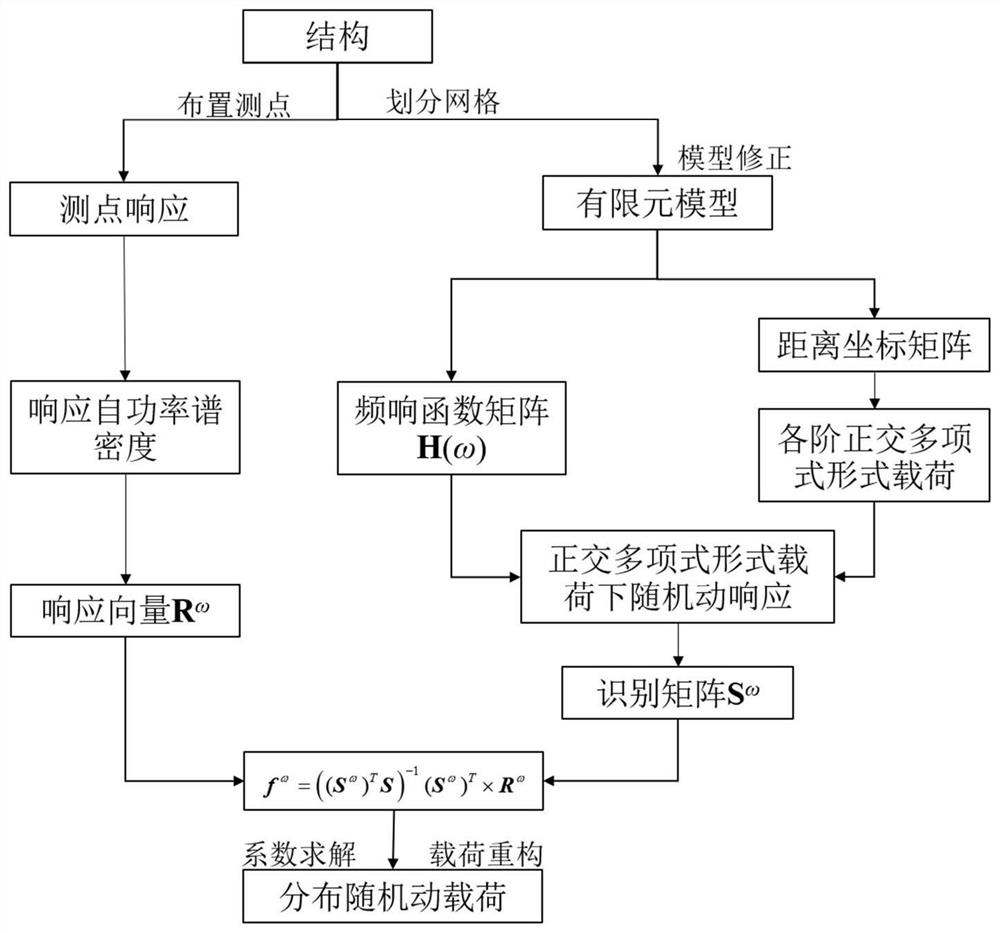

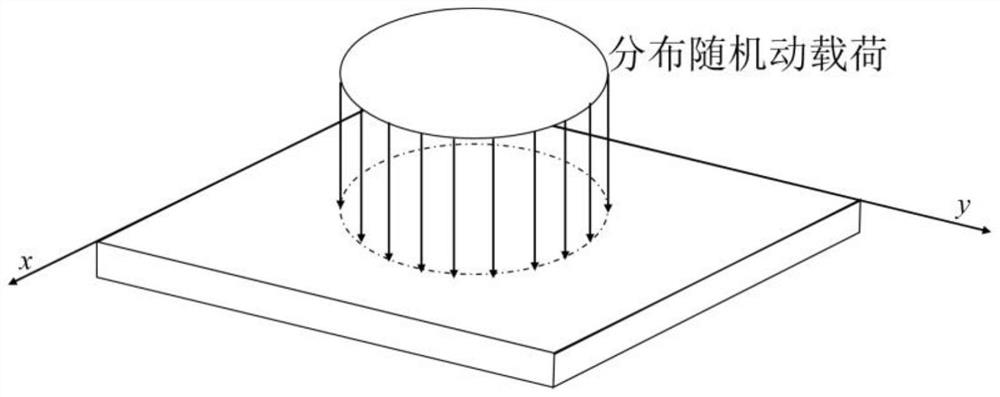

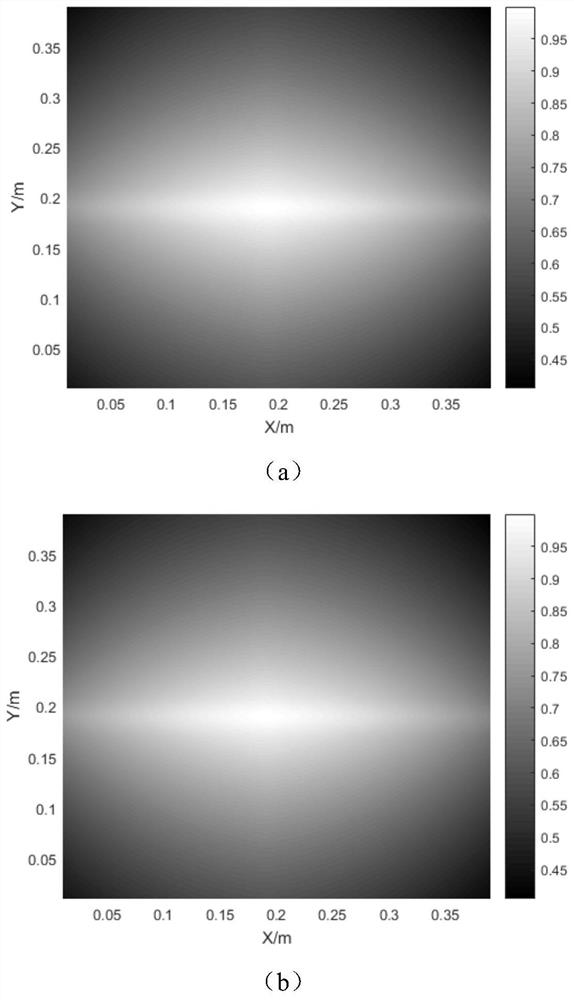

Frequency domain distribution random dynamic load identification method considering spatial correlation

PendingCN113392547AImprove recognition accuracyReduce polynomial orderGeometric CADDesign optimisation/simulationSpatial correlationElement model

The invention discloses a frequency domain distribution random dynamic load identification method considering spatial correlation. The method comprises the steps: S1, establishing a finite element model of the thin-wall structure according to the geometrical shape of the thin-wall structure; S2, measuring points are arranged on the actual thin-wall structure, and a self-power spectral density function of the response is calculated according to the dynamic response of the measurement; S3, determining a corresponding measuring point position on the finite element model according to the geometric position of an actual measuring point, calculating a measuring point response in the finite element model under the excitation action of a random dynamic load distributed in an orthogonal polynomial form in a distance space, and assembling into a recognition matrix; S4, calculating a cross-power spectral density function of the distributed random dynamic load according to the identification matrix and the responded auto-power spectral density function, and reconstructing the distributed random dynamic load. The distributed random dynamic load outside the structure is identified through the structural strain response, the spatial distribution function of the distributed random dynamic load can be accurately obtained, and an indirect distributed random dynamic load obtaining method is provided.

