Array type mixed dust removal device

A dust removal device and an array technology, applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of inability to completely shut down the offline maintenance function, inability to achieve ultra-clean emissions, inability to handle dust removal tasks, etc. problems, to achieve the effect of saving investment cost and maintenance cost, reducing the use of cloth bags, and saving the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

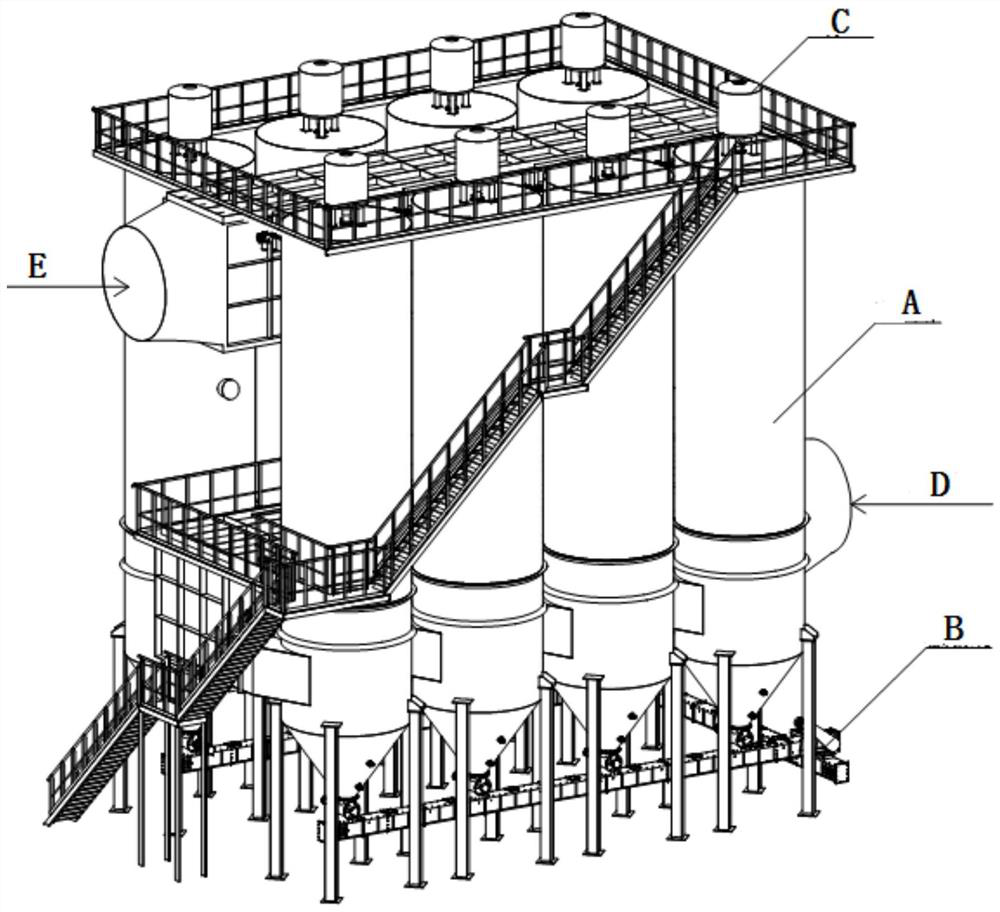

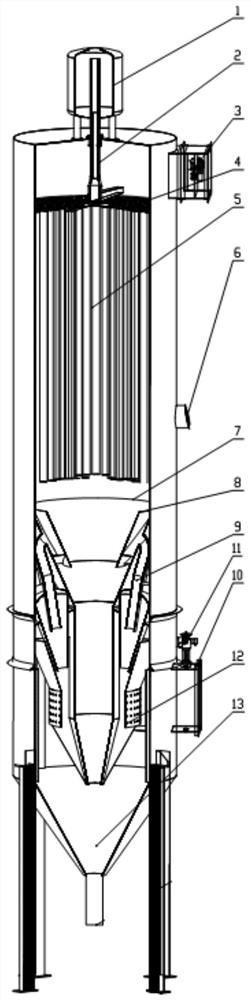

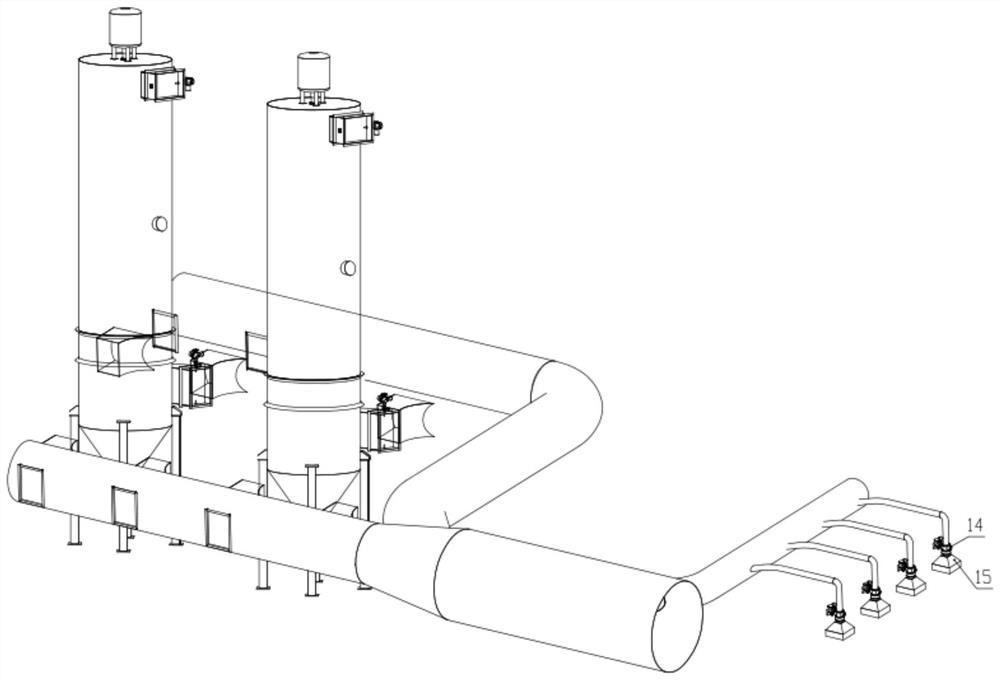

[0038] see Figure 1-3 , the present invention provides a kind of embodiment as follows:

[0039] An array type mixed dust removal device, including several vertical cylindrical dust removal tanks A arranged in an array, an ash conveying system B and a blowing system C, and is also provided with a total air inlet D and a total air outlet E, which are connected with each tank respectively. The air inlet and air outlet of the body are connected; the ash conveying system B is connected with the dust removal tank A through a pipeline, and the blowing system C is arranged on the top of the dust removal tank A, and each dust removal tank A includes a tank body, and the inner upper end of the tank body is set There is a dust-removing bag 5, the top of the dust-removing bag 5 is a clean air chamber 4, a wide-mouth ash hopper 7 is arranged in the center of the tank body, and a bottom ash hopper 13 is arranged at the bottom, and a variable-diameter small cyclone pipe 9 is arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com