Treatment method of iron and steel smelting dust mud and iron correction material

A technology of iron correction materials and treatment methods, which is applied in the field of resource utilization of solid waste, can solve problems such as low-taste dust, mud cakes that are difficult to dispose of, consume energy, and consume a large amount of energy, so as to achieve resource utilization and prevent Effects of raising dust and saving disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

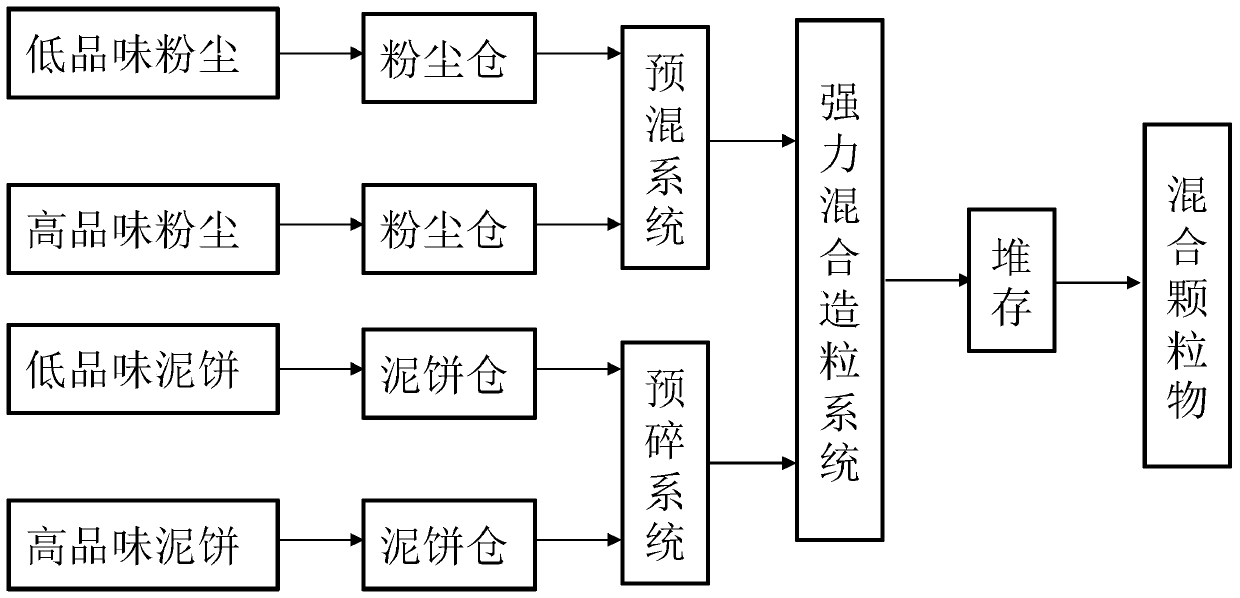

[0046] Such as figure 1 Shown, a kind of treatment method of iron and steel smelting dust sludge, comprises the following steps:

[0047] S1, dust premixing, quantitatively send low-grade dust and high-grade dust into the premixing system and mix them evenly to obtain mixed dust;

[0048] When the dust is premixed, the low-grade dust and high-grade dust are sent into the low-grade dust bin and the high-grade dust bin respectively through the tanker, and then sent to the pre-mixing system through the quantitative conveying system at the bottom of the bin to fully mix the low-grade dust and high-grade dust. Mixing, so that the components in the premixing system are more uniformly distributed, and the mixed dust is obtained; the particle size of the mixed dust is 0.075-0.85mm, and the moisture content is 0.9%;

[0049] S2, pre-crushing and mixing of mud cakes, sending low-grade mud cakes and high-grade mud cakes to the pre-crushing system for crushing and mixing to obtain a mud ...

Embodiment 2

[0061] Such as figure 1 Shown, a kind of treatment method of iron and steel smelting dust sludge, comprises the following steps:

[0062] S1, dust premixing, quantitatively send low-grade dust and high-grade dust into the premixing system and mix them evenly to obtain mixed dust;

[0063] When the dust is premixed, the low-grade dust and high-grade dust are sent into the low-grade dust bin and the high-grade dust bin respectively through the tanker, and then sent to the pre-mixing system through the quantitative conveying system at the bottom of the bin to fully mix the low-grade dust and high-grade dust. Mixing, so that the components in the premixing system are distributed more uniformly, and the mixed dust is obtained; the particle size of the mixed dust is 0.075-0.85mm, and the moisture content is 0.8%;

[0064] S2, pre-crushing and mixing of mud cakes, sending low-grade mud cakes and high-grade mud cakes to the pre-crushing system for crushing and mixing to obtain a mud ...

Embodiment 3

[0076] Such as figure 1 Shown, a kind of treatment method of iron and steel smelting dust sludge, comprises the following steps:

[0077] S1, dust premixing, quantitatively send low-grade dust and high-grade dust into the premixing system and mix them evenly to obtain mixed dust;

[0078] When the dust is premixed, the low-grade dust and high-grade dust are sent into the low-grade dust bin and the high-grade dust bin respectively through the tanker, and then sent to the pre-mixing system through the quantitative conveying system at the bottom of the bin to fully mix the low-grade dust and high-grade dust. Mixing, so that the components in the premixing system are distributed more evenly, and the mixed dust is obtained; the particle size of the mixed dust is 0.075-0.85mm, and the moisture content is 1.0%;

[0079] S2, pre-crushing and mixing of mud cakes, sending low-grade mud cakes and high-grade mud cakes to the pre-crushing system for crushing and mixing to obtain a mud cak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com