Owner:SOUTHEAST UNIV

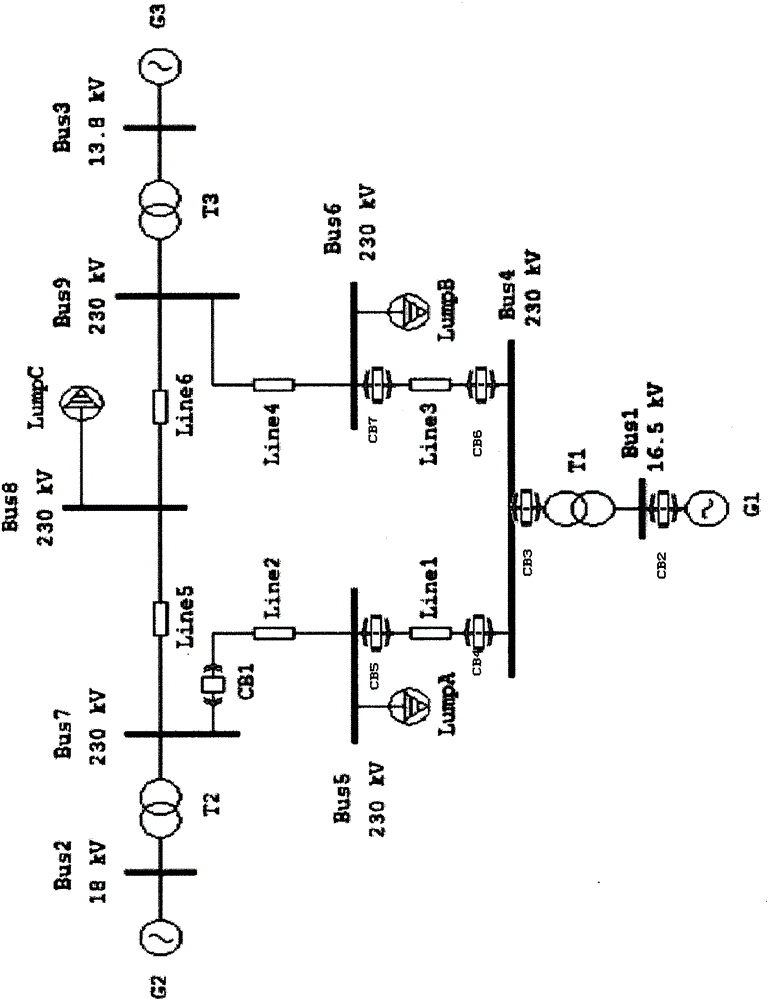

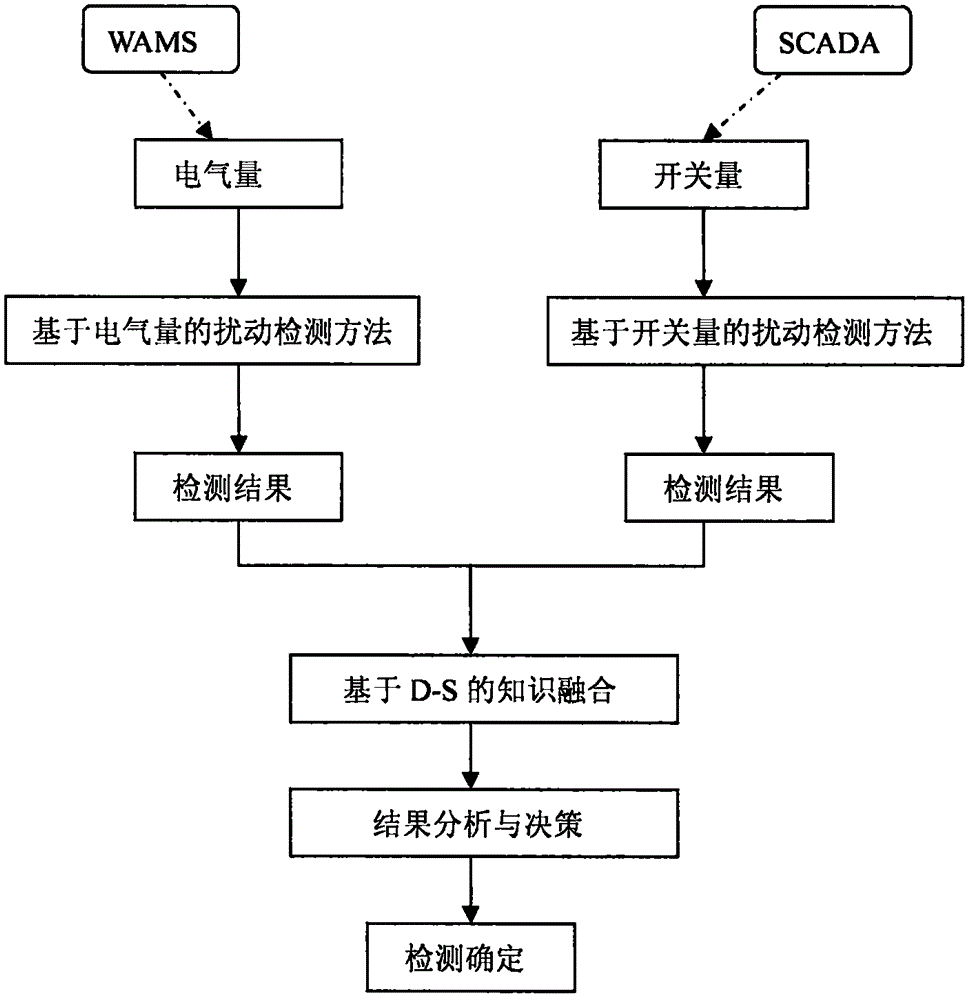

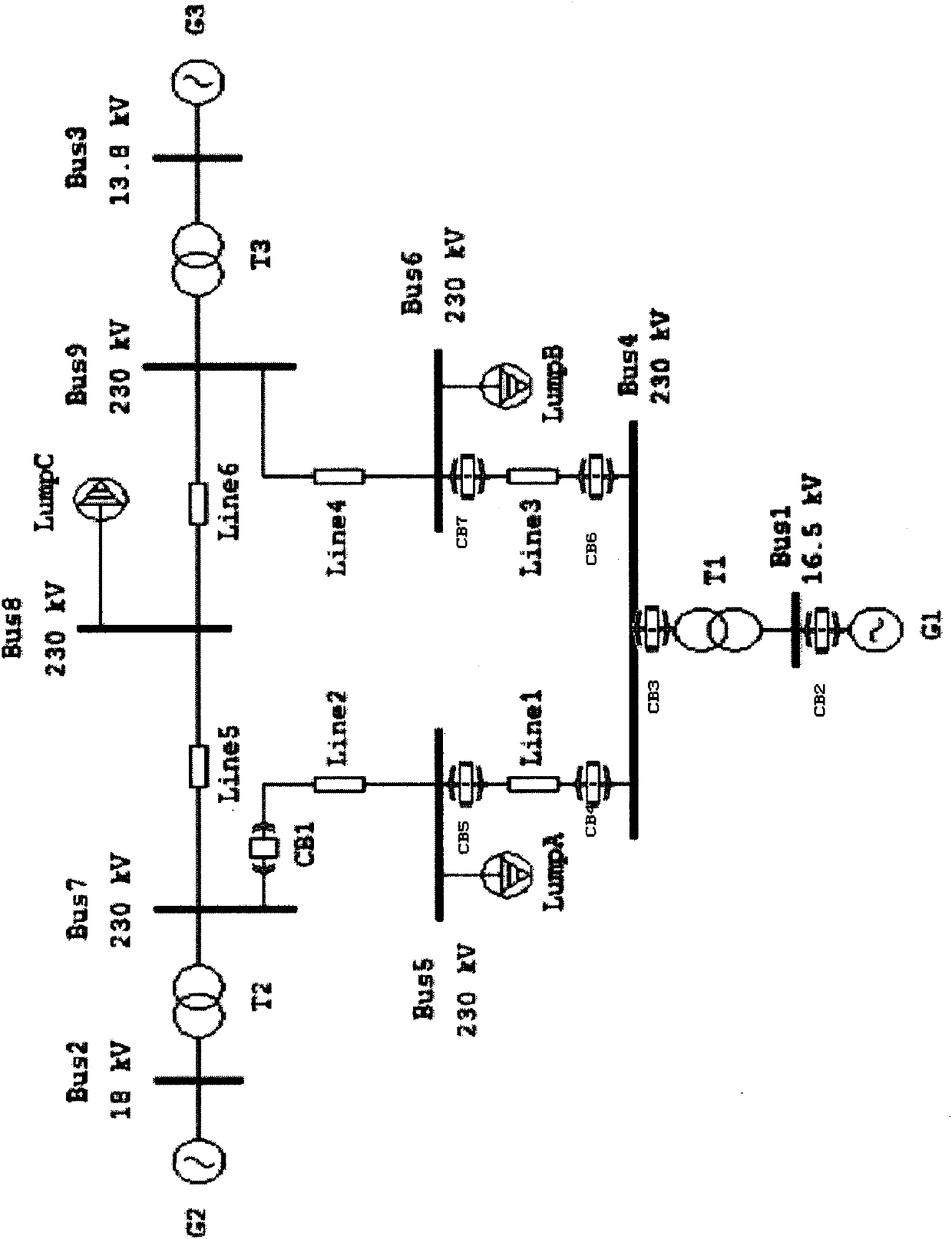

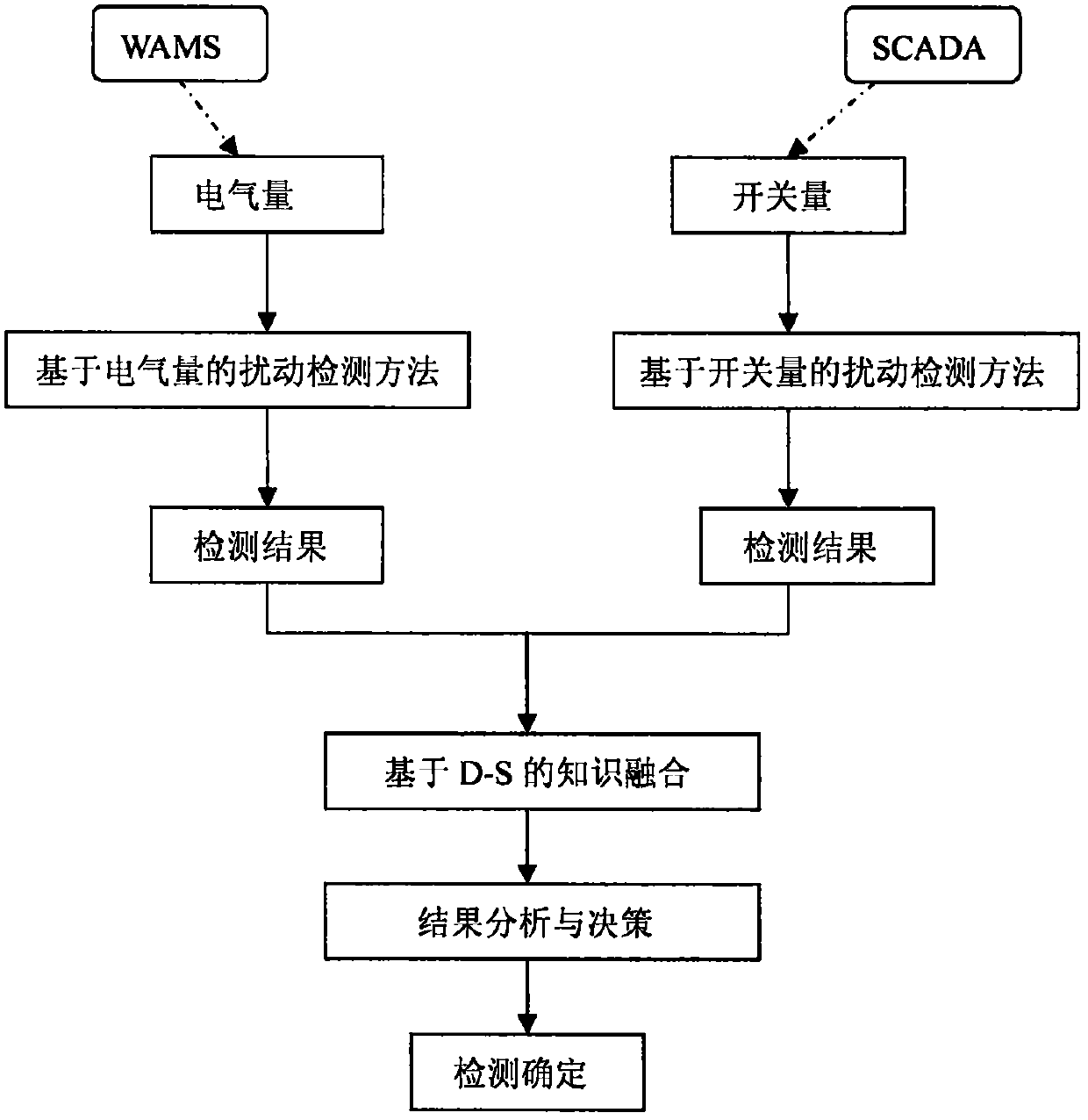

Power grid single large disturbance online detection method based on WAMS

ActiveCN105844542ARealize the judgment of whether a large disturbance occursThe detection process is fastData processing applicationsCharacter and pattern recognitionSCADAPower grid

The invention discloses a power grid single large disturbance online detection method based on a WAMS. The method comprises steps of 1), information acquisition; 2), disturbance detection; 3), information fusion; and 4), diagnosis and decision. According to the method, the algorithm is simple, the detection speed is relatively fast, accuracy is relatively high, the precise phase angle information is provided through utilizing a PMU, so whether disturbance occurs is detected, and a determination problem that whether single large disturbance occurs is solved, moreover, as the uploaded information is with a certain error probability, whether disturbance occurs is verified by utilizing the data fusion theory in combination with the data uploaded by the WAMS and a SCADA, and a problem of an error large disturbance occurrence determination result caused by the error uploaded information is solved.

Owner:韩小学

A method for diagnosing abnormal sound of turbocharger metal percussion

ActiveCN111366347BQuick searchShorten the development cycleMachine part testingSound sourcesTurbocharger

The invention relates to a turbocharger abnormal sound diagnosis method. The method comprises steps of 1) noise vibration analysis; 2) filtering playback, the engine crankshaft rotating speed and theturbocharger rotor rotating speed corresponding to the frequency when abnormal sound occurs in the noise in a vehicle and the turbocharger near-field noise are filtered and separated; 3) excitation source control, the opening and closing time proportion of a turbocharger waste gas bypass valve is controlled by adjusting the duty ratio; 4) subjective evaluation, subjective evaluation is performed on in-vehicle abnormal sounds and turbocharger near-field noise in three states of an original vehicle state, adjustment of the duty ratio of a waste gas bypass valve controller to be zero and fixationof a waste gas bypass valve; 5) confirmation of the source of abnormal noise; and 6) conclusion verification, a pressure stabilizer is arranged at an air outlet of an air compressor of the turbocharger, and the conclusion is verified through objective improvement of abnormal sound quantification. The method is advantaged in that the abnormal sound source is quickly found by controlling possible excitation source state change, and the test period is short.

