Polycarboxylic acid water reducing agent with narrow molecular weight distribution and preparation method thereof

A narrow molecular weight distribution, polycarboxylic acid technology, applied in the field of polycarboxylate water reducing agent preparation, can solve the problems of poor temperature control accuracy, difficulty in achieving dispersion effect, and inability to achieve the best environment, avoiding temperature control, and having a good environment. Beneficial effects on heat transfer as well as cold transfer, molecular weight distribution and improved controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

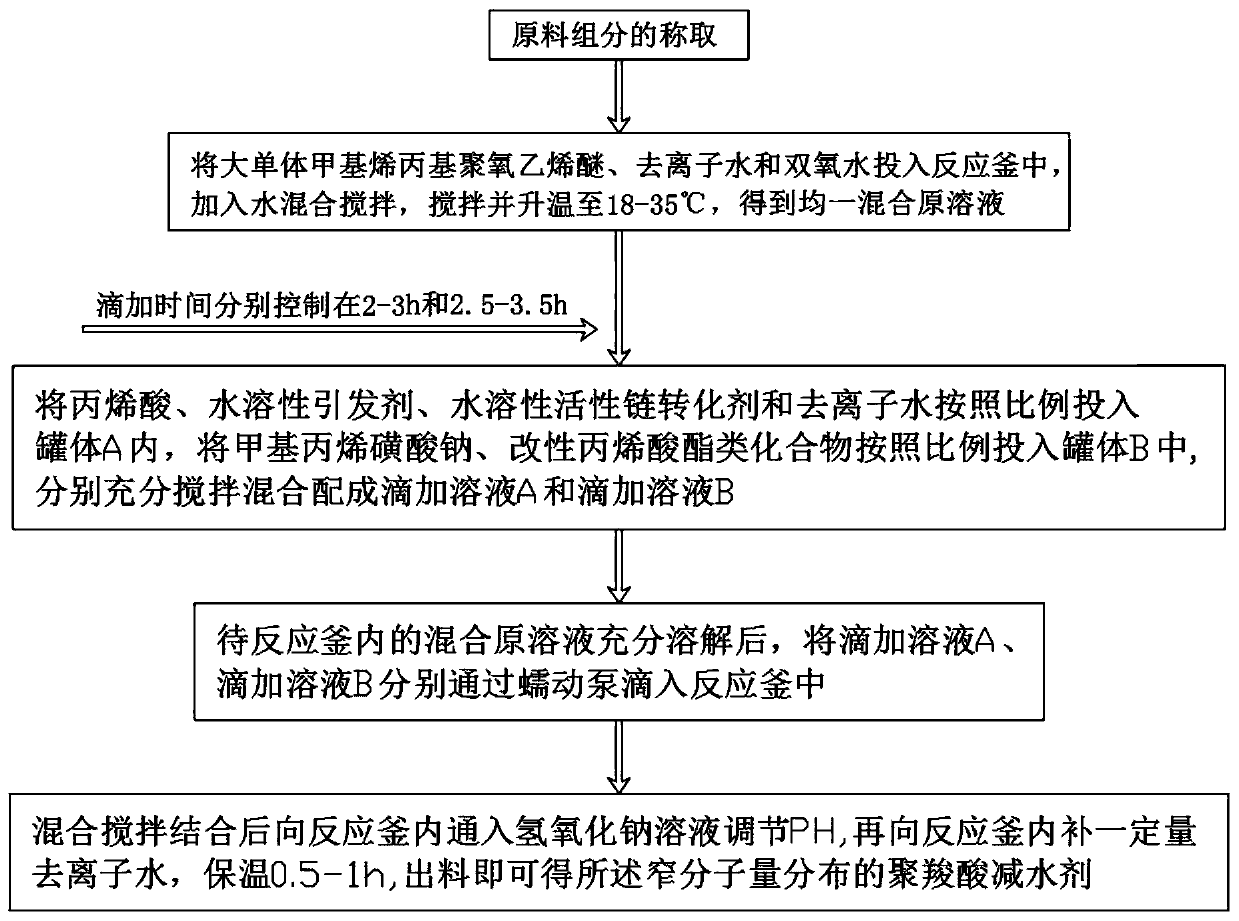

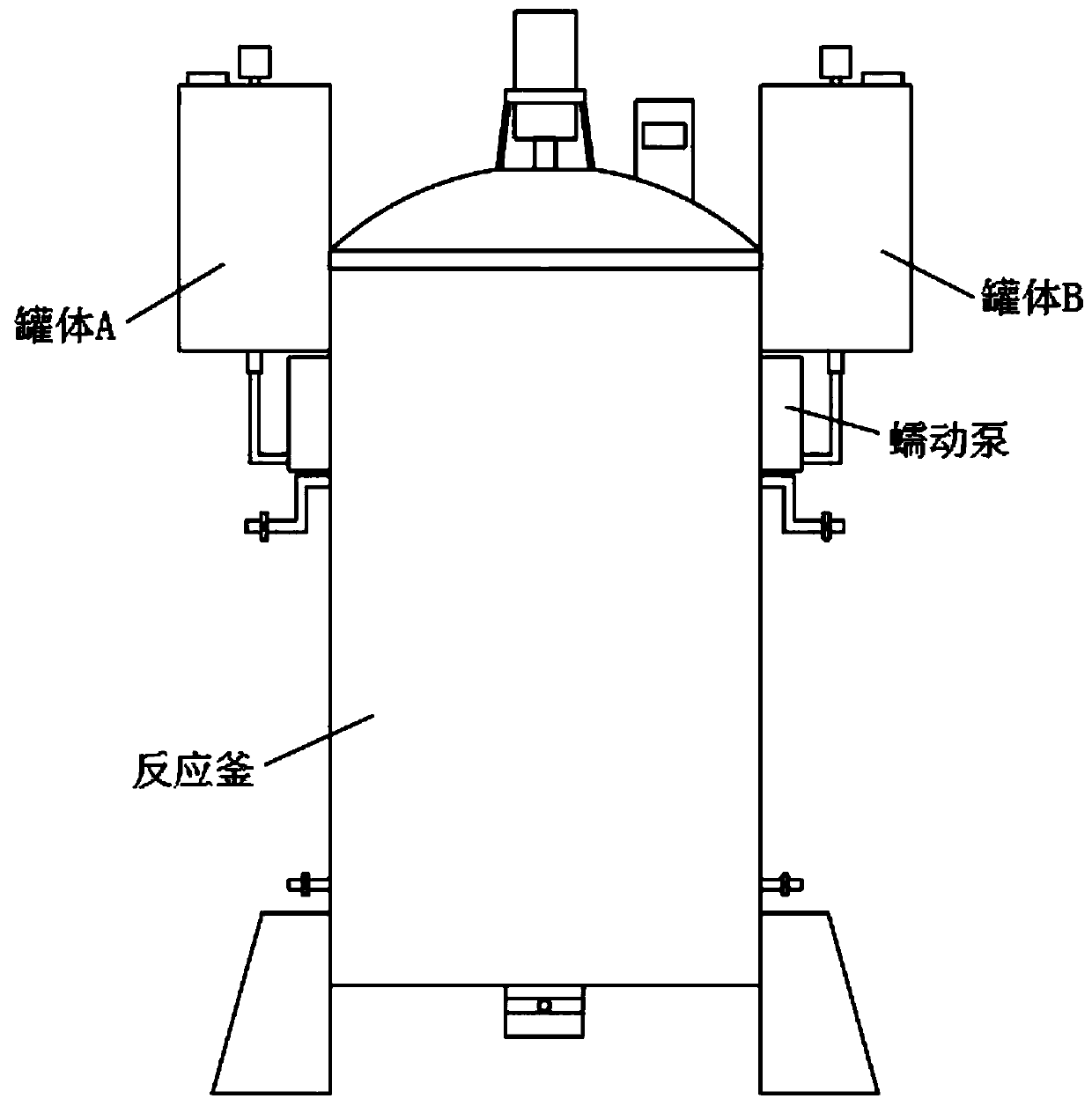

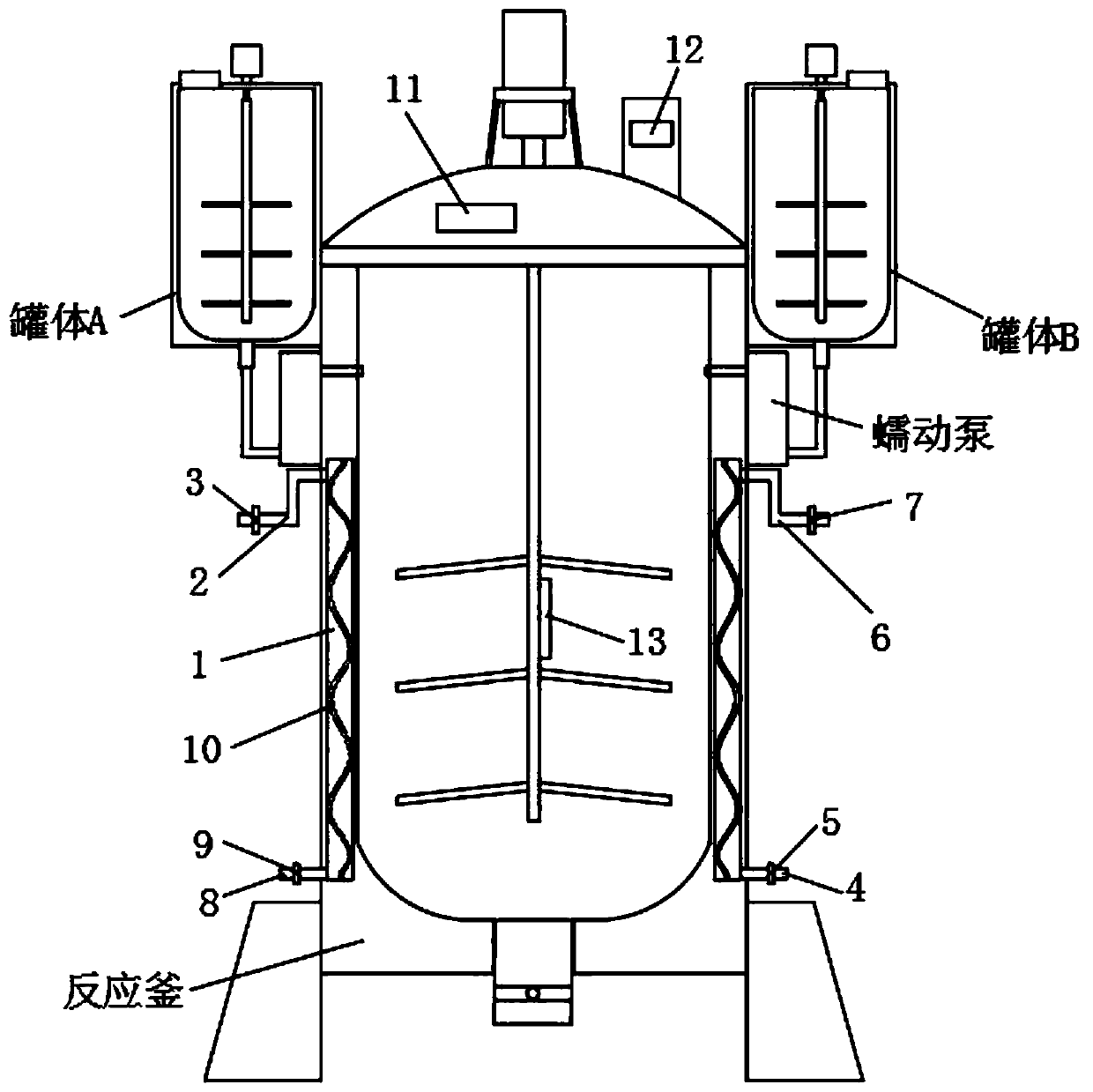

[0047] see figure 1 , a polycarboxylate water reducer with a narrow molecular weight distribution, comprising the following components in parts by mass: 60 parts of macromonomer methallyl polyoxyethylene ether, 10 parts of acrylic acid, 8 parts of methacrylic sulfonic acid Sodium, 5 parts of modified acrylate compounds, part of water-soluble initiator, 0.5 part of water-soluble active chain transfer agent, 2 parts of deionized water, 5 parts of hydrogen peroxide, 2 parts of sodium hydroxide solution, the preparation method is as follows: step:

