Movable slide bed tunnel type coke oven and use method thereof

A coke oven and tunnel-type technology, applied in the field of coke ovens, can solve problems such as inability to recover gas and chemical products, slow drying speed affecting output, and inaccurate differentiation of furnace bodies, etc., to achieve a wide range of raw material procurement, low power generation costs, and high-quality products. The effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

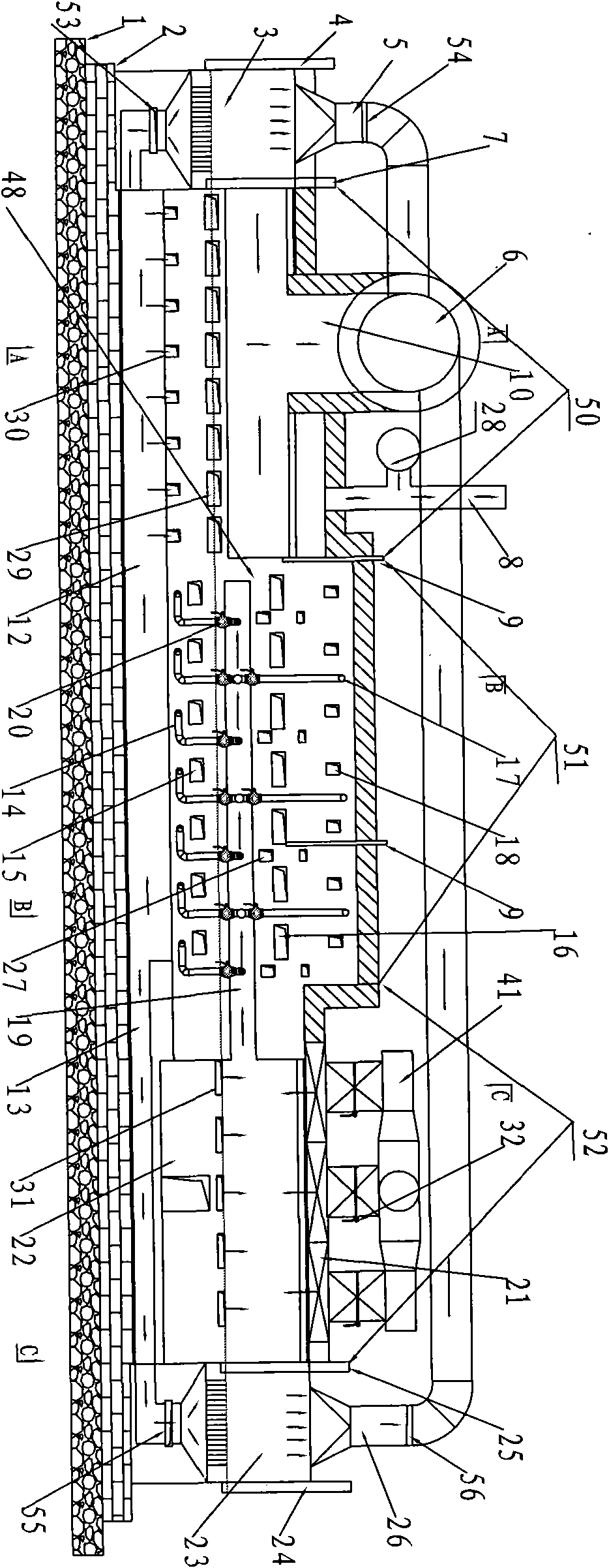

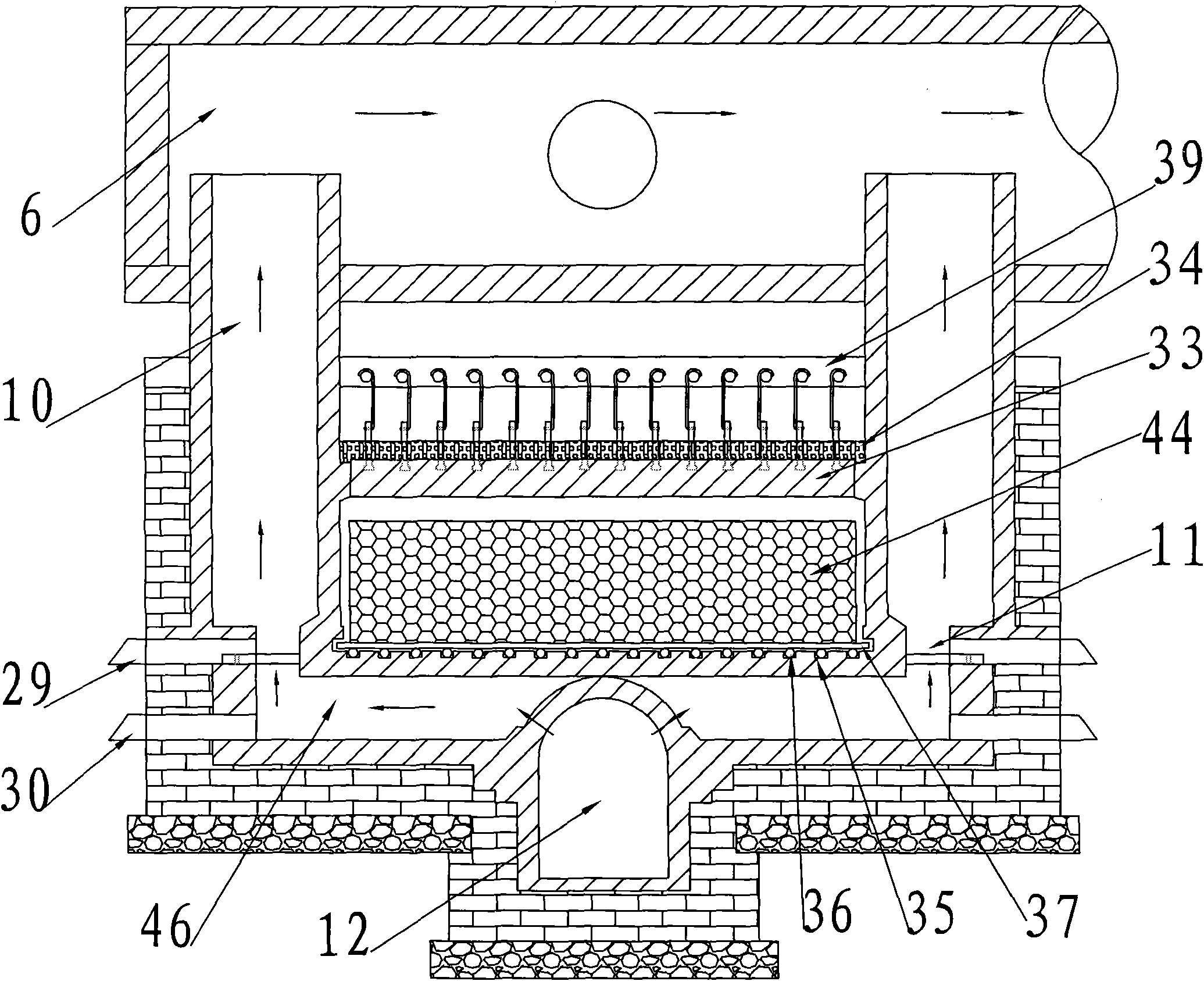

