System for joint production of carbide, lime nitrogen and carbon black and method

A joint production and lime nitrogen technology, applied in the direction of nitrogen fertilizer, carbide, cyanamide fertilizer, etc., can solve the problems of environmental pollution, withering, and small proportion of powdered lime nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

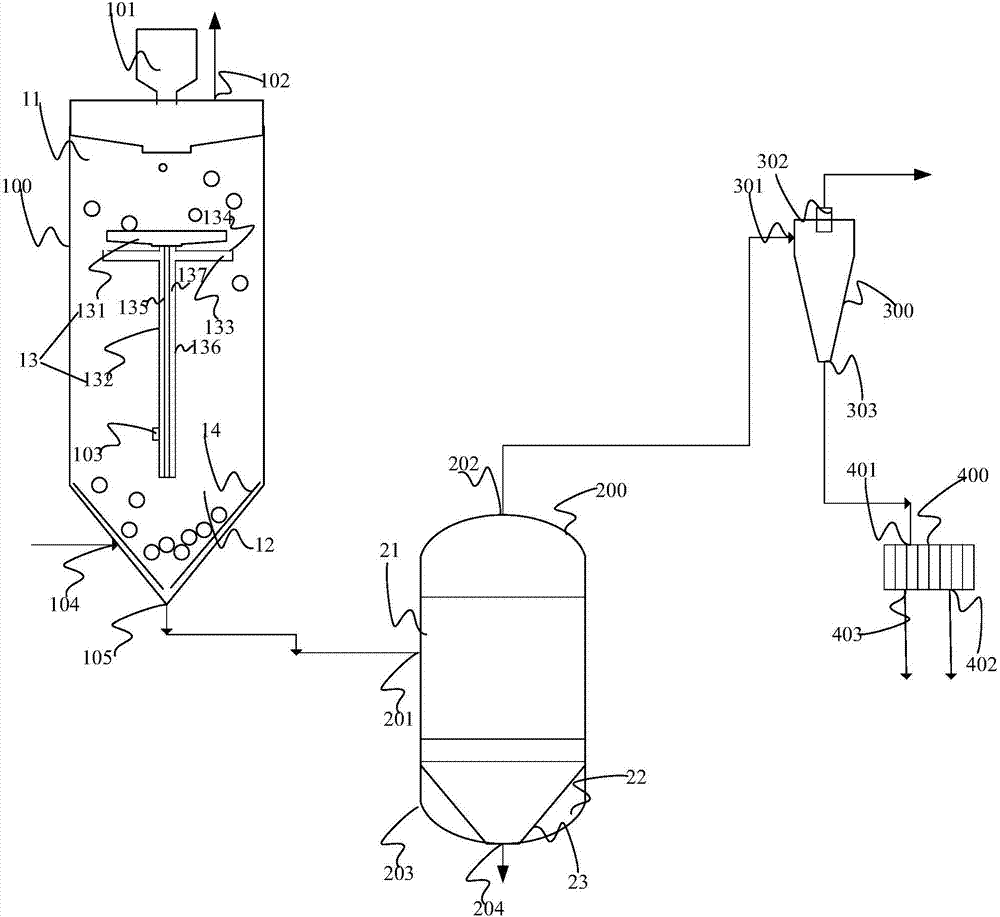

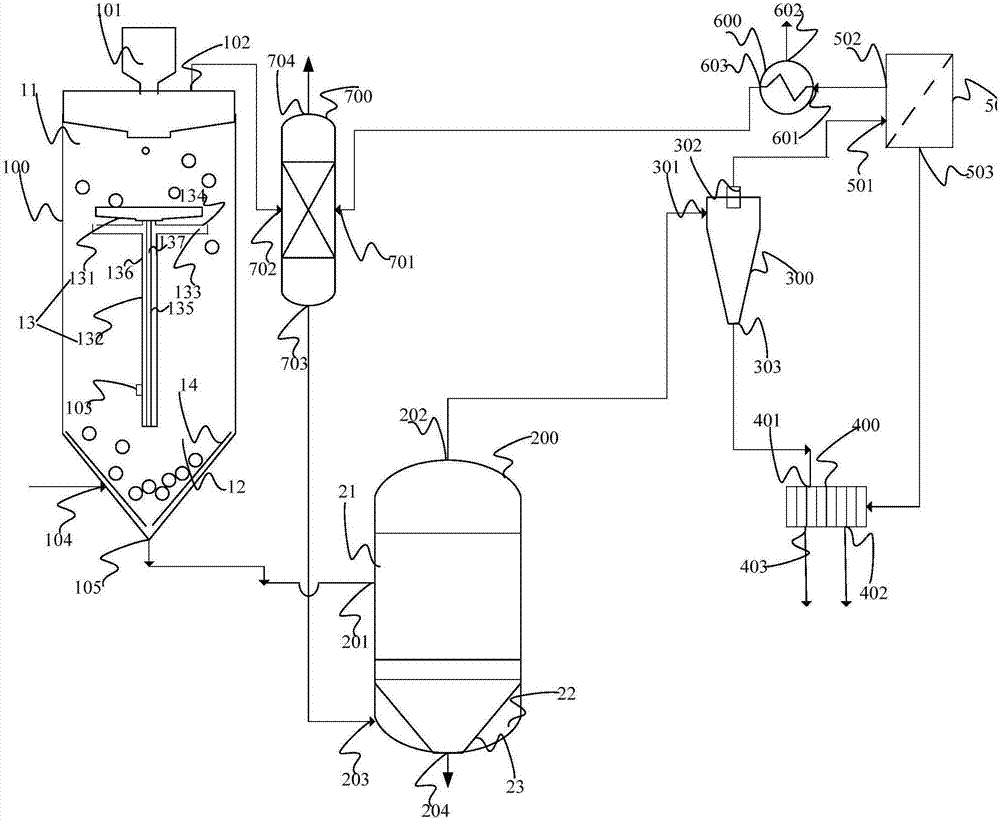

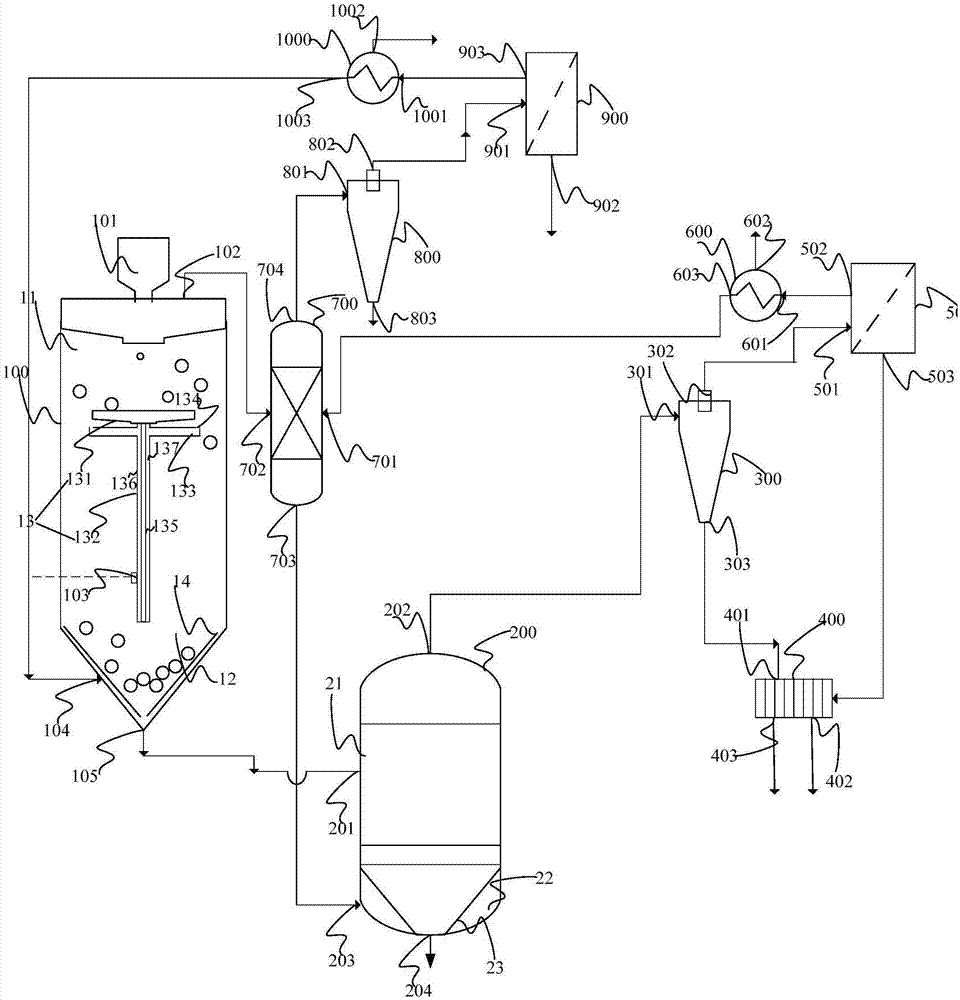

[0091] Put the calcium carbide liquid (1800-2200 degrees Celsius) released from the liquid outlet of the calcium carbide furnace into the calcium carbide crucible, hoist it from the workshop crane to the top of the calcium carbide granulation tower and pour it into the middle tank of the calcium carbide liquid, control the flow at the outlet of the middle tank, and flow at a certain height To the upper part of the rotating disk of the rotary granulator, relying on the centrifugal force generated by the rotation of the rotating disk, the calcium carbide liquid disperses and flows to the circumference and the lower part of the rotating disk to distribute the cold CO 2 The action of the airflow forms a slit with the rotating disk so that the airflow ejects the cutting calcium carbide liquid film at a high speed to form droplets, and the speed of the rotating disk adopts the method of frequency conversion speed regulation. By adjusting the rotating disk speed and the gas flow rate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com