Owner:XIANGYANG DAAN AUTOMOBILE TEST CENT

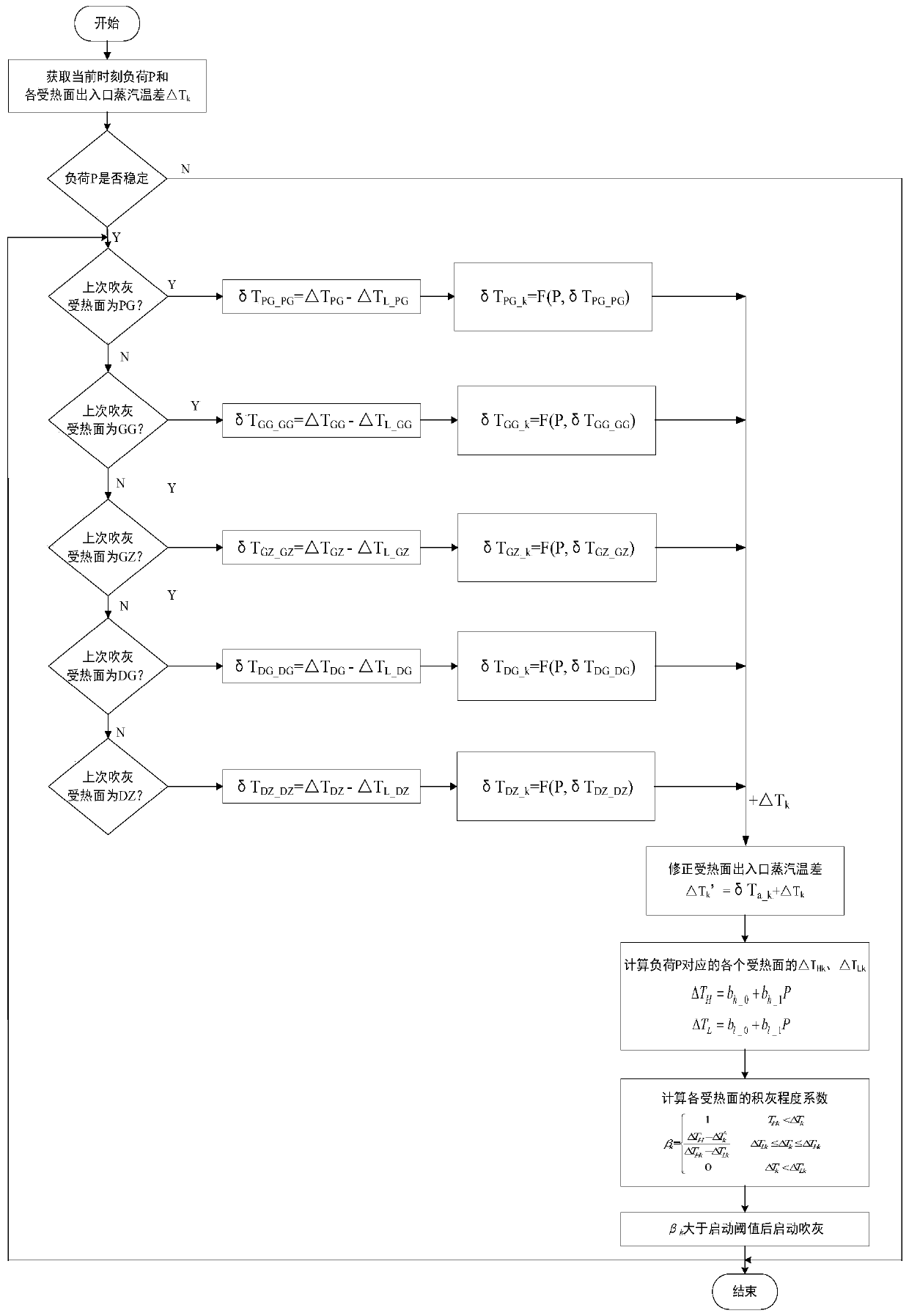

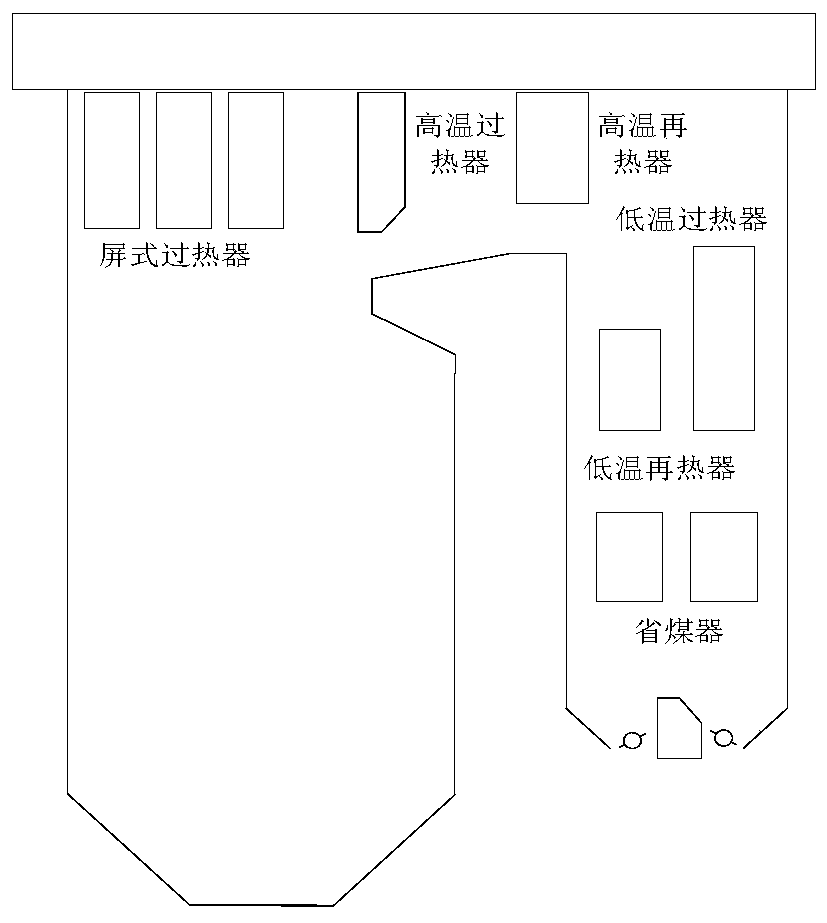

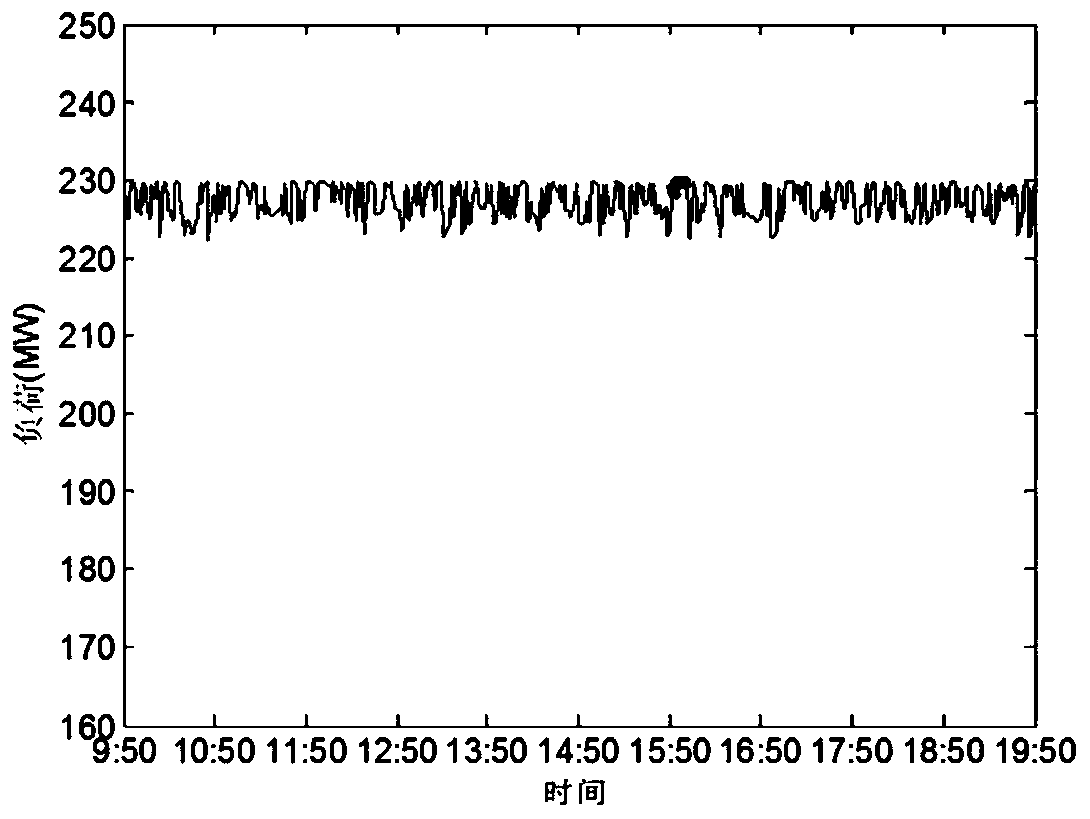

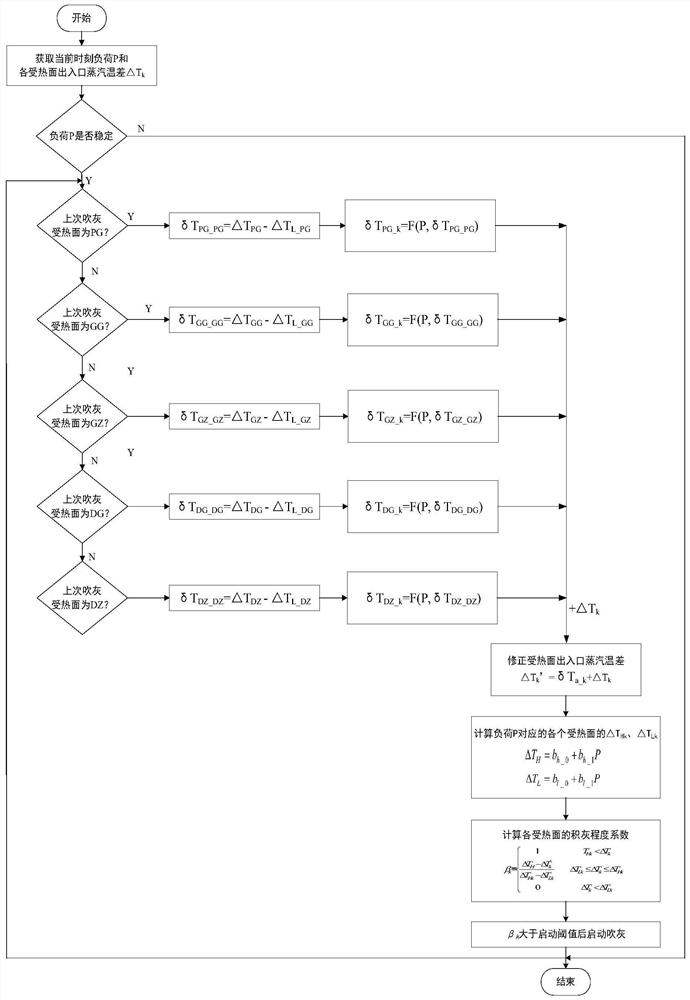

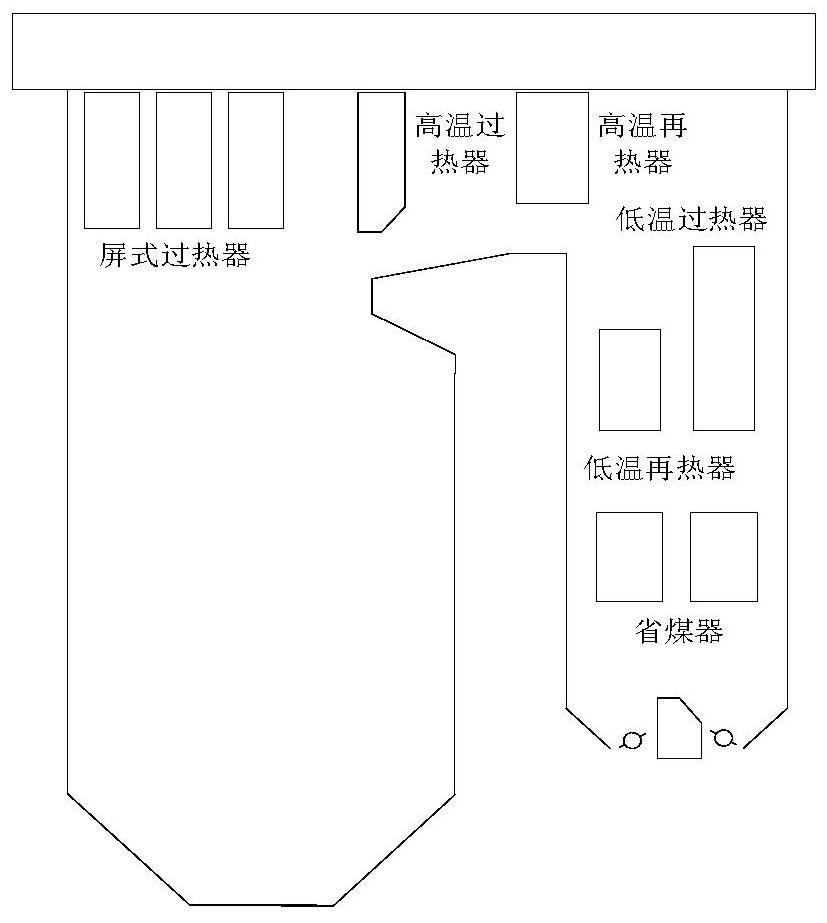

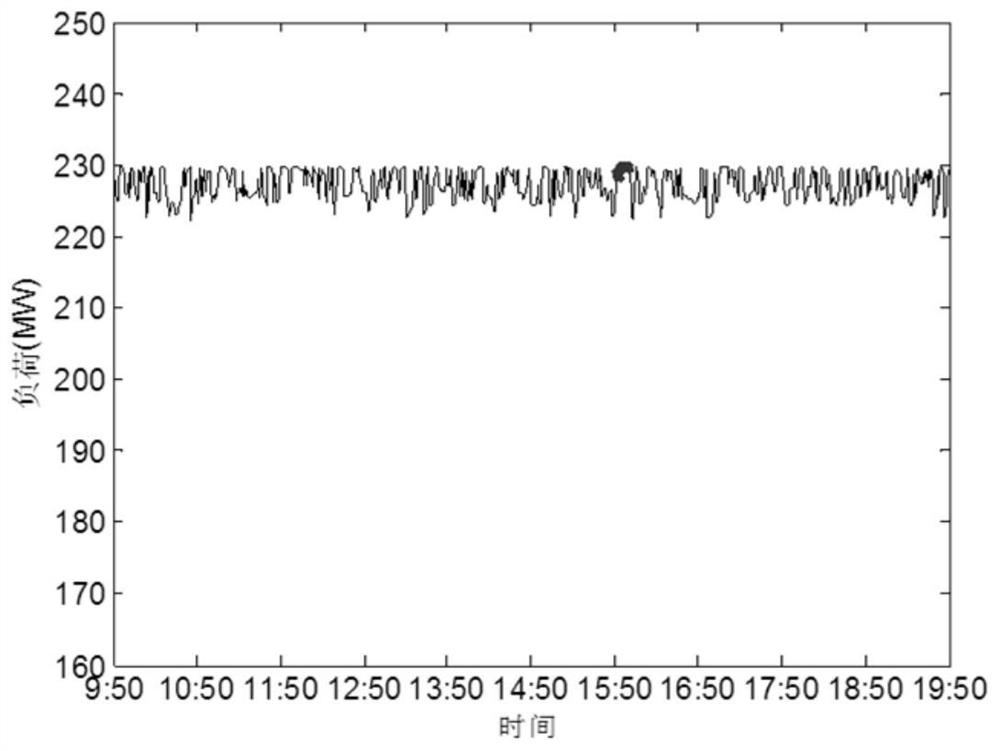

Heating area ash degree judgment method considering global heat transfer influence of coal-fired boiler

The invention relates to a heating area ash degree judgment method considering global heat transfer influence of a coal-fired boiler. The heating area ash degree judgment method comprises the following steps of 1) acquiring a load P of a current moment and inlet and outlet steam temperature difference Delta Tk of each convection heating surface; 2) acquiring an inlet and outlet steam temperature difference change value vector Delta T<a-k> of a heating surface k which is not ash-blown; 3) correcting inlet and outlet steam temperature difference of other heating surfaces to obtain a corrected inlet and outlet steam temperature difference correction value Delta T'<k>; 4) calculating an ash degree coefficient Beta k of each heating surface according to the inlet and outlet steam temperature difference correction value Delta T'<k> of the heating surface; and 5) starting ash blowing until ash accumulation coefficient is reduced to a value below a starting threshold when the ash accumulationcoefficient of a certain heating surface is larger than the starting threshold, and completing ash blowing of the heating surface of the coal-fired boiler. Compared with the prior art, the heating area ash degree judgment method is scientific, practical, accurate and simple.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

System Structure and Application Method of High Pressure Heater System of Double Reheat Million Units

ActiveCN108167806BAchieve double reheatAchieve double reheat millionFeed-water heatersStart timeEngineering

