Electrostatic bag type mixed dust collector

A technology of dust collector and cloth bag, applied in the field of electrostatic cloth bag mixed dust collector, can solve the problems of shortened service life of cloth bag, high pressure drop of filter bag, unreachable efficiency of electrostatic precipitator, etc., so as to reduce and improve the dust concentration. The effect of cleaning dust, improving performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

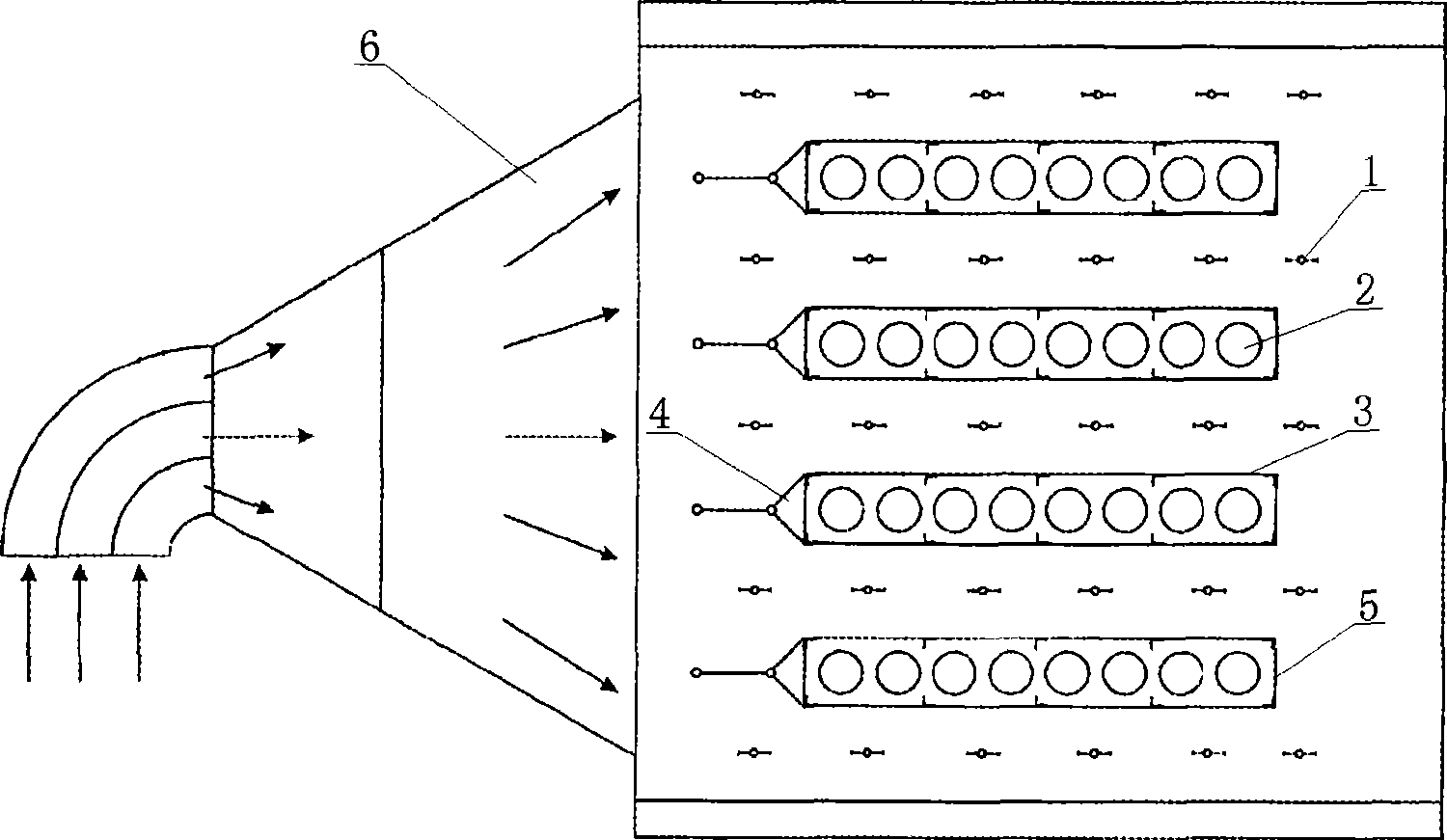

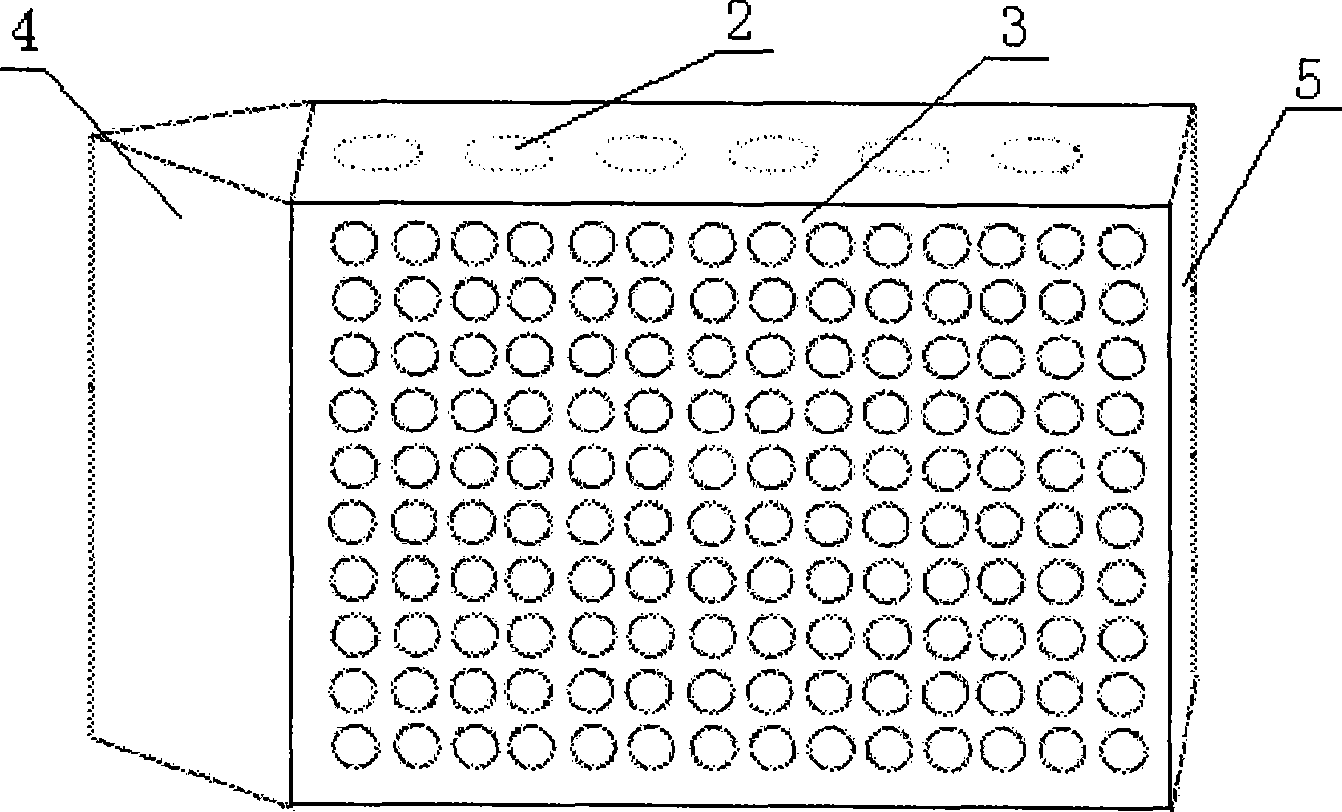

