Judgment method of ash degree of heating area considering the influence of global heat transfer of coal-fired boilers

A technology of heating area and coal-fired boiler, which is applied in the field of judging the ash level of the heating area considering the influence of the global heat transfer of the coal-fired boiler, can solve the problems such as difficulty in guaranteeing the accuracy, and achieve the effects of accurate judgment, few measuring points and simple calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

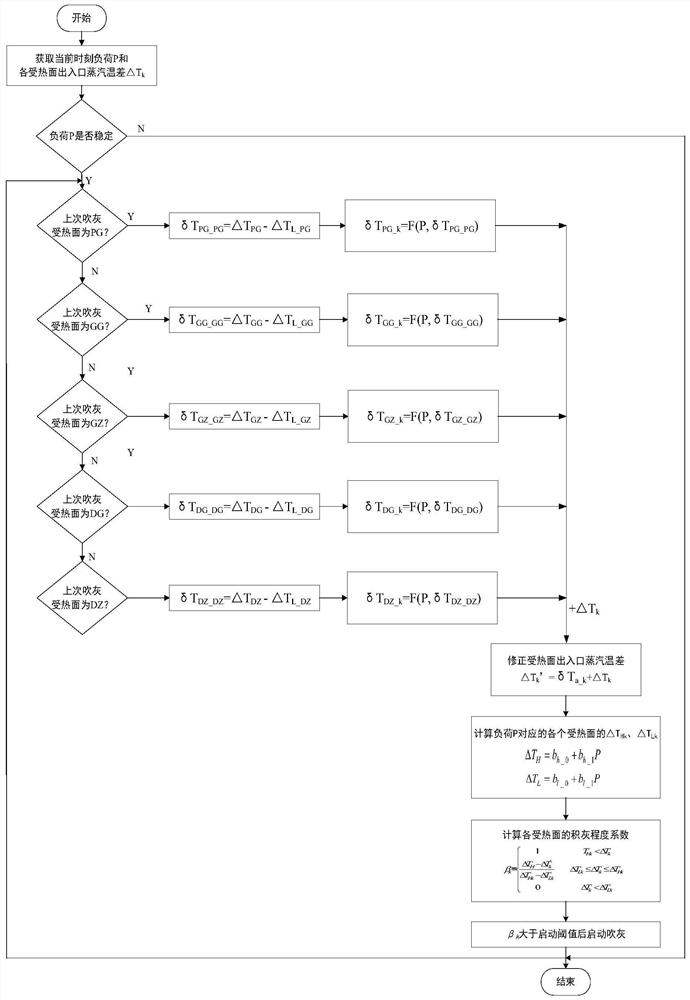

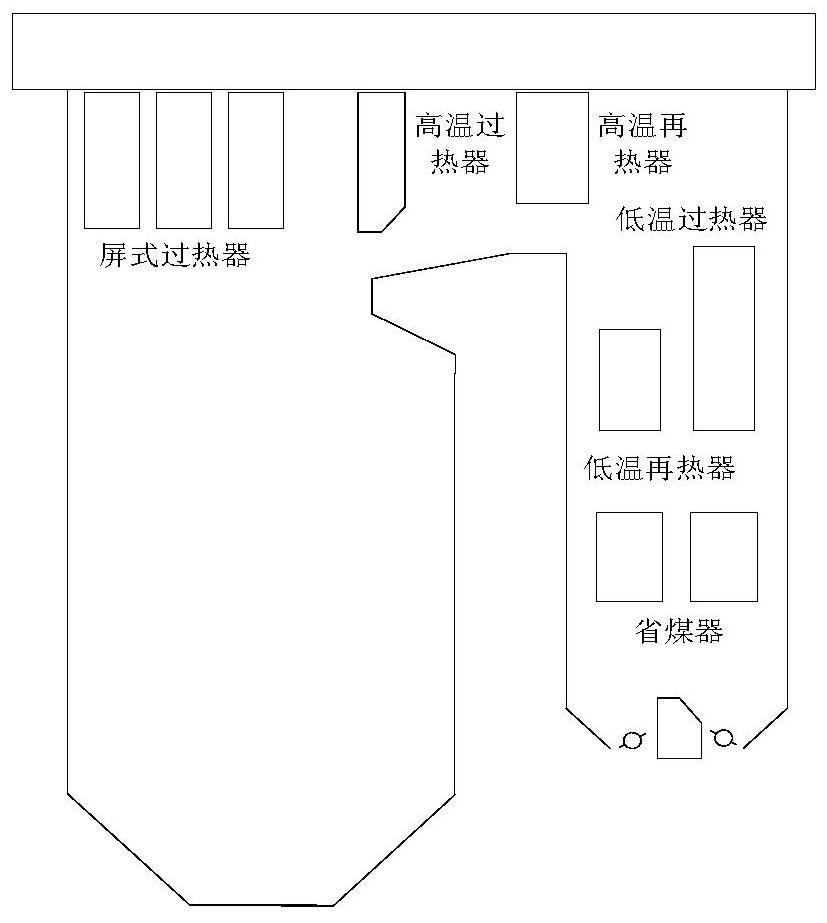

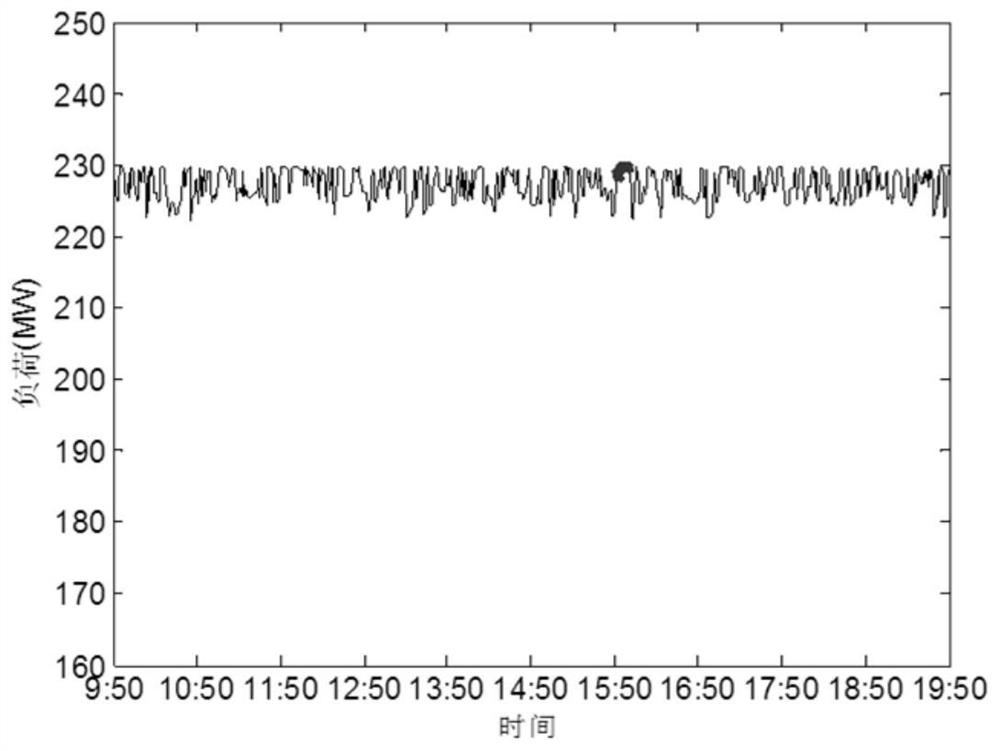

[0048] Based on the thermodynamic mechanism, the characteristics of convective heat transfer and steam heat absorption affected by dust accumulation are analyzed, and a large amount of actual production data is excavated to calculate the gray correlation characteristics of the steam temperature difference between the inlet and outlet of the convective heating surface and the heat transfer coefficient, and the establishment of The temperature difference between the inlet and outlet of the heating surface represents the model of the soot deposition degree coefficient; considering that soot blowing on a certain heating surface will have a certain impact on the temperature distribution of the flue gas and the heat absorbed by the heating surface, and will cause changes in the temperature differences of other heating surfaces, through the temperature difference The revised algorithm further optimizes the method of temperature difference to characterize the degree of ash accumulation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com