The invention discloses a secondary reheating million unit high-pressure heater system structure. The structure comprises a steam turbine, a high-pressure heater set and an external steam cooler set;the high-pressure heater set comprises a first high-pressure heater, a second high-pressure heater, a third high-pressure heater and a fourth high-pressure heater; single-row coiler vertical high-pressure heaters are adopted; the first high-pressure heater, the second high-pressure heater and the third high-pressure heater are arranged in a zero-meter layer of a steam machine room; the fourth high-pressure heater is arranged in an operation layer of a deaeration room; the external steam cooler set comprises a second external steam cooler and a fourth external steam cooler; U-shaped tube vertical heaters are adopted; the second external steam cooler is arranged in a middle layer of the steam machine room; and the fourth external steam cooler is arranged in the operation layer of the deaeration room. Meanwhile, the invention discloses an application method of the secondary reheating million unit high-pressure heater system structure. The structure has the characteristics of capability ofreducing the manufacturing cost of the steam machine room, simplification of the system, reduction of the engineering quantity, improvement of the unit economy, acceleration of the unit start time and the like.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST +1

A fault diagnosis method for wind turbines based on bispectral entropy

ActiveCN104897277BReduce distractionsEasy extractionSubsonic/sonic/ultrasonic wave measurementElectricityDiagnosis methods

The invention relates to a method for fault diagnosis of wind power generators based on bispectrum entropy, the steps of which are: collecting vibration signals of wind power generators in normal operation state, mild faults, moderate faults and severe faults; calculating faults of all vibration signals Characteristic band; establish a fault alienation detection model; collect the vibration signal of the wind turbine to be detected, calculate the fault characteristic band of the vibration signal to be detected, input the obtained fault characteristics into the fault alienation detection model, and calculate the fault state and the four types The minimum distance obtained is the fault state of the fan. The invention can effectively extract the fault features of the non-stationary signal, and carry out the fault diagnosis of the wind power generating set, improve the precision of the fault diagnosis, and can be widely used in the fault diagnosis of the wind generating set equipment.