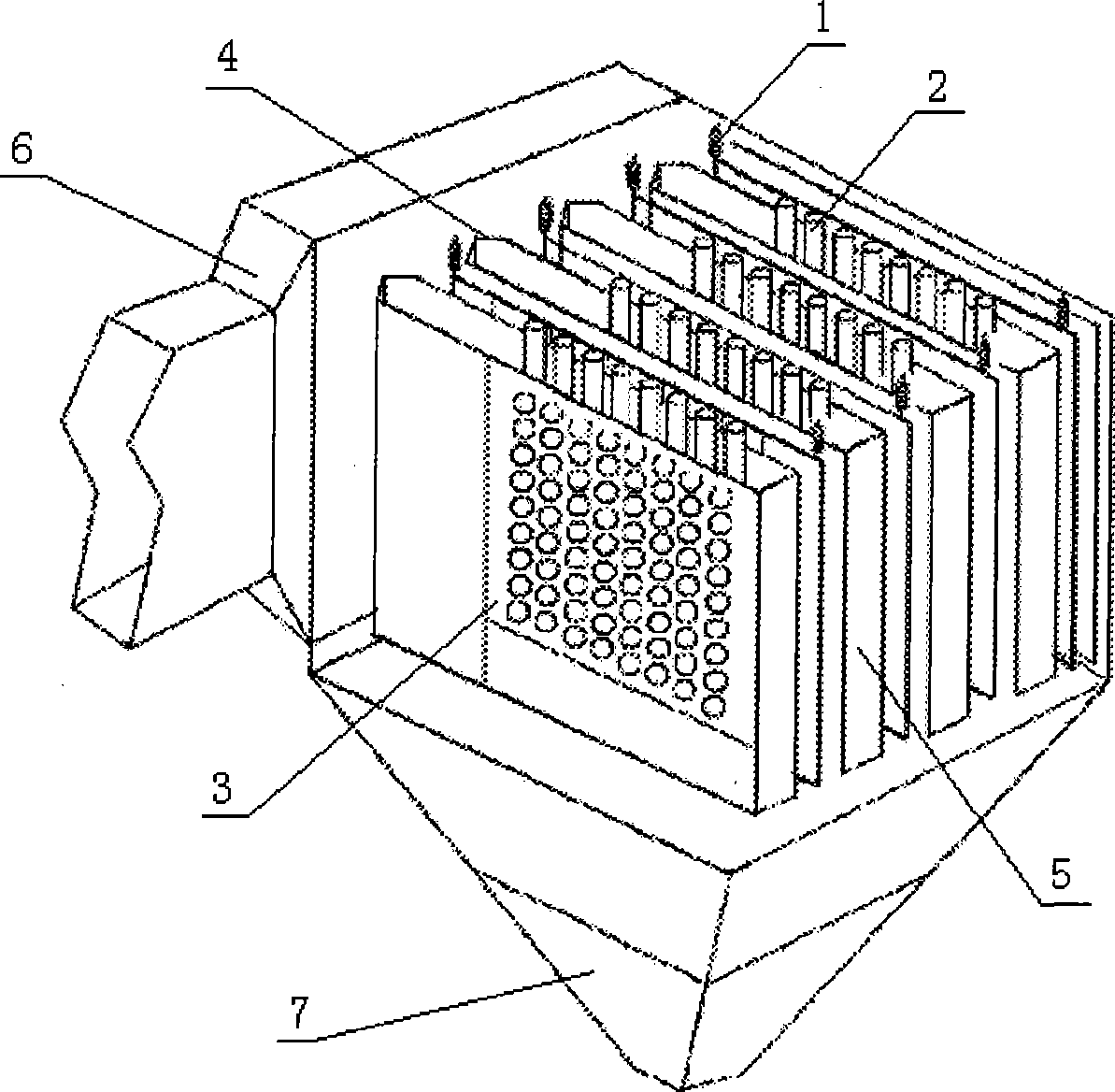

[0025] see Figure 3 to Figure 11 , the present invention includes several rows of electric electrodes 1 and several rows of filter bags 2 arranged at intervals along the inlet airflow direction. Two sides of each row of filter bags 2 are provided with dust collection pole plates 3 , and the front and rear ends of two adjacent dust collection pole plates 3 are respectively provided with V-shaped deflector plates 4 and sealing plates 5 . Each dust collection pole plate 3 includes a front dust collection pole plate 31 connected to the deflector 4 at the front section, a dust collection hole plate 33 connected to the upper part of the front dust collection pole plate 31 at the rear section, and a front dust collection pole plate 33 connected to the front dust collection pole plate 31. The lower part of the pole plate 31 is connected with the dust collecting pole plate 32 . Each part of each dust-collecting pole plate 3 is connected as an integral structure or is a movable embedd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com