Solid fuel for torch burner and preparation method thereof

A technology of solid fuel and torch combustion, which is applied in the field of hand-held solid fuel torch charge, and can solve the problems that fuel cannot be ignited normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

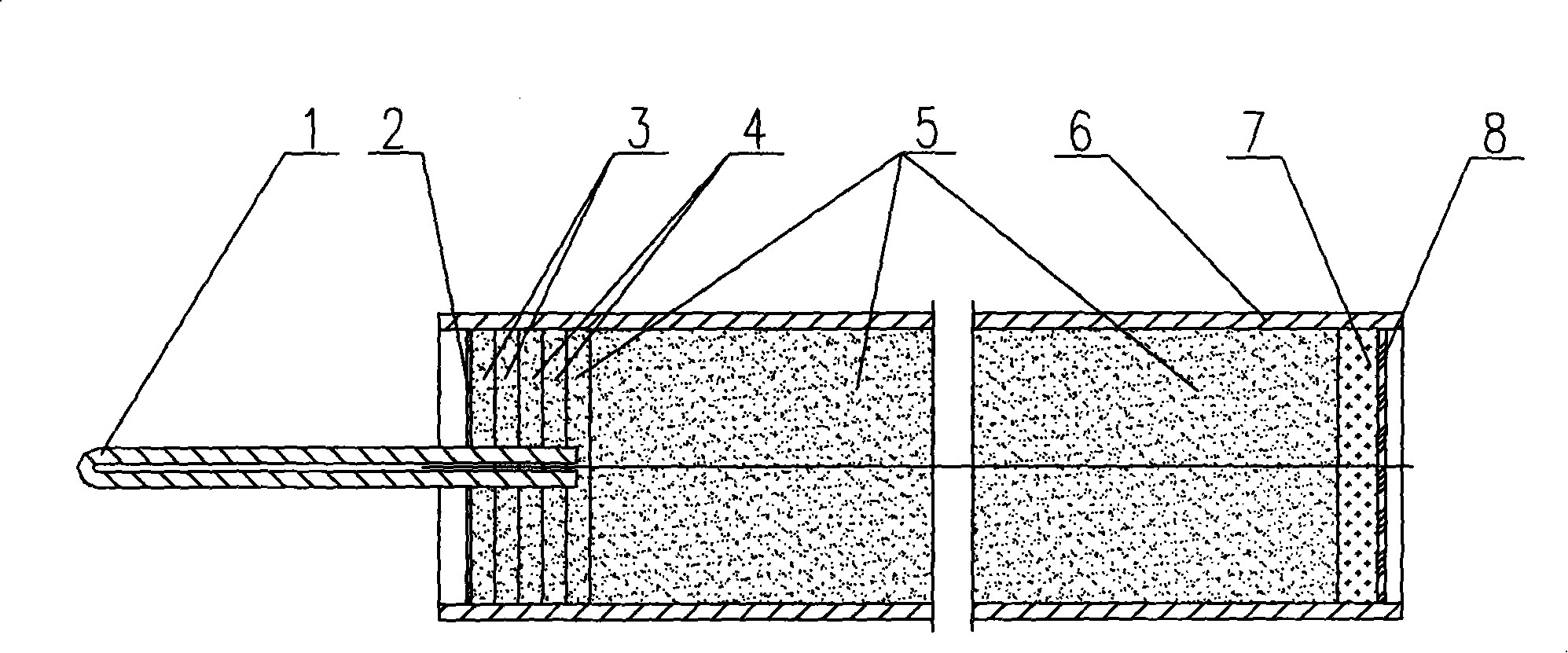

Image

Examples

preparation example Construction

[0051] The specific steps of the preparation method of ignition charge, transition charge and main charge are as follows:

[0052] a) After pulverizing the oxidant ammonium perchlorate and ammonium nitrate respectively, cross 200 meshes to get the sieve;

[0053] b) After pulverizing the fuel lignocellulose, pass through 200 meshes to get the sieve;

[0054] c) After crushing the flame colorant strontium carbonate, pass through 150 meshes to get the sieve;

[0055] d) dissolving shellac in an appropriate amount of alcohol to prepare a 5% to 10% alcohol solution;

[0056] e) oxidant and fuel are sieved and mixed evenly with a 60-mesh sieve;

[0057] f) then pour the shellac alcohol solution into the sieve and mix the material evenly;

[0058] g) granulating with 20 mesh sieves;

[0059] h) Dry naturally for 2 hours, then dry at 50°C for 24 hours;

[0060] i) The measured water content should be less than 0.2%, and the tested components meet the requirements;

[0061] j) T...

