Secondary reheating million unit high-pressure heater system structure and application method thereof

A technology of high-pressure heaters and millions of units, applied in feed water heaters, lighting and heating equipment, preheating, etc., can solve problems such as long steam extraction and high-pressure water supply pipelines, complex double-column high-pressure systems, and increased volume of turbine rooms , to achieve the effect of reducing the amount of pipeline engineering, saving the cost of the plant structure, and reducing the resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

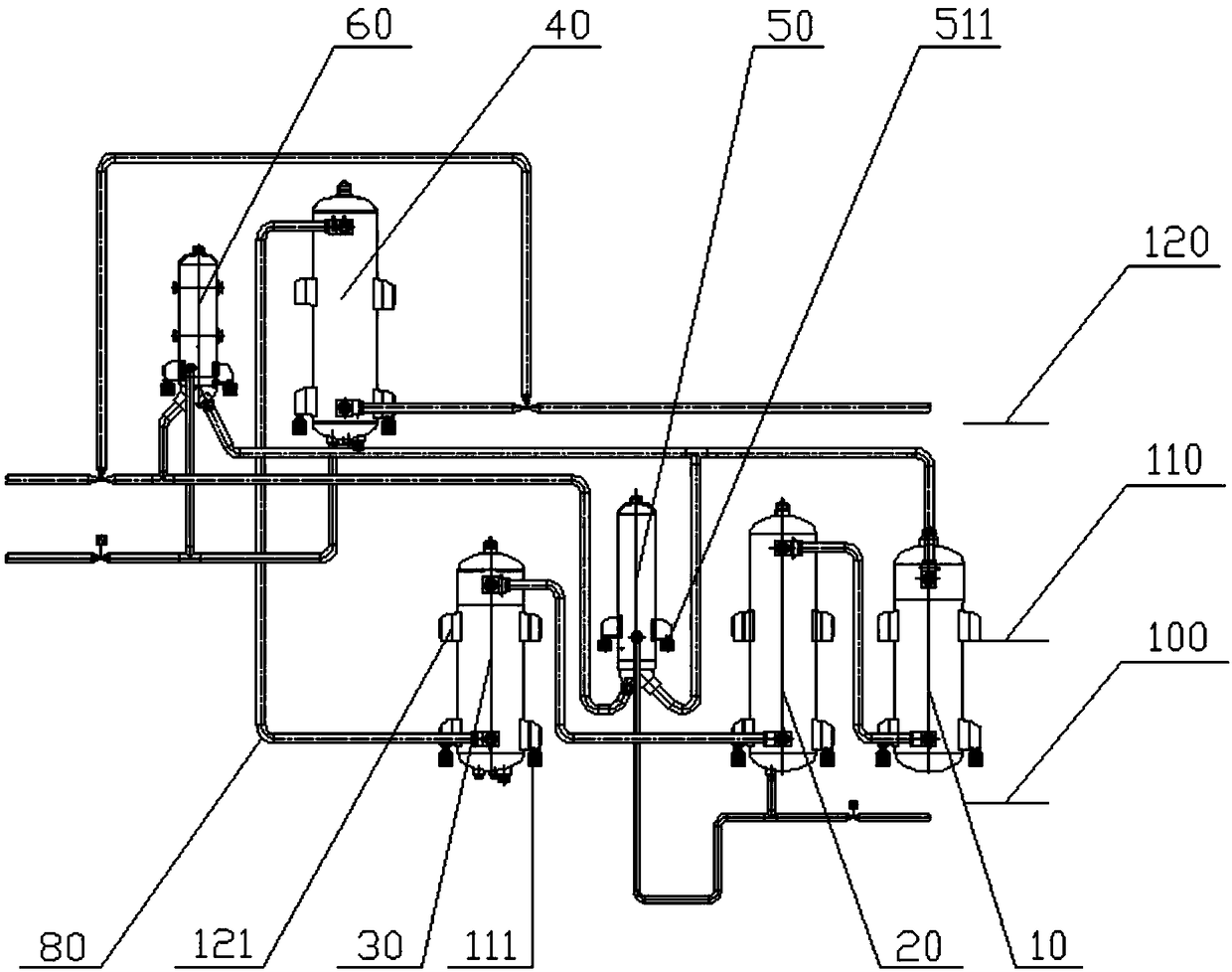

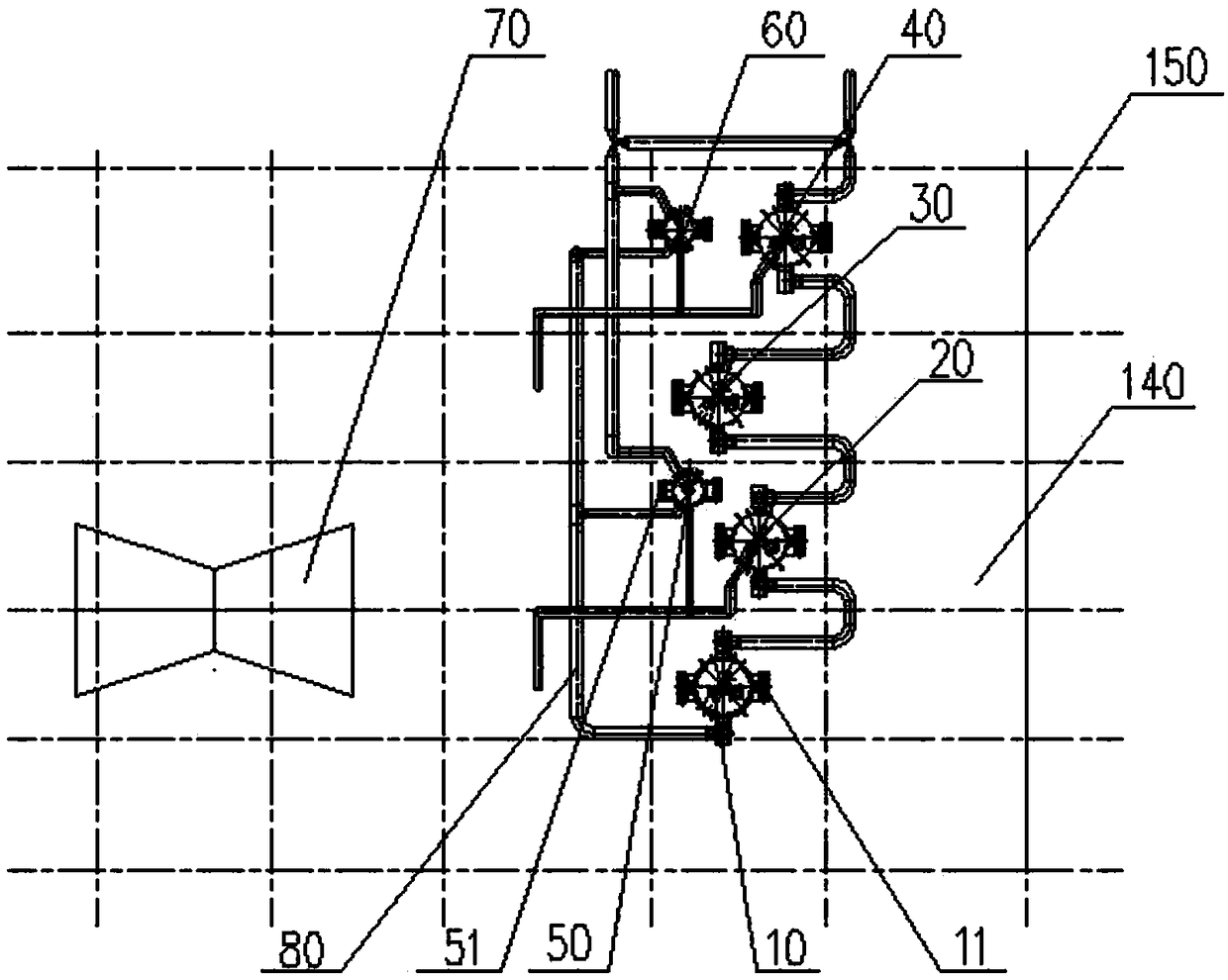

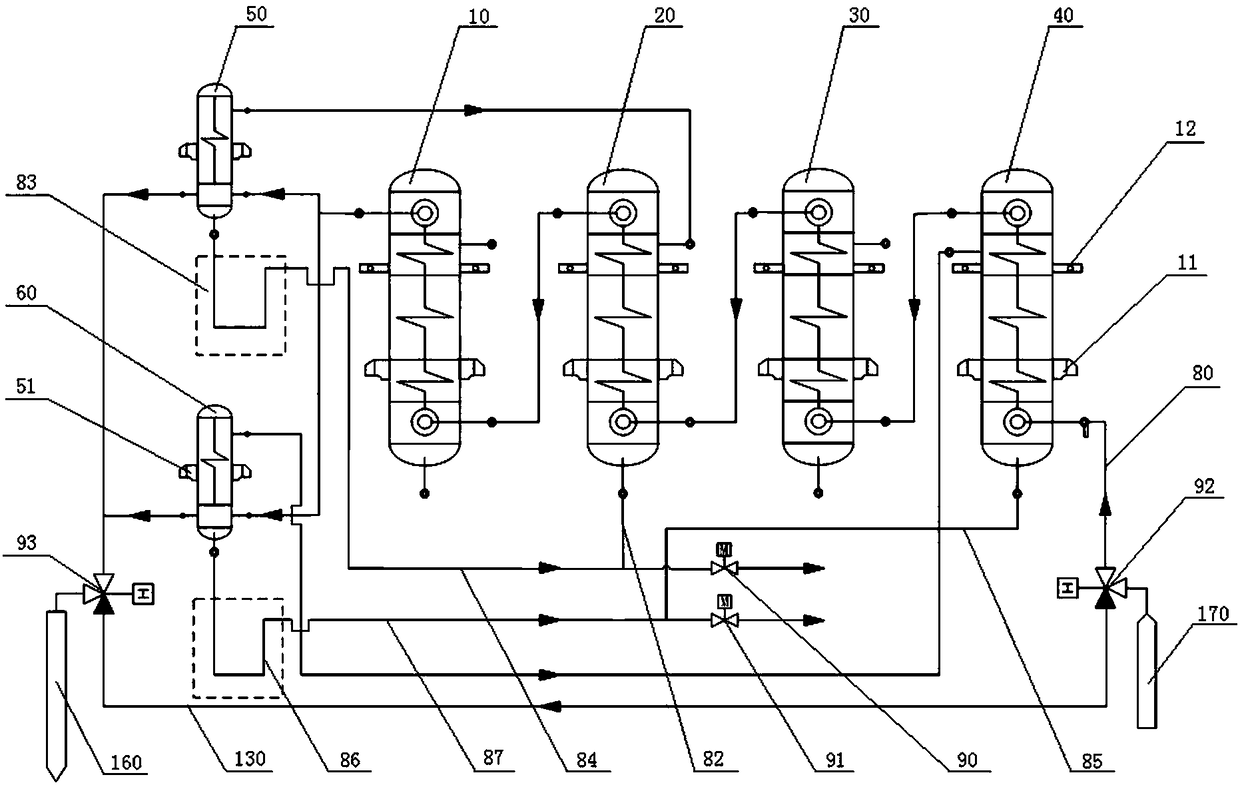

[0030] Such as figure 1 , figure 2In the structure of the high-pressure heater system with double reheating million units shown, the first high-pressure heater 10, the second high-pressure heater 20, the third high-pressure heater 30, and the fourth high-pressure heater 40 adopt a serpentine tube vertical structure , the second external steam cooler 50 and the fourth external steam cooler 60 adopt a U-shaped tube vertical structure; the high-pressure heater bottom support 11 is divided into two high-pressure heater bottom large support 111, and the high-pressure heater bottom The large support 111 is symmetrically arranged on the respective side surfaces of the first high-pressure heater 10, the second high-pressure heater 20, the third high-pressure heater 30 and the fourth high-pressure heater 40, and is used to bear all the weight in high-pressure operation , the elevation of the high pressure heater bottom support 11 of the first high pressure heater 10, the second high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com