Mixed dust removal device

A technology for dust collectors and dust removal chambers, applied in chemical instruments and methods, separation of electrostatic effects, filtration of dispersed particles, etc., can solve problems such as failure to reach, different dust removal principles, etc., to prolong service life, reduce tension, and improve dust removal efficiency and the effect of the dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

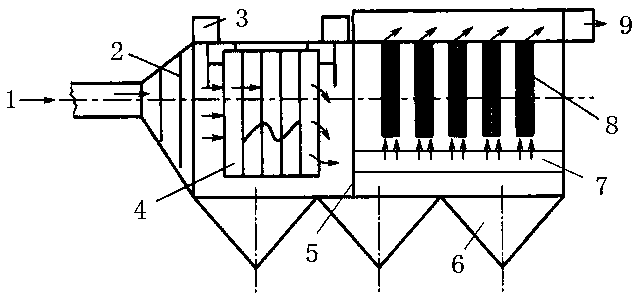

[0013] like figure 1 As shown, a hybrid dust collector device includes a dust removal chamber, and an ash hopper 6 is arranged at the bottom of the dust removal chamber. Generally, several ash hoppers 6 are arranged at the bottom of the dust removal chamber. For example, three dust hoppers 6 are evenly arranged at the bottom of the dust removal chamber. Ash bucket6. The dedusting chamber is divided into an electric dedusting chamber and a bag dedusting chamber by the isolation plate 5, an airflow inlet 1 is arranged on one side of the electric dedusting chamber, a pole plate 4 is arranged in the electric dust removing chamber and a power supply 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com