Embodiment 1

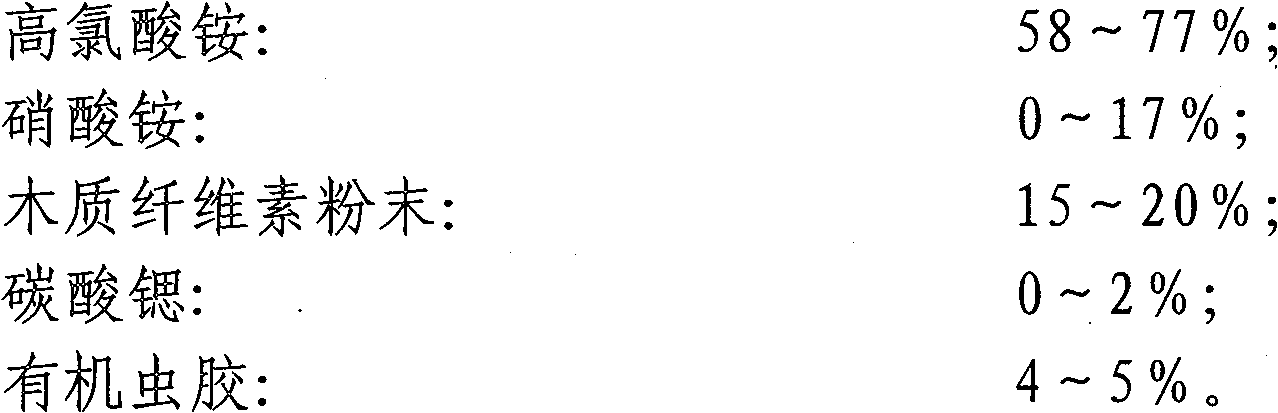

[0064] There are three kinds of formulas as the ignition medicine formula:

[0065] Recipe 1:

[0066] Ammonium perchlorate: 75%;

[0067] Lignocellulose powder: 20%;

[0068] Strontium carbonate: 0%;

[0069] Organic Shellac: 5%.

[0070] Recipe 2:

[0071] Ammonium perchlorate: 76%;

[0072] Lignocellulose powder: 19%;

[0073] Strontium carbonate: 0.5%;

[0074] Organic Shellac: 4.5%.

[0075] Recipe 3:

[0076] Ammonium perchlorate: 77%;

[0077] Lignocellulose powder: 18%;

[0078] Strontium carbonate: 1%;

[0079] Organic Shellac: 4%.

[0080] The oxygen difference in the above formula is n=-(13~14)g / 100g, the burning rate at 0.3bar and -50°C is about 0.7mm / s, non-hygroscopic and easy to ignite, in solid torch charge Used as a igniter.

Embodiment 2

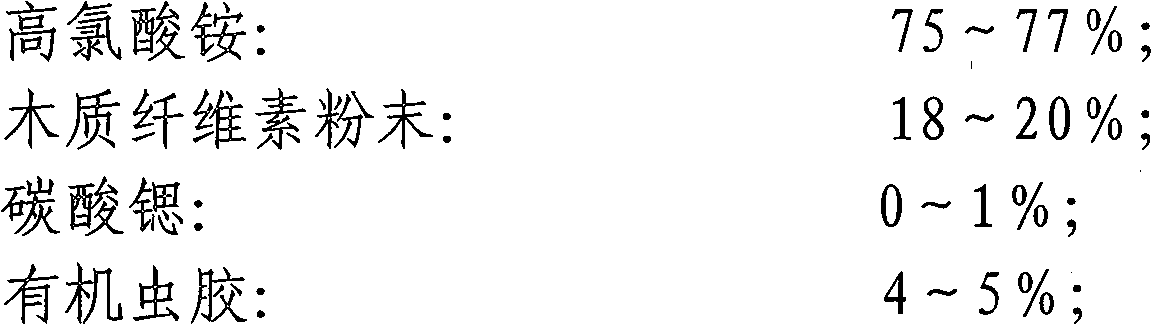

[0082] There are three kinds of formulations as the main charge formula:

[0083] Recipe 1:

[0084] Ammonium perchlorate: 58%;

[0085] Ammonium nitrate: 17%;

[0086] Lignocellulose powder: 20%;

[0087] Strontium carbonate: 1%;

[0088] Organic Shellac: 4%.

[0089] Recipe 2:

[0090] Ammonium perchlorate: 60%;

[0091] Ammonium nitrate: 16%;

[0092] Lignocellulose powder: 19%;

[0093] Strontium carbonate: 0%;

[0094] Organic Shellac: 5%.

[0095] Recipe 3:

[0096] Ammonium perchlorate: 62%;

[0097] Ammonium nitrate: 13%;

[0098] Lignocellulose powder: 18%;

[0099] Strontium carbonate: 2%;

[0100] Organic Shellac: 5%.

[0101] The oxygen difference in the above formulation is n=-(21~23)g / 100g, the burning rate at 0.3bar and -45°C is about 0.5mm / s, it is hygroscopic, and its ignition performance is slightly worse than that of formulation 1. It is used as the main charge in the solid flare charge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com