Owner:BEIJING INFORMATION SCI & TECH UNIV

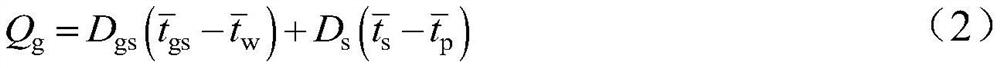

Heat consumption characteristic analysis method for main pipe thermal power plant turboset

ActiveCN110619485AEasy to monitor onlineAdaptableMachines/enginesSafety/regulatory devicesDeaeratorOperation mode

The invention discloses a heat consumption characteristic analysis method for a main pipe thermal power plant turboset, and belongs to the technical field of turboset heat consumption characteristics.The method aims at solving the technical problems that in the prior art, the operation condition of a main pipe thermal power plant is complex, instrument measuring points are incomplete, and real-time monitoring and thermal economy evaluation of a unit are difficult. The method includes: dividing operation mode of a turboset of the main pipe thermal power plant into operation without a deaeratorand operation with the deaerator; respectively establishing a heat consumption model of the running unit without the deaerator and a heat consumption model of the running unit with the deaerator; collecting measuring point data of a main pipe thermal power plant turboset; and analyzing the heat consumption characteristics of the main pipe thermal power plant in different operation modes based onthe collected measuring point data and the established heat consumption model. According to the method, the heat consumption models are respectively established by dividing the unit into a deaerator-free operation mode and a deaerator-containing operation mode, so that the thermal economy of the unit can be analyzed only through a small amount of measuring point data, and the operation condition of the unit can be conveniently monitored on line.

Owner:JIANGSU FRONTIER ELECTRIC TECH +1

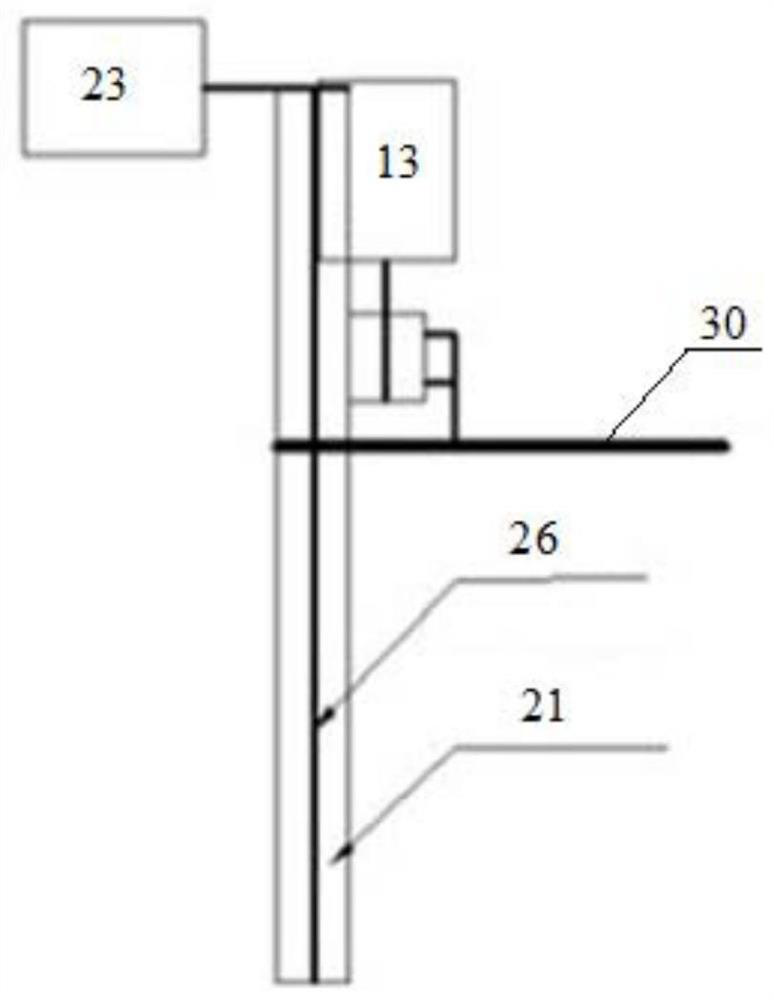

Underwater movable measuring device for measuring high-temperature steam spraying condensation temperature

