Method and device for recycling hot-dip copper waste liquid

A waste solution and plating solution technology, applied in chemical instruments and methods, metallurgical wastewater treatment, water/sludge/sewage treatment, etc., can solve problems such as high energy consumption, complicated process flow, high sewage treatment fees, etc. Low cost, convenient process, and the effect of saving sewage treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

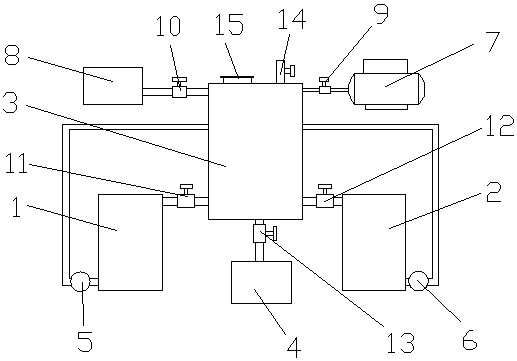

[0033] refer to figure 1 , the production device is: there are two plating solution pools of the first plating solution pool 1 and the second plating solution pool 2, and another oxidation pool 3 with a stirring device inside, and the top surface of the oxidation pool 3 is provided with an air release valve 14 and Filling and pH value material test port 15; the delivery pipeline is connected between the bottom of the first plating solution pool 1 and the oxidation tank 3, and the first booster pump 5 is arranged on the delivery pipeline, and the top of the first plating solution pool 1 is connected to the oxidation tank 3. The bottom of the pool 3 is connected to the delivery pipeline, and the first clear liquid on-off valve 11 is provided on the delivery pipeline; the delivery pipeline is connected between the bottom of the second plating solution pool 2 and the oxidation tank 3, and a second Booster pump 6, the second plating solution tank 2 top and oxidation tank 3 bottoms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com