High-density calcined petroleum coke and preparation technology thereof

A petroleum coke, high-density technology, applied in the petroleum industry, coke ovens, special forms of dry distillation, etc., can solve the problems affecting multiple ranges of applications, product quality control difficulties, production control difficulties, etc., to achieve high product cost and anti-shattering Increased strength and contact densification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: A kind of high-density calcined petroleum coke, the true specific gravity of this petroleum coke is 2.00-2.04g / cm 3 , Apparent porosity: 32-36%, particle size: 10-150mm; sulfur content: 0.2-0.7wt%, ash content: 0.2-0.7wt%, volatile matter: 0.2-0.6wt%, moisture: 0.4-3wt%, fixed Carbon: 95-99.0 wt%.

Embodiment 2

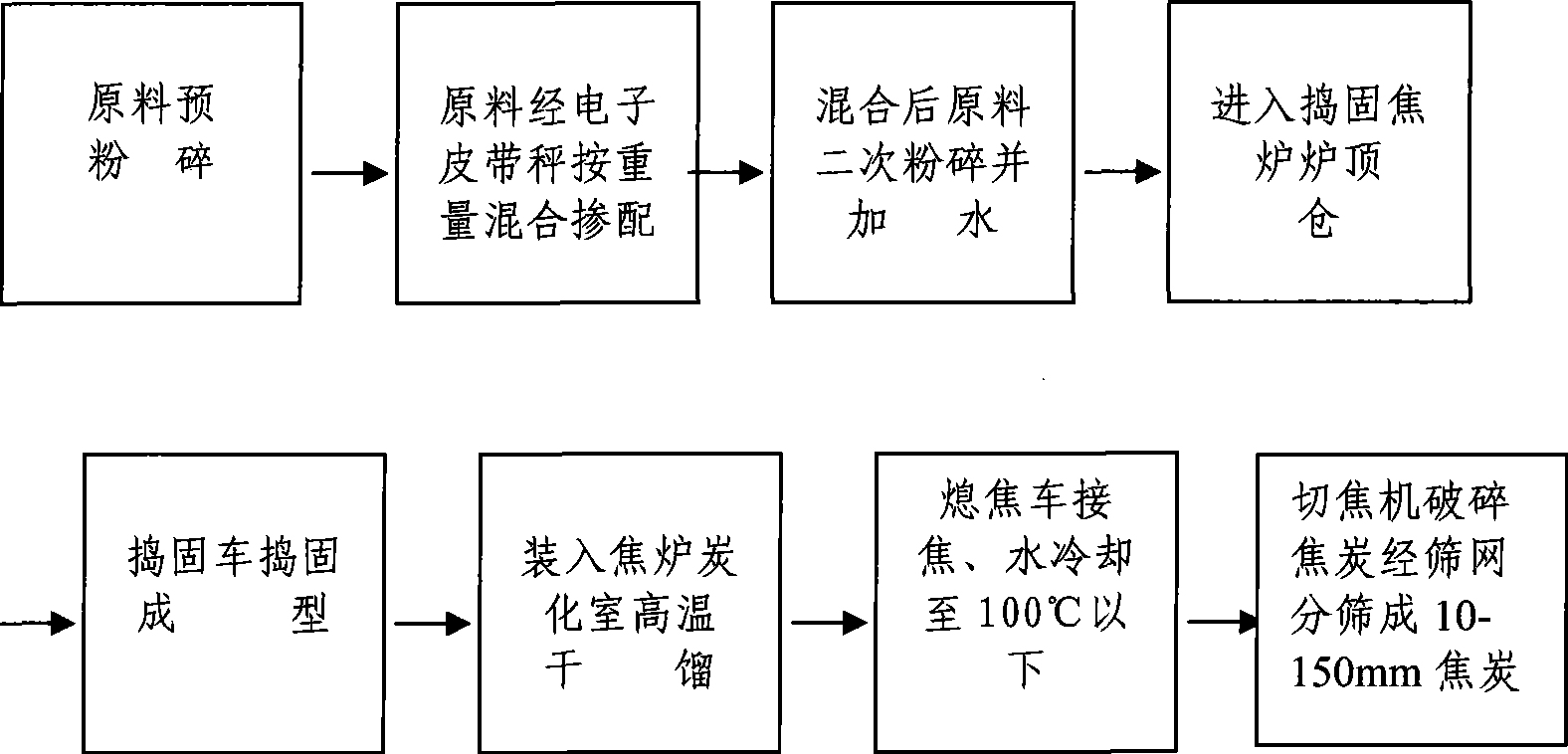

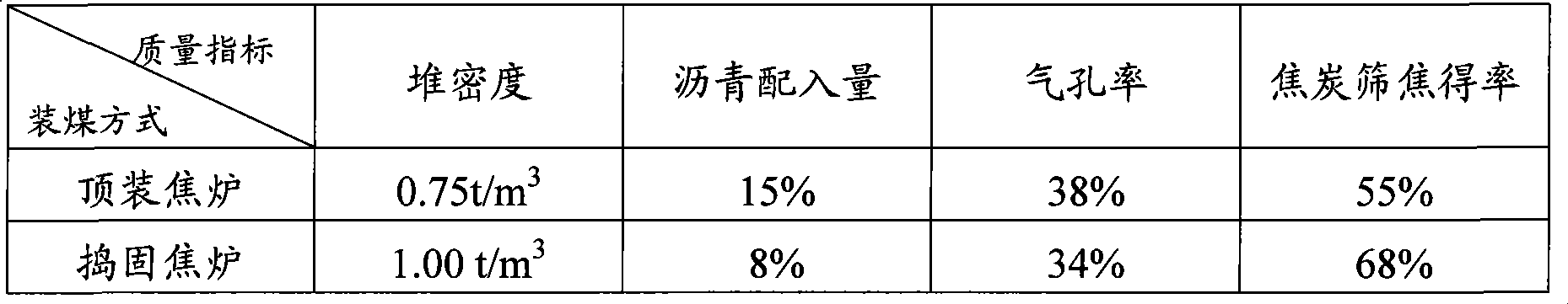

[0014] Embodiment 2: A method for producing high-density calcined petroleum coke, the production steps are: raw material mixing and crushing: delayed petroleum coke and pitch are pre-crushed respectively, and the delayed petroleum coke weight ratio is 85%, and the pitch weight is 15%. Proportional blending, and then mixed and crushed, the mixed raw materials are crushed so that particles with a fineness of less than 3mm account for more than 60% of the mass fraction of the mixed raw materials; raw material water content adjustment: add water to the crushed raw materials to make the mixed raw materials water content Control at 12wt% of the total mass fraction of the mixed raw materials; coke oven dry distillation: the raw materials that have been treated with the water content adjustment in the previous step are sent to a tamping coke oven for high-temperature dry distillation and calcination, and the calcination temperature is controlled to be 1100 ° C. The coking time is 35 hou...

Embodiment 3

[0024] Embodiment 3: A method for producing high-density calcined petroleum coke, the production steps are: mixing and crushing of raw materials: after the delayed petroleum coke and pitch are pre-crushed respectively, the delayed petroleum coke weight ratio is 94%, and the pitch weight is 6%. Proportional blending, and then mixed and crushed, the mixed raw materials are crushed so that particles with a fineness of less than 3mm account for more than 60% of the mass fraction of the mixed raw materials; raw material moisture content adjustment: add water to the crushed raw materials to control the moisture content of the mixed raw materials Accounting for 16wt% of the total mass fraction of the mixed raw materials; coke oven dry distillation: the raw materials processed by adjusting the water content in the previous step are sent to a tamping coke oven for high-temperature dry distillation and calcination, the calcination temperature is controlled to be 1300 ° C, and the coking t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com