Remelting slag for electroslag remelting plate blank and manufacturing method thereof

A technology of electroslag remelting and remelting slag, which is applied in the field of remelting slag of electroslag remelting slabs and its manufacturing, can solve problems such as fluorine pollution, high fluorite content, and slag grooves on the surface of ingots, and achieve reduction Pollution, effects of low fluorspar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

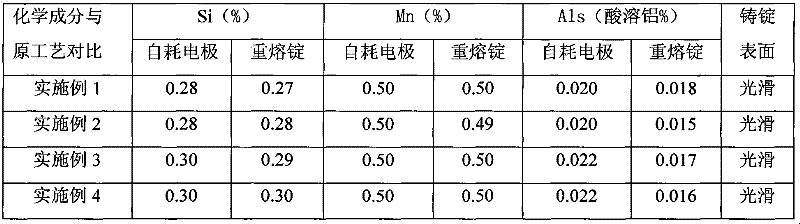

Examples

Embodiment 1

[0017] A remelting slag for electroslag remelting slabs, which consists of the following components by weight percentage:

[0018] Lime 28%, alumina 29%, fluorite 41%, magnesium oxide 2%, after mixing the above raw materials evenly, pre-melt at a high temperature of 1200 ℃ ~ 1550 ℃, cool it to room temperature, and break it into 3 ~ 20mm particles .

Embodiment 2

[0020] A remelting slag for electroslag remelting slabs, which consists of the following components by weight percentage:

[0021] Lime 29%, alumina 30%, fluorite 40%, magnesium oxide 1%, after mixing the above raw materials evenly, pre-melt at 1200℃~1550℃ high temperature, cool it to room temperature, break into 3~20mm particles .

Embodiment 3

[0023] A remelting slag for electroslag remelting slabs, which consists of the following components by weight percentage:

[0024] 30% lime, 30% alumina, 39% fluorite, 1% magnesium oxide, mix the above raw materials evenly, pre-melt at 1200℃~1550℃ high temperature, cool it to room temperature, and break it into 3~20mm particles .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com