Heat consumption characteristic analysis method for main pipe thermal power plant turboset

A steam turbine unit, characteristic analysis technology, applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the complex operating conditions of the main tube thermal power plant, imperfect instrument measurement points, real-time monitoring of units and difficulties in thermal economic evaluation, etc. problem, to achieve the effect of saving project investment, less measuring points, and convenient online monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

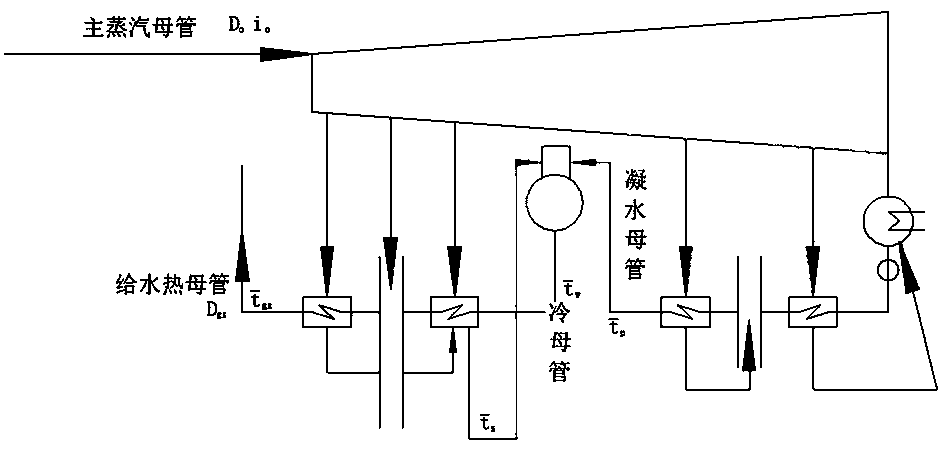

[0039] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0040] There are usually two types of actual operation modes for parallel operation of steam turbine generator sets in a parent-control thermal power plant, one is to operate without a deaerator, and the other is to operate with a deaerator. The heat consumption model of the unit without deaerator and the heat consumption model of the unit with deaerator were respectively established.

[0041] When the turbo-generator unit is operated without a deaerator, the incoming steam is sent from the main steam pipe, expands in the steam turbine and discharges into the condenser, and then is sent to the condensate main pipe by the condensate pump through the low feeder, and the high-pressure heater discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com