Resource utilization method of blast furnace dust and coke furnace dust

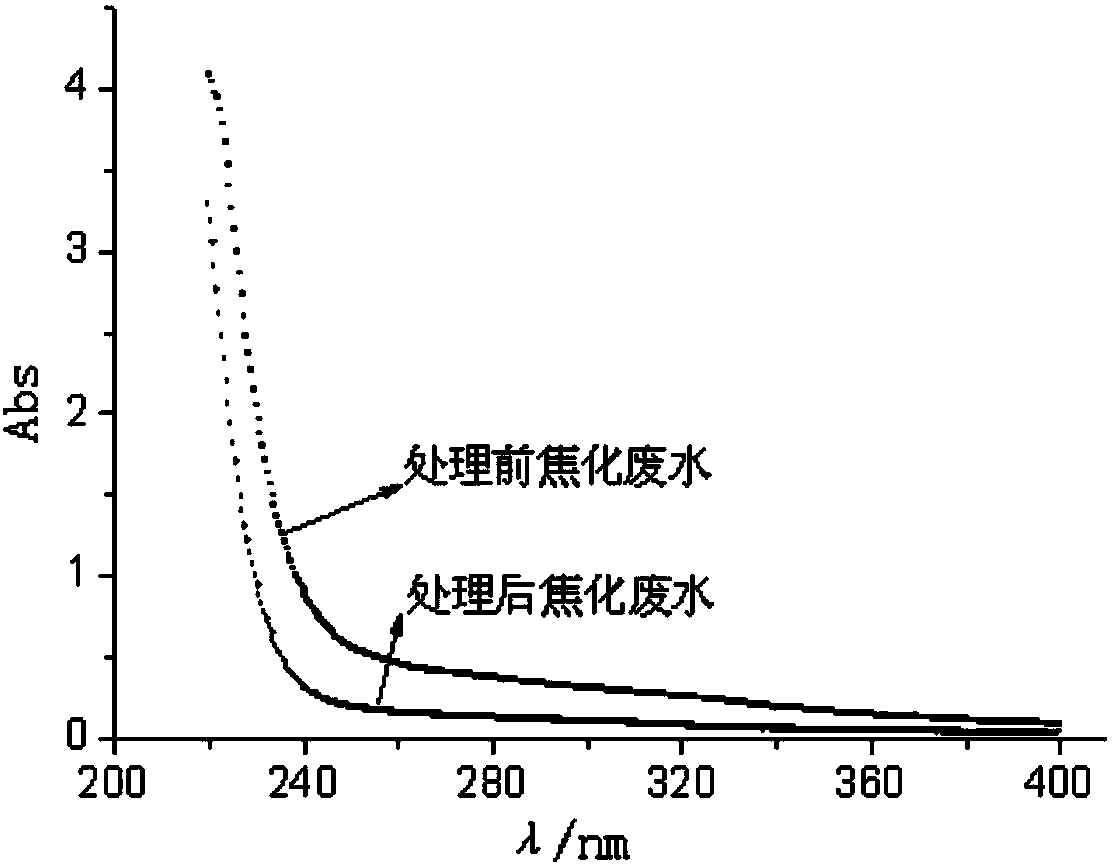

A technology for blast furnace dust removal and coke oven dust removal, which is applied in the field of solid waste recycling, can solve the problems of land occupation, environmental pollution of blast furnace dust removal and coke oven dust removal, and reduce the cost of coking wastewater treatment, and achieves high adsorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