[0048] S1. Weighing the components according to the ratio of the above components;

[0049] S2. Put the macromonomer methallyl polyoxyethylene ether, deionized water and hydrogen peroxide into the reaction kettle, add water to mix and stir, stir and heat up to 18-35°C to obtain a uniform mixed original solution;

[0050] S3. Put acrylic acid, water-soluble initiator, water-soluble active chain transfer agent and deionized water into ...

Embodiment 2

[0054] see figure 1 , a polycarboxylate water reducer with a narrow molecular weight distribution, comprising the following components in parts by mass: 65 parts of macromonomer methallyl polyoxyethylene ether, 11 parts of acrylic acid, 9 parts of methacrylic sulfonic acid Sodium, 5.5 parts of modified acrylate compounds, 1.5 parts of water-soluble initiator, 0.6 part of water-soluble active chain transfer agent, 2.5 parts of deionized water, 6 parts of hydrogen peroxide, 2.5 parts of sodium hydroxide solution, the preparation method is: comprising The following steps:

[0055] S1. Weighing the components according to the ratio of the above components;

[0056] S2. Put the macromonomer methallyl polyoxyethylene ether, deionized water and hydrogen peroxide into the reaction kettle, add water to mix and stir, stir and heat up to 18-35°C to obtain a uniform mixed original solution;

[0057] S3. Put acrylic acid, water-soluble initiator, water-soluble active chain transfer agent...

Embodiment 3

[0061] see figure 1 , a polycarboxylate water reducer with a narrow molecular weight distribution, comprising the following components in parts by mass: 70 parts of macromonomer methallyl polyoxyethylene ether, 12 parts of acrylic acid, 10 parts of methacrylic sulfonic acid Sodium, 6 parts of modified acrylate compounds, 2 parts of water-soluble initiator, 0.8 part of water-soluble active chain transfer agent, 3.5 parts of deionized water, 7 parts of hydrogen peroxide, 3 parts of sodium hydroxide solution, the preparation method is as follows: step:

[0062] S1. Weighing the components according to the ratio of the above components;

[0063] S2. Put the macromonomer methallyl polyoxyethylene ether, deionized water and hydrogen peroxide into the reaction kettle, add water to mix and stir, stir and heat up to 18-35°C to obtain a uniform mixed original solution;

[0064] S3. Put acrylic acid, water-soluble initiator, water-soluble active chain transfer agent and deionized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com