PendingCN112102976AEasy to record accuratelyFew measuring pointsThermometer detailsNuclear energy generationPower couplingMeasurement device

The invention discloses an underwater movable measuring device for measuring the high-temperature steam spraying condensation temperature, and the device comprises a first sliding rail and a first sliding block which are in sliding connection, wherein the first sliding block is provided with a measurer; a first driving mechanism and a first transmission mechanism, wherein the first driving mechanism is in power coupling connection with the first transmission mechanism, and the first transmission mechanism is connected with the first sliding block; a second sliding rail and a second sliding block which are connected in a sliding mode, wherein the second sliding block is fixedly connected with the first sliding rail; and a second driving mechanism and a second transmission mechanism, whereinthe second driving mechanism is in power coupling connection with the second transmission mechanism, and the second transmission mechanism is connected with the second sliding block. According to themeasuring device, a multi-dimensional movable measuring scheme is provided, measuring points can be greatly reduced, the arrangement difficulty is reduced, the cost is saved, the measuring device canbe moved out of the steam plume, and the flow pattern of the steam plume can be conveniently and accurately recorded.

Owner:STATE POWER INVESTMENT CORP RES INST

Judgment method of ash degree of heating area considering the influence of global heat transfer of coal-fired boilers

The invention relates to a method for judging the ash level of a heating area considering the influence of the global heat transfer of a coal-fired boiler. k ; 2) Obtain the change value vector δT of the steam temperature difference between the inlet and outlet of the heating surface k without soot blowing a_k ;3) Correcting the steam temperature difference between the inlet and outlet of other heating surfaces to obtain the corrected value ΔT' of the steam temperature difference between the inlet and outlet k ;4) According to the correction value ΔT' of the steam temperature difference between the inlet and outlet of the heating surface k Calculate the ash degree coefficient β of each heated area k 5) When the ash accumulation degree coefficient of a certain heating surface is greater than the starting threshold, start soot blowing until the ash accumulation degree coefficient decreases below the starting threshold, and complete the soot blowing on the heating surface of the coal-fired boiler. Compared with the prior art, the present invention has the advantages of scientific utility, precision and simplicity.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

A Method for Analyzing Heat Consumption Characteristics of Steam Turbine Units in Main Tube Cogeneration Power Plant

ActiveCN110619485BEasy to monitor onlineAdaptableMachines/enginesSafety/regulatory devicesEngineeringProcess engineering

The invention discloses a method for analyzing heat consumption characteristics of a steam turbine unit in a main control thermal power plant in the technical field of steam turbine unit heat consumption characteristics. To solve the technical problems of difficult monitoring and thermal economic evaluation, the operation mode of the steam turbine unit in the parent-controlled thermal power plant is divided into operation without deaerator and operation with deaerator; respectively establish the heat consumption model of the unit without deaerator and with The heat consumption model of the deaerator operating unit; collect the measurement point data of the steam turbine unit of the main pipe thermal power plant; analyze the heat consumption characteristics of the main pipe thermal power plant under different operating modes based on the collected measurement point data and the established heat consumption model. In the present invention, the heat consumption models are respectively established by dividing the unit into the operation without deaerator and the operation with deaerator, and only need a small amount of measuring point data to realize the analysis of the thermal economy of the unit, which is convenient for the operation of the unit The status is monitored online.

Owner:JIANGSU FRONTIER ELECTRIC TECH +1

A high-speed straight line formula integral verification method and its verification equipment for a current meter

ActiveCN105954543BStill water condition is goodAccurate standard inputTesting/calibration of speed/acceleration/shock measurement devicesCurrent meterMean square

The invention discloses a current meter high-speed linear formula integration detection method and a detection device. The method comprises the following steps: cleaning a ball bearing; detecting average frictional resistance moment M of the ball bearing; detecting a propeller current meter rotating speed V0 and an instrument rotation bearing internal frictional resistance moment M, and confirming that a standard is reached; fixedly installing three detected current meters at the lower end of a measuring rod and placing them into water of a detection water tank; adjusting an axial directions of the current meters; tranquilizing a water body in the tank; starting a motor, a detection vehicle running from a lowest speed and gradually increasing its speed, and detecting instrument output signals and data; and according to a GB / T21699 detection method of rotor type current meter in linear open channel, by use of a least square method, calculating values of a and b of a detection formula and a middle and high-speed whole-line average mean square deviation sigma. According to the invention, the program and steps of a conventional detection method in the prior art are substantially simplified, the precision of detection results of the current meters can be ensured, at the same time, the production efficiency is improved, the working conditions are improved, the management rules are simplified, manpower and material resources are reduced, and the production operation cost is decreased.

Owner:JIANGSU NANSHUI WATER AFFAIRS TECH CO LTD +1

Method for detecting exhaust enthalpy of turbine

InactiveCN102749156BThe calculation process is simple and clearNo need to know structure parametersCalorimeterObservational errorMeasuring instrument

The invention discloses a method for detecting exhaust enthalpy of a turbine. The method includes the following steps of measuring and calculating a change rule of a specific parameter when a working condition changes according to designed data or test measured data, calculating to obtain a numerical value of the specific parameter under one certain working condition, acquiring partial heating power data of a low pressure cylinder under the certain working condition by the aid of a measuring instrument, reasonably assuming on the basis of a stage loss theory to obtain a numerical model for calculating the exhaust enthalpy of the turbine, substituting the numerical value of the specific parameter and the partial heating power data into the numerical model for calculating the exhaust enthalpy of the turbine to calculate the value of exhaust enthalpy of the turbine under the certain working condition. On the basis of stage loss theory, stage losses of the turbine are sorted into exhaust steam loss relating to volume flow, moisture loss relating to moisture and other losses relating to ideal enthalpy drop, and the calculation is simple, clear and highly precise. Detailed structural parameter of the low pressure cylinder is not needed, so measure points are reduced, and influence on calculated result caused by measuring error is small.

Owner:SOUTHEAST UNIV

A near-field acoustic holography testing method and device based on the basic solution of the spherical function

ActiveCN106124037BScientific and effective selectionConvenient sound pressure measurementSubsonic/sonic/ultrasonic wave measurementPosition fixationRotational axisSound pressure

The invention provides a near-field acoustic holography test method based on a spherical function basic solution and a near-field acoustic holography test device thereof. The test method comprises the steps that the order N of the used spherical function basic solution and the number and the position of microphones on a spherical holographic measuring surface are determined, sound pressure measurement is performed on the determined measurement points and the acoustic physical quantity of the surface of a vibration structure is reversely reconstructed by using the acquired measurement result. The device comprises a base (1), a rotating shaft (2), a semicircular support (3) and a test mechanism (4). The semicircular support (3) can circumferentially rotate along with the rotating shaft (2). The test mechanism (4) is fixedly installed on the semicircular support (3) and can measure acoustic pressure information of the spherical holographic measuring surface surrounding the vibration structure (5).

