Determination method for dispersity of dust in air of working field

A technology for workplaces and measurement methods, applied in the field of dust dispersion measurement, can solve the problems of many human influence factors, difficult error control, visual fatigue, etc., and achieve the effects of easy unification and standardization, avoiding observation errors and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below in conjunction with the accompanying drawings and embodiments, the purpose is only to better understand the content of the present invention.

[0043] A method for measuring the degree of dispersion of dust in the air of a workplace is carried out according to the following steps:

[0044]a. Preparation of dust suspension: dissolve the perchlorethylene filter membrane with dust collected in 3ml-6ml butyl acetate to make a dust suspension;

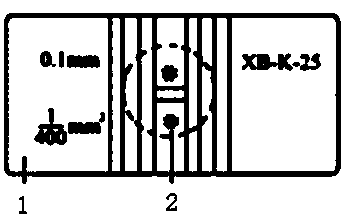

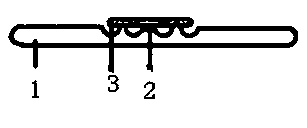

[0045] b. Preparation of dust samples: put the clean hemocytometer 1 and cover glass 3 away, use a disposable dropper to absorb the fully mixed dust suspension, fill it into the counting pool 2 of the hemocytometer 1, and let it stand 2-3 minutes, so that the dust particles naturally settle on the bottom of the counting tank 2;

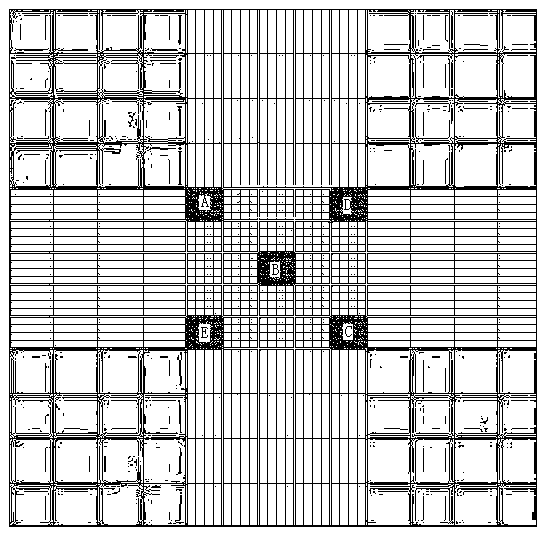

[0046] c. Calibration of the eyepiece micrometer: put the eyepiece micrometer to be calibrated into the eyepiece tube, place the objective lens micromete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com