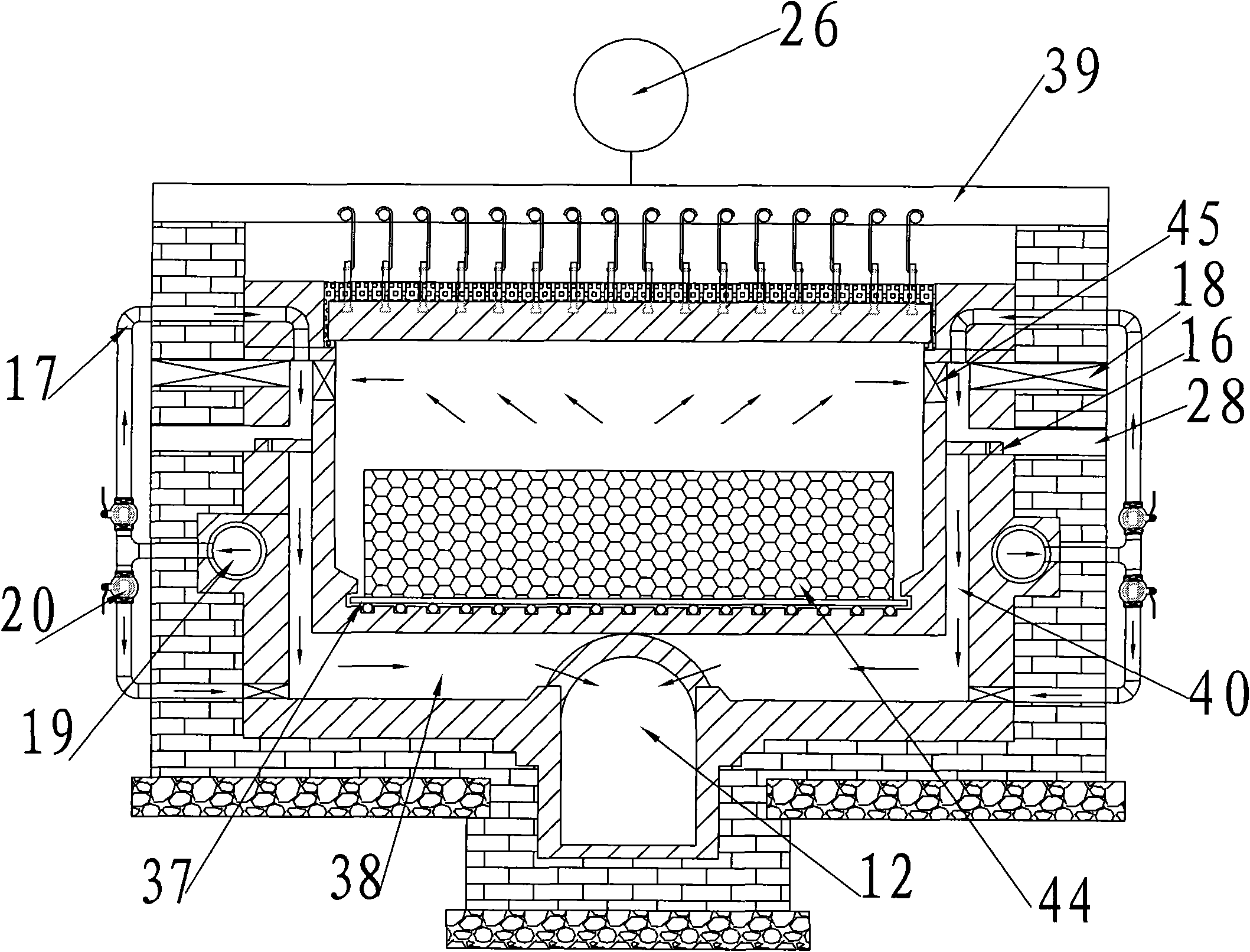

[0033] Combined with the accompanying drawings below ( figure 1 -- Figure 4 ) to illustrate specific embodiments of the present invention

[0034] A moving sliding bed tunnel coke oven according to the present invention comprises a furnace roof 33, a furnace roof insulation layer 34, a ceiling girder 39, furnace walls on both sides, and a furnace bottom composed of a furnace body foundation 1 and a furnace bottom insulation layer 2 body 48 and the front sealing door 7 of the coke oven body, the rear sealing door 25 of the coke oven body, the branch flue 10, the bottom flue 12 and the main flue 6, the tunnel coke oven is set as a coal charging preparation room 3, preheating The section 50, the carbonization section 51, the CDQ section 52 and the coke discharge preparation room 23 are five parts, and the structures of each part are arranged differently in series and communicate with each other.

[0035] Bottom insulation layer 2 is provided with several mutually independent b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com