Owner:SHANGHAI JIAOTONG UNIV

On-line detection method of single large disturbance in power grid based on wams

ActiveCN105844542BRealize the judgment of whether a large disturbance occursFew measuring pointsData processing applicationsCharacter and pattern recognitionSCADAPower grid

Owner:韩小学

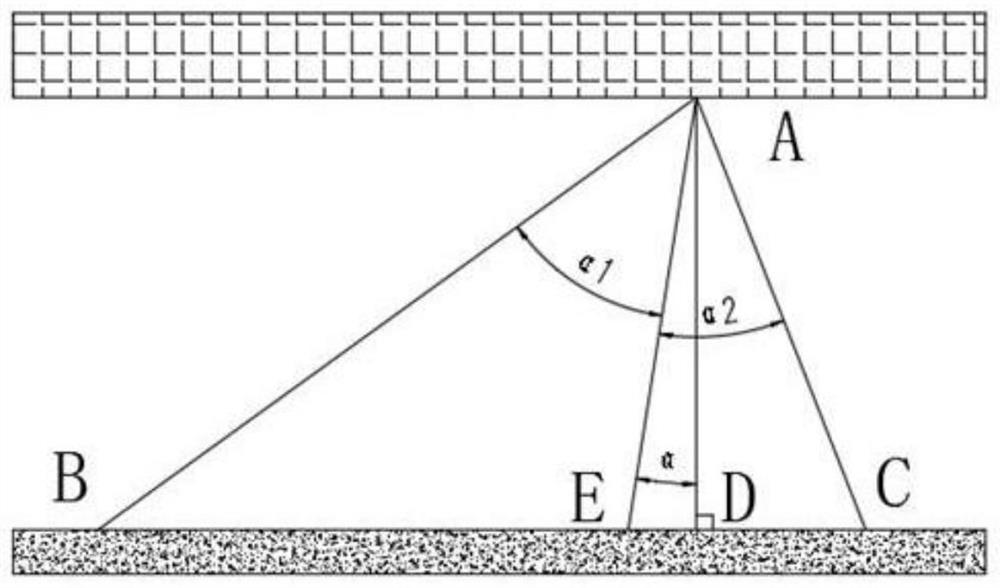

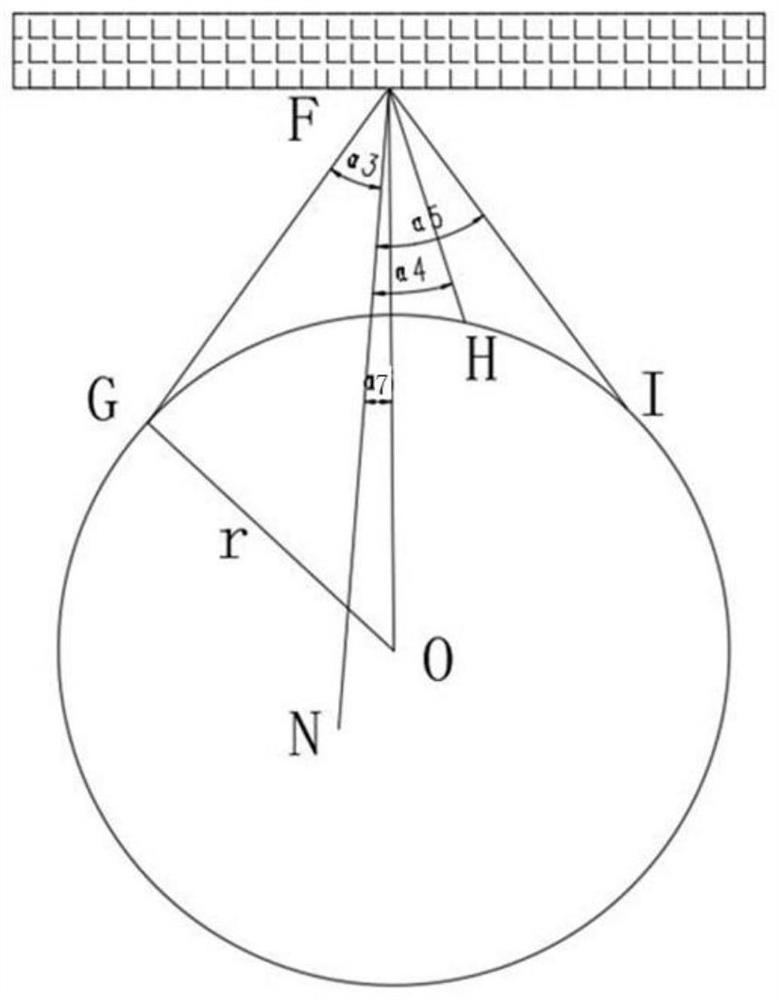

A Judgment Method for Vertical Section in Non-contact Measurement of Railway Platform Gauge

ActiveCN111750829BUnlimited measurement timeImprove securityAngle measurementElectromagnetic wave reradiationClassical mechanicsEngineering

The invention discloses a method for judging the vertical section in the non-contact measurement of the railway platform limit, which includes the measurement of the straight line section and the measurement of the curved section, wherein the measurement of the straight line section includes the following steps: step S110, determining the measurement point, taking the rail closest to the platform as the For reference, take any point on the other side of the rail as the measurement point A; step S120, select a comparison point, take the measurement point A as the origin, measure the distance AE between the two in comparison with any point E on the rail, and on both sides of the point E Select comparison point B and point C respectively on the railroad track; Step S130, data measurement; Step S140, data calculation; Curve segment measurement comprises the following steps: Step S210, determine measurement point; Step S220, select comparison point; Step S230, data calculation . The beneficial effect is that: non-contact measurement is adopted, the measurement time is not limited, the position of the vertical section can be measured and determined in real time, and there is no need to go on the road, and the safety is good; there are few measurement points, the measurement operation is simple, and the data is reliable.

Owner:沈阳铁道科学技术研究所有限公司

Measuring method of deepwater reservoir vertical direction water temperature distribution

ActiveCN103162869BAvoid missingExcellent measurement methodTemperature measurement of flowing materialsMeasurement pointWater temperature

The invention discloses a measuring method of deepwater reservoir vertical direction water temperature distribution. Control spacing of measuring points is obtained according to measuring accuracy of an instrument, from the water depth of 10 meters to 15 meters to the bottom of a reservoir, the points are measured in every 10 meters to 15 meters, temperature gradients of the points are calculated by a method of back inserting, if the temperature gradient of a certain point is larger than 0.05 DEG C / m, the ratio of the absolute value of the difference of the temperature gradient of the certain point and that of an adjacent point to the temperature gradient of the certain point is calculated, if the ratio is larger than 15%, measuring water temperature is increased to a middle point of the certain point and the adjacent point so as to enable the water temperature of all points to satisfy the condition that the absolute value of the temperature gradient of water temperature is not more than 0.05 DEG C / m or the ratio of the absolute value of the difference of the temperature gradient of the certain point and that of the adjacent point to the temperature gradient of the certain point is not more than 15% or the spacing of the measuring points is not more than two times of the control spacing. The temperatures of all points are sequenced according to the water depth, and then the deepwater reservoir vertical direction water temperature distribution can be obtained through spline interpolation.

Owner:CHINA THREE GORGES CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com