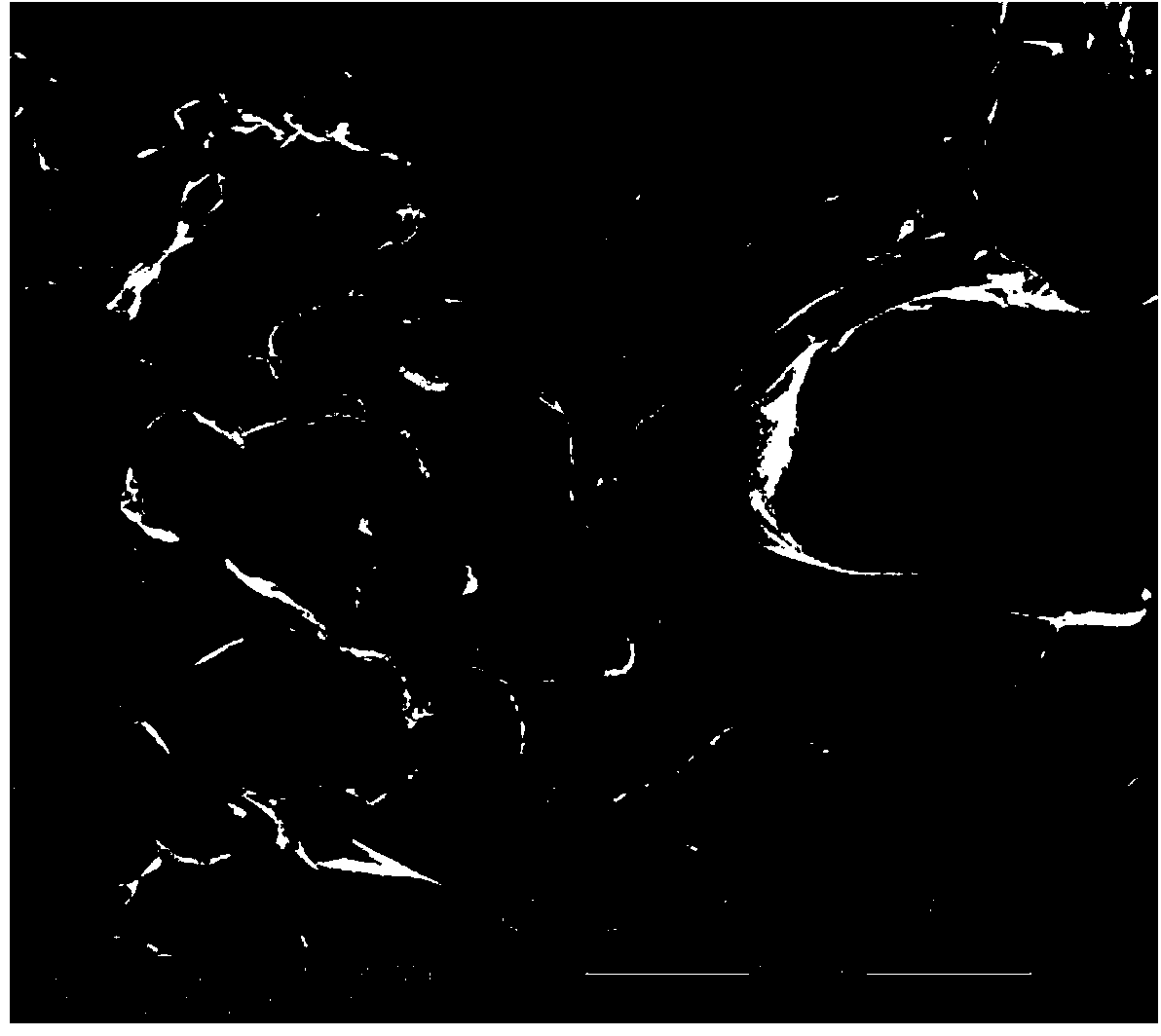

[0028] 1) Take blast furnace dust and coke oven dust, and screen them separately, and screen out blast furnace dust and coke oven dust with a particle size of 150 mesh as raw materials; wherein, blast furnace dust contains 41.8% C, 33.4% TFe, 6.51% SiO 2 , 2.83% Al 2 o 3 , 2.38% CaO, 1.58% Na 2 O, 3.60% K 2 O, 2.12% Zn, and the rest are unavoidable impurities; coke oven dust contains 81.3% fixed C, 15.8% ash, 1.49% volatile matter and 1.41% sulfur;

[0029] 2) get above-mentioned blast furnace dedusting ash 200g after sieving and coke oven dedusting ash after 100g sieving mix, then add 30g bentonite as binding agent, then add mass percentage concentration again and be 5% (NH 4 )HCO 3 Solution, after stirring and mixing, press it into balls under 30MPa pressure, the particle diameter of the spherical particles is 1.5-5mm, preferably 2.0mm; wherein, (NH 4 )HCO 3 The solution is added in a volume ratio of 0.3:1 to the total volume ratio of blast furnace dust and coke oven ...

Embodiment 2

[0035] 1) get blast furnace dust removal and coke oven dust removal, screen respectively, and screen out blast furnace dust removal and coke oven dust removal particle diameter as raw material;

[0036] 2) Mix 500 g of blast furnace dust removal dust after the above-mentioned screening and 100 g of screening coke oven dust removal dust, then add 180 g of bentonite as a binding agent, and then add mass percent concentration of 2% (NH 4 )HCO 3 Solution, (NH 4 )HCO 3 The solution is added in a volume ratio of 0.6:1 to the total volume ratio of blast furnace dedusting ash and coke oven dedusting ash. After stirring and mixing, it is pressed into balls under a pressure of 20 MPa. The particle size of the spherical particles is about 3.5 mm;

[0037] 3) Dry the spherical particles obtained in step 2) in an oven at 100° C. for 30 minutes and then transfer them to a muffle furnace. 2 In the atmosphere, the temperature was raised to 500°C at a heating rate of 15°C / min, and then roas...

Embodiment 3

[0042] 1) get blast furnace dust removal and coke oven dust removal, screen respectively, and screen out blast furnace dust removal and coke oven dust removal particle diameter as raw material;

[0043] 2) Get the blast furnace dust removal dust 300g after above-mentioned sieving and the coke oven dust removal dust removal dust after 100g screening and mix, then add 80g bentonite as binding agent, then add mass percentage concentration again and be 10% (NH 4 )HCO 3 Solution, (NH 4 )HCO 3 The solution is added in a volume ratio of 0.5:1 to the total volume ratio of blast furnace dust and coke oven dust. After mixing, press it into balls under a pressure of 25MPa. The particle size of the spherical particles is about 2.0mm;

[0044] 3) Dry the spherical particles obtained in step 2) in an oven at 100° C. for 30 minutes and then transfer them to a muffle furnace. 2 In the atmosphere, the temperature was raised to 650°C at a heating rate of 15°C / min, and then roasted